Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve temperature resistance performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

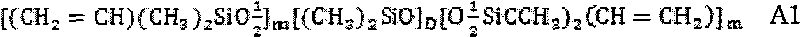

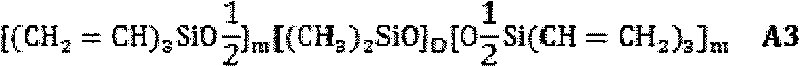

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

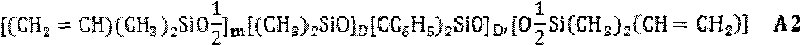

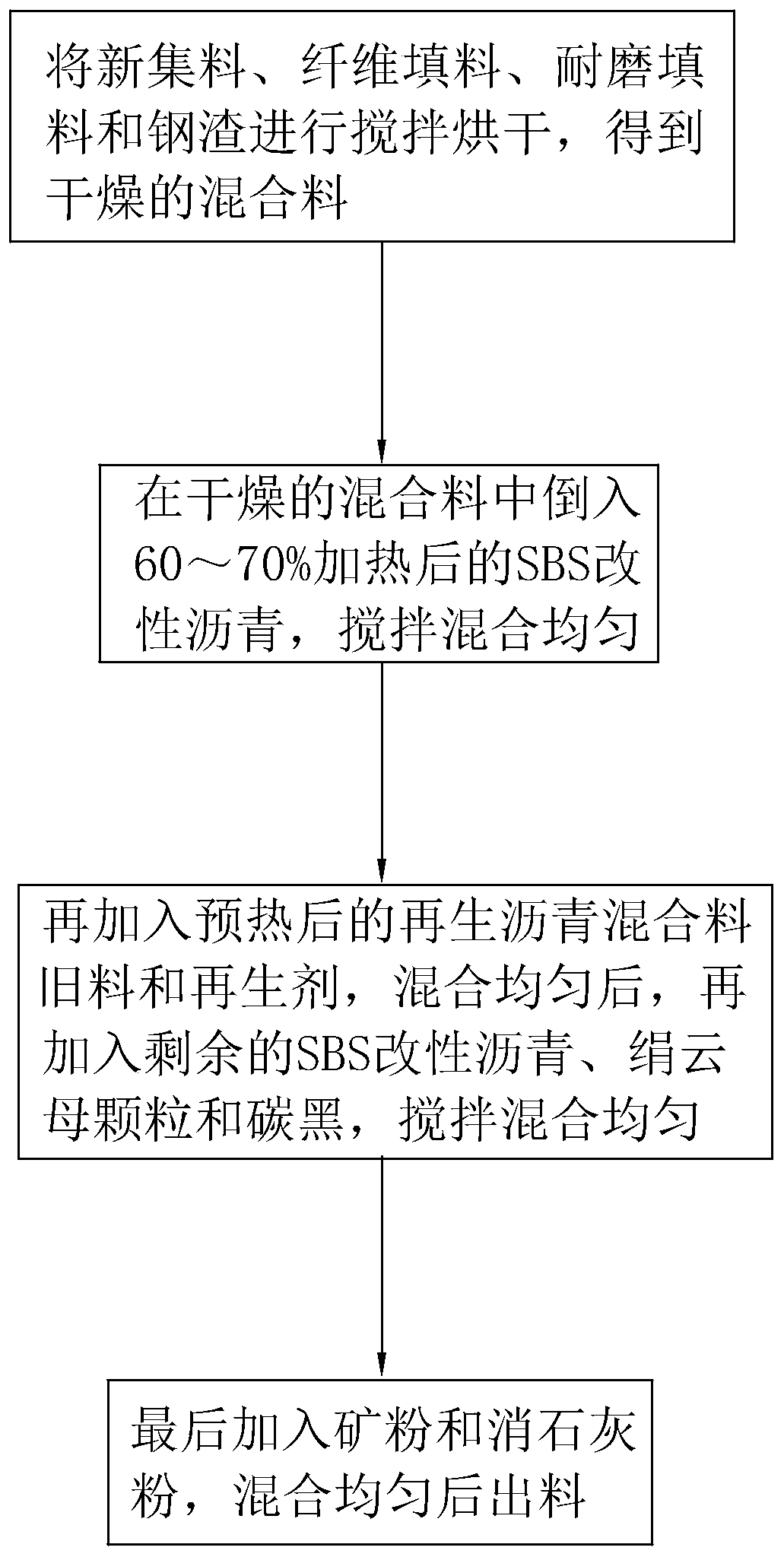

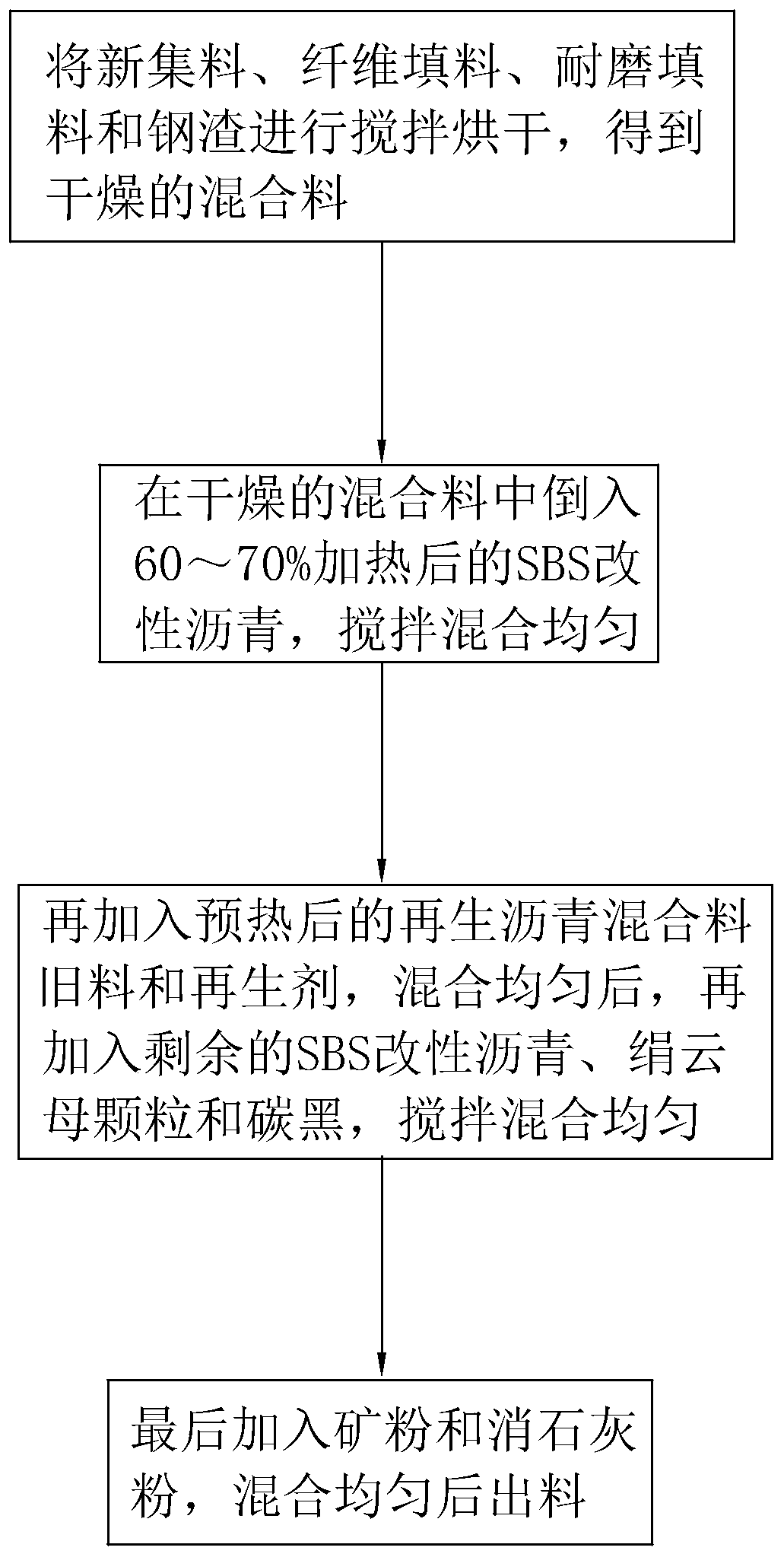

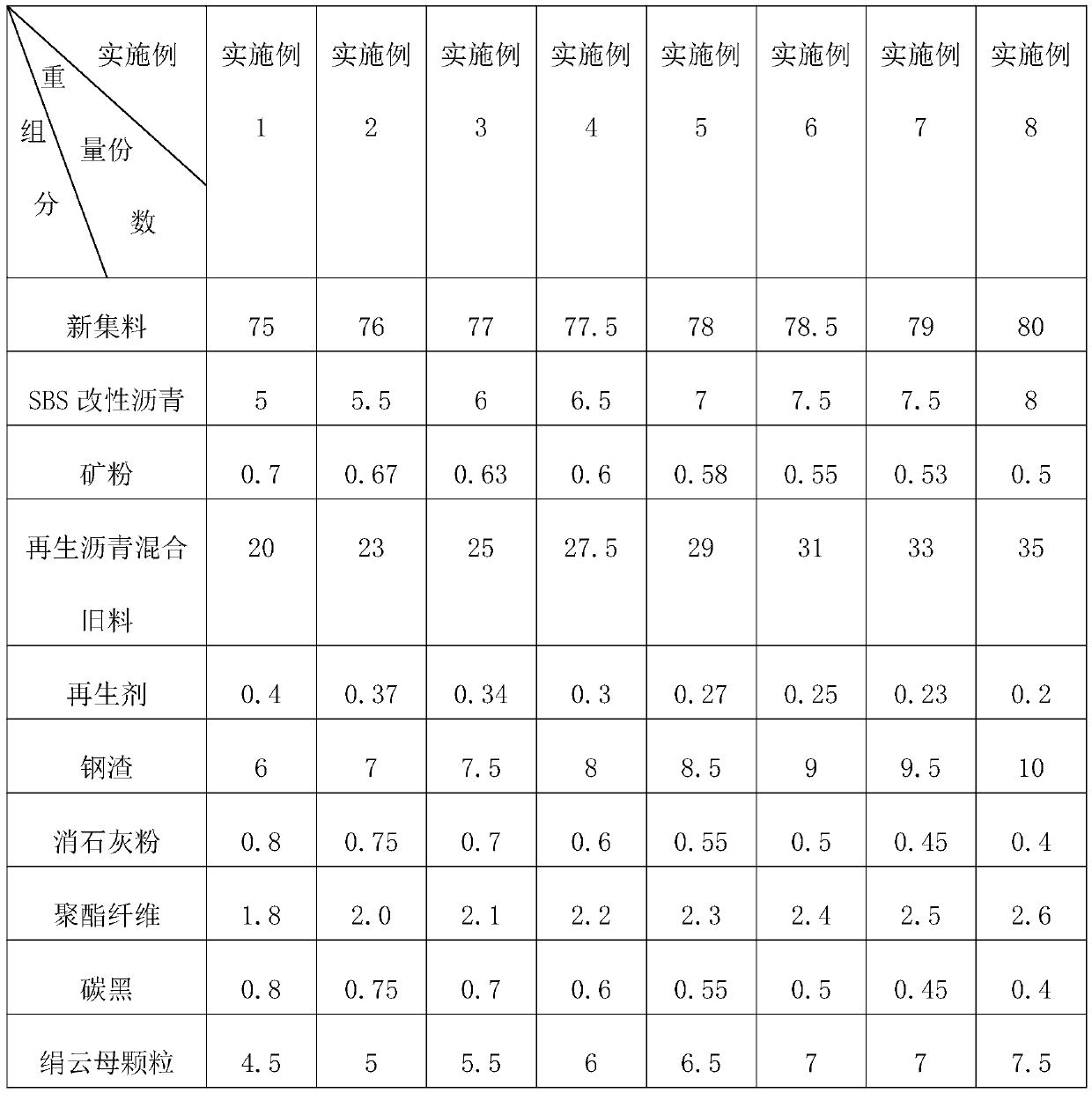

Abrasion-resistant recycled asphalt concrete and preparation process thereof

The invention discloses an abrasion-resistant recycled asphalt concrete and a preparation process thereof, relates to the technical field of asphalt concrete processing, and solves the problem that asphalt concrete pavement is prone to ageing due to frequent temperature changes and is prone to large abrasion during use. The abrasion-resistant recycled asphalt concrete comprises the following components in parts by weight: 75 to 80 parts of new aggregate, 5 to 8 parts of SBS modified asphalt, 0.5 to 0.7 part of mineral powder, 20 to 35 parts of a recycled asphalt mix old material, 0.2 to 0.4 part of a regenerating agent, 6 to 10 parts of steel slag, 0.4 to 0.8 part of hydrated lime powder, 1.8 to 2.6 parts of fiber filler, 0.5 to 1.5 part of abrasion-resistant filler, 0.4 to 0.8 part of carbon black, 4.5 to 7.5 parts of sericite particles. The abrasion-resistant recycled asphalt concrete in the invention has good stability in the use process, is not easy to age due to intermittent friction heat generated between the abrasion-resistant recycled asphalt concrete and a wheel, and is not easy to greatly wear.

Owner:上海宝新特种沥青混凝土有限公司

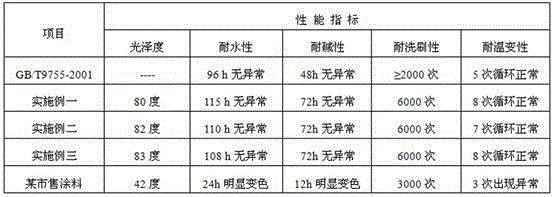

Anti-corrosion coating

InactiveCN103694851AGood curing activityImprove temperature denaturationFireproof paintsNatural resin coatingsSolventCorrosion resistant

