Self-centering fixture

A self-centering fixture and a pair of technology, applied in the field of workpiece fixtures, can solve the problems of inability to achieve self-centering, complex fixture structure, poor machining accuracy, etc., and achieve the effects of simple structure, reliable structure, and improved machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

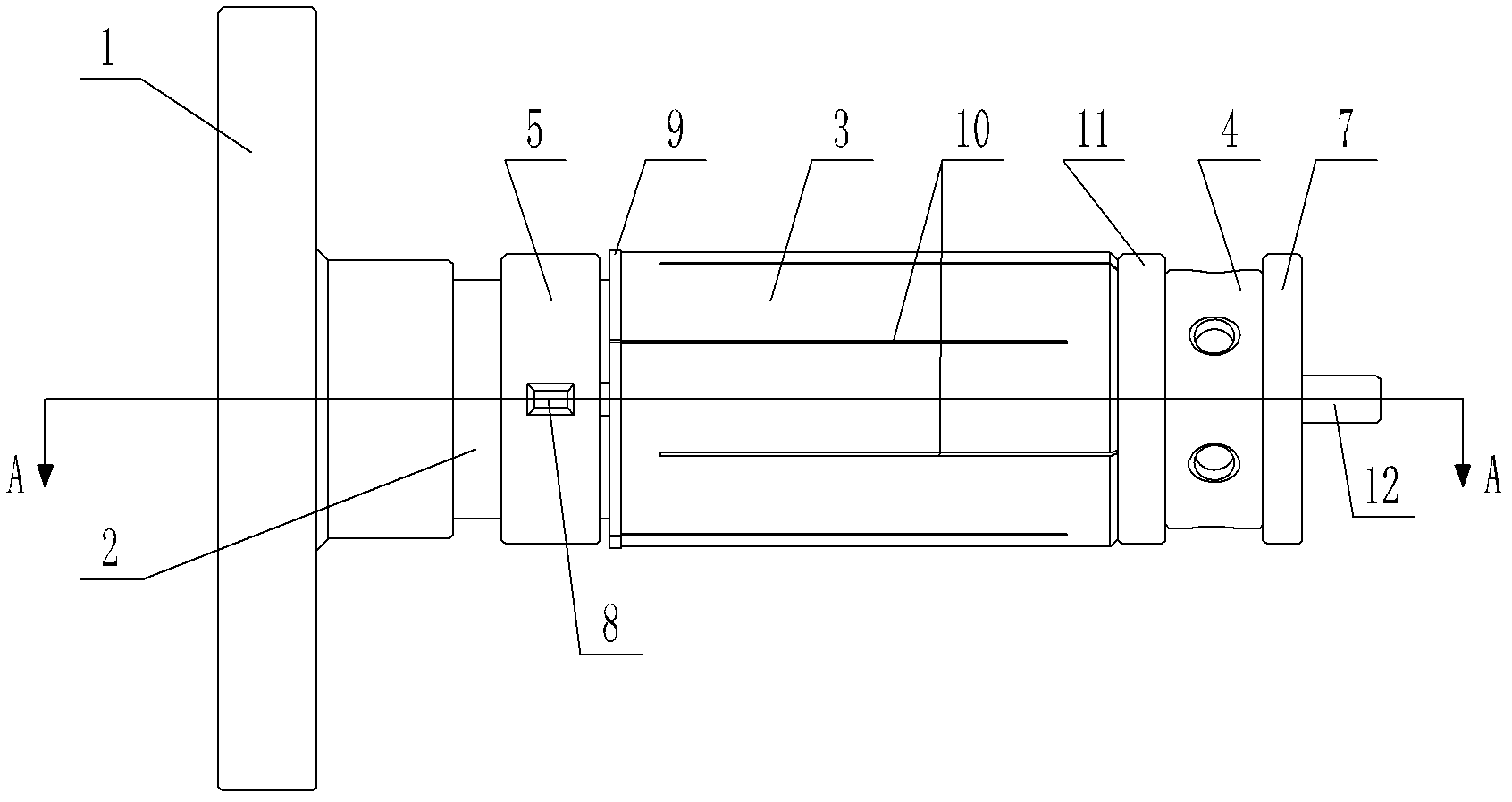

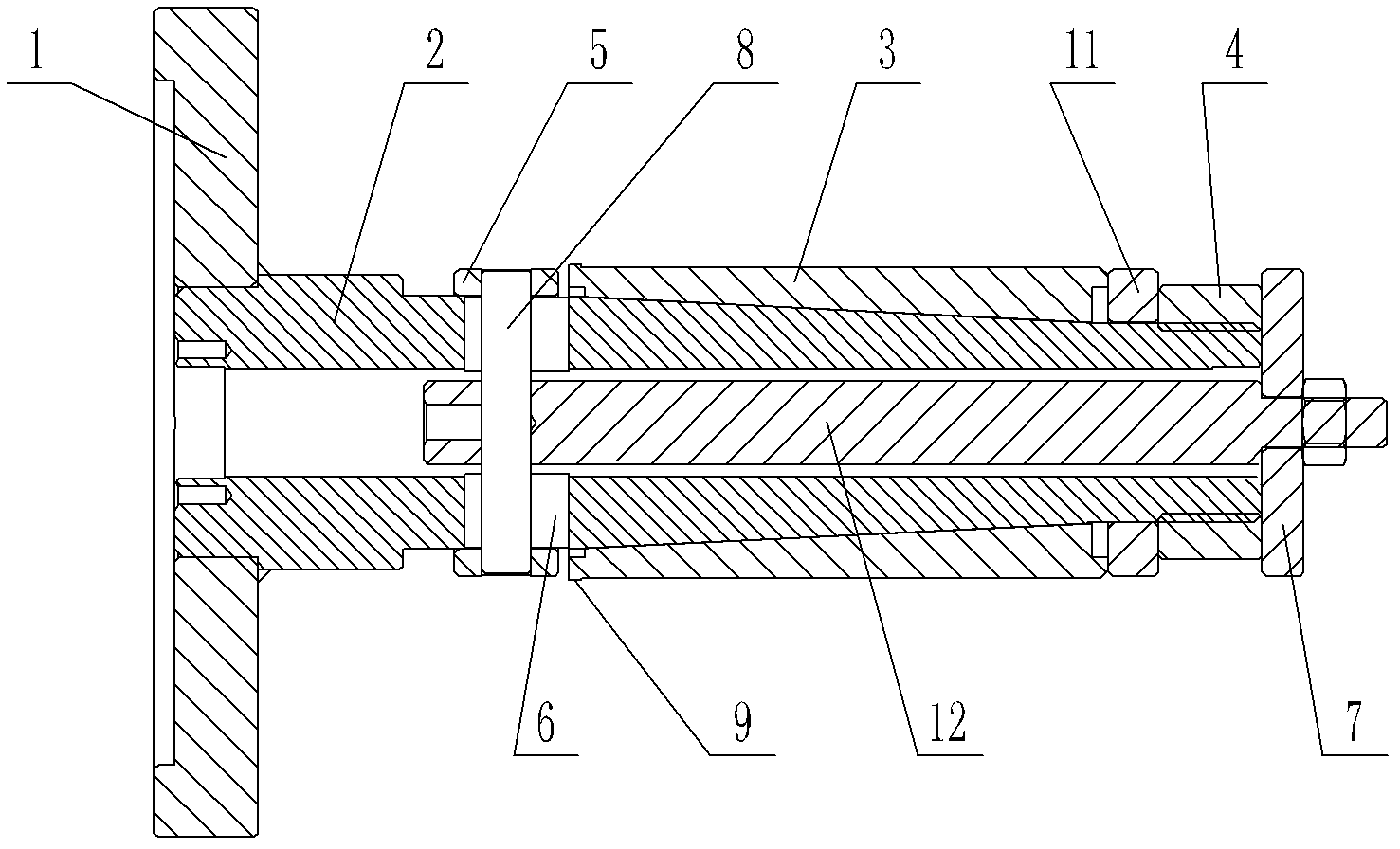

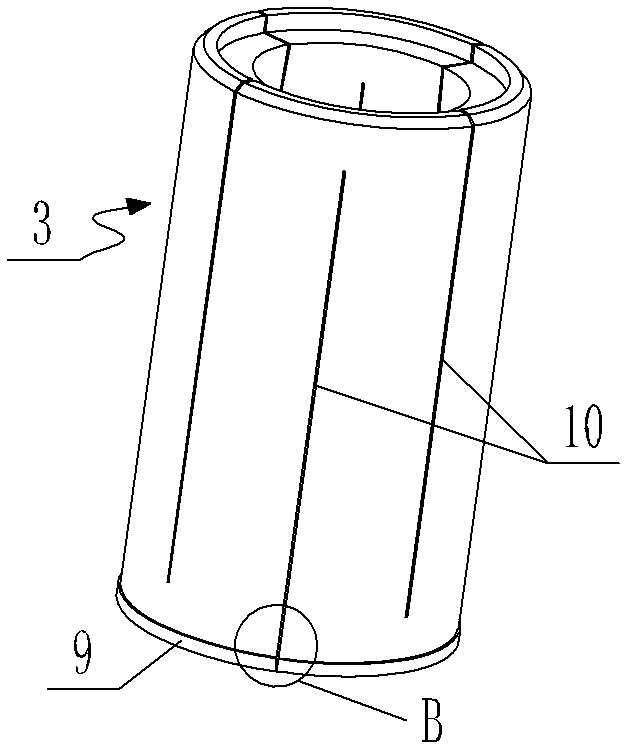

[0016] The technical scheme of the present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

[0017] as attached figure 1 , attached figure 2 , attached image 3 and attached Figure 4 As shown, the self-centering fixture of the present invention includes a mandrel 2 installed on the machine tool through a flange 1, an expansion sleeve 3 sleeved on the outer periphery of the mandrel 2 and capable of moving axially, and the mandrel 2 is a hollow cone , and the outer diameter of the near flange 1 end is greater than the outer diameter of the far flange 1 end, the far flange 1 end of the mandrel 2 has a section of external thread, and the section of the external thread is equipped with an adjusting nut 4, and the outer circumference of the mandrel 2 A slidable retaining ring 5 is provided on the sleeve, a pair of axially distributed chute 6 is provided on the mandrel 2, a pull rod 12 is suspended from the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com