Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Verticality is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy battened steel column construction process

ActiveCN102434003AEasy to controlEliminate the effects of positive tolerancesBuilding material handlingStructural engineeringSteel columns

The invention discloses a heavy battened steel column mounting construction process. The mounting construction process comprises the following steps of: A) detecting foundation dimension of a cup opening and adjusting a dimension error; B) snapping a line on the foundation and correcting elevation; C) measuring the distance from a bracket surface to the lower surface of a column bottom plate; D) lifting a heavy battened steel column; E) adjusting a column foot center line relative to a locating axis; F) adjusting the verticality of an axis of the heavy battened steel column; and G) fixing the heavy battened steel column. According to the invention, the heavy battened steel column correcting process is improved so that the working efficiency is largely enhanced and the labor intensity is reduced; and compared with the traditional correcting method, the heavy battened steel column mounting construction process disclosed by the invention has the advantages of short time in the adjusting process, capability of reducing 1 / 3 working time and engineering cost conservation.

Owner:山东寿光第一建筑有限公司

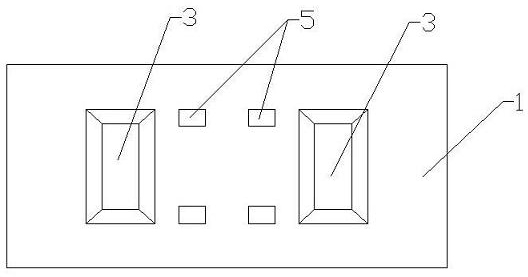

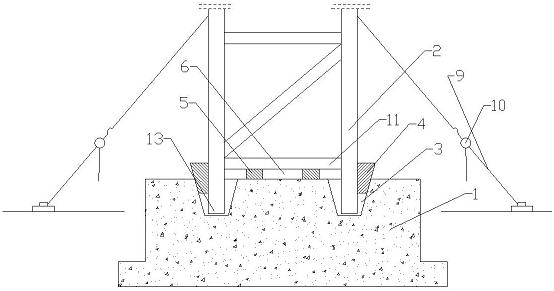

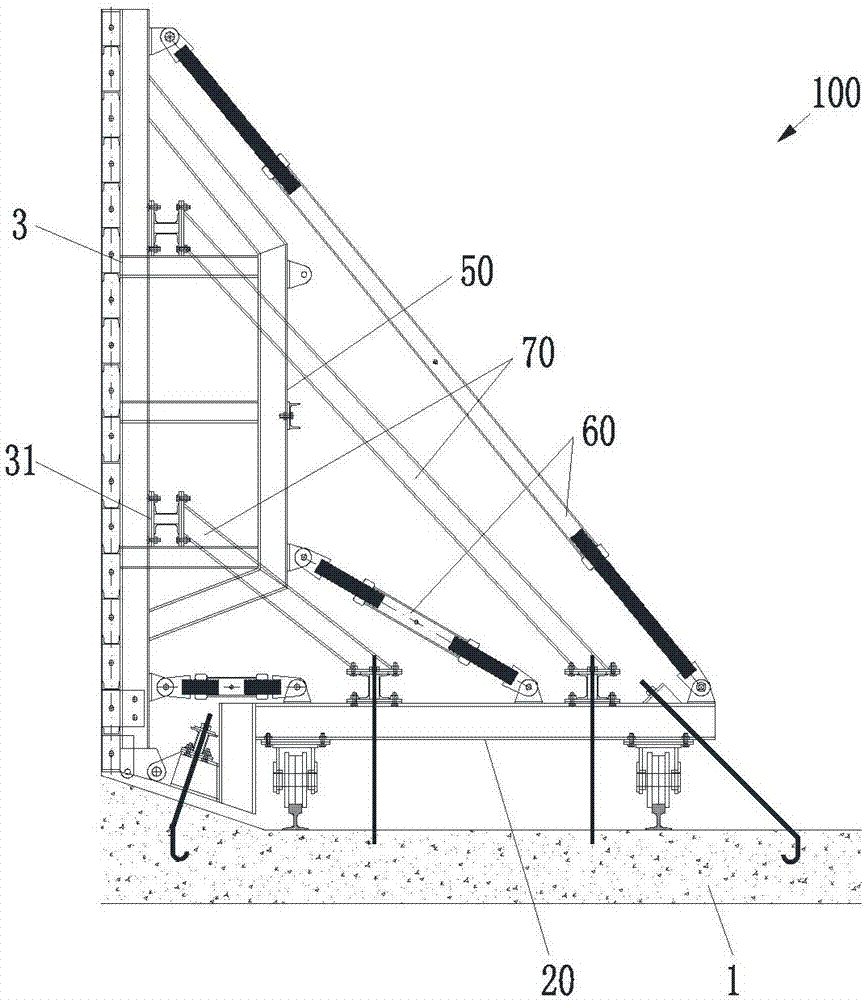

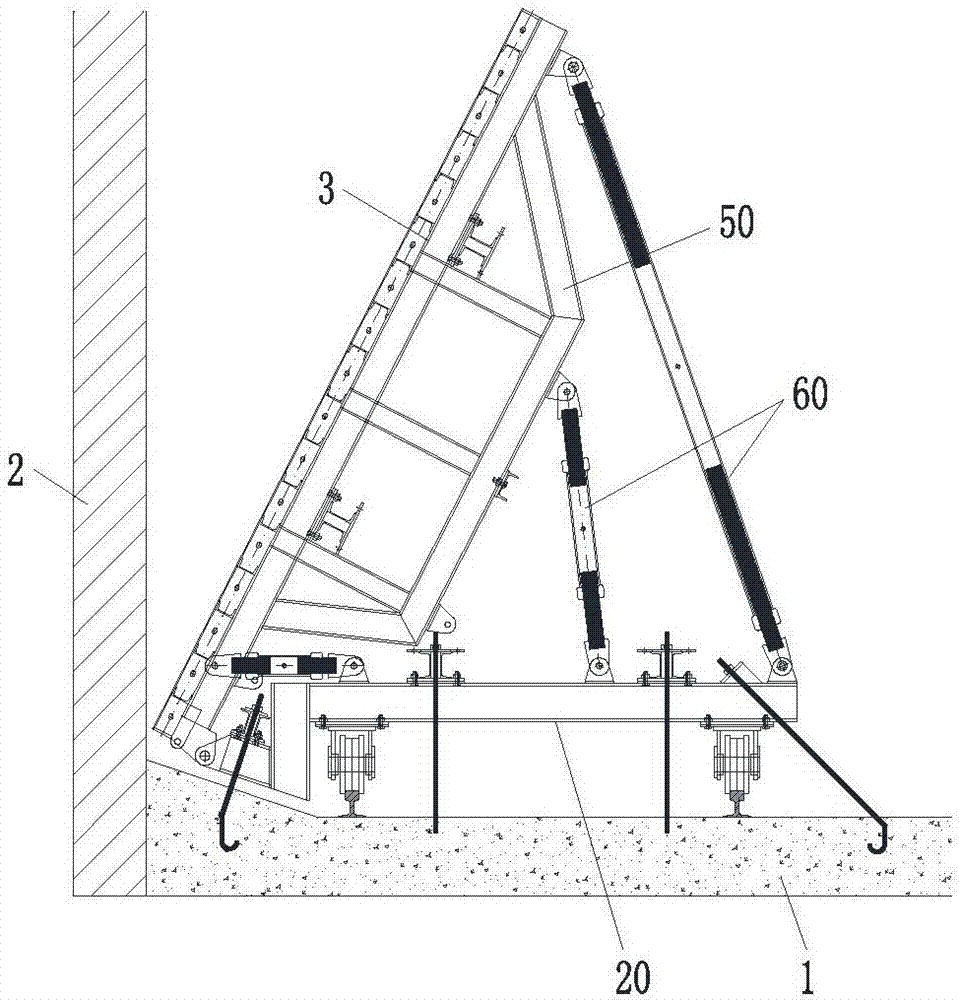

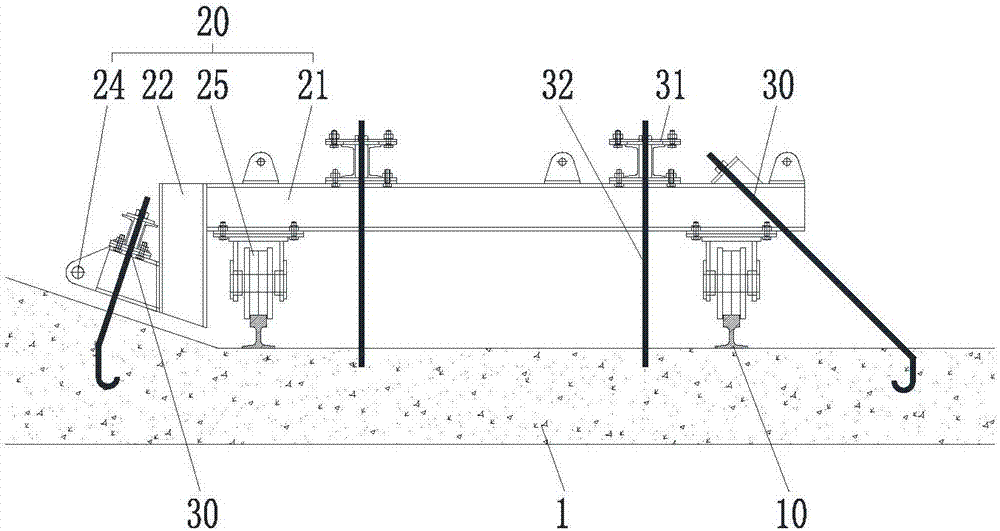

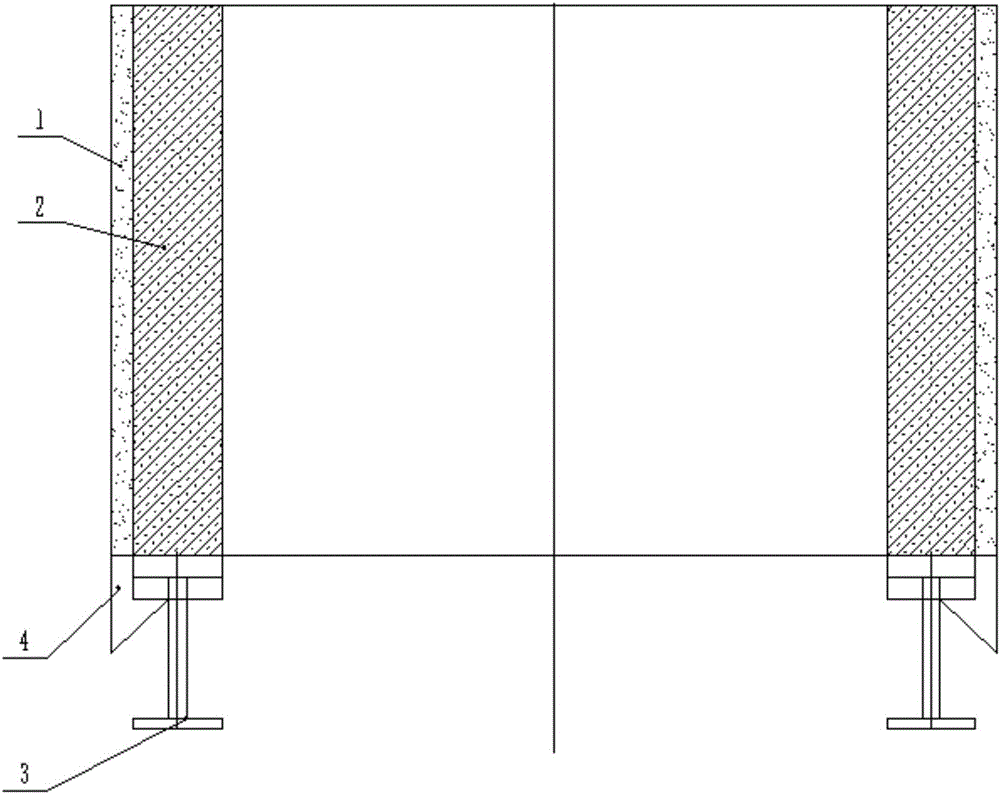

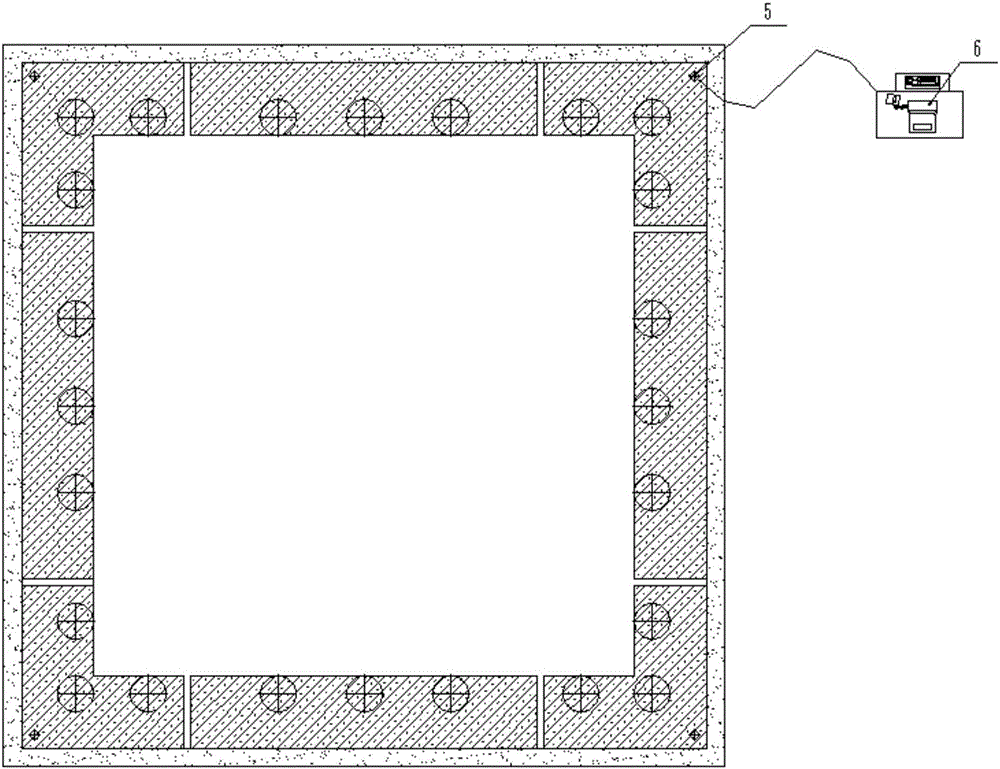

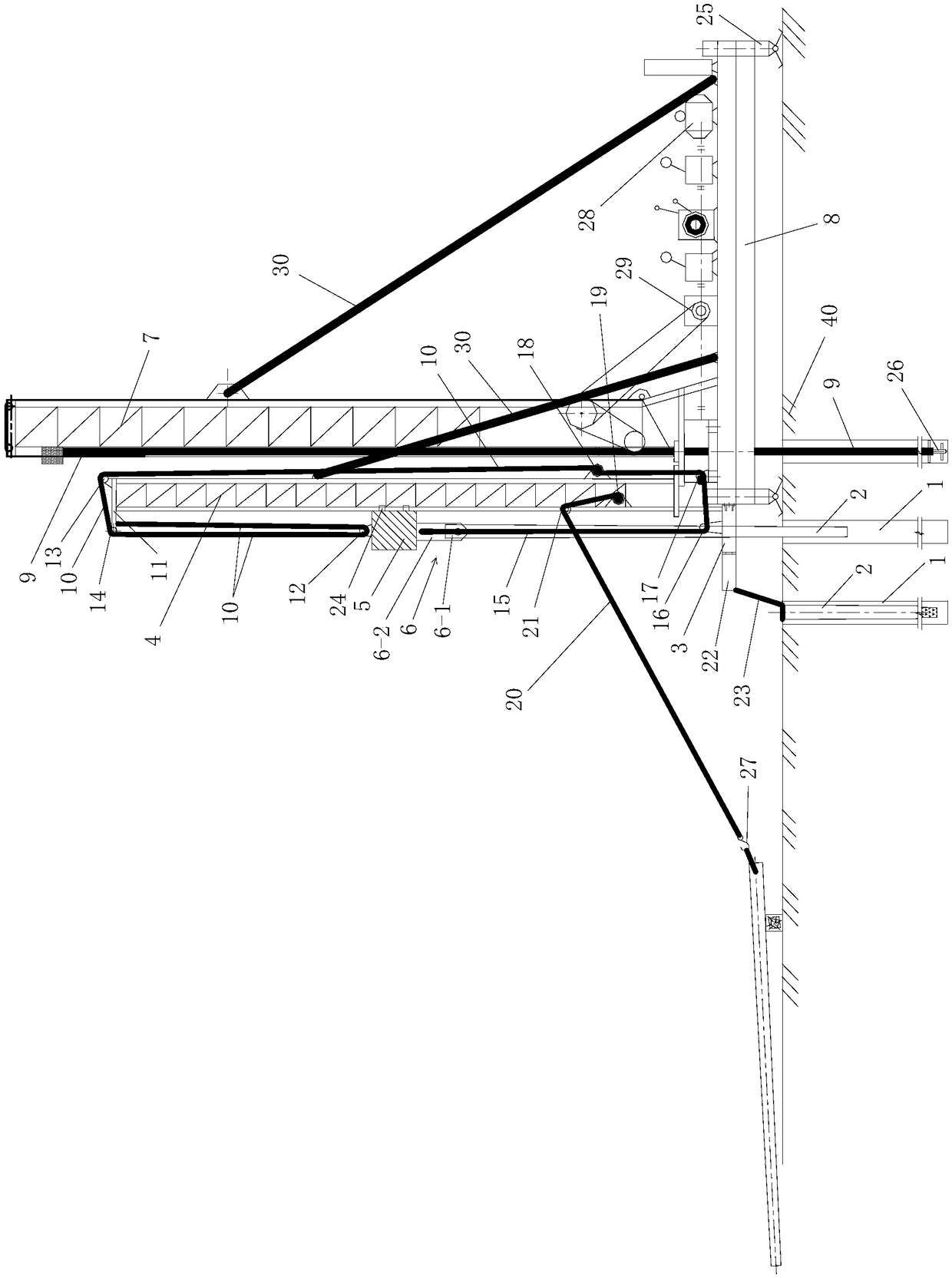

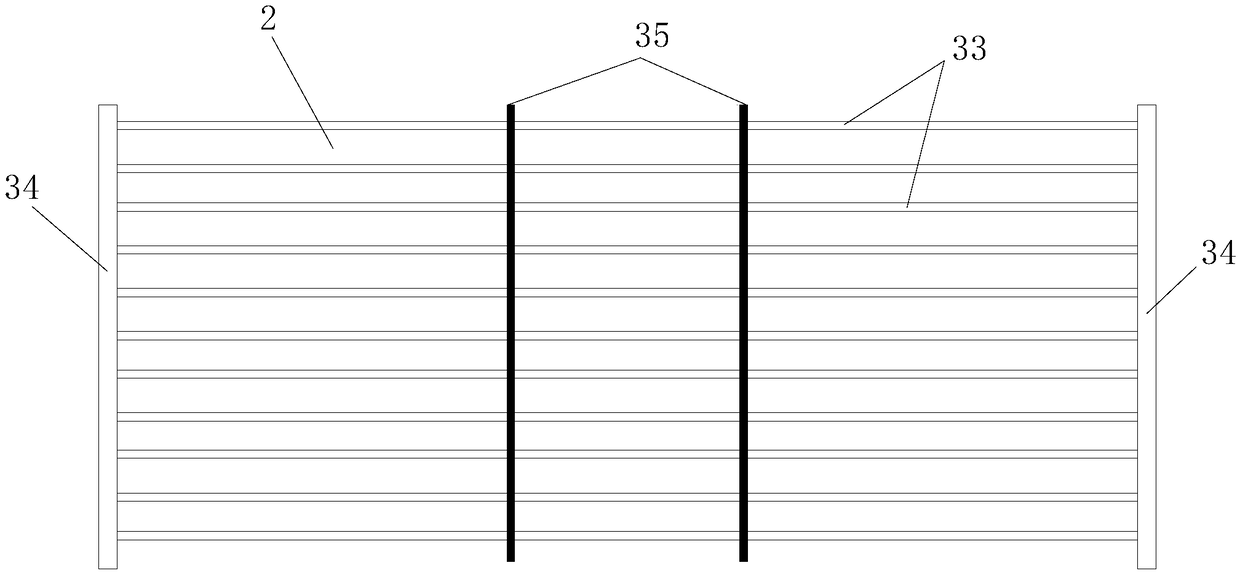

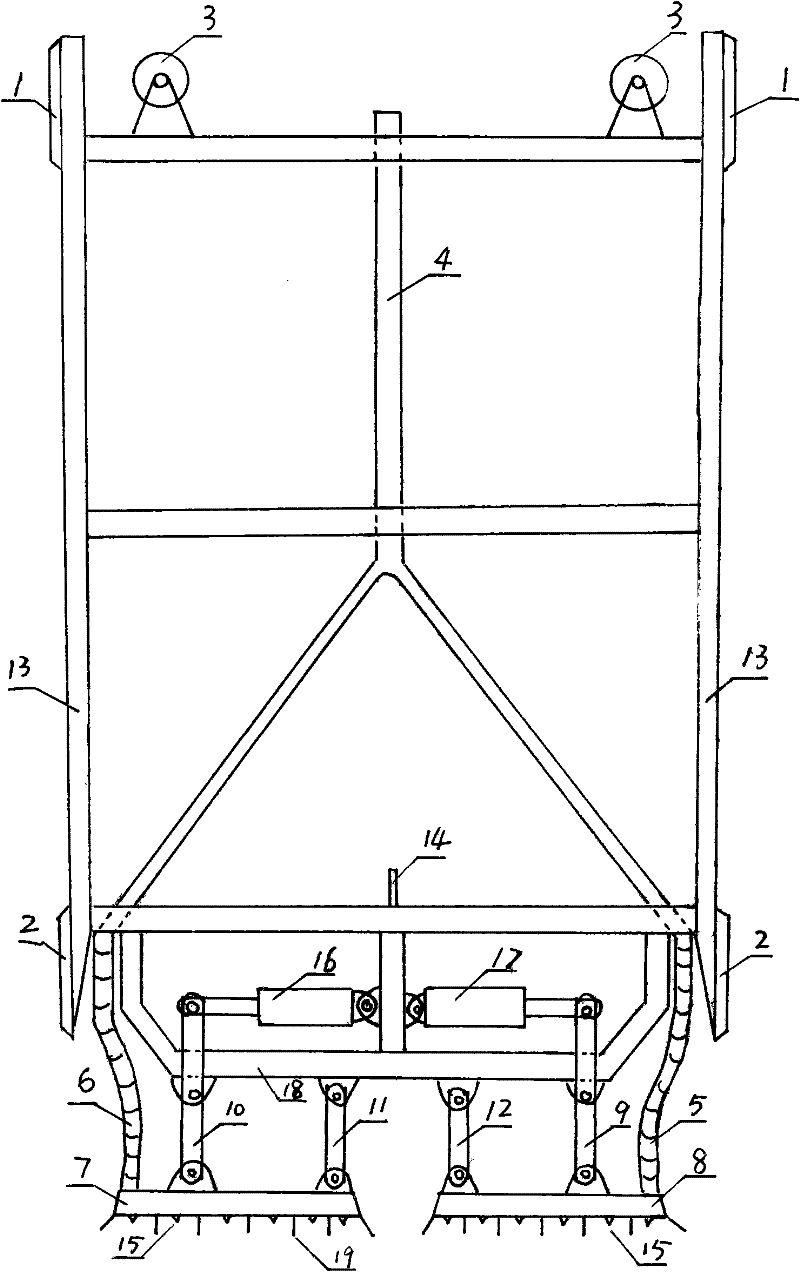

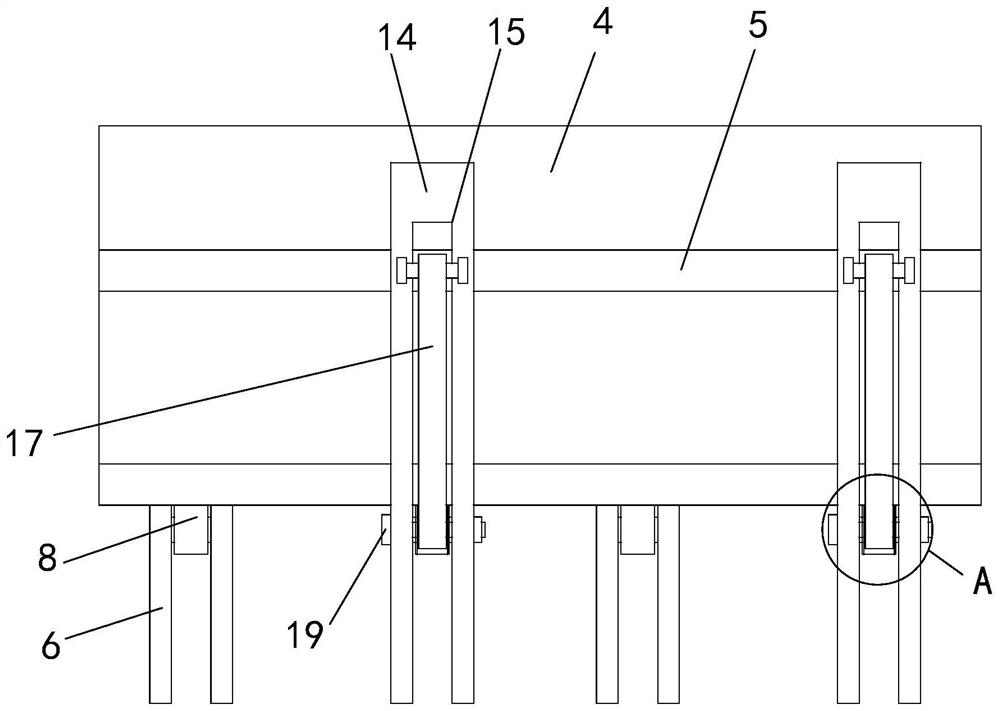

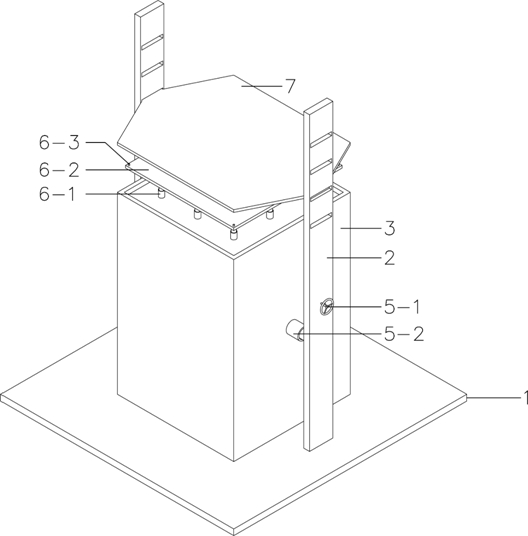

Basement outer wall single-side steel formwork supporting system and construction method thereof

PendingCN107313589AVerticality is easy to controlGuaranteed verticalityAuxillary members of forms/shuttering/falseworksBuilding material handlingSupporting systemArchitectural engineering

The invention provides a basement outer wall single-side steel formwork supporting system and a construction method thereof, and relates to the technical filed of constructional engineering equipment. Aiming at the problems that the labor intensity of construction personnel is high and formwork supporting work efficiency is low existing in the available supporting system, the basement outer wall single-side steel formwork supporting system and the construction method thereof are provided. The basement outer wall single-side steel formwork supporting system comprises a pair of