The invention discloses an anti-corrosion coating, belonging to the technical field of coatings. The anti-corrosion coating solves the problems of poor corrosion-resistant effect and short corrosion-resistant life of the traditional coating. The anti-corrosion coating comprises the following raw materials in percentage by weight: 25%-40% of epoxy resin, 25%-40% of modified paint phenolphthalein resin, 5%-10% of titanium nanoparticles, 10%-15% of pigment fillers, 10%-15% of solidifying agents and 15%-20% of solvents. According to the anti-corrosion coating, the solidifying agents are capsule solidifying agents which take ethylene diamine as a core material and polymethyl methacrylate as a wall material and overcome the defects of the traditional epoxy resin solidifying agent, so that the temperature change resistance of the coating can be effectively enhanced; talcum powder and graphite can not only be taken as the components of the pigment fillers, but also have flame-retardant effects. The anti-corrosion coating disclosed by the invention has the advantages of resistance to the corrosion of liquid mediums, such as acid, alkali, salt, organic solvents, oil and the like as well as resistance to boiling water, can be used for a long time in an environment at 220 DEG C, keeps the characteristic of ultra durability of natural raw lacquer, and has no anaphylactic reaction on human bodies.

Owner:SHANDONG LANXING WASHING & ANTI CORROSION

Process for preparing low temperature baking silver mirror back lacquer

InactiveCN1900189ALow baking temperatureShort baking timeInstrumentsPolyester coatingsOrganic solventLacquer

The lower temperature baked silver mirror back lacquer consists of priming lacquer and finishing paint. The priming lacquer consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, and organic solvent in certain weight proportion. The finishing paint consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, leveling agent and organic solvent in certain weight proportion. The present invention has silver mirror back lacquer with baking temperature lowered to 100 deg.c, raised adhesion, high wet head resistance, high temperature change tolerance, high salt fog resistance, high salt water resistance, high corrosion resistance and good post finishing property.

