Low-density high-entropy alloy material oriented for high temperature applications and preparation method of low-density high-entropy alloy material

A high-entropy alloy and low-density technology, applied in the field of high-entropy alloys, can solve the problems of high-entropy alloys with high density and poor plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

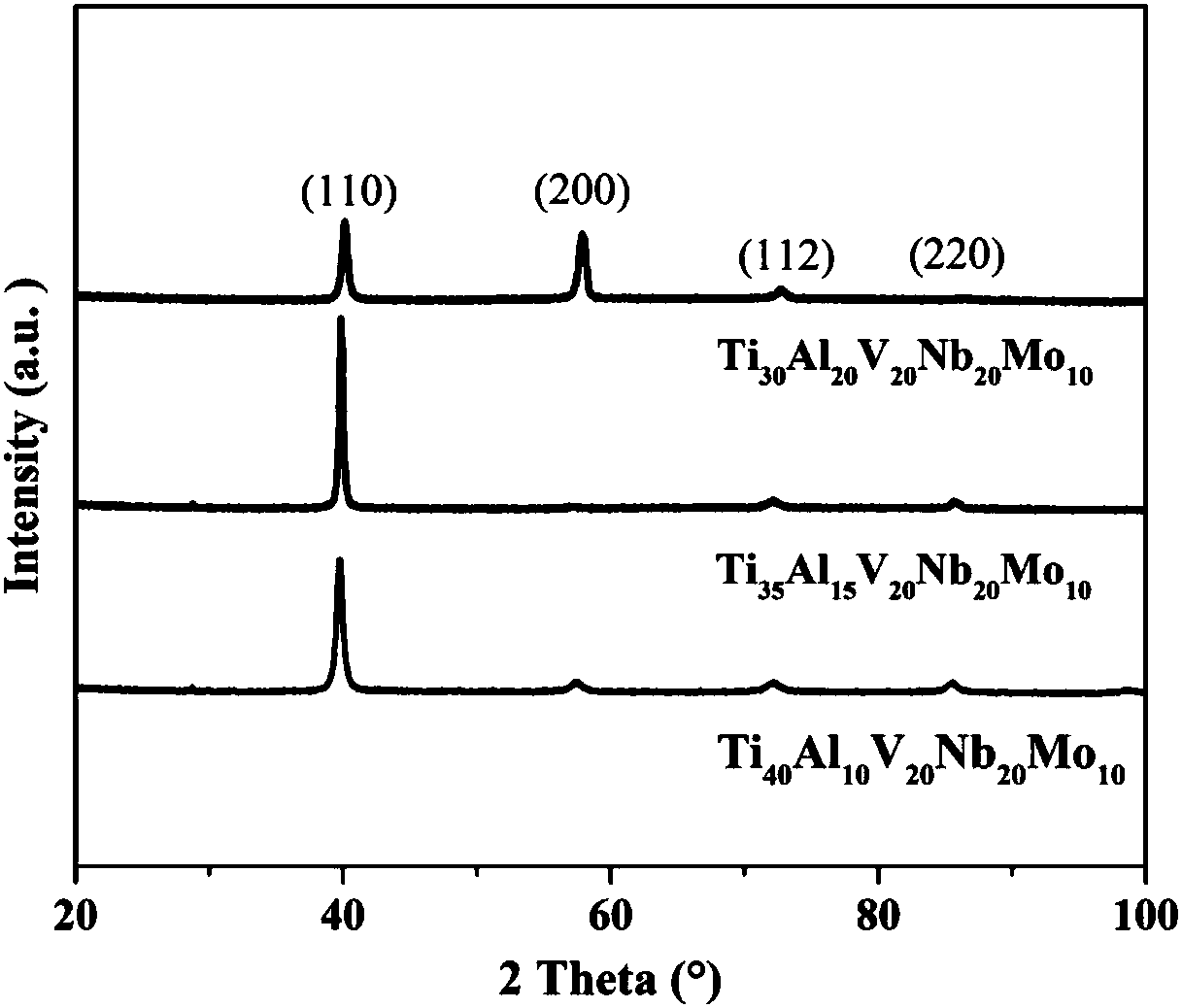

[0023] This embodiment is a Ti 35 al 15 Nb 20 V 20 Mo 10 It is a high-entropy alloy, composed of five elements such as Ti, Al, V, Nb, Mo, etc. The relative atomic percentage content of Ti is 35%, the relative atomic percentage of Al is 15%, the relative atomic percentage of V is 20%, and the relative atomic percentage of Nb The relative atomic percentage of Mo is 20%, and the relative atomic percentage of Mo is about 10%. Ti 35 al 15 Nb 20 V 20 Mo 10 For single-phase BCC structure, such as figure 1 shown.

[0024] The purity of the Ti, Al, V, Nb, Mo and other metal raw materials is higher than 99.99wt%;

[0025] The Ti 35 al 15 Nb 20 V 20 Mo 10 The preparation method of high entropy alloy is:

[0026] Step 1: Select five metal elements such as Ti, Al, V, Nb, Mo, etc., remove the surface oxide skin with a small grinding wheel, and use an ultrasonic cleaner to clean the metal raw material. According to Ti 35 al 15 Nb 20 V 20 Mo 10 The atomic percentage of ...

Embodiment 2

[0032] This embodiment is a Ti 40 al 10 Nb 20 V 20 Mo 10 It is a high-entropy alloy, composed of five elements such as Ti, Al, V, Nb, and Mo. The relative atomic percentage of Ti is 40%, the relative atomic percentage of Al is 10%, the relative atomic percentage of V is 20%, and the relative atomic percentage of Nb is 40%. The relative atomic percentage of Mo is 20%, and the relative atomic percentage of Mo is about 10%. Ti 40 al 10 Nb 20 V 20 Mo 10 For single-phase BCC structure, such as figure 1 shown.

[0033] The purity of the Ti, Al, V, Nb, Mo and other metal raw materials is higher than 99.99wt%;

[0034] The Ti 40 al 10 Nb 20 V 20 Mo 10 The preparation method of high entropy alloy is:

[0035] Step 1: Select five metal elements such as Ti, Al, V, Nb, Mo, etc., remove the surface oxide skin with a small grinding wheel, and use an ultrasonic cleaner to clean the metal raw material. According to Ti 40 al 10 Nb 20 V 20 Mo 10 The atomic percentage of h...

Embodiment 3

[0040] This embodiment is a Ti 30 al 20 Nb 20 V 20 Mo 10 It is a high-entropy alloy, composed of five elements such as Ti, Al, V, Nb, Mo, etc. The relative atomic percentage content of Ti is 30%, the relative atomic percentage of Al is 20%, the relative atomic percentage of V is 20%, Nb The relative atomic percentage of Mo is 20%, and the relative atomic percentage of Mo is about 10%. Ti 30 al 20 Nb 20 V 20 Mo 10 For single-phase BCC structure, such as figure 1 shown.

[0041] The purity of the Ti, Al, V, Nb, Mo and other metal raw materials is higher than 99.99wt%;

[0042] The Ti 30 al 20 Nb 20 V 20 Mo 10 The preparation method of high entropy alloy is:

[0043] Step 1: Select five metal elements such as Ti, Al, V, Nb, Mo, etc., remove the surface oxide skin with a small grinding wheel, and use an ultrasonic cleaner to clean the metal raw material. According to Ti 30 al 20 Nb 20 V 20 Mo 10 The atomic percentage of high-entropy alloys accurately weighs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com