tracks, bases, and a plurality of supporting trusses, wherein the pair of tracks is laid at a foundation slab and parallel to an outer wall steel formwork, the bases are arranged on the tracks and can slide along the tracks, and the multiple supporting trusses are vertically arranged at intervals and are connected with the outer wall steel formwork; and bottom parts of the supporting trusses are hinged to the bases, and the supporting trusses are detachably connected with top ends of the bases through a plurality of adjusting rod pieces. The construction method comprises the steps that the steel formwork supporting system is spliced and fixed, after outer wall concrete is poured, a ground anchor assembly and a diagonal bracing are disassembled, an adjusting rod piece is retracted, so that the demoulded outer wall steel formwork are made to be supported on the base, and the next working section is started to continue pouring construction of outer wall concrete.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Silicon through hole etching method

InactiveCN102431960AAvoid pollutionVerticality is easy to controlDecorative surface effectsChemical vapor deposition coatingMicro nanoSilicon etching

The invention provides a silicon through hole etching method and belongs to the field of micro nano machining of micro electro mechanical systems, and the method can be used for solving the problems that the side wall of a substrate generates ripples, a photoresist can be easily damaged and metal pollution is caused when an existing Bosch process and a metal mask are utilized to carry out deep silicon etching. The method provided by the invention comprises a pattern preparation step, an etching step, a culture slice adding step, a penetrating step and a photoresist removing step. In the etching step, processing is stopped after circulative and alternative etching is finished, so that the photoresist is cooled and the protective action of the photoresist is prevented from being reduced; then circulative etching is carried out again; passivating gas is added into etching gas; and the etching gas is added into the passivating gas for improving the smoothness of the side wall. In the culture slice adding step, a silicon wafer is adhered to the upper surface of a culture slice,thus preventing silicon wafer fracture and equipment damage after etching penetration. The method provided by the invention has the advantages that the process is simple and the etching speed is quick; the photoresist utilized as the mask can be easily removed after being etched, and metal pollution is avoided; the verticality of the side wall of a through hole is easily controlled; the smoothness of the side wall is improved; and the ripples on the side wall are eliminated.