Owner:SHANGHAI JIAO TONG UNIV

Method of preparing single-coating-type paint for copper layer free glass silver mirror back

InactiveCN101012352AImprove corrosion resistanceImprove temperature resistance performancePicture framesDomestic mirrorsOrganic solventUltra fine

The invention discloses a making method of single-painting typed copper-free layer glass back paint, which comprises the following parts: 7.0-8.0wt% metal oxide, 9.0-11.0wt% ultra-fine talcum powder, 15.0-37.0wt % ultra-fine barium sulfate, 20.0-30.0wt% short-oil alkide resin, 3.0-10.0wt% coloring dye, 0.05- 0.15wt% anti-crust agent, 0.01-0.08wt% drier, 0-3.5wt% glossing agent and organic solvent.

Owner:SHANGHAI JIAO TONG UNIV

High-elasticity external wall coating with enhanced anti-corrosive performance of composite epoxy resin emulsion

InactiveCN106634358ALower surface energyImprove protectionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a high-elasticity external wall coating with enhanced anti-corrosive performance of composite epoxy resin emulsion. The high-elasticity external wall coating is prepared from, by weight, 20-22 parts of methyl methacrylate, 29-31 parts of butyl acrylate, 8.5-9.5 parts of hexafluorobutyl acrylate, 4-5 parts of vinyl triethoxy silane, 0.1-0.12 part of ammonium persulfate, 2-3 parts of OP-1, proper amount of deionized water, proper amount of amino water, 1.5-2 parts of n-dodecanol ester, 8-10 parts of superfine kaoline, 3-4 parts of polyether polyol, 2-3 parts of epoxy resin, 7-8 parts of epoxy resin emulsion, and 1-2 parts of boron trifluoride diethyl etherate. The high-elasticity coating has water-based formula and is free from toxic and pollution, high in ductility, excellent in weather fastness, convenient to construct; the coating is especially suitable for the waterproof use of the external wall of the building engineering; the coating film is smooth and beautiful.

