Prefabrication platform and prefabrication method for jacketed pipe

A jacketed pipe and platform technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of complex prefabricated construction operations and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

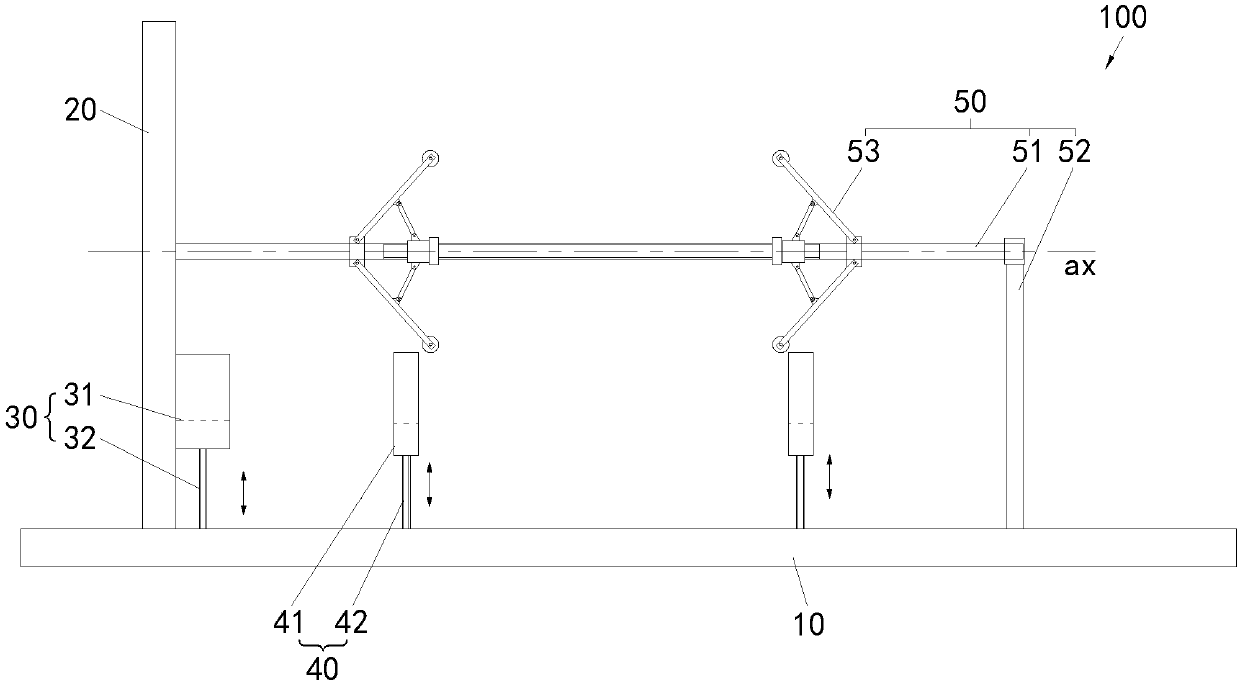

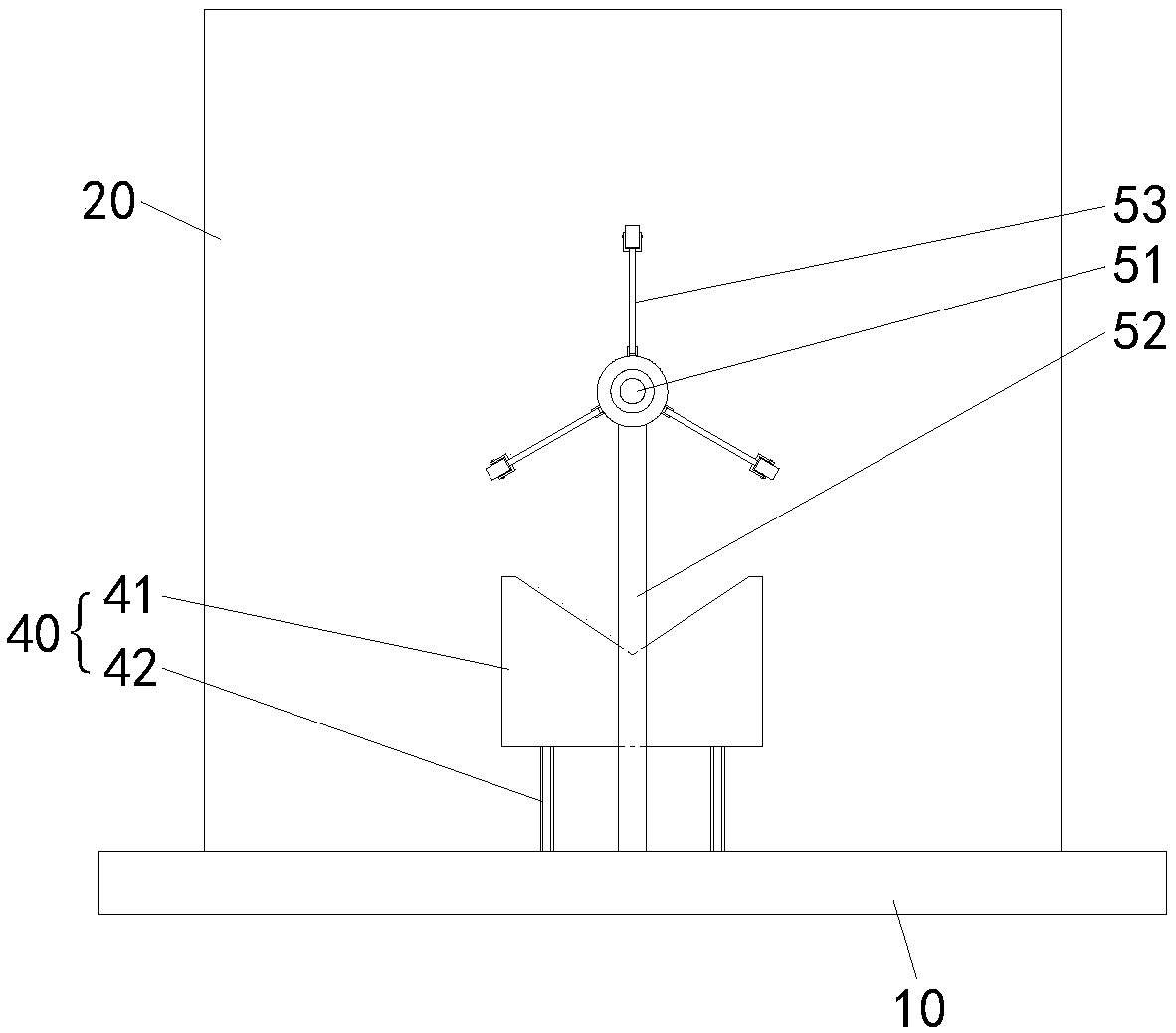

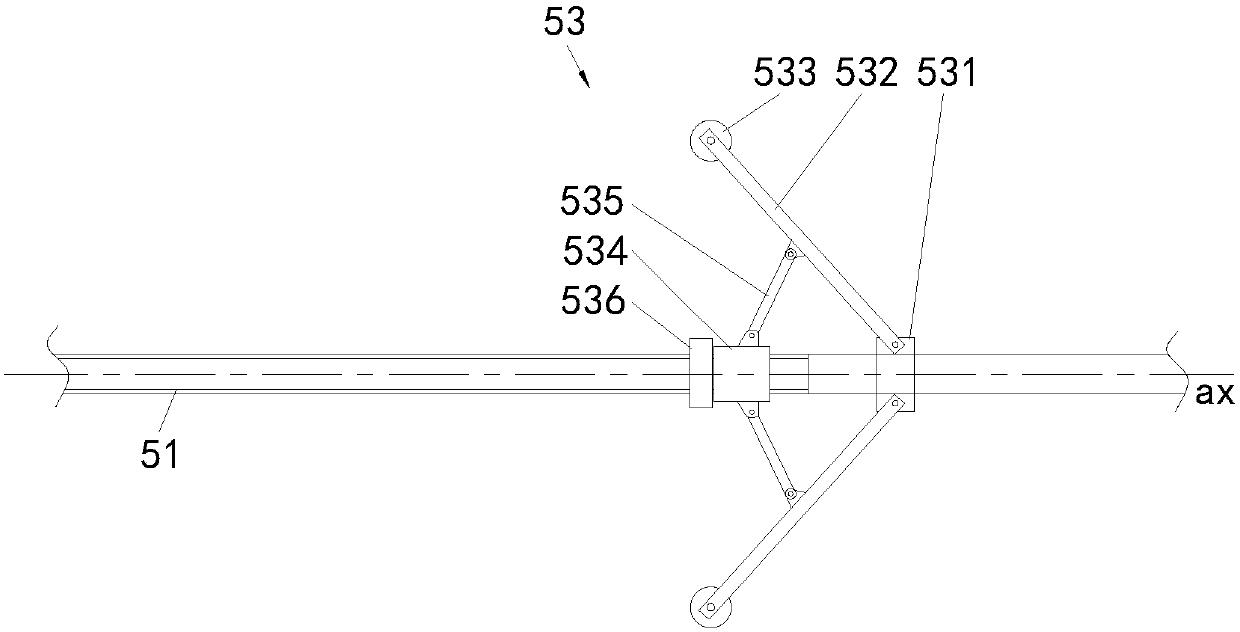

[0032] Example 1: Combining Figure 1 to Figure 7 Illustrate the prefabricated platform 100 of the jacketed pipe of the present invention, it comprises the base plate 10 that is arranged horizontally, the back plate 20 that is vertically fixed on the left side of base plate 10, the flange plate positioning frame 30 that is arranged close to the back plate 20, respectively with the base plate 10 and the inner tube positioning assembly 50 connected to the back plate 20, and two sets of outer tube positioning components 40 arranged at intervals and arranged side by side on the bottom plate; wherein, the back plate 20 needs to ensure a certain flatness to meet the requirements of the flange plate 200 The