Owner:HUAZHONG UNIV OF SCI & TECH

Construction method of reinforced concrete current-poured pile

ActiveCN104452749AImprove carrying capacityEasy constructionBulkheads/pilesSocial benefitsReinforced concrete

The invention relates to a construction method of a reinforced concrete current-poured pile. The method mainly comprises the steps that (1), a slurry protecting wall is drilled for hole forming, a drilling machine is used for drilling a hole in the hole forming process, and then the hole bottom is chambered through a branch tray forming machine; (2), the expanding end at the bottom of the pile is poured in an underwater concrete pouring mode; (3), a reinforcing cage is manufactured, stirrups are provided with reinforced protection cushion blocks at intervals, and a positioning support is formed; (4), inner side mould bags and outer side mould bags are attached to the inner side and the outer side of the positioning support respectively, and end boards are installed at the bottom of the positioning support; (5), the positioning support and the mould bags are pressed into the hole together; (6), micro-expansion concrete is poured in the space of the inner side mould bags and the outer side mould bags; (7), after the concrete of a pile body reaches the intensity, a pile top closing body and a cover board are constructed. The reinforcing cage is arranged in the reinforced concrete current-poured pile, the pile bearing capacity is improved, influence on the quality of the finished pile from foundation soil is reduced, the construction speed is high, quality is convenient to ensure, and good economic benefits and social benefits are obtained.

Owner:山东恒祥城市建设发展集团有限公司

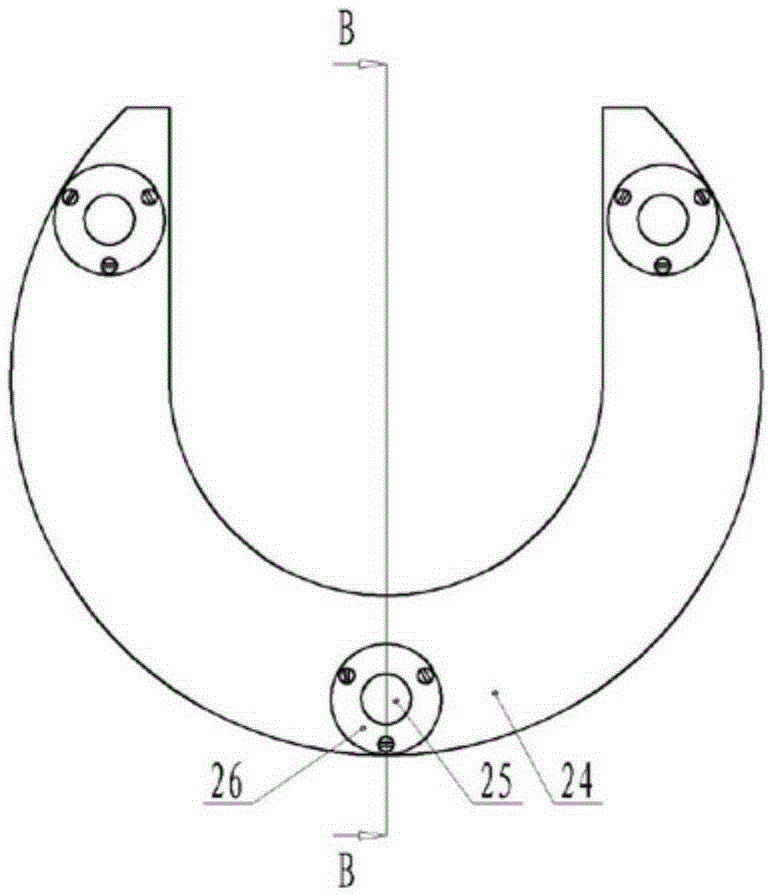

Construction method for embedding latticed column through reverse building method

ActiveCN105951747AVerticality is easy to controlArtificial islandsUnderwater structuresStructural engineering

The invention discloses a construction method for embedding a latticed column through a reverse building method. The construction method is characterized by comprising the following steps that a positioning frame is customized, a field is flattened, a pile position is set out, a pile hole is formed, a reinforcement cage is placed downwards, the positioning frame is placed in place and corrected, the latticed column is placed downwards, the perpendicularity of the latticed column is adjusted, a guide pipe is placed downwards and secondary hole cleaning is conducted, concrete pouring is conducted, and protection work is conducted. By the adoption of the method, control over the perpendicularity of the latticed column embedded through the reverse building method is facilitated.

Owner:温州市建设工程咨询有限公司

A construction method for reinforced concrete cast-in-place pipe piles

ActiveCN104452749BImprove carrying capacityEasy constructionBulkheads/pilesSocial benefitsReinforced concrete

The invention relates to a construction method of a reinforced concrete current-poured pile. The method mainly comprises the steps that (1), a slurry protecting wall is drilled for hole forming, a drilling machine is used for drilling a hole in the hole forming process, and then the hole bottom is chambered through a branch tray forming machine; (2), the expanding end at the bottom of the pile is poured in an underwater concrete pouring mode; (3), a reinforcing cage is manufactured, stirrups are provided with reinforced protection cushion blocks at intervals, and a positioning support is formed; (4), inner side mould bags and outer side mould bags are attached to the inner side and the outer side of the positioning support respectively, and end boards are installed at the bottom of the positioning support; (5), the positioning support and the mould bags are pressed into the hole together; (6), micro-expansion concrete is poured in the space of the inner side mould bags and the outer side mould bags; (7), after the concrete of a pile body reaches the intensity, a pile top closing body and a cover board are constructed. The reinforcing cage is arranged in the reinforced concrete current-poured pile, the pile bearing capacity is improved, influence on the quality of the finished pile from foundation soil is reduced, the construction speed is high, quality is convenient to ensure, and good economic benefits and social benefits are obtained.