Owner:岳承华

Production process of double-sided film-coated color steel plate for building

InactiveCN110481135ASimple structureImproved alkali resistance and temperature difference resistanceLamination ancillary operationsLaminationHeating systemFilm-coated tablet

The invention discloses a production process of a double-sided film-coated color steel plate for a building. The method comprises the following steps: heating the front surface and the back surface ofa substrate coil material through a drying oven, with adhesive layers being formed on the front and back surfaces of the substrate coil material after the substrate coil material passes through the drying oven; coating the front surface of the treated substrate coil material with front film through an upper heat-conducting film-coating steel roller and coating the back surface of the substrate with PET film through a lower film-coating rubber roller, with the upper heat-conducting film-coating steel roller being provided with an oil path heating system inside to allow the surface temperatureof the steel roller to be 90-100 DEG C; and after the double-sided film coating, immediately spraying cold water for a cooling purpose; after spraying, performing extrusion to remove water with a wringing roller, and drying water points on the front surface and the back surface through hot air blowing, with the temperature of the cooled substrate being 25-40 DEG C, and therefore, color film layersoutside the substrate are formed, and PE protective film is attached to the color film layers at room temperature. The aging resistance, damp-heat resistance, acid resistance, alkali resistance and temperature difference resistance of the steel plate provided by the invention are obviously improved.

Owner:SHANDONG JINGHONG INTELLIGENT TECH CO LTD

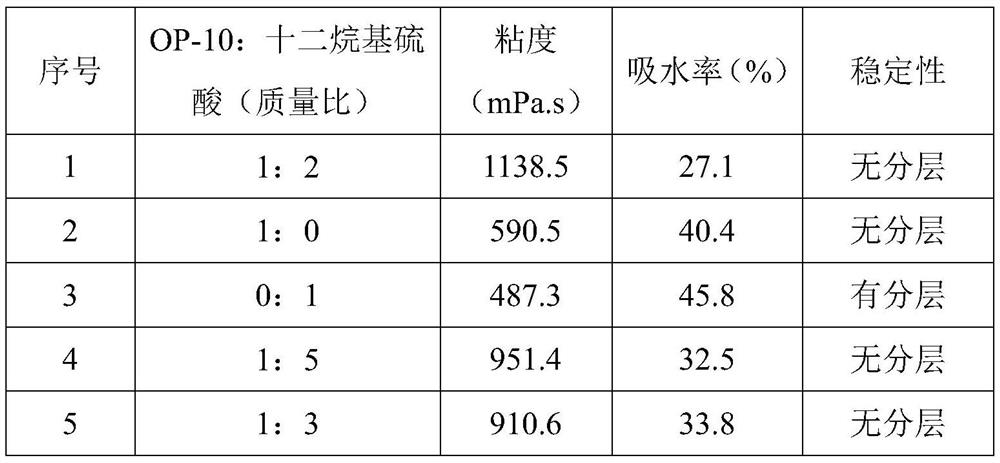

Modified lanthanum hexaboride heat-insulating property enhanced exterior wall acrylic high-elasticity waterproof coating

The invention discloses a modified lanthanum hexaboride heat-insulating property enhanced exterior wall acrylic high-elasticity waterproof coating. The exterior wall acrylic high-elasticity waterproof coating is prepared from the following raw materials in parts by weight: 20 to 22 parts of methyl methacrylate butyl acrylate, 29 to 31 parts of butyl acrylate, 8.5 to 9.5 parts of hexafluorobutyl acrylate, 4 to 5 parts of vinyltriethoxysilane, 0.1 to 0.12 part of ammonium persulfate, 2 to 3 parts of OP-10, an appropriate amount of deionized water and an appropriate amount of ammonia water, 1.5 to 2 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 12 to 13 parts of lanthanum hexaboride powder, 1.2 to 1.3 parts of polyvinylpyrrolidone, 0.8 to 1 part of sodium dodecyl benzene sulfonate, an appropriate amount of anhydrous ethanol, 7 to 8 parts of rutile type titanium dioxide, and 1 to 1.5 parts of sodium carboxymethylcellulose. The coating prepared by the invention has good heat insulation properties, can prevent infrared rays from entering, and further prevents heat from radiating outdoors, and has good water resistance and weather resistance after applied onto outdoor wall bodies; in addition, a prepared coating film is not easy to crack, thereby well protecting the wall bodies and prolonging the service life of the wall bodies.

Owner:岳承华

Building external wall temperature-change-resistant anti-oxidative color coating

InactiveCN106381045AHigh tensile strengthGood flexibilityPolyurea/polyurethane coatingsAluminium hydroxidePOLYOXYETHYLENE ETHER

The invention discloses a building external wall temperature-change-resistant anti-oxidative color coating, which is prepared from the following raw materials in parts by weight: 20 to 25 parts of carboxylic waterborne polyurethane, 19 to 24 parts of pure silicon resin emulsion, 11 to 16 parts of cobalt blue, 10 to 15 parts of mill base, 8 to 12 parts of bentonite, 7 to 11 parts of mica powder, 6 to 10 parts of kaolin, 5 to 9 parts of talcum powder, 12 to 14 parts of sodium carbonate, 9 to 11 parts of sodium tripolyphosphate, 10 to 12 parts of polyoxyethylene aliphatic ester, 8 to 10 parts of sodium polyacrylate, 13 to 16 parts of sheet zinc powder, 7 to 11 parts of aluminum hydroxide, 5 to 8 parts of silicon nitride, and 30 to 35 parts of deionized water. A preparation method comprises the following steps of S1, adding the carboxylic waterborne polyurethane, the pure siliconresin emulsion, the cobalt blue, the mill base and the deionized water into a stirrer, and stirring with the stirring speed of 30 to 40rpm for 20 to 30min at the temperature of 40 to 50 DEG C; S2, adding the sheet zinc powder, the aluminum hydroxide and the silicon nitride for stirring with the stirring speed of 100 to 150rpm for 5 to 10min. The building external wall temperature-change-resistant anti-oxidativecolor coating provided by the invention has excellent temperature alternating resistance and oxidation resistance, has high tensile strength and favorable flexibility, and is simple in preparation process, convenient to use, and low in cost.

