Production method of antibacterial moisture-absorbing and quick-drying fabric

A hygroscopic and quick-drying, production method technology, applied in biochemical fiber treatment, fabric surface trimming, weaving, etc., can solve the problems of unsatisfactory hygroscopic performance, unsatisfactory, easy to stick to the body and antibacterial performance, etc., and achieve excellent quick-drying performance, Reduce stickiness, soft texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The production method of a kind of antibacterial moisture-absorbing quick-drying fabric that the present invention proposes comprises the following steps:

[0023] S1, the preparation of warp thread: take sea-island fiber as the first warp thread, take 300D polyester long fiber as the second warp thread, weave, and the warp direction density of the first warp thread is 300 / 10cm, twist direction is Z twist, the second The warp direction density of the two warp threads is 200 / 10cm, the twist direction is Z twist, and the arrangement ratio of the two is 1:1 to obtain the warp thread;

[0024] S2, the modification of warp: the warp prepared by step S1 is placed in the sodium hydroxide solution of 0.5mol / L, the warp is completely immersed in the sodium hydroxide solution, and the polyquaternium of 1.3% of the sodium hydroxide solution quality is added Salt-7, and 0.5% propylene glycol monolaurate of sodium hydroxide solution, warm up to 95°C, stir for 40 minutes, take it out...

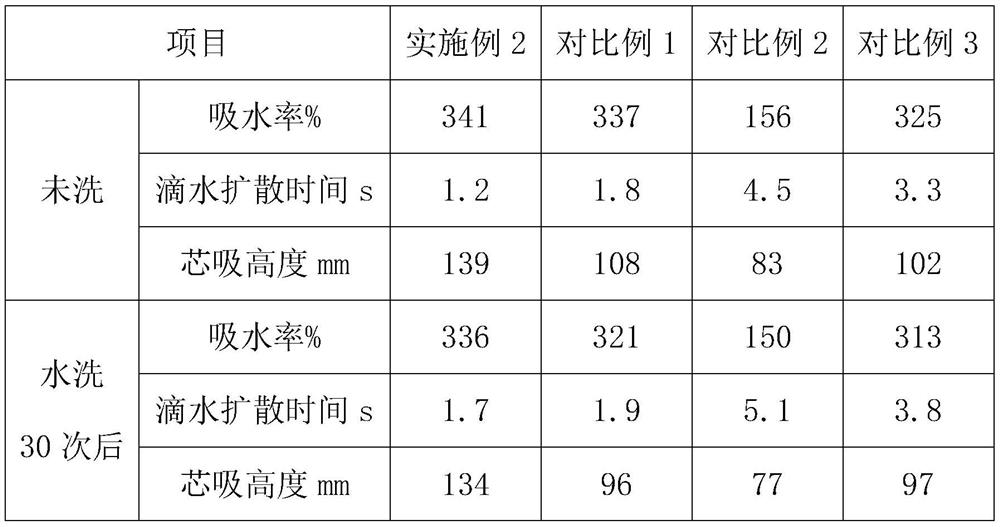

Embodiment 2

[0032] The production method of a kind of antibacterial moisture-absorbing quick-drying fabric that the present invention proposes comprises the following steps:

[0033] S1, the preparation of warp thread: take sea-island fiber as the first warp thread, take 300D polyester long fiber as the second warp thread, weave, and the warp direction density of the first warp thread is 320 / 10cm, twist direction is Z twist, the second The warp direction density of the two warps is 210 / 10cm, the twist direction is Z twist, and the arrangement ratio of the two is 1:1, and the warp is obtained;

[0034]S2, the modification of warp: the warp prepared by step S1 is placed in the sodium hydroxide solution of 0.5mol / L, the warp is completely immersed in the sodium hydroxide solution, and the polyquaternium of 1% of the sodium hydroxide solution quality is added Salt-7, and 0.7% propylene glycol monolaurate of sodium hydroxide solution, warm up to 95°C, stir for 50 minutes, take it out, rinse wi...

Embodiment 3

[0042] The production method of a kind of antibacterial moisture-absorbing quick-drying fabric that the present invention proposes comprises the following steps:

[0043] S1, the preparation of warp thread: take sea-island fiber as the first warp thread, take 300D polyester long fiber as the second warp thread, carry out weaving, and the warp direction density of the first warp thread is 350 / 10cm, twist direction is Z twist, the second The warp direction density of the two warp threads is 230 / 10cm, the twist direction is Z twist, and the arrangement ratio of the two is 1:1, and the warp thread is obtained;

[0044] S2, the modification of warp thread: the warp thread prepared by step S1 is placed in the sodium hydroxide solution of 0.5mol / L, makes the warp thread soak in the sodium hydroxide solution completely, adds the polyquaternium of 0.8% of the sodium hydroxide solution quality Salt-7, and 0.8% propylene glycol monolaurate of sodium hydroxide solution, warm up to 90°C, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com