Owner:山东恒祥城市建设发展集团有限公司

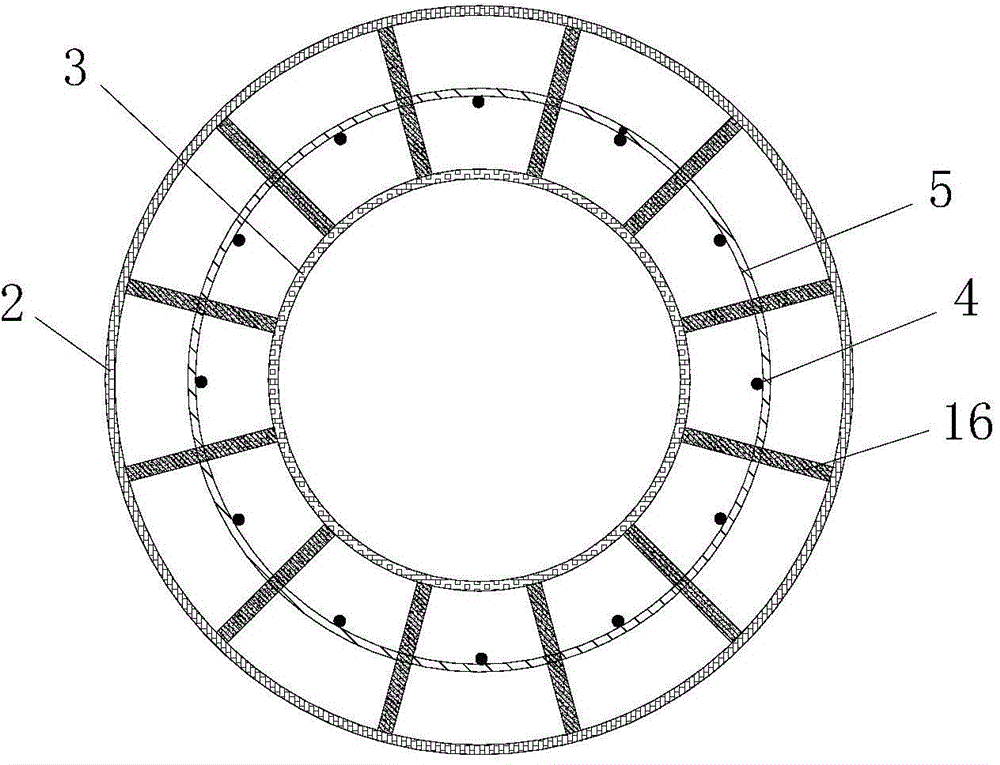

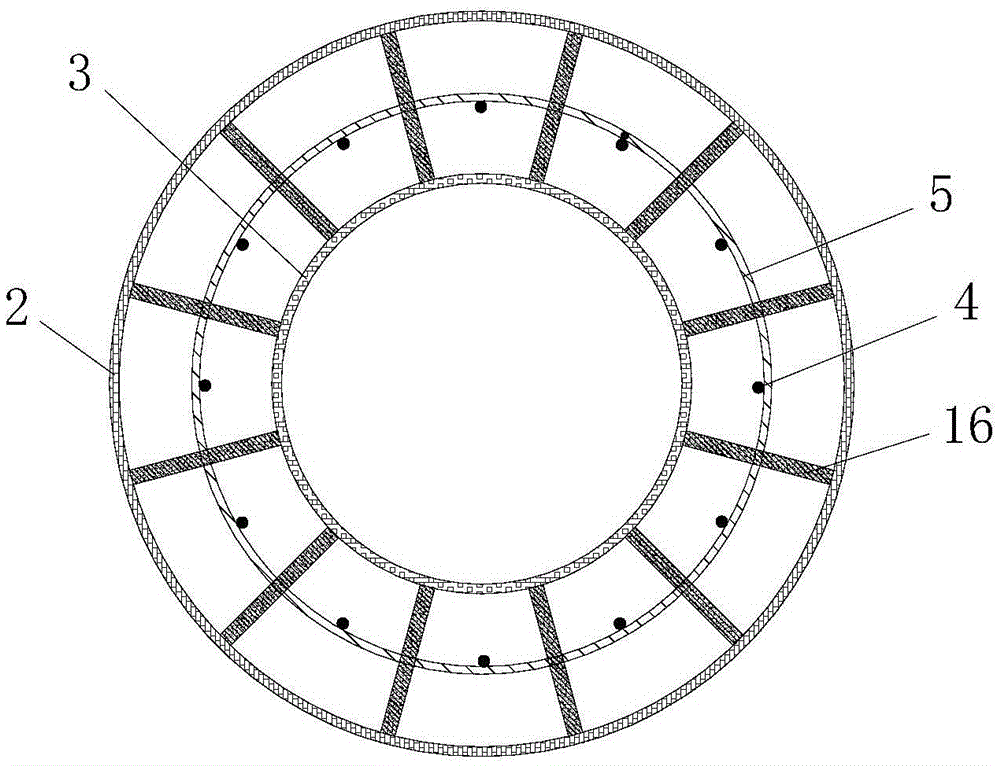

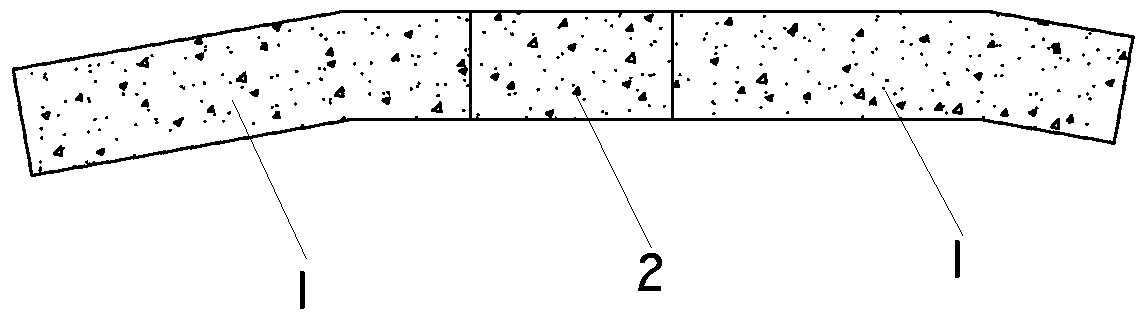

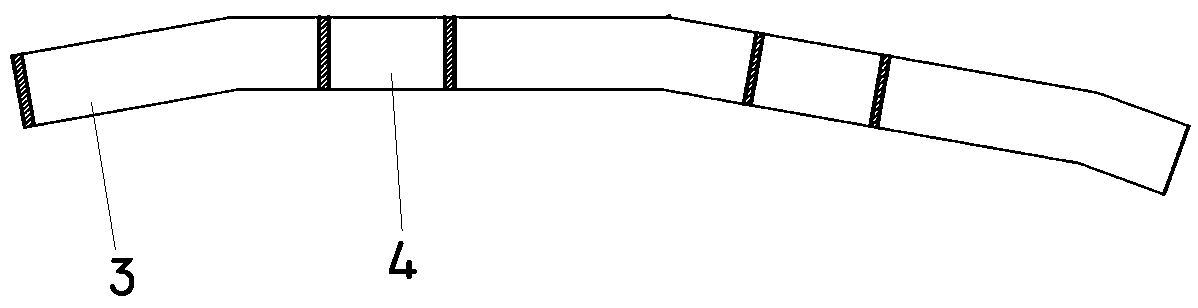

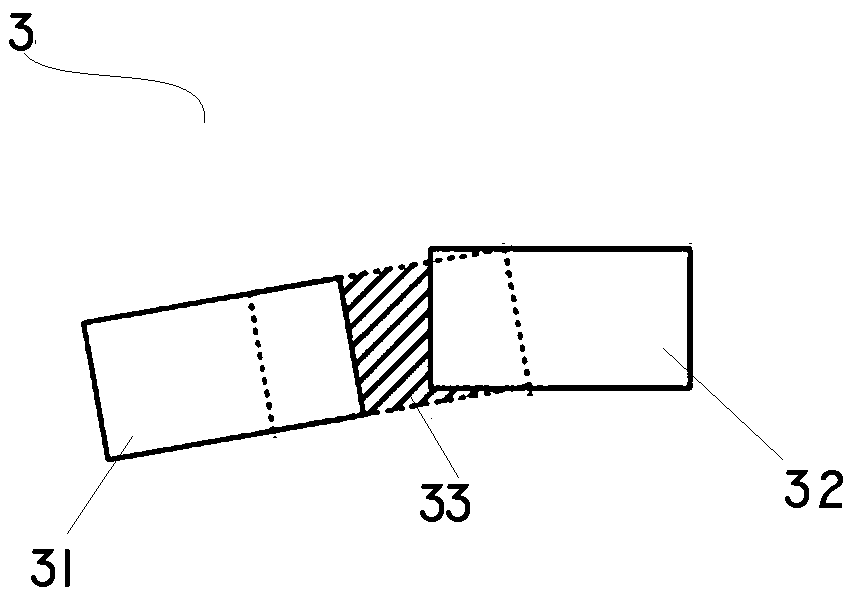

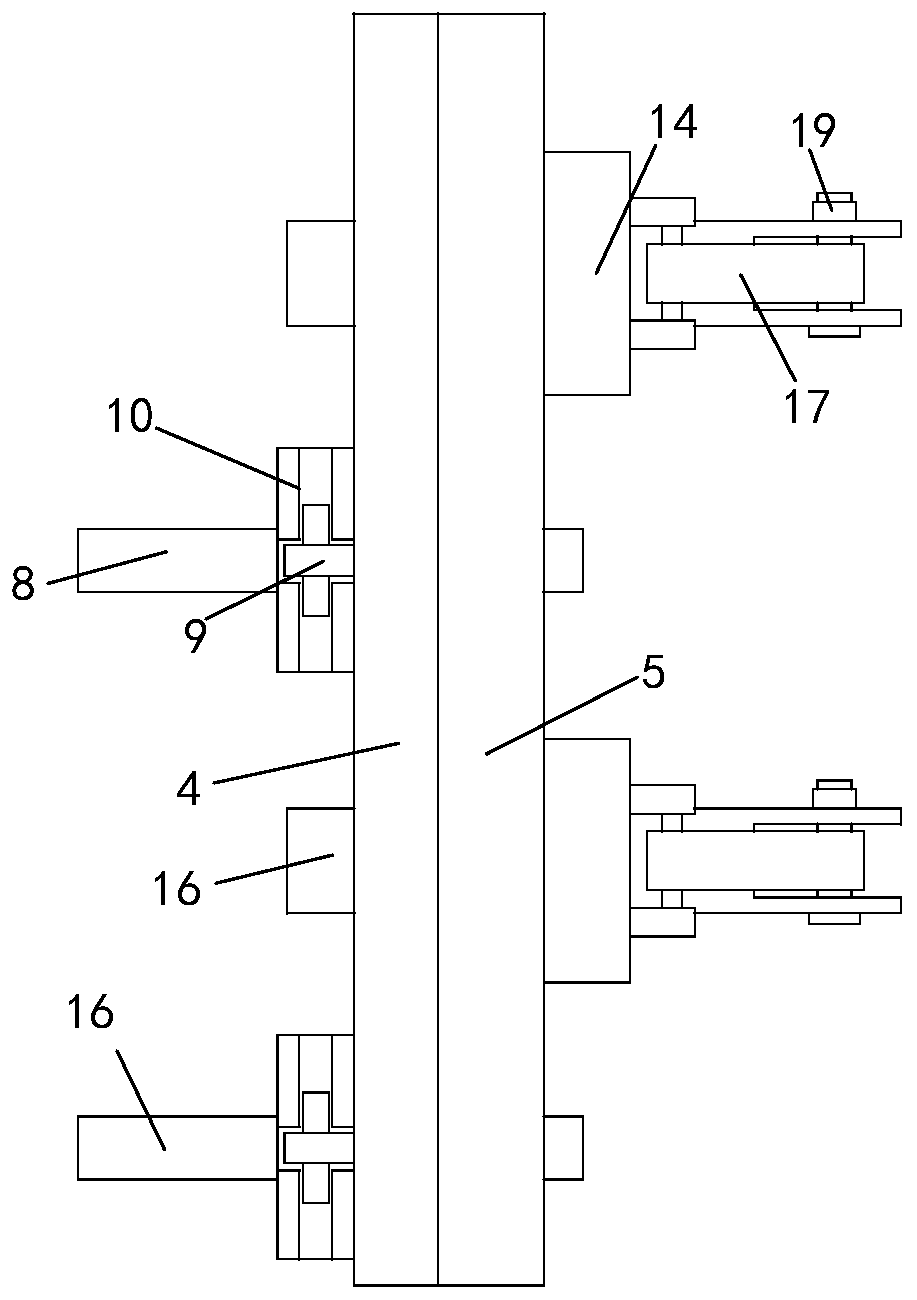

Reclamation area ultra-deep concrete diaphragm wall structure and construction method thereof

InactiveCN110512593AIngenious designImprove construction efficiencySoil-shifting machines/dredgersBulkheads/pilesImportance factorWell control

The invention discloses a reclamation area ultra-deep concrete diaphragm wall structure and a construction method thereof. The concrete diaphragm wall structure is in a ring shape, the concrete diaphragm wall structure comprises I type concrete diaphragm walls and II type concrete diaphragm walls which are arranged at intervals, the I type concrete diaphragm walls comprise I type groove sections,reinforcement cages arranged in the I type groove sections and cast-in-situ concrete, and the II type concrete diaphragm walls comprise II type groove sections, reinforcement cages arranged in the IItype groove sections and cast-in-situ concrete. Groove grasping technology construction can be conducted in advance, the construction main line time is not occupied, the construction efficiency is greatly improved, and the construction time is shortened. A reclamation area belongs to soft soil ground, soil reinforcement is conducted by using three-axis mixing before concrete diaphragm wall construction. Perpendicularity is well controlled, the width of sleeve connection is guaranteed, and later stage leakage is avoided. The formed concrete diaphragm wall structure is firm and durable, the safety level of a foundation pit support structure is the first level, and the importance factor is 1.1. The service life of the foundation pit temporary support structure is designed to be two years, andthe service life of the foundation pit support structure for permanent using is 50 years.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

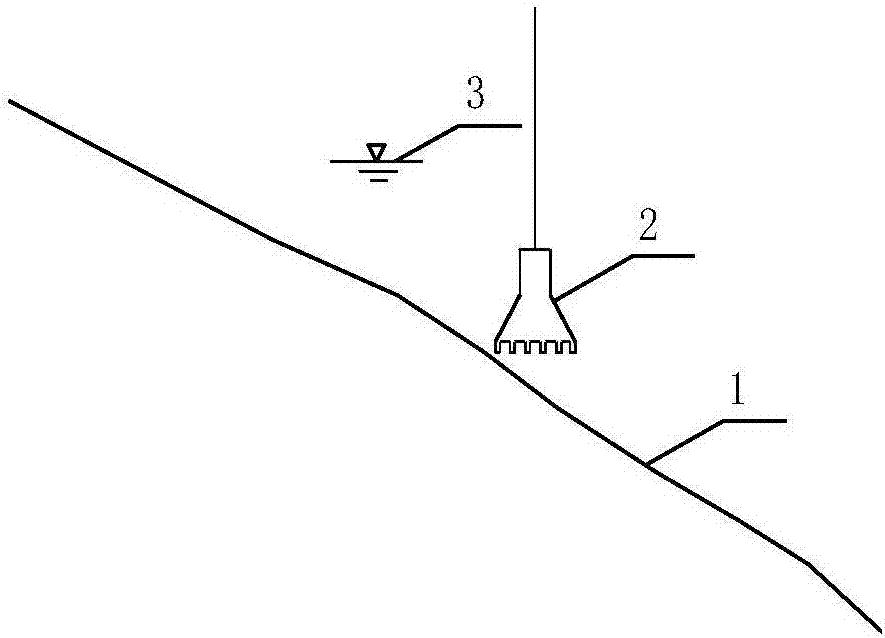

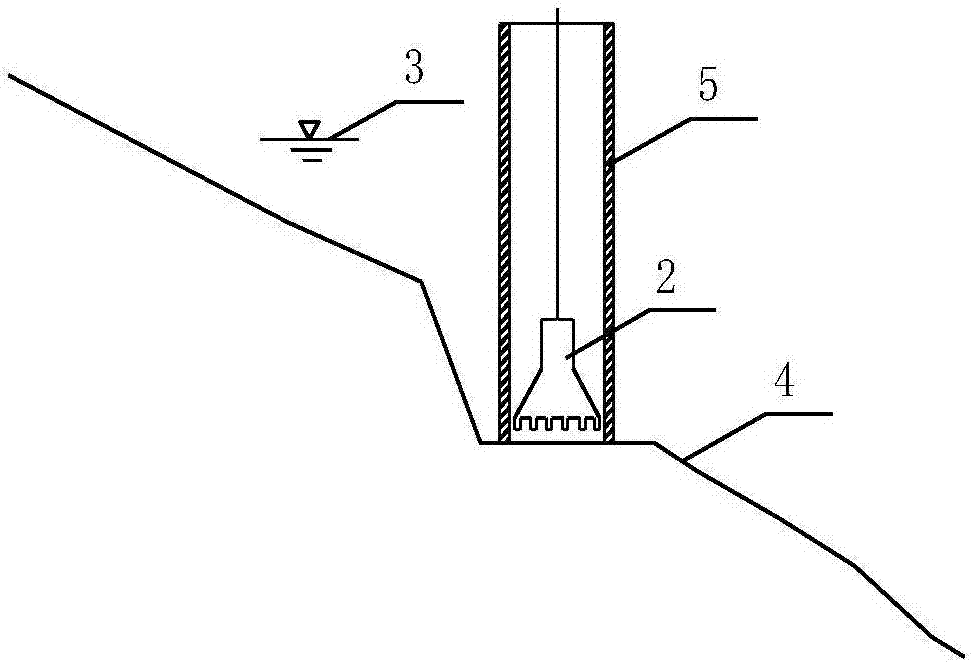

Steel protection tube following method under deep water inclined rock surface condition

InactiveCN107059857AVerticality is easy to controlPosition is easy to controlBreakwatersQuaysGeomorphologyDrill bit

The invention discloses a steel protection tube following method under a deep water inclined rock surface condition. The method comprises the following steps: step one, building a drilling platform in a pier position, placing an impact drilling machine in a drilling pile position of the drilling platform, and flatly impacting and tamping a river bed surface of the drilling pile position of the drilling platform through the impact drilling machine; step two, putting the steel protection tube down, enabling the steel protection tube to be in contact with the flat rock surface, drilling a hole with depth of 30-50cm in the rock surface on the inner side of the steel protection tube by using a drilling head, lifting up the drilling head and mounting a driving device at the top of the steel protection tube, striking and driving in short distance by using the drilling head and enabling the steel protection tube to gradually enter the hole; and step three, repeatedly carrying out the step two and enabling the steel protection tube to gradually follow into the preset depth. The steel protection tube following method has the advantages of simple operation, low cost and easily controllable perpendicularity and plane position of the steel protection tube.

Owner:CCCC SECOND HARBOR ENG

Foundation pile hole drilling construction process

InactiveCN104141300AEasy to moveIncrease drilling speedExcavationsBulkheads/pilesEngineeringFoundation engineering

The invention discloses a foundation pile hole drilling construction process, which comprises the following technical flow processes of construction preparation, field flattening, pile position lofting, protection tube burying, drilling machine place taking, drilling, hole cleaning, hole forming quality checking, steel bar cage and catheter mounting, catheter mounting, secondary hole cleaning, underwater concrete filling, protection tube pulling and removing and pile forming quality checking. The foundation pile hole drilling construction process has the advantages that the construction time of the foundation engineering is shortened, the construction period pressure of a lower part structure is reduced, and in addition, a part of labor, machine and material investment is reduced, so the total construction cost of the project is reduced.

Owner:LUOYANG GUANGXIN CONSTR GRP

Method for treating soft soil foundation through deep compound vacuum pre-compaction

The invention relates to a method for treating soft soil foundation through deep compound vacuum pre-compaction. According to the method, a pressurizing system is improved on the basis of pressurized vacuum pre-compaction, a plastic draining plate substitutes a pressurizing filtration pipe, and a steel wire soft pipe substitutes a PVC (polyvinyl chloride) pipe in a transverse pressurizing system. The problems of difficulty in driving the pressurizing filtration pipe, difficulty in controlling perpendicularity and the like when a deep soil body is pressurized are mainly solved. The atmospheric pressure difference between a vertical draining plate in the pressurizing system and a vertical draining plate in a vacuumizing system is increased by pressurizing the deep soil body by the vertical draining plate in the pressurizing system, so that the radial seepage velocity of pore water is increased; furthermore, due to the fact that the pressurizing effect back flushes a sludge layer with relatively dense texture formed nearby the vertical draining plate during a vacuumizing period, the permeability is improved; meanwhile, due to the fact that mud particles contained in a membrane filtering pore of the vertical draining plate can also be reversely blown out through the pressurizing effect, the water permeability of the vertical draining plate is enhanced. The soft soil foundation can be relatively well treated.

Owner:WENZHOU UNIVERSITY

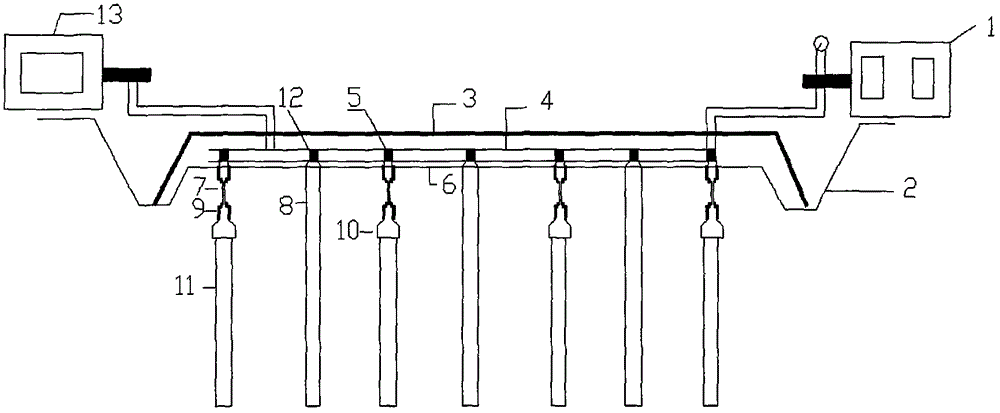

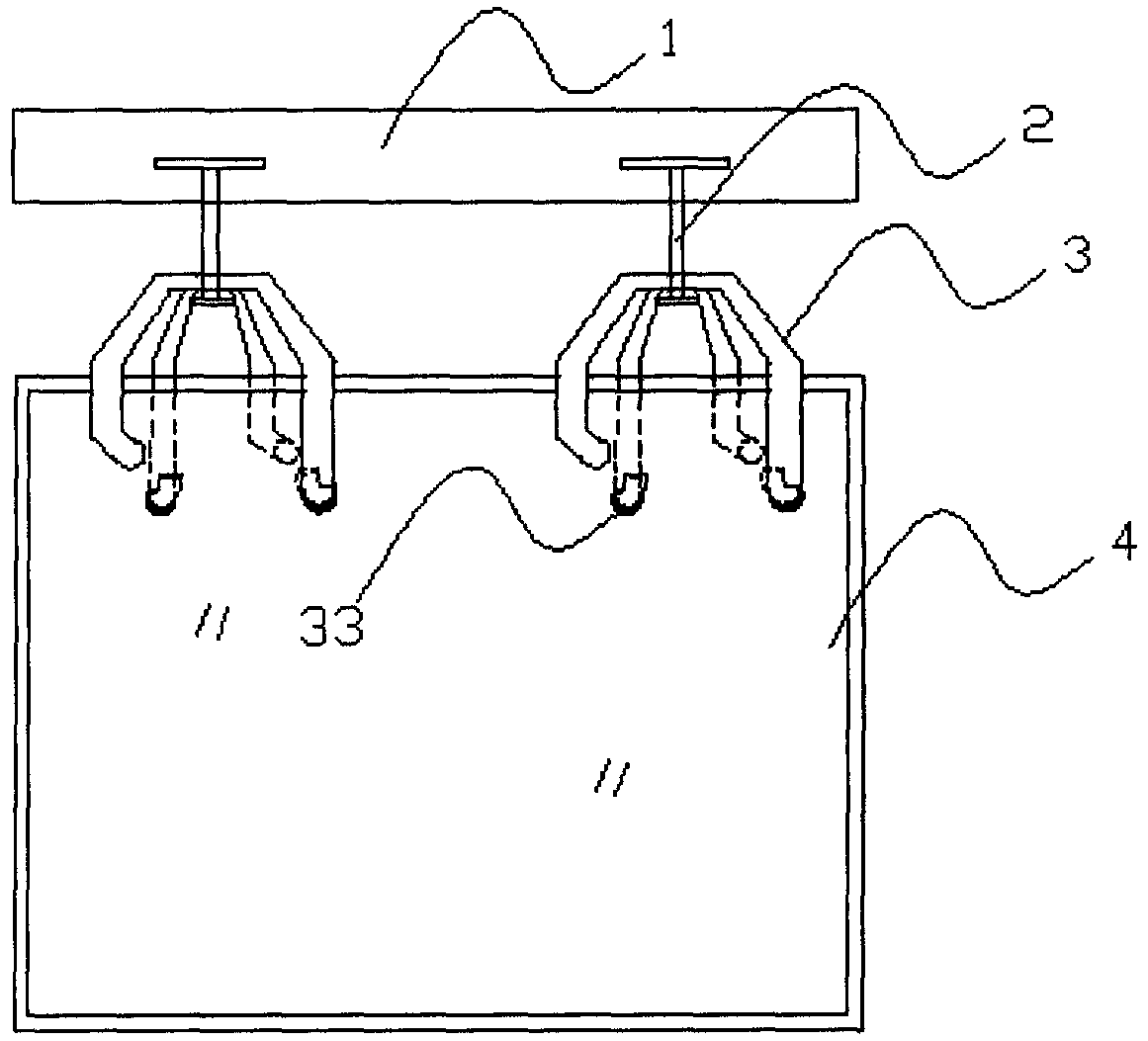

Pre-buried latticed column verticality measurement construction method

ActiveCN103103995AEnsure safetyImprove construction progressFoundation testingBasementEconomic benefits

The invention discloses a pre-buried latticed column verticality measurement construction method, and belongs to the technical field of building-construction. The steps of the pre-buried latticed column verticality measurement method includes that: pre-buried latticed columns are processed, a biaxial inclinometer is chosen, a sensor is calibrated, the inclinometer is assembled, a position is chosen for installation of the inclinometer, the pre-buried latticed columns and the inclinometer are installed and placed, biaxial inclination angles of the pre-buried latticed columns are measured and adjusted, after concrete pouring is finished, the inclinometer is detached, and the like. According to the pre-buried latticed column verticality measurement method, due to the facts that the inclinometer is arranged on the pre-buried latticed columns, in the construction process of the pre-buried latticed columns, angle ranges are regulated timely to enable the angle ranges to be within designed ranges according to the perpendicular angel changing displayed on a displayer, and then the pre-buried latticed columns are fixed, the accuracy and perpendicularity degree of the locating of the pre-buried latticed columns and the direction of the pre-buried latticed columns are convenient to control, and therefore the pre-buried latticed column verticality measurement method is applicable for construction of basements with large excavation depths, safety of building foundation pits, surrounding roads and pipelines is guaranteed, overall project construction progress is accelerated at the same time, project manufacture cost is saved, and economic benefit is improved.