Owner:CHENGDU PUJIANG KEXIAN TECH

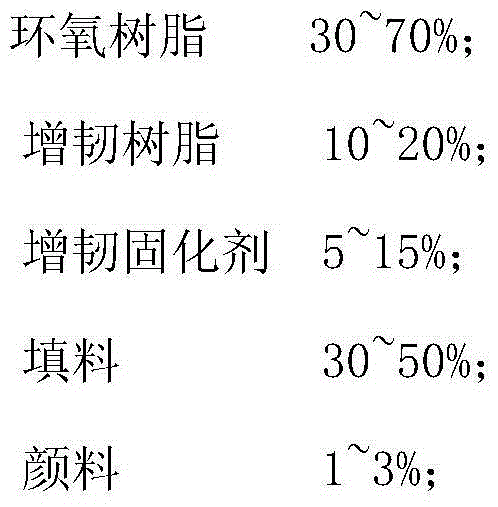

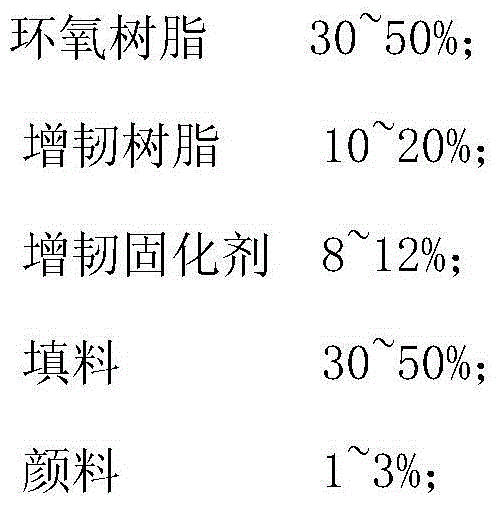

Epoxy grout

InactiveCN104804686AImprove temperature resistance performanceImprove adhesion performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyTemperature difference

The invention relates to epoxy grout which comprises the following components: epoxy resin, filler and pigment, and is characterized by further comprising toughening resin and a toughening curing agent, wherein the toughening curing agent is polyether arylamine. According to the epoxy grout, polyether arylamine is adopted as the toughening curing agent in a breakthrough manner, and a precise formula is adopted, so as to achieve the effect that the epoxy grout has high temperature difference resistance and high adhesive force performance; besides, the adhesive force of the epoxy grout after curing reaches 9 Mpa, the cold and heat resisting cycle temperature reaches to minus 30 to 80 DEG C, and the elongation reaches 8%.

