Electric spark and electrochemical composite machining method of micro-electrode

A composite processing and micro-electrode technology, which is applied in the field of electro-spark electrochemical composite processing and electro-spark electrochemical composite processing of micro-electrodes, can solve the problems of poor electrode surface quality, low processing efficiency, processing taper error, etc., and achieve surface quality Good, fast processing speed, high productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

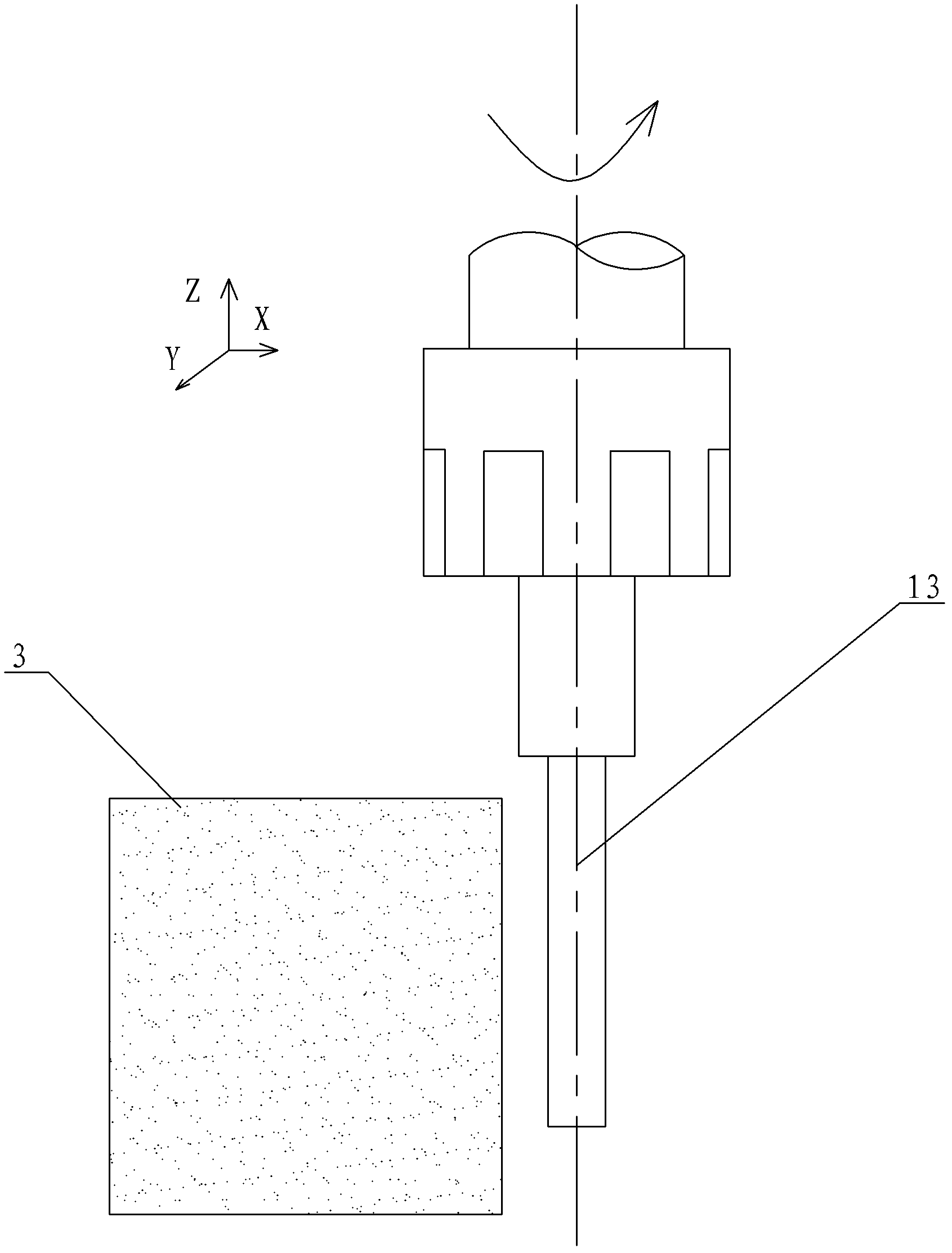

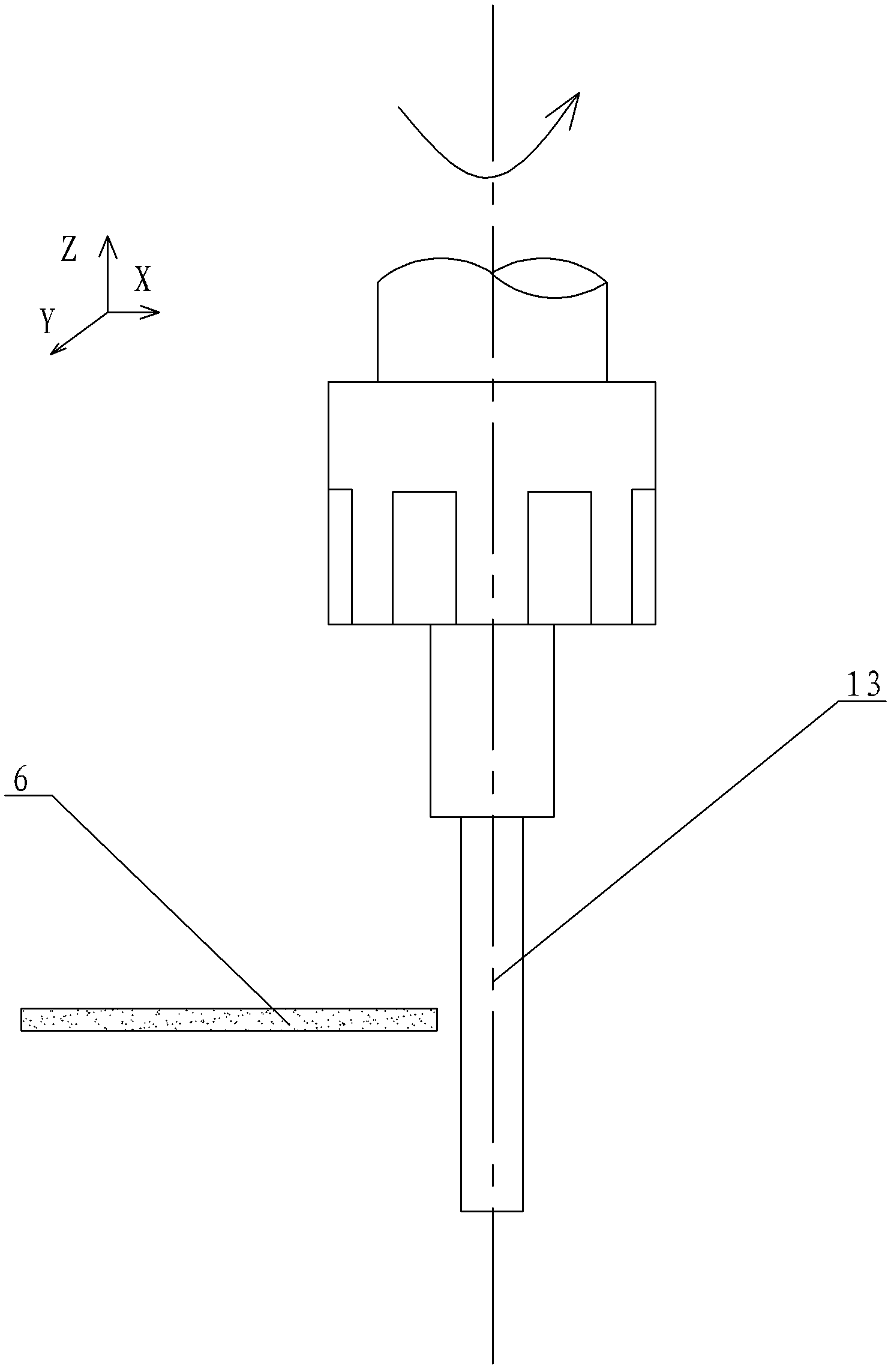

[0018] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment mode, a kind of electrospark electrochemical composite processing method of the fine electrode of this embodiment mode, described electrospark electrochemical composite processing method comprises the following steps:

[0019] Step 1: Initialize the machine tool and clamp the tool and electrode;

[0020] The machine tool is initialized, the high-frequency pulse power supply 8 is fixed on the machine tool work platform 4, the frequency of the high-frequency pulse power supply 8 is 1MHz, the EDM working fluid tank 1 and the electrolyte tank 5 are arranged on the machine tool work platform 4 in sequence from right to left , the anti-copy block 3 and the tool cathode 6 are respectively arranged in the EDM working fluid tank 1 and the electrolyte tank 5, and the anti-copy block 3 and the tool cathode 6 are connected to the cathode of the high-frequency pulse power supply 8, and the electrod...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination Figure 4 To describe this embodiment, the tool cathodes 6 in step 1 and step 3 of this embodiment are both sheet-shaped tool cathodes, and a layer of insulating film 15 is attached to the upper and lower surfaces of the sheet-shaped tool cathodes. Such setting effectively improves the localization and dimensional accuracy of the stray corrosion in the electrolytic grinding process. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 This embodiment is described. In Step 4 of this embodiment, the CCD observation system 14 is used to detect whether the electrode 13 has reached the designed size, cylindricity and surface quality. With such a setting, it is convenient to use and accurate in detection. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com