Owner:WENZHOU CONSTR GROUP

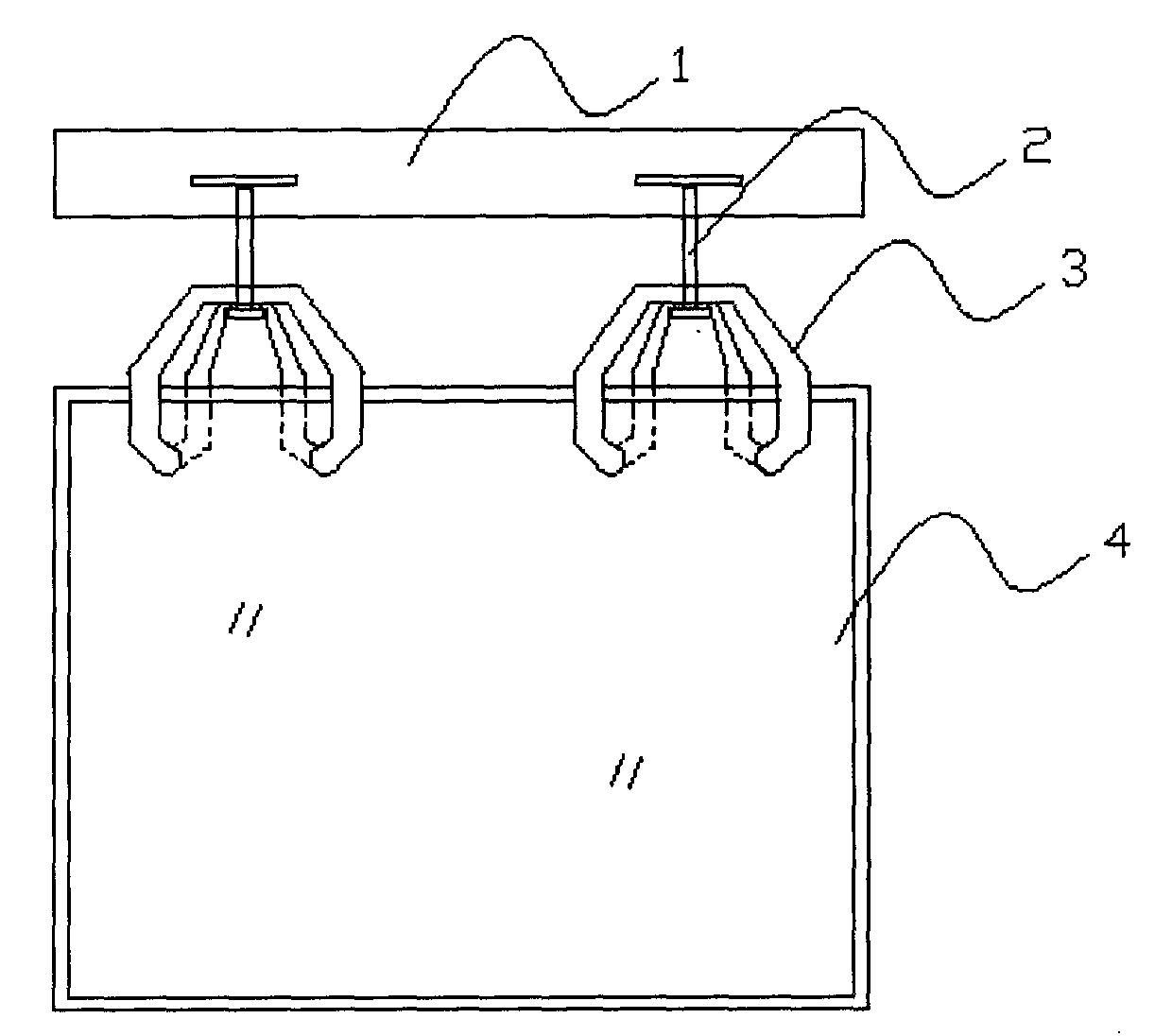

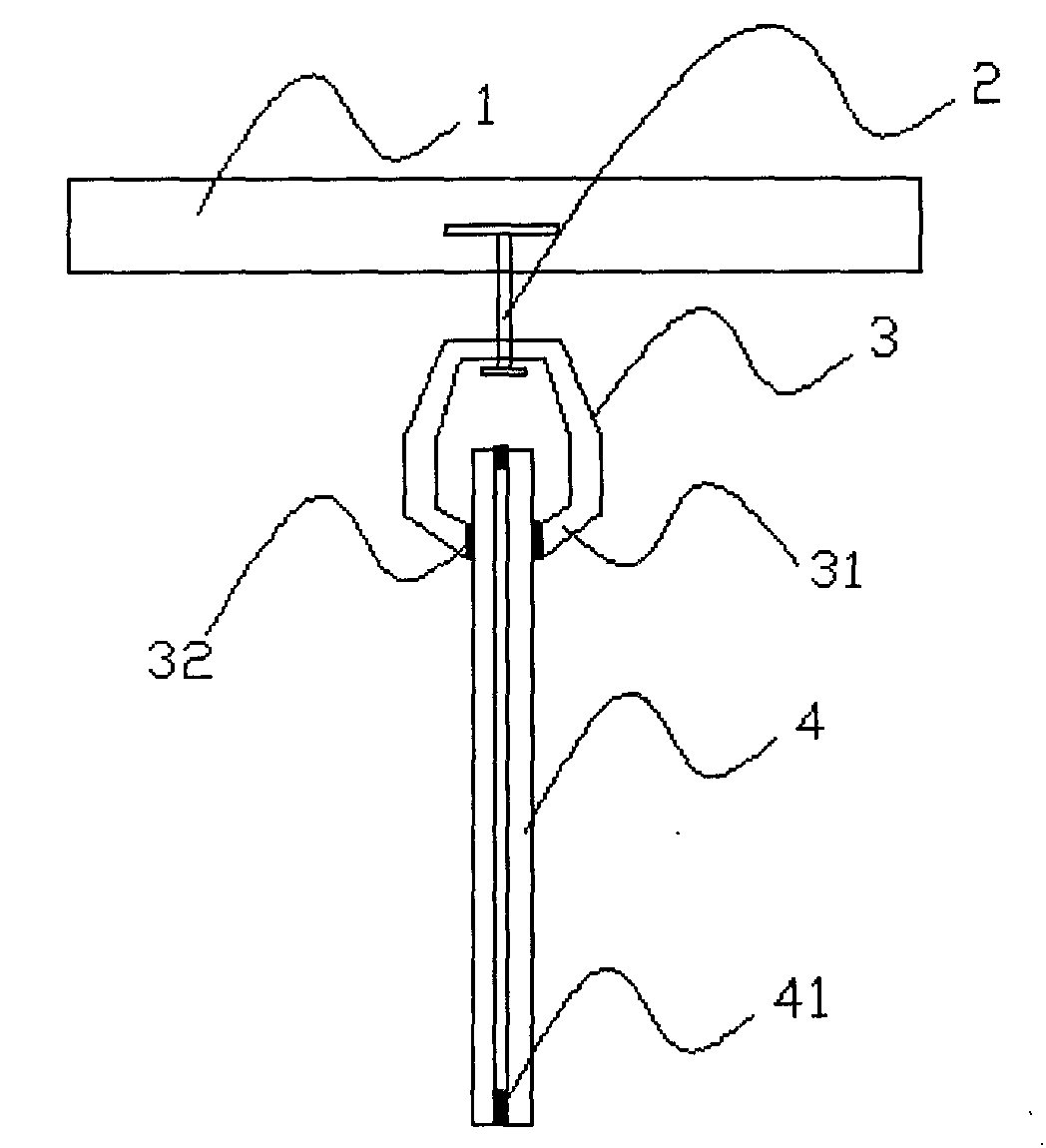

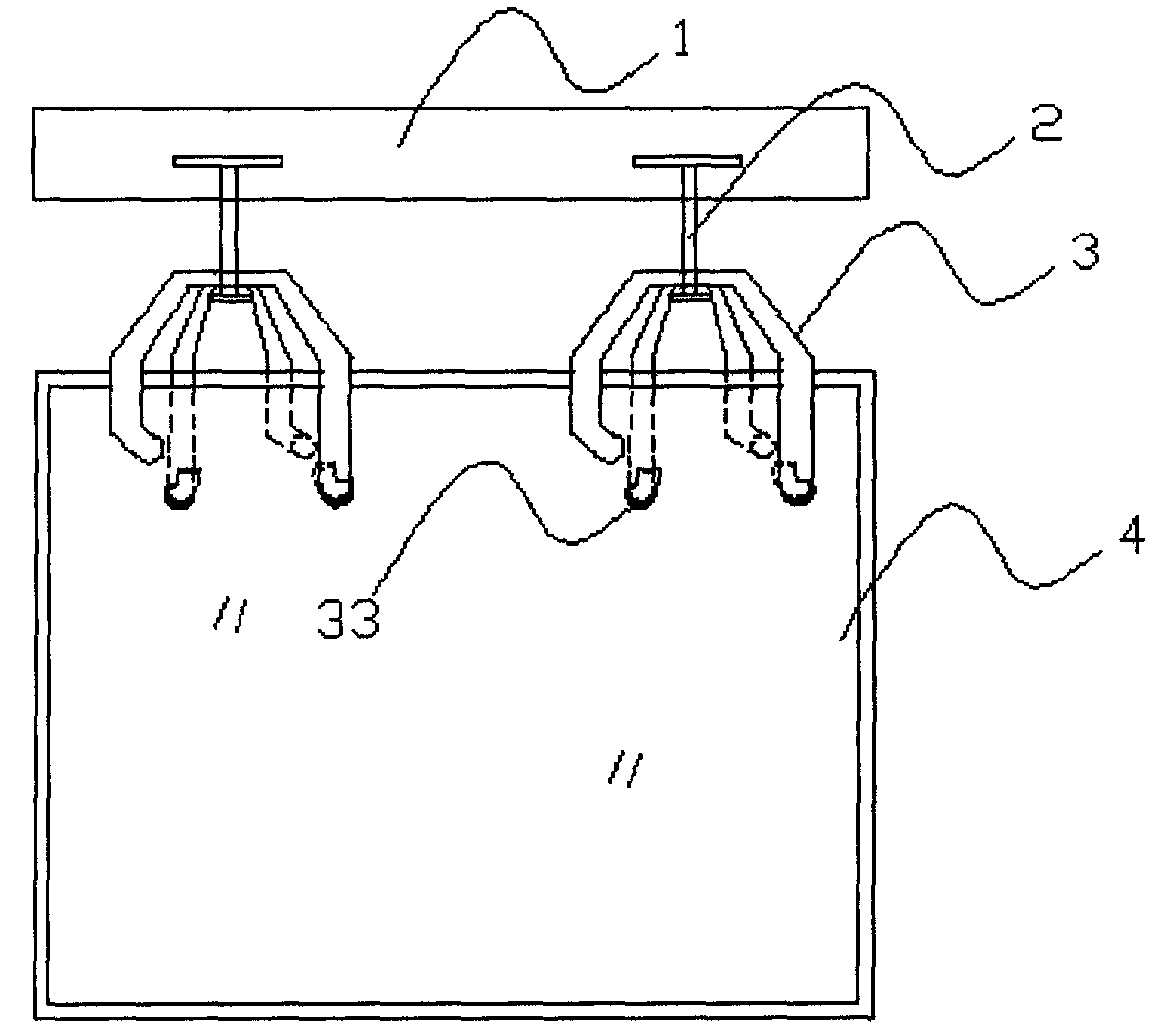

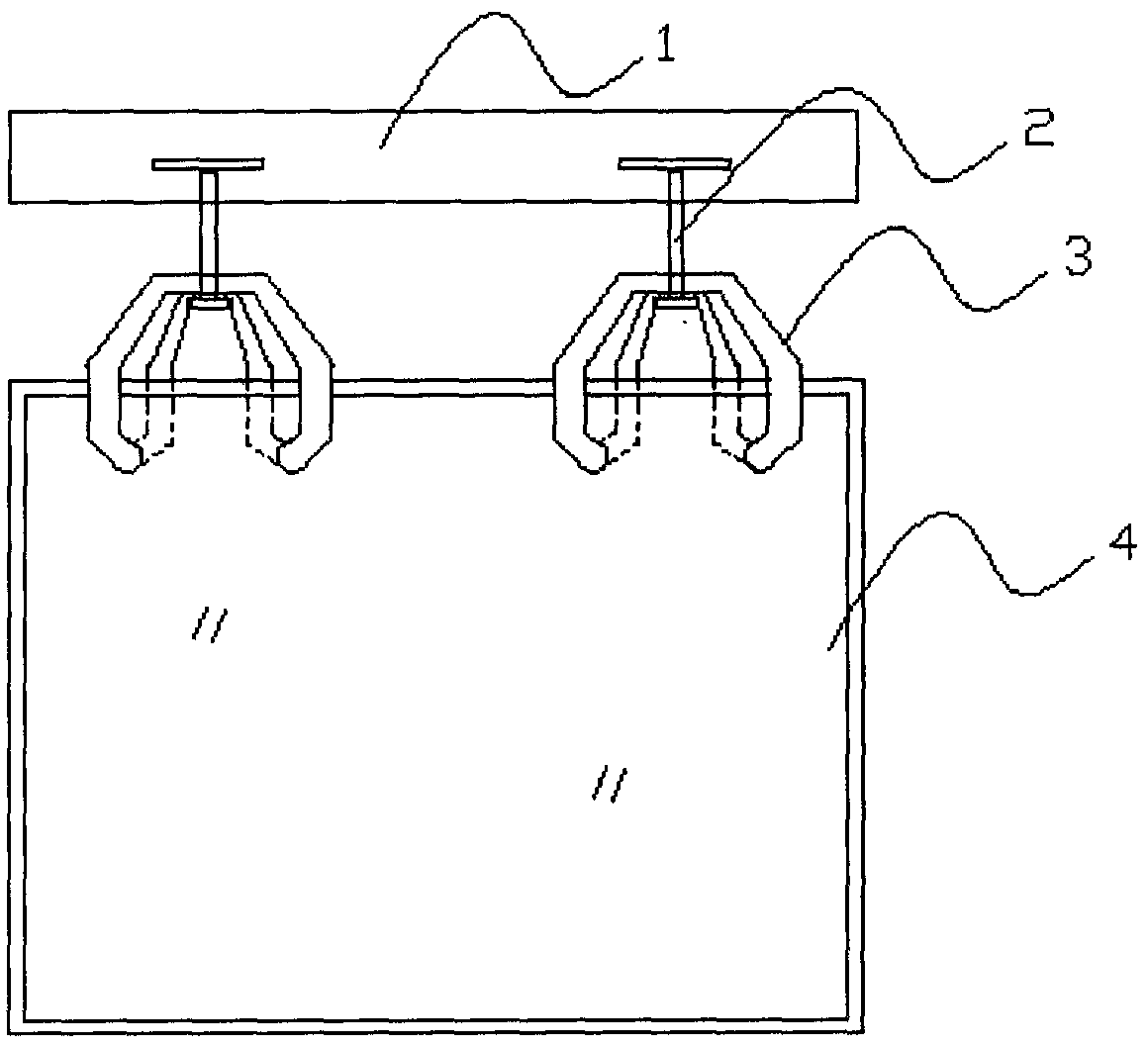

Suspension type glass inner curtain wall

InactiveCN103362240ASimple and transparent structureEasy to control verticalityWallsMechanical engineeringSupport system

The invention belongs to the technical field of building structural members, and particularly relates to a suspension type glass inner curtain wall. The suspension type glass inner curtain wall comprises a suspension rod, a suspension part and a glass panel, the upper end of the suspension rod is embedded in a ceiling in advance, the lower end of the suspension rod is connected with the suspension part, the suspension part is fixedly connected with the top end of the glass panel, and the suspension part can be a suspension claw or a mounting groove. The perpendicularity of the suspension type glass inner curtain wall can be controlled easily, support systems on the ground and fixing structures on the two side wall faces are of no need, and the suspension type glass inner curtain wall is not prone to falling and is transparent and tidy in structure. Further, the lower end of the two sides of the glass panel can be designed to be suspended in the air, no sanitation blind corners are formed, the glass panel can be detached conveniently, no traces are formed on a base board and walls when the glass panel is replaced, and the aesthetic requirements for modern interior decoration are met. The suspension type glass inner curtain wall has revolutionary significance in fundamentally solving the problems that the support system with high bearing capability is needed in the prior art and the perpendicularity of the glass panel is difficult to guarantee. Further, the suspension type glass inner curtain wall has good application prospects in the technical field of the building structural members.

Owner:JIN GUANG DAO ENVIRONMENTAL CONSTR GRP

Cutter suction dredger reamer beam long-axle-hole reaming support mounting method

ActiveCN104594421AReduce the need to useEliminate the disadvantages of on-site boring installationMechanical machines/dredgersEngineeringReamer

The invention provides a cutter suction dredger reamer beam long-axle-hole reaming support mounting method. Lines are scribed on a reaming point base and a ship hull block respectively, then scribed line alignment mounting is conducted on the reaming point base and the ship hull block, the perpendicularity of the reaming point base is controlled in the mounting process, the two sides of the reaming point base are symmetrically welded when the reaming point base is welded, and a reaming shaft and a reaming cover are arranged after the reaming point base is arranged on a ship hull. According to the method, a reamer beam can be prefabricated due to arrangement of the reaming point base, the defect of field boring and mounting is overcome, the production cycle can be shortened effectively, and working efficiency is improved; meanwhile, the requirement for using auxiliary tools is reduced greatly, the machining difficulty is lowered, no dummy shaft is needed to conduct auxiliary machining, and the machining difficulty and production cost are lowered.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Open caisson construction technology