Owner:常州市天安特种涂料有限公司

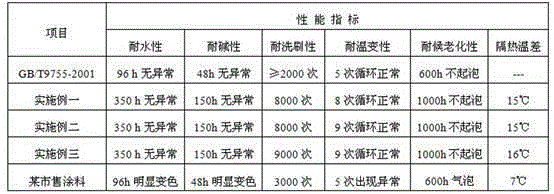

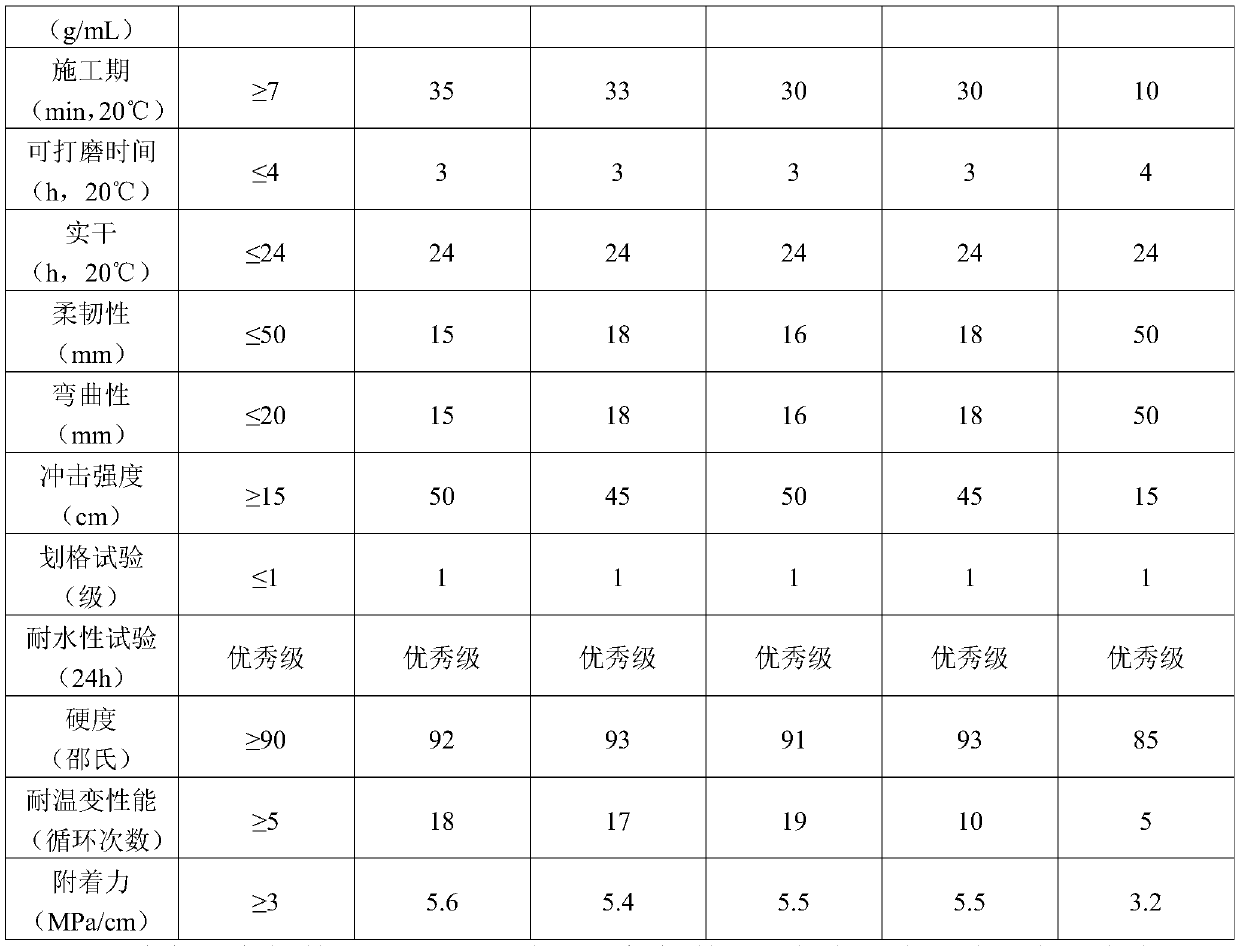

Exterior wall coating and preparation method thereof

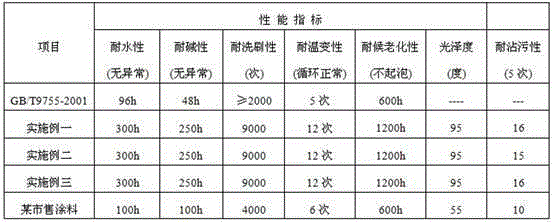

The invention provides exterior wall coating and a preparation method thereof. The exterior wall coating is prepared from the following components in parts by weight: 41-48 parts of phosphate modified acrylic emulsion, 15-25 parts of pigment and filler, 0.5-0.8 part of sodium dodecyl sulfate, 5-15 parts of jatropha curcas biodiesel, 0.1-0.5 part of an antioxidant, 1.5-2.3 parts of a coalescing agent, 10-18 parts of tween-80, 0.5-1.2 parts of triton X-100 and 40-50 parts of water. The performance of the exterior wall coating is improved by adopting the nonionic surfactant tween-80 and triton X-100 under scientific matching and synergistic effect of the components and the synergistic effect of the jatropha curcas biodiesel and the antioxidant. The exterior wall coating has good ultraviolet ray resistance, weather resistance, chemical corrosion resistance, scrubbing resistance and other performances, and can far meet the requirement of GB / T9755-2001 national standard for synthetic resin emulsion exterior wall coating.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Heat insulation exterior wall coating

InactiveCN105062232AImprove insulation performanceImproves UV resistanceRadiation-absorbing paintsAluminum magnesium silicateActive agent

The invention discloses a heat insulation exterior wall coating, and belongs to the technical field of coatings. The heat insulation exterior wall coating comprises, by weight, 30-40 parts of a pure styrene acrylic emulsion, 5-10 parts of ferric oxide, 5-10 parts of ferrous oxide, 10-20 parts of talcum powder, 10-20 parts of heavy calcium carbonate, 30-40 parts of deionized water, 10-20 parts of Tween-80, 1-5 parts of an anti-ultraviolet additive, 1-5 parts of hydroxyethyl cellulose, 1-5 parts of magnesium aluminum silicate, 1-5 parts of nanometer zinc oxide, 1-3 parts of nano-flake aluminum powder and 1-3 parts of nano-flake zinc powder. The heat insulation performance of the exterior wall coating is enhanced by using the nonionic surfactant Tween-80 through using the anti-ultraviolet additive and nanometer additives under the cooperation of hydroxyethyl cellulose and magnesium aluminum silicate, and the exterior wall coating also has the advantages of good ultraviolet resistance, good ageing resistance, good weatherability, good chemical corrosion resistance, good scrubbing resistance, improved heat insulation performance, economy and practicality.

Owner:QINGDAO WINCHANCE TECH

Oxidation-resistant coating composition

InactiveCN104893439AModified AdhesionModified water resistancePolyether coatingsPolyester coatingsOxidation resistantMaterials science

The invention relates to an oxidation-resistant coating composition. The oxidation-resistant coating composition comprises various resins and auxiliaries and is highly resistant to ultraviolet irradiation and temperature difference change by means of combination of all the components.

Owner:周美琴

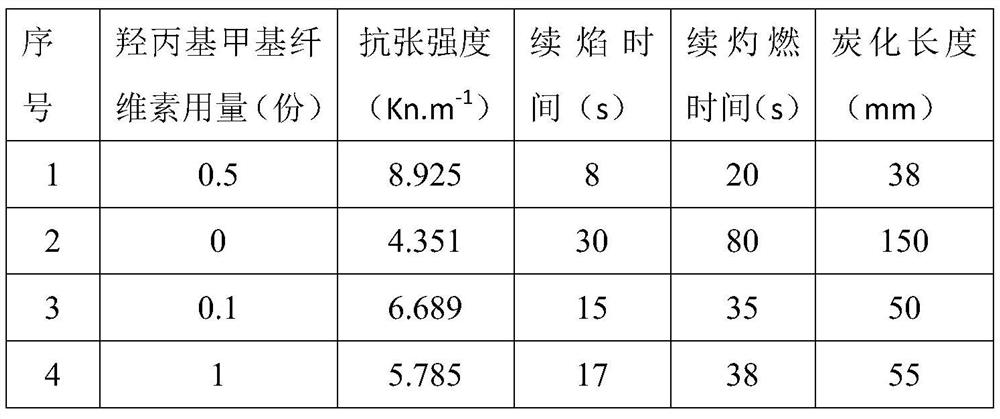

Paper flame retardant with high film-forming property and preparation method thereof

ActiveCN108978341AGood film formingEvenly distributedPaper/cardboardIgnifugeants additionEmulsionCarvacryl acetate

The invention discloses a paper flame retardant with high film-forming property and a preparation method thereof, and aims to solve the problems of non-uniform distribution, poor film-forming propertyand susceptibility to aging and fracturing of a flame retardant in the prior art. The paper flame retardant with high film-forming property is prepared from the following raw materials in parts by weight: 10 to 30 parts of ammonium polyphosphate, 40 to 100 parts of decabromodiphenyl ethane and 200 to 500 parts of modified vinyl acetate copolymer emulsion. The preparation method comprises the following steps: adding other raw materials into the modified vinyl acetate copolymer emulsion served as a dispersion liquid; mixing uniformly; discharging. The paper flame retardant has the advantages ofhigh film-forming property, uniform distribution of the flame retardant is realized, high mechanical performance is achieved, and the aging and fracturing are not easy to occur.

