Fire resistant material for furnace wall mouth of nonferrous smelting furnace and preparing method thereof

A technology of refractory materials and furnaces, applied in the field of refractory materials, can solve the problems of easy damage to the internal structure of refractory materials, and achieve the effects of reducing related thermal reactions, avoiding reaction damage, and reducing decomposition reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

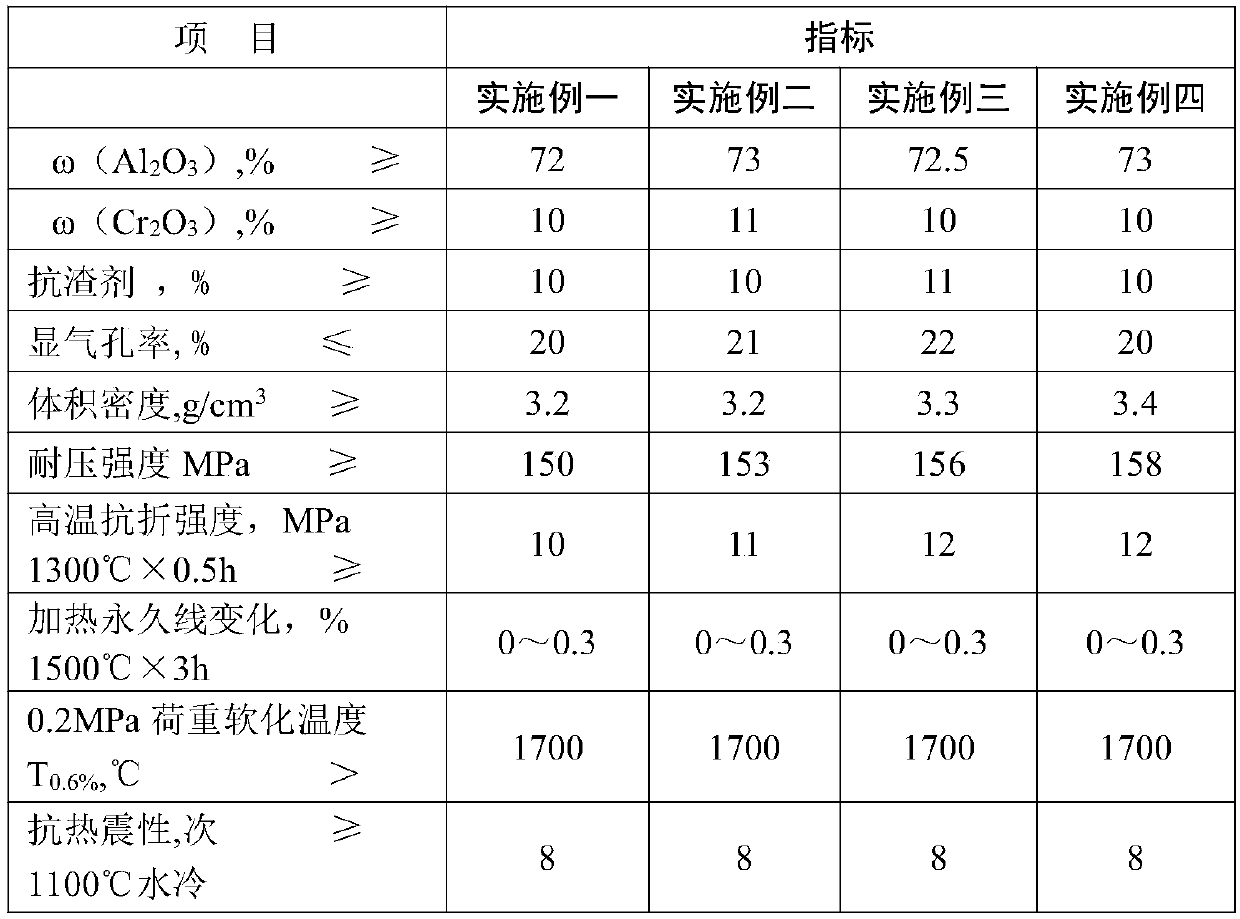

Examples

Embodiment 1

[0028] 90 parts of fused chromium corundum and 5 parts of chromium oxide are composed according to the particle size. According to the principle of first coarseness and then fineness, first dry blend in a wet mill. After the particles and fine powder are mixed evenly, add 90 parts of fused chromium corundum and 5 parts A mixture of white aleurone blended liquid and water with a mass ratio of 7:3 is pressed at a pressure of 400T to form brick adobes, and the resulting brick adobes are placed in a dryer and dried at 200°C for 48 hours.

Embodiment 2

[0030] 92 parts of fused chromium corundum and 6 parts of chromium oxide are composed according to the particle size. According to the principle of first coarseness and then fineness, first dry mix in a wet mill, and after the particles and fine powder are mixed evenly, add 5 parts with a mass ratio of 7:3 The mixture binder of white aleur powder blending liquid and water is pressed at a pressure of 480T to form brick adobes, and the obtained brick adobes are placed in a dryer and dried for 48 hours at a temperature of 250°C.

Embodiment 3

[0032] 94 parts of fused chromium corundum and 7 parts of chromium oxide are composed according to the particle size. According to the principle of first coarseness and then fineness, first dry blend in a wet mill, and after the particles and fine powder are mixed evenly, add 5.5 parts. The mass ratio is 7:3 The mixture binder of white aleur powder blending liquid and water is pressed at a pressure of 500T to form brick adobes, and the obtained adobes are placed in a dryer and dried at a temperature of 240°C for 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com