InactiveCN106812148AImprove the construction environmentSimple caisson constructionCaissonsComputer monitoringEngineering

The invention relates to an open caisson construction technology, a jack set is placed into a foundation pit, a concrete plate is placed at the upper end of the jack set, and the periphery of the foundation pit is filled with a lubrication water-stop agent which has the functions of reducing displacement of peripheral soil, increasing concrete sinking power and stopping water; the jack set has the function of adjusting the perpendicularity; the blade foot has the cut soil sinkingfunction; a computer monitoring system monitors the perpendicularity of the open caisson in real time by a perpendicularity monitoring point. According to the open caisson construction technology, the problems that in the conventional construction technologies the sinking speed cannot be controlled, the peripheral sinking is large, damage to the peripheral environment is large, the perpendicularity adjustment is inconvenient and inflexible and the construction quality cannot be guaranteed are solved, the construction is easy, and the cost is saved.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

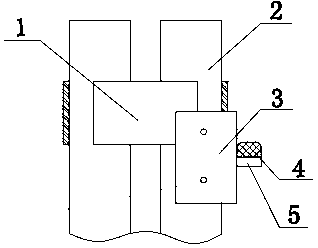

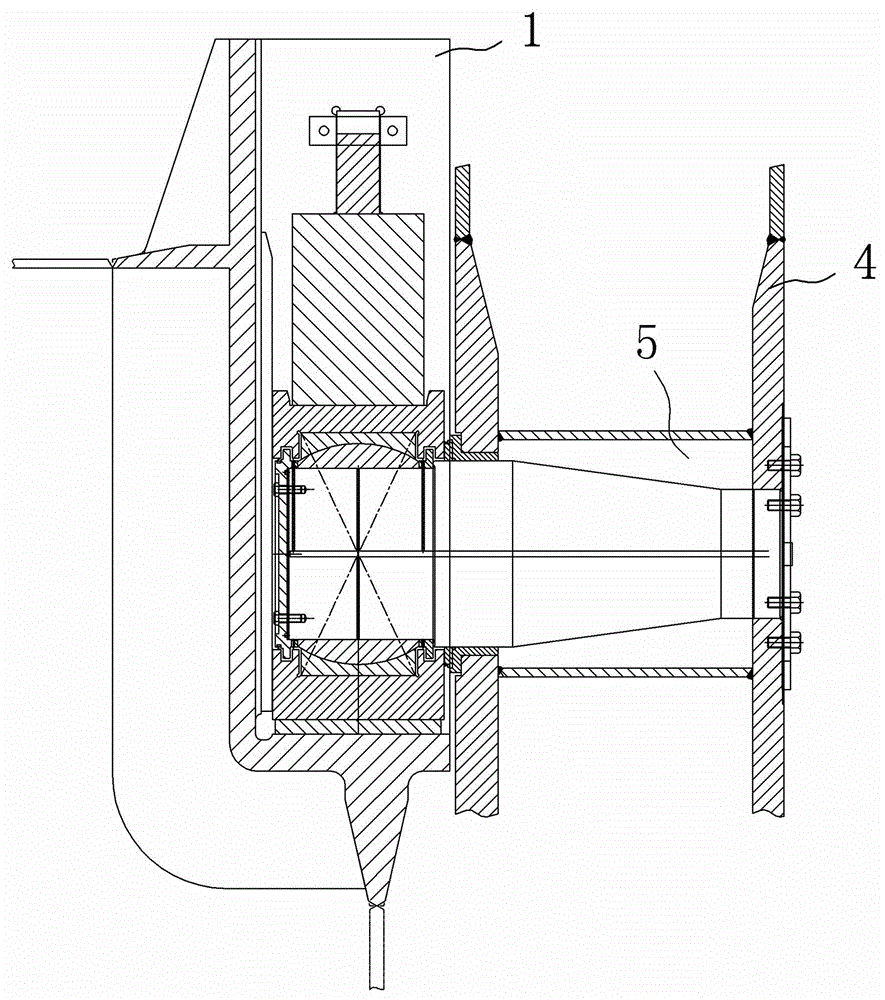

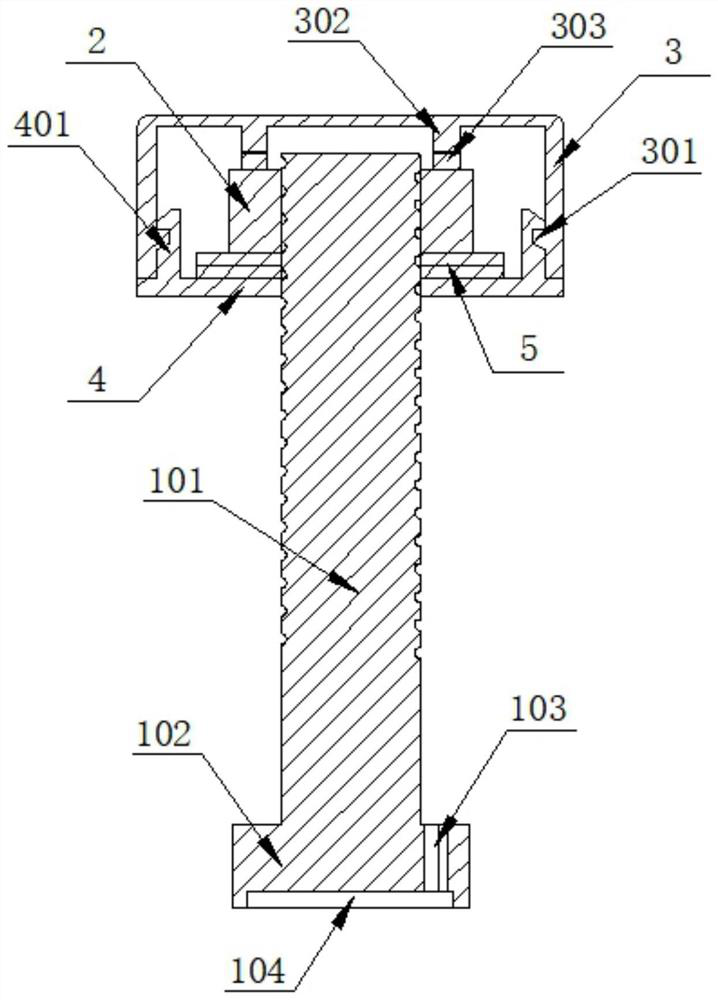

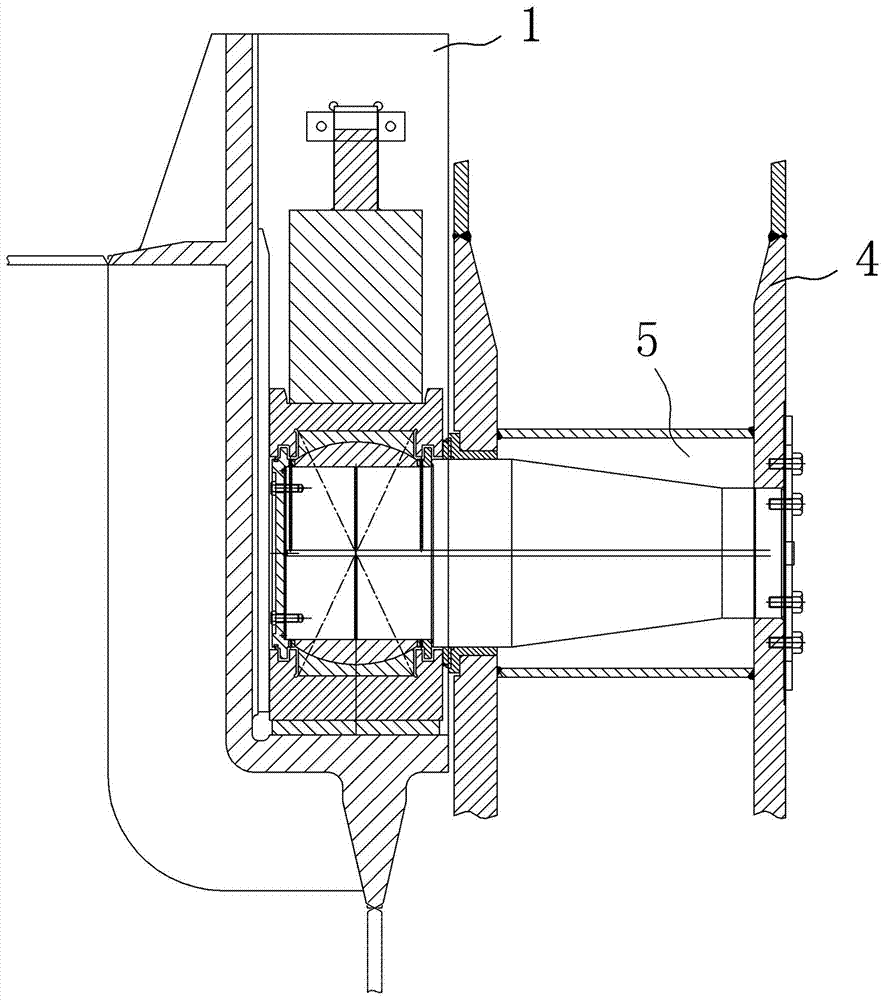

Adjustable Rod Type Oxygen Lance Quick Changer

InactiveCN104152626BVerticality is easy to controlMake up for assembly deviationManufacturing convertersEngineeringOxygen

The invention relates to a self-aligning rod-type oxygen lance quick replacing device. The self-aligning rod-type oxygen lance quick replacing device comprises a trolley platform for an oxygen lance, wherein the trolley platform for the oxygen lance carries an oxygen lance, an oxygen lance fixing device and three oxygen lance locating devices, and jacking pipes in the three oxygen lance locating devices are respectively movably plugged in three jacks of a connecting plate in the oxygen lance fixing device; during dismounting, the oxygen lance can be detached and lifted away only by removing quick-detach nuts in the oxygen lance fixing device; during mounting, a metal hose in each oxygen lance locating device can horizontally move on a horseshoe sliding seat, so that assembly deviation among three elbows of the oxygen lance can be made up, adjusting is convenient, the jacking pipes can be conveniently butted with the jacks, and communication between the three jacking pipes and the three elbow pipes of the oxygen lance is completed; during aligning, a matching surface of a connecting pipe of each oxygen lance locating device and one corresponding jacking pipe is a cambered surface, so that the perpendicularity of the oxygen lance can be easily controlled, and adjusting is convenient; after aligning, the quick-detach nuts are mounted again. The whole process can be completed in only dozens of minutes, and time and manpower are saved.

