Heavy-anticorrosive epoxy finishing coat and preparation method thereof

An epoxy surface, heavy-duty anti-corrosion technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve excellent anti-corrosion performance, operational continuity, and reduce surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

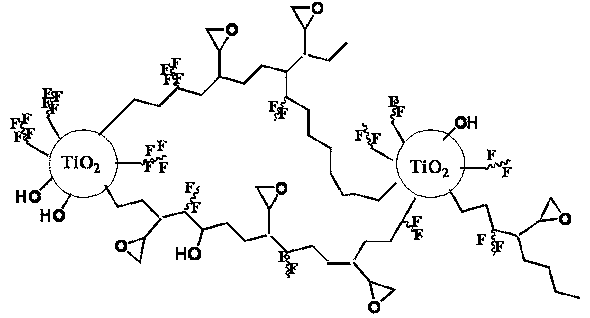

Image

Examples

Embodiment 1

[0049](1) Dissolve 5 parts by mass of butyl titanate and 3 parts by mass of dodecylfluoroalkyltrimethoxysilane in 5 parts by mass of xylene solution, add dropwise to 2 parts by mass of isopropanol, 5 parts by mass of In a mixed solution composed of toluene, 0.5 parts by mass of water, and 0.1 parts by mass of nitric acid, react at 25°C for 8 hours;

[0050] (2) To maintain the acidic condition of the system, add 3 parts by mass of water and 40 parts by mass of solvent, and then dropwise add 10 parts by mass of γ-(2,3-epoxypropoxy)propyltrimethyl Oxysilane, 3 parts by mass of dodecafluoroalkyltrimethoxysilane and 10 parts by mass of dimethyldimethoxysilane mixed solution, continue to stir for 8h;

[0051] (3) Add 10 parts by mass of anhydrous sodium sulfate to remove water and filter, add a small amount of ammonia dropwise to adjust the pH of the system to 7~8, react at 50°C for 8 hours; finally add a small amount of concentrated hydrochloric acid to adjust the system to neutra...

Embodiment 2

[0057] Embodiment 2: Change the reaction conditions of (5) and (6), and the rest are the same as in Embodiment 1.

[0058] (1) Dissolve 5 parts by mass of butyl titanate and 3 parts by mass of dodecylfluoroalkyltrimethoxysilane in 5 parts by mass of xylene solution, add dropwise to 2 parts by mass of isopropanol, 5 parts by mass of In a mixed solution composed of toluene, 0.5 parts by mass of water, and 0.1 parts by mass of nitric acid, react at 25°C for 8 hours;

[0059] (2) To maintain the acidic condition of the system, add 3 parts by mass of water and 40 parts by mass of solvent, and then dropwise add 10 parts by mass of γ-(2,3-epoxypropoxy)propyltrimethyl Oxysilane, 3 parts by mass of dodecafluoroalkyltrimethoxysilane and 10 parts by mass of dimethyldimethoxysilane mixed solution, continue to stir for 8h;

[0060] (3) Add 10 parts by mass of anhydrous sodium sulfate to remove water and filter, add a small amount of ammonia dropwise to adjust the pH of the system to 7~8, ...

Embodiment 3

[0064] Embodiment 3: change the reaction condition of (1), all the other are the same as embodiment 1.

[0065] (1) Dissolve 20 parts by mass of butyl titanate and 10 parts by mass of dodecafluoroalkyltrimethoxysilane in 20 parts by mass of xylene solution, add dropwise to 5 parts by mass of isopropanol, 10 parts by mass of In a mixed solution composed of toluene, 2 parts by mass of water, and 0.4 parts by mass of nitric acid, react at 25°C for 8 hours;

[0066] (2) To maintain the acidic condition of the system, add 3 parts by mass of water and 40 parts by mass of solvent, and then dropwise add 10 parts by mass of γ-(2,3-epoxypropoxy)propyltrimethyl Oxysilane, 3 parts by mass of dodecafluoroalkyltrimethoxysilane and 10 parts by mass of dimethyldimethoxysilane mixed solution, continue to stir for 8h;

[0067] (3) Add 10 parts by mass of anhydrous sodium sulfate to remove water and filter, add a small amount of ammonia dropwise to adjust the pH of the system to 7~8, react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com