Owner:NEIJIANG NORMAL UNIV

Multifunctional outer wall coating

InactiveCN105038348AImproves UV resistanceImprove aging resistanceAnti-corrosive paintsCelluloseAluminum silicate

The invention discloses a multifunctional outer wall coating and belongs to the technical field of building materials. The multifunctional outer wall coating comprises, by weight parts, 30-40 parts of silicone modified acrylate emulsion, 30-40 parts of packing, 10-20 parts of pigment, 30-40 parts of deionized water, 1-10 parts of tween-80, 1-10 parts of alkyl sodium sulfonate, 1-10 parts of span-80, 1-10 parts of substituted acrylate ester, 1-10 parts of hydroxyethyl cellulose, 1-10 parts of magnesium aluminum silicate, 1-10 parts of magnesium oxide, 1-10 parts of emulsified silicone oil and 1-10 parts of mineral oil corrosion-resistant bactericide. Under the scientific matching and synergistic effects of components, the ultraviolet resistance, ageing resistance, weather resistance, chemical resistance and scrubbing resistance of the coating are greatly improved; the brightness of the surface of an outer wall is improved, the overall attractiveness of a building is improved, and the shortcoming that an existing outer wall coating is easily subject to color fading, dropping and powder falling is overcome.

Owner:QINGDAO WINCHANCE TECH

Oxidation-resistant binder composition

ActiveCN104893622AModified AdhesionModified water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePolymer chemistry

The invention relates to an oxidation-resistant binder composition. The oxidation-resistant binder composition comprises different types of resin and auxiliaries. The oxidation-resistant binder composition with various components which are combined with one another has the advantages of excellent ultraviolet radiation resistance and temperature difference change resistance.

Owner:永清霍尔茨门业有限公司

Ceramic burner plate

InactiveCN101413665ALow alkali contentReduce contentBurner material specificationsGaseous fuel burnerLithium oxideCalcium silicate

The present invention relates to a ceramic burner plate for infrared radiators which includes a lithium silicate as a main constituent. The burner plates according to the invention can have a content of lithium oxide within the range of 0.63% by weight to 7.6% by weight and they exhibit a high temperature resistance and are extremely durable.

Owner:SCHWANK GMBH

Long-acting protective coating for furnace wall of gas nitriding furnace and preparation method thereof

ActiveCN112876887AWill not crack and peelAvoid crackingFireproof paintsAlkali metal silicate coatingsMolten stateCopper oxide

The invention provides a long-acting protective coating for a furnace wall of a gas nitriding furnace and a preparation method thereof. The protective coating comprises an adhesive, silicon dioxide, boric anhydride, calcium oxide, copper oxide and sylvite, and preferably further comprises an anti-seepage agent. The melting point of a glass coating is adjusted, so that the coating is of a glass molten state structure at high temperature and has good viscosity and sealing effects, the coating is converted into solid glass after being cooled to the normal temperature, and the coating can keep a complete structure under temperature difference impact. The coating also contains functional elements such as boron, silicon, copper and potassium, the physical and chemical properties of a coating layer can be improved, and the coating has a good application prospect.

Owner:武汉铭高新材料有限公司

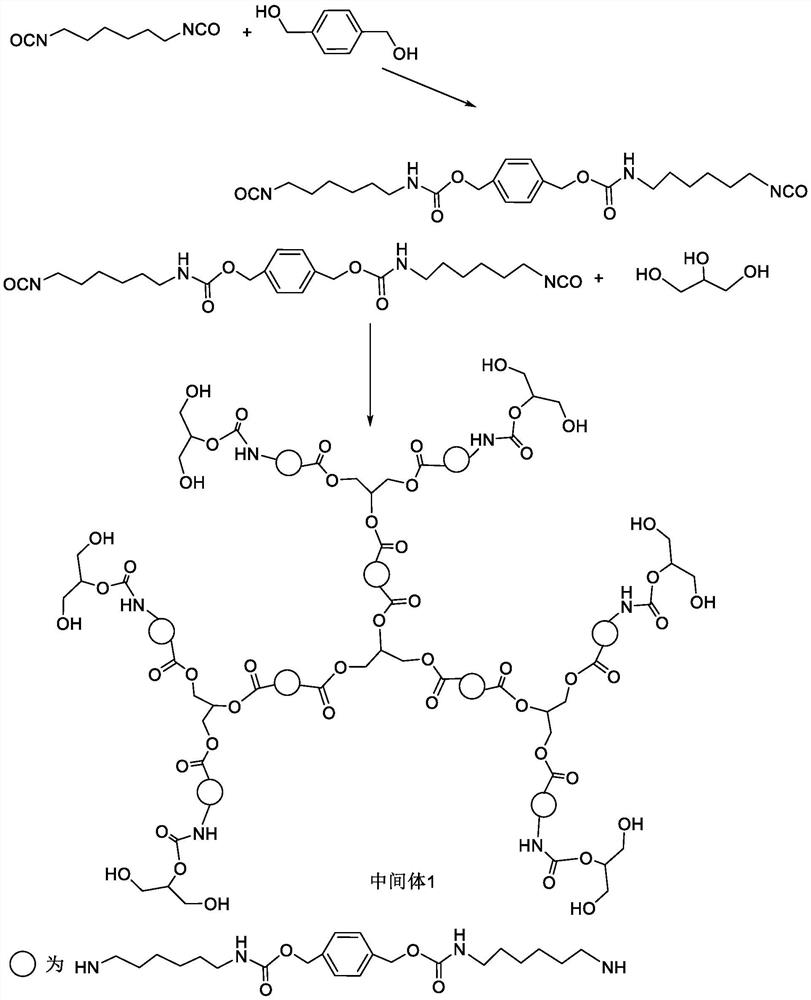

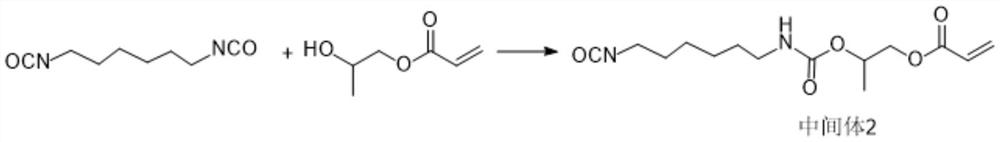

A kind of water-based uv paint and preparation method thereof

The invention discloses a water-based UV paint and a preparation method thereof, belonging to the technical field of UV paint manufacture. The water-based UV paint comprises the following raw materials in parts by weight: 20-40 parts of hyperbranched polyurethane acrylate emulsion, 20 parts of modified acrylate emulsion ‑40 parts, 15‑25 parts of absolute ethanol, 5‑15 parts of ethylene glycol butyl ether, 5‑10 parts of talcum powder, 1‑5 parts of photoinitiator, 0.1‑0.5 parts of defoamer, 0.1 part of amine neutralizer -0.5 parts. And the present invention has synthesized hyperbranched urethane acrylate with highly branched structure, and contains a large amount of terminal acrylate groups and end-capped double bonds in the molecule, which synergistically provides high UV curing speed and shortens UV curing time; the present invention The provided water-based UV paint has excellent adhesion and hardness, and the obtained paint film has excellent mechanical strength, as well as excellent water resistance, oil resistance and stain resistance.