Owner:王志敏 +1

Device and method for eliminating side friction resistance of test piles

ActiveCN109056857AEliminate frictionInfluence of single pile bearing capacity valueFoundation testingEngineeringClose contact

The invention discloses a device and method for eliminating side friction resistance of test piles. The device comprises inner sleeves, outer sleeves, anti-turbulence devices and limiting devices, wherein the anti-turbulence devices are arranged at the lower end surfaces of the outer sleeves, the anti-turbulence devices comprise annular rubber plates which extend from the outer sleeves to the interiors of the outer sleeves, the limiting devices are used for being coaxially hoisted inside the outer sleeves, the inner sleeves coaxially penetrate through the limiting devices and then extend out of the annular rubber plates at the lower ends of the outer sleeves, the annular rubber plates are in close contact with the inner sleeves in the circumferential direction, the limiting devices can beused for coaxially positioning the inner sleeves and the outer sleeves, and gaps, located above the top surfaces of the limiting devices, between the outer sleeves and the inner sleeves are sealed bywaterproof sealing layers. The invention further discloses a method for eliminating side friction resistance of the test piles. According to the device and method for eliminating side friction resistance of the test piles, influence of the pile side friction resistance of the test piles in the depth range of foundation pit excavation in a static load test of the test piles can be eliminated, so that the static load test of the test piles can accurately reflect the bearing capacity and the sedimentation amount of engineering piles, and convenient use is achieved.

Owner:SHANGHAI JIANKE ENG CONSULTING

Soft soil foundation reinforcing method based on cement concrete cored piles

InactiveCN109162270ASimple construction methodReasonable designSoil preservationMaterials sciencePrefabrication

The invention discloses a soft soil foundation reinforcing method based on cement concrete cored piles. Multiple cement concrete cored piles, vertically distributed, are adopted to reinforce a soft soil foundation; and the method comprises the steps of: (1) prefabrication of the cored piles; (2) conveying of the cored piles; and (3) reinforcement of the foundation: the cement concrete cored pilesare constructed by adopting an integrated cored pile machine; and when any one cement concrete cored pile is constructed, six steps of placement of the pile machine in place, construction of cement stirring piles, shifting of the pile machine, installation of the cored piles, vertical placement of the cored piles and pressing of the piles are carried out. The method is simple in step, reasonable in design, convenient for construction, high in construction efficiency and excellent in use effect; after prefabrication of all the cored piles, the integrated cored pile machine finishes the construction of the cement stirring piles in the cement concrete cored piles and the pressing process of the cored piles, so that the construction speed is high; and the verticality of the cored piles in thepile pressing process is easily controlled, so that the quality of the formed cement concrete cored piles can be effectively guaranteed, and the reinforcing effect of the soft soil foundation is guaranteed.

Owner:NO 1 ENG LIMITED OF CR20G

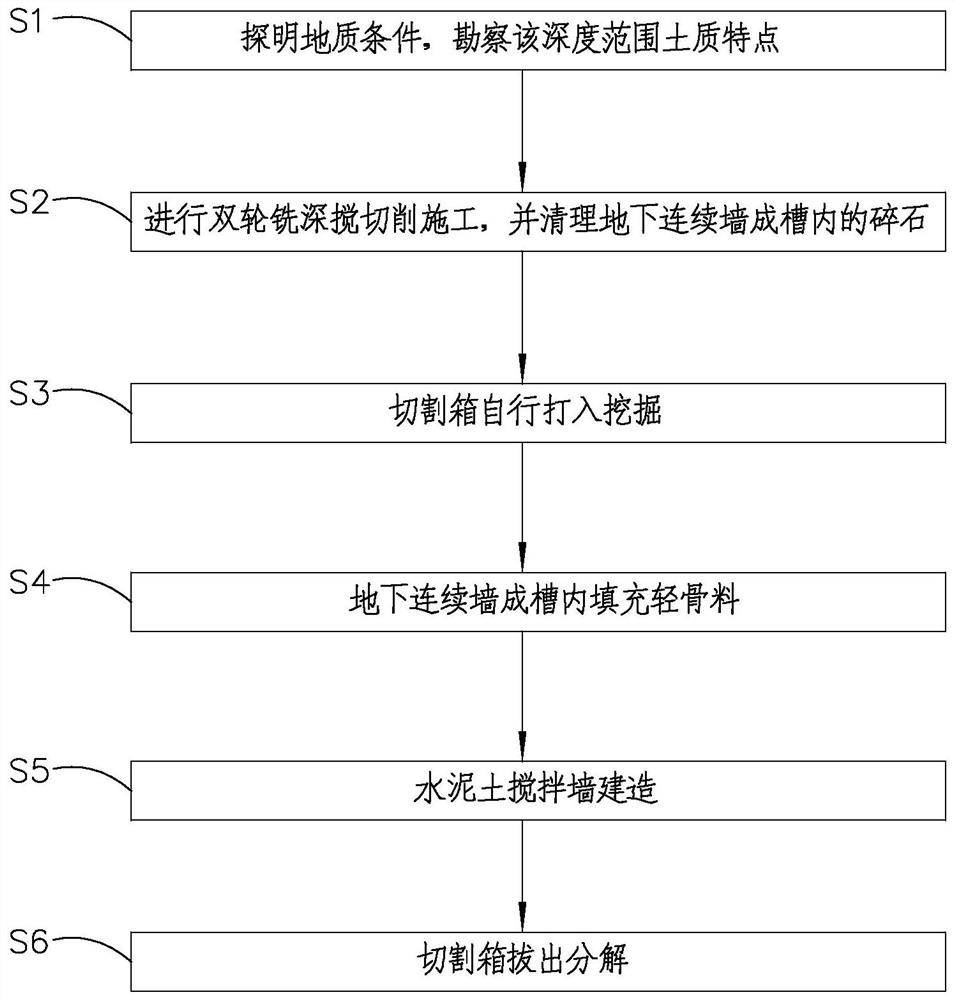

Construction technology of equal-thickness cement-soil stirring continuous wall

InactiveCN112942310AReduce the difficulty of cutting constructionReduce liquiditySoil-shifting machines/dredgersBulkheads/pilesSlurry wallSoil science

The invention relates to the field of underground continuous engineering, in particular to an equal-thickness cement-soil stirring continuous wall construction technology which comprises the following steps that geological conditions are ascertained, and soil texture characteristics in the depth range are investigated. Double-wheel milling deep stirring cutting construction is carried out, and broken stones in the underground diaphragm wall groove are cleaned. The cutting box is automatically driven for excavation. The underground diaphragm wall groove is filled with lightweight aggregate. A cement-soil stirring wall is built. The cutting box is pulled out and decomposed. According to the construction method, the construction problem of the equal-thickness cement-soil stirring continuous wall in the thick and high-strength dense and hard stratum is solved, the construction efficiency and quality of the underground continuous wall are improved, and material waste is reduced.

Owner:上海兴庚基础工程有限公司

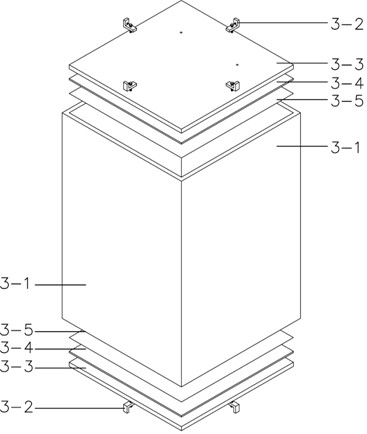

Reactor pressure vessel integral top cover with inner platform

InactiveCN109065190APosition is easy to controlVerticality is easy to controlNuclear energy generationContainmentReactor pressure vesselEngineering

The invention discloses a reactor pressure vessel integral top cover with an inner platform, comprising an integrated flange and a spherical head. A platform structure is integrally forged on the concave spherical surface of the spherical head, so that the concave spherical surface of the spherical head is gradually changed from a continuously gradual curved surface to a flat surface and then gradually changed to a continuous gradual curved surface. The platform structure is a solid body defined by a spherical surface and a circular plane, wherein the spherical surface of the platform structure and the concave spherical surface of the spherical head are integrally matched and connected, the circular plane of the platform structure is horizontally arranged, and the height of the circular plane in the vertical direction is higher than the height of the upper end surface of a flange in the vertical direction. The reactor pressure vessel integral top cover also comprises a tube socket mounting through hole penetrating through the spherical head and the platform structure, a tube socket inserted into the tube socket mounting through hole, and a circular tube socket weld, wherein the tube socket weld is arranged on the platform structure and covers the tube socket. The problem that vertical deviation of the tube socket caused by the traditional asymmetric weld is out of tolerance issolved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Novel big-thickness concrete terrace formwork structure, and use method thereof

ActiveCN111042484AReduce adhesionAvoid damageForms/shuttering/falseworksBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to the technical field of terrace formworks, and discloses a novel big-thickness concrete terrace formwork structure. The novel big-thickness concrete terrace formwork structurecomprises a formwork, two cross-shaped brackets and a flag-shaped bracket, wherein the two cross-shaped brackets and the flag-shaped bracket are installed on the bottom of the formwork in a staggeredway; the formwork comprises one piece of vertical groove steel and one piece of angle steel, wherein the angle steel is installed on the upper side of the right side wall of the groove steel; the twocross-shaped brackets are installed on the inner side of the groove steel; and the flag-shaped bracket is installed on the outer side of the groove steel. By use of the novel big-thickness concrete terrace formwork structure and the use method thereof, a construction joint formed by the structure has a smooth and straight line and good apparent mass. After the cross-shaped brackets are separated from the formwork, the cross-shaped brackets can be folded so as to be convenient for disassembling, assembling and transporting whole equipment. After the formwork and the flag-shaped brackets are separated, the flag-shaped brackets can be folded so as to be convenient for assembling, disassembling and moving the whole equipment. The whole equipment has a high assembling and disassembling speed, has a high circulation frequency, a small damage rate and a short construction period, and saves construction cost.

Owner:MCC TIANGONG GROUP

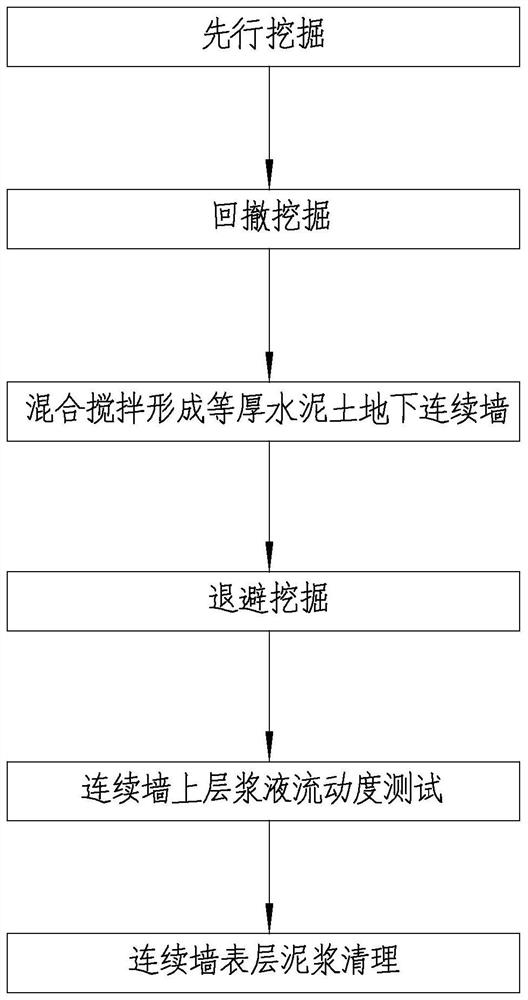

Double-cylinder hydraulic grooving machine

InactiveCN101709586BPrecise positioningVerticality is easy to controlArtificial islandsSoil-shifting machines/dredgersHydraulic cylinderArchitectural engineering

The invention discloses a double-cylinder hydraulic grooving machine, comprising two upper derivation correcting plates, a left lower derivation correcting plate and a right lower derivation correcting plate, two lifting pulley blocks, a inclinometer in a middle position, a water inlet pipe, a water inlet rubber pipe A and a water inlet rubber pipe B. The grooving machine is characterized in thata left hydraulic cylinder A is hinged with the upper end of a left drive rocker A, the lower end thereof is in pin joint on a left knife rest A, and the middle part thereof is in pin joint on a beam;a right hydraulic cylinder B is hinged with the upper end of a right drive rocker B, the lower end thereof is in pin joint on a right knife rest B, and the middle part thereof is in pin joint on the beam; the upper end of a left driven rocker A is in pin joint on the beam, and the lower end thereof is in pin joint on the left knife rest A; the upper end of the right driven rocker B is in pin joint on the beam, and the lower end thereof is in pin joint on the right knife rest B; and a left water inlet rubber pipe A is connected on the left knife rest A, a right water inlet rubber pipe B is connected on the right knife rest B, and the flooding water is ejected by a water spray nozzle.

Owner:NANTONG HUAZHENGLONG STEEL MFG

Collapsible loess geology static pressure compaction pile construction method

PendingCN114319466ALarge hole depthFast hole formingFoundation testingBulkheads/pilesLoessImmersed tube

The invention discloses a static pressure compaction pile construction method for collapsible loess geology, which adopts a plain soil compaction pile to treat a foundation, and performs static pressure compaction pile construction through original ground treatment, measurement positioning, static pressure pore forming, pore forming inspection, filler moisture content test, plain soil layered ramming and filling, comprehensive inspection and pile forming. The static pressure compaction pile construction problem of the collapsible loess geology is effectively solved, the construction is safe, the quality is reliable, the progress is fast, the input cost is low, and compared with traditional compaction pile construction methods such as hammering immersed tube hole forming, vibrating immersed tube hole forming and impact hole forming, the static pressure hole forming cost is high, and the construction efficiency is high. However, compared with a CFG pile and a prefabricated square pile with the same foundation treatment effect, the investment cost of the static pressure compaction pile is greatly reduced.

Owner:RAILWAY TENTH GROUP NORTHWEST ENG

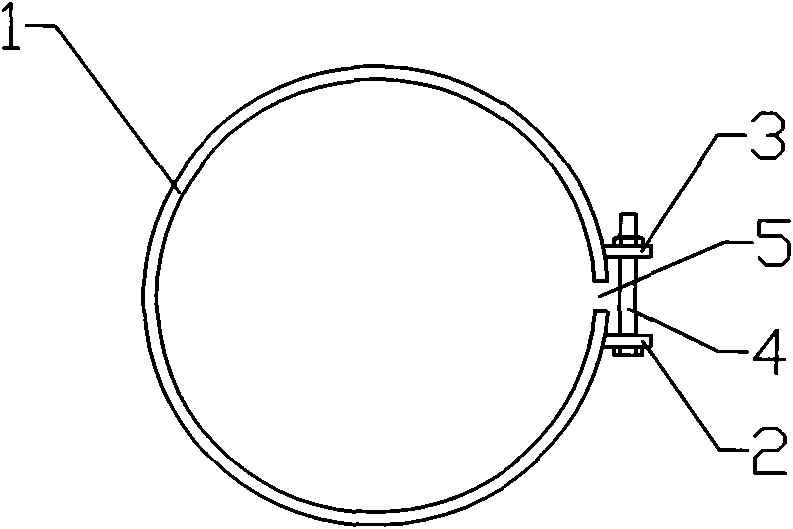

Method for fixing pile head in filling pile static loading test

InactiveCN101565953BEasy to installEasy to removeFoundation testingMaterial consumptionConstruction design

The invention relates to a method for fixing a pile head in a filling pile static loading test. After the filling pile is formed, the pile head is fixed and then the filling pile static loading test is carried out. The method for fixing the pile head is to fix the pile head by using a steel hoop, wherein the steel hoop comprises an annular metallic sheath which is provided with an opening and a fastening mechanism; and the steel loop is provided with an opening and an adjustable connecting bolt. Therefore, the method has the advantages of achieving the extremely convenient installation and detachment of the steel loop and the easy control of the verticality and elevation of the steel hoop during the installation, greatly reducing a re-work rate during the installation of the steel hoop andthe labor force and the material consumption during the adjustment of the verticality and the elevation of the steel loop, realizing high economy, meeting construction design requirements and improving working efficiency.