dimensional accuracy requirements of the installation; the flange positioning frame 30 includes a positioning base 31 and an adjusting rod one 32 arranged up and down and detachably connected, and the bottom of the adjusting rod one 32 is fixed on the bottom plate 10; the inner tub...

Embodiment 2

[0037] Embodiment 2: Combination Figure 5 Illustrate the prefabricated platform 100 of the jacketed pipe of the present invention. Unlike the first embodiment, the central rod 51 does not have external threads, and the telescopic support includes a fixed sleeve one 537 sleeved and fixedly connected to the central rod 51, and two ends The hydraulic telescopic rod 538 hinged with the fixed sleeve 1 537 and the support rod 532 respectively adjusts the radial displacement of the support rod 532 by controlling the extension and contraction of the hydraulic telescopic rod 538, so as to achieve the purpose of horizontal positioning of the inner tube 300 , using the hydraulic telescopic rod 538 connected with the control system signal, the operation is more flexible, the degree of automation is high, and the work efficiency is further improved.

Embodiment 3

[0038] Example Three: Combining Figure 1 to Figure 7 Illustrate and utilize the prefabrication method of jacket pipe of the present invention, concrete steps are as follows:

[0039] S1: Assemble the prefabricated platform 100 of the jacketed pipe as described in Embodiment 1 or 2, remove the support frame 52, and insert the flange 200 into the central rod 51, so that the flange 200 is close to the back plate 20 and positioned The base 31 is supported, and the elevation of the positioning base 31 is adjusted through the adjusting rod 32, so that the flange 200 is coaxial with the central rod 51, that is, the axes of the two coincide;

[0040] S2: Set the inner tube 300 on the inner tube positioning assembly 50, adjust the telescopic support of the telescopic guide wheel support frame 53, so that the guide wheel 533 of the support rod 532 is against the inner wall of the inner tube 300;

[0041] S3: Put the outer tube 400 on the two outer tube brackets 41 of the outer tube po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com