Owner:安徽名士达新材料有限公司

Preparation method of antioxidation paint composition

InactiveCN104910704AModified AdhesionModified water resistancePolyester coatingsOrganic chemistryComposite material

The invention relates to a preparation method of an antioxidation paint composition. The paint composition comprises multiple different types of resins and assistants. Due to the combination of the components, the paint composition has the advantages of favorable ultraviolet irradiation resistance and favorable temperature difference change resistance.

Owner:周美琴

Cold-resistant insulating bandage capable of being used in severe environment

InactiveCN106118523AImprove heat resistanceModerate porosityNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylatePolyvinyl chloride

The invention discloses a cold-resistant insulating bandage capable of being used in the severe environment. The cold-resistant insulating bandage is prepared from raw materials in parts by weight as follows: 1.5-1.6 parts of indianite nano tubes, 0.75-0.77 parts of a silane coupling agent kh 570, a proper amount of deionized water, a proper amount of absolute ethyl alcohol, 1.2-1.4 parts of sodium dodecyl sulfate, 1.4-1.5 parts of alkylphenol ethoxylates, 55-60 parts of butyl acrylate, 40-43 parts of ethylhexyl acrylate, 40-44 parts of isotactic polypropylene, 53-55 parts of polyvinyl chloride, 3-4 parts of dibenzylidene sorbitol, a proper amount of dioctyl phthalate, 9-10 parts of dioctyl adipate, 0.6-0.7 parts of tricresyl phosphate, 6-8 parts of stearin ester, 2-3 parts of sunflower oil and 8-9 parts of nano clay. The prepared product can be used for cable binding in the severe outdoor environment and is high in viscosity, ageing-resistant, cold-resistant and high-temperature-resistant.

Owner:合肥得润电子器件有限公司

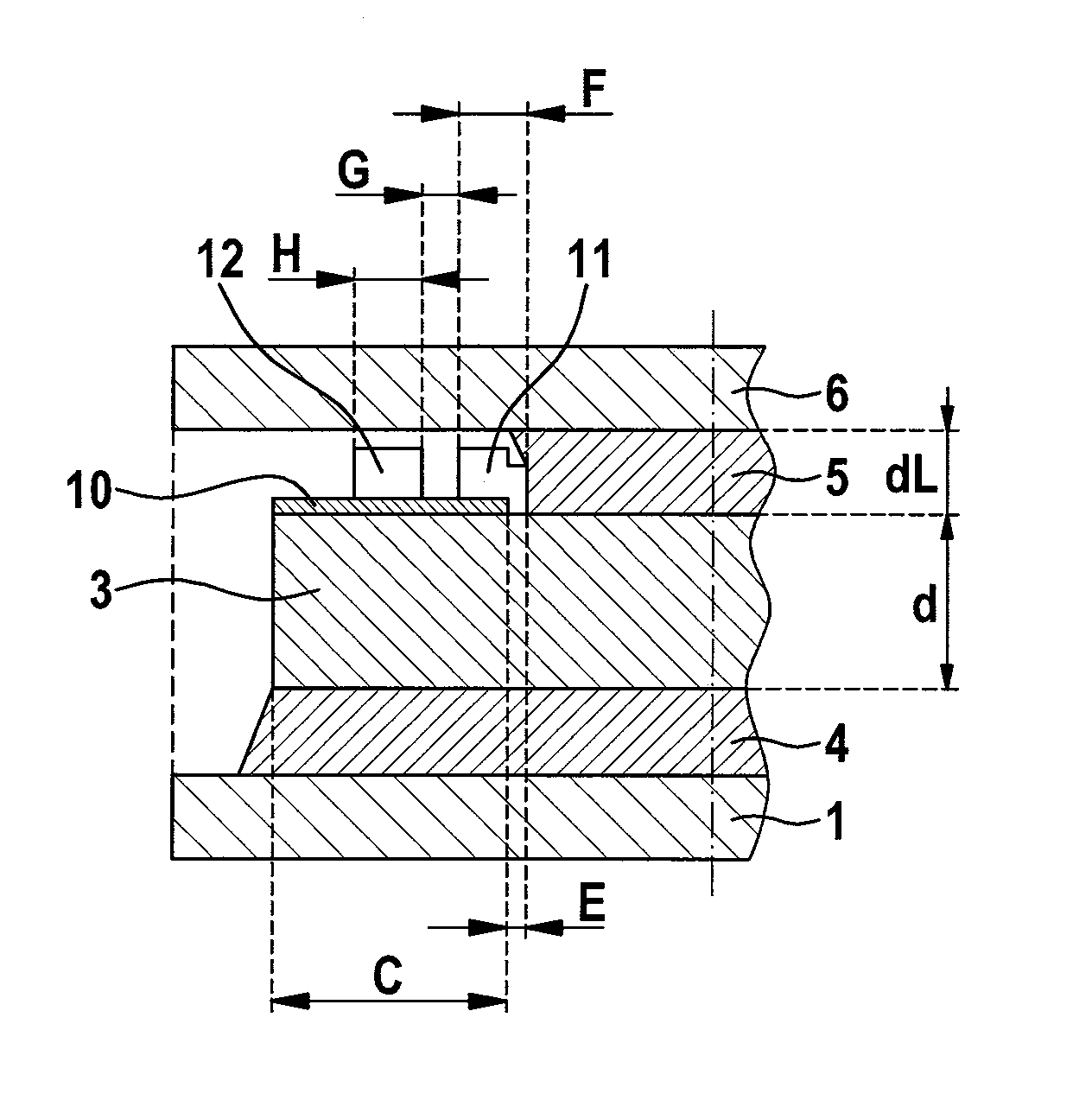