Owner:WEIFANG CHANGDA CONSTR GROUP

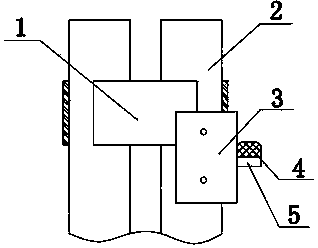

A fastener for high-speed railway plate and its construction technology

The invention discloses a fastener used for a high-speed rail pressing plate and a construction process thereof, and relates to the technical field of fasteners. The invention includes a road stud body, a nut, a fastening cover and a support gasket. The road stud body includes a screw rod, and a nut is fixed at one end of the screw rod. The nut is a cylindrical structure, and a number of material penetration holes are arranged in a ring shape on the nut. Several material penetration holes are all located between the inner side of the nut and the outer side of the screw rod, and the support gasket is arranged on the outer side of the screw rod. In the present invention, the nut of the road stud body is designed as a cylindrical structure with the same outer diameter as the inner diameter of the pre-embedded hole, and it is convenient to control the verticality between the road stud body and the road tie when the pre-embedded road stud body is placed in the pre-embedded hole At the same time, a material penetration hole is set on the nut. When the road stud body is pre-embedded, the anchoring agent at the lower part of the nut can be transferred to the top of the nut through the material penetration hole, which solves the problem that the existing road stud body is difficult to locate when pre-embedding. and the problem of calibrating perpendicularity.

A large-thickness concrete floor formwork structure and its application method

ActiveCN111042484BReduce adhesionAvoid damageForms/shuttering/falseworksBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to the technical field of floor formwork, and discloses a large-thickness concrete floor formwork structure, which includes a formwork, two cross supports and a flag-shaped support, and the two cross supports and a flag-shaped support are alternately installed on the formwork The bottom of the formwork, the formwork includes a vertical channel steel and an angle steel, the angle steel is installed on the upper side of the right side wall of the channel steel, the two cross brackets are installed on the inner side of the channel steel, and the flag-shaped The bracket is installed on the outside of the channel steel. The structure of the large-thickness concrete floor formwork and its use method, the construction joints formed by this structure are straight and the appearance quality is good. After the cross bracket is separated from the formwork, the cross bracket can be folded , to facilitate the disassembly and transportation of the entire equipment. When the template is separated from the flag-shaped bracket, the flag-shaped bracket can also be folded to facilitate the disassembly and movement of the entire equipment. Small size, short construction period, saving construction cost.

Owner:MCC TIANGONG GROUP

A method for installing the cutter beam long axis hole cutter bracket of cutter suction dredger

ActiveCN104594421BReduce the need to useEliminate the disadvantages of on-site boring installationMechanical machines/dredgersEngineeringReamer

A method for installing the long axis hole winch support of the cutter beam of a cutter suction dredger, respectively draw lines on the winch point seat and the general section of the hull, and then align and install the two lines, and control the joints during the installation process. Verticality, when welding the twist point seat, carry out symmetrical welding on both sides. After the twist point seat is installed on the hull, install the twist shaft and the twist cover. The setting of the reaming point seat can prefabricate the reamer beam, thereby avoiding the disadvantages of on-site boring installation, which can effectively shorten the production cycle and improve work efficiency; at the same time, it greatly reduces the need for auxiliary tooling and reduces the processing difficulty. There is no need to use dummy shafts for auxiliary processing, which reduces processing difficulty and production costs.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

A hanging glass inner curtain wall

InactiveCN103362240BSimple and transparent structureMeet aesthetic needsWallsSupporting systemArchitectural engineering

The invention belongs to the technical field of building structural members, and particularly relates to a suspension type glass inner curtain wall. The suspension type glass inner curtain wall comprises a suspension rod, a suspension part and a glass panel, the upper end of the suspension rod is embedded in a ceiling in advance, the lower end of the suspension rod is connected with the suspension part, the suspension part is fixedly connected with the top end of the glass panel, and the suspension part can be a suspension claw or a mounting groove. The perpendicularity of the suspension type glass inner curtain wall can be controlled easily, support systems on the ground and fixing structures on the two side wall faces are of no need, and the suspension type glass inner curtain wall is not prone to falling and is transparent and tidy in structure. Further, the lower end of the two sides of the glass panel can be designed to be suspended in the air, no sanitation blind corners are formed, the glass panel can be detached conveniently, no traces are formed on a base board and walls when the glass panel is replaced, and the aesthetic requirements for modern interior decoration are met. The suspension type glass inner curtain wall has revolutionary significance in fundamentally solving the problems that the support system with high bearing capability is needed in the prior art and the perpendicularity of the glass panel is difficult to guarantee. Further, the suspension type glass inner curtain wall has good application prospects in the technical field of the building structural members.

Owner:JIN GUANG DAO ENVIRONMENTAL CONSTR GRP

Pre-buried latticed column verticality measurement construction method

ActiveCN103103995BEnsure safetyImprove construction progressFoundation testingBasementEconomic benefits

The invention discloses a pre-buried latticed column verticality measurement construction method, and belongs to the technical field of building-construction. The steps of the pre-buried latticed column verticality measurement method includes that: pre-buried latticed columns are processed, a biaxial inclinometer is chosen, a sensor is calibrated, the inclinometer is assembled, a position is chosen for installation of the inclinometer, the pre-buried latticed columns and the inclinometer are installed and placed, biaxial inclination angles of the pre-buried latticed columns are measured and adjusted, after concrete pouring is finished, the inclinometer is detached, and the like. According to the pre-buried latticed column verticality measurement method, due to the facts that the inclinometer is arranged on the pre-buried latticed columns, in the construction process of the pre-buried latticed columns, angle ranges are regulated timely to enable the angle ranges to be within designed ranges according to the perpendicular angel changing displayed on a displayer, and then the pre-buried latticed columns are fixed, the accuracy and perpendicularity degree of the locating of the pre-buried latticed columns and the direction of the pre-buried latticed columns are convenient to control, and therefore the pre-buried latticed column verticality measurement method is applicable for construction of basements with large excavation depths, safety of building foundation pits, surrounding roads and pipelines is guaranteed, overall project construction progress is accelerated at the same time, project manufacture cost is saved, and economic benefit is improved.

Owner:WENZHOU CONSTR GROUP

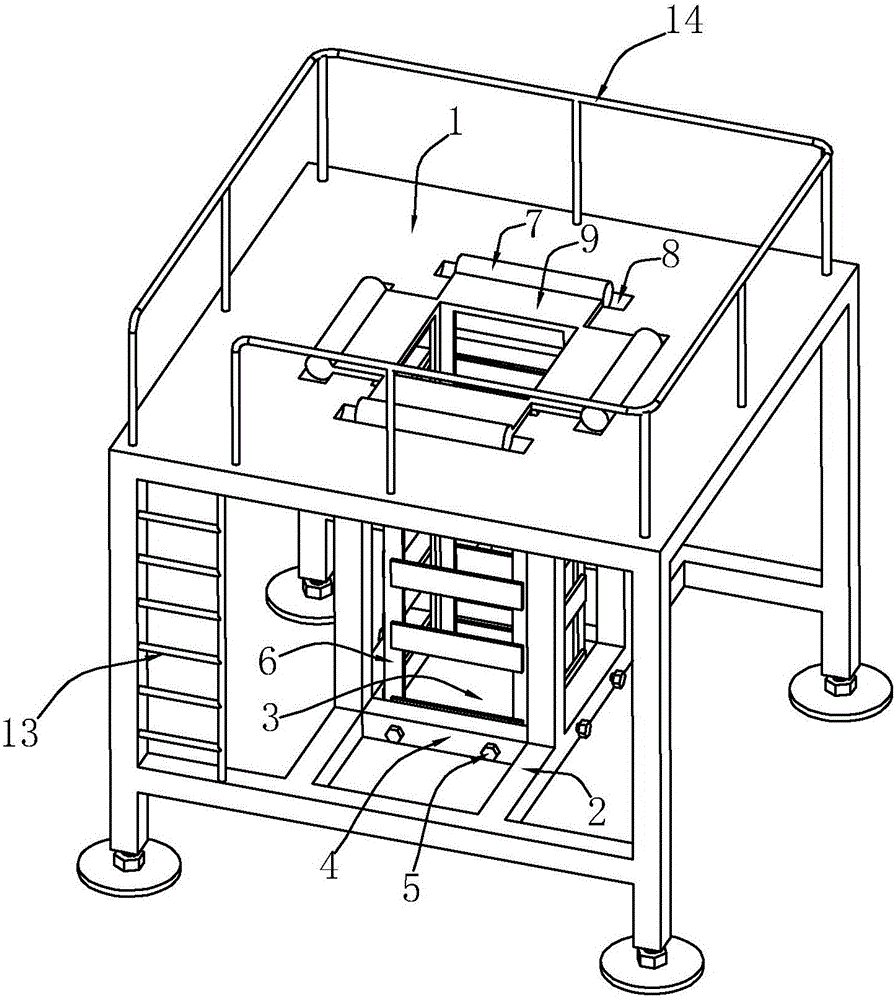

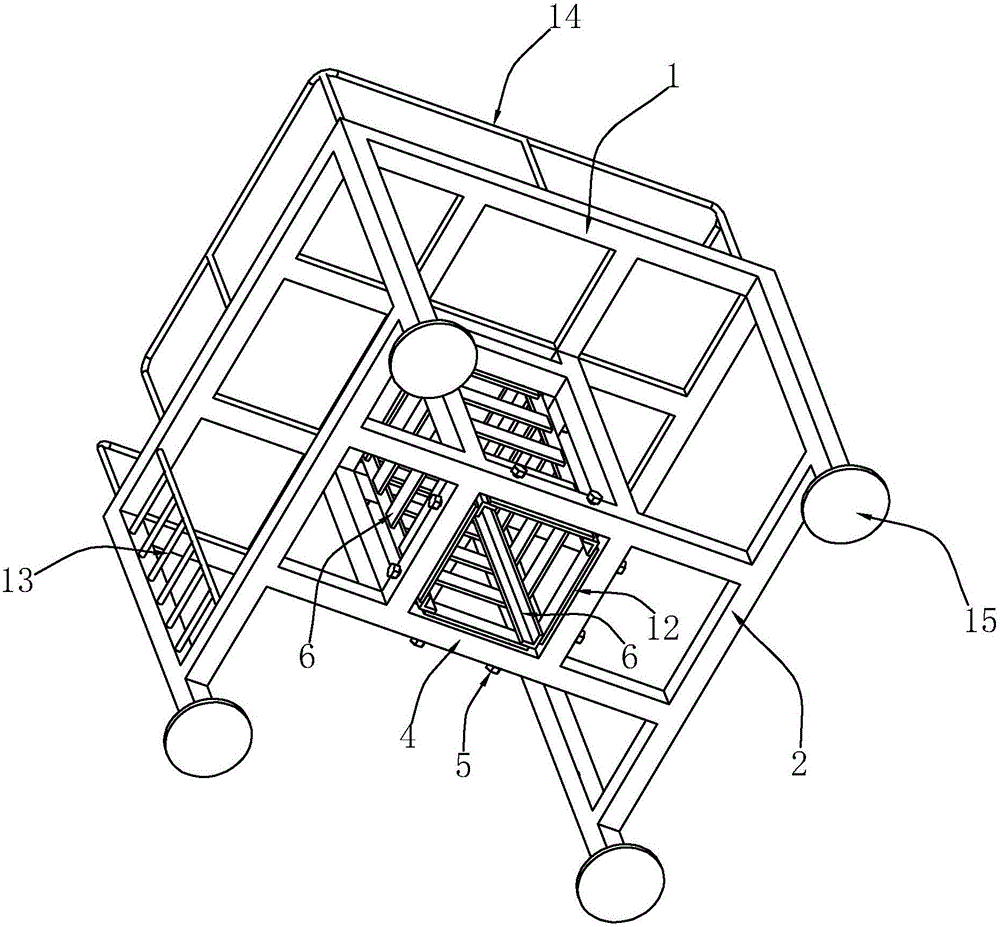

A kind of pile foundation indoor model test device and test method

ActiveCN113529823BHigh degree of reductionIncrease moisture contentFoundation testingMaterial testing goodsSoil scienceModel test

The invention relates to a pile foundation indoor model test device and a test method. The test device comprises a base, a stand, a model box, a model pile, a vertical auxiliary device, a rotating auxiliary device, and a reaction force plate. The mud prepared from the soil sample to be tested is graded and pressurized to discharge half of the water in the mud, and the model box is rotated by 180° using the rotating auxiliary system, and the pressure is continued until all the remaining water in the mud is discharged, and then the vertical auxiliary device is used. The model piles shall be driven to the required depth with jacks and indoor model tests shall be carried out. The present invention reverses the unconsolidated soil body, and performs two-way drainage and consolidation of the reshaped soil under the reversal of gravity, so as to realize the uniformity of water content, density and consolidation in each depth range of the soil sample, and avoid the need for soil samples. The deviation of the basic parameters caused by the unevenness of the pile body is strictly controlled, and the test accuracy is better.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

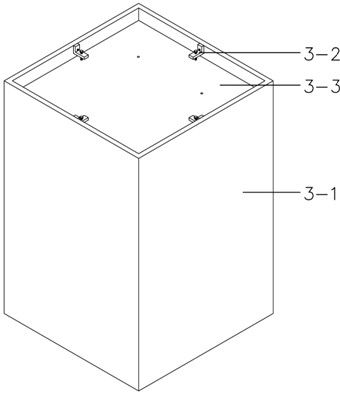

Integrated prefabricated giant column steel formwork support system

ActiveCN112681728BHigh turnoverVerticality is easy to controlForms/shuttering/falseworksSupporting systemKeel

The invention discloses an integrated prefabricated giant column steel formwork support system, which relates to the technical field of giant column steel formwork support equipment. Combined installation and reinforcement; the main body of the steel formwork is a steel plate, and several vertical and evenly distributed vertical keels are welded on the steel plate. One side of the steel plate is welded with a channel steel group as the main keel in the horizontal direction. The angle steel connected with the adjacent steel formwork, the channel steel group of the two adjacent steel formwork is fixedly connected by the reinforcement. The beneficial effects of the invention are as follows: the system replaces wood with steel, which increases the turnover times of materials and realizes green construction; the combination of the pull-screw can provide effective strength, and also simplifies the later surface treatment; The connection relationship is simple, the installation is simple, and the focus of safety and quality inspection and control is obvious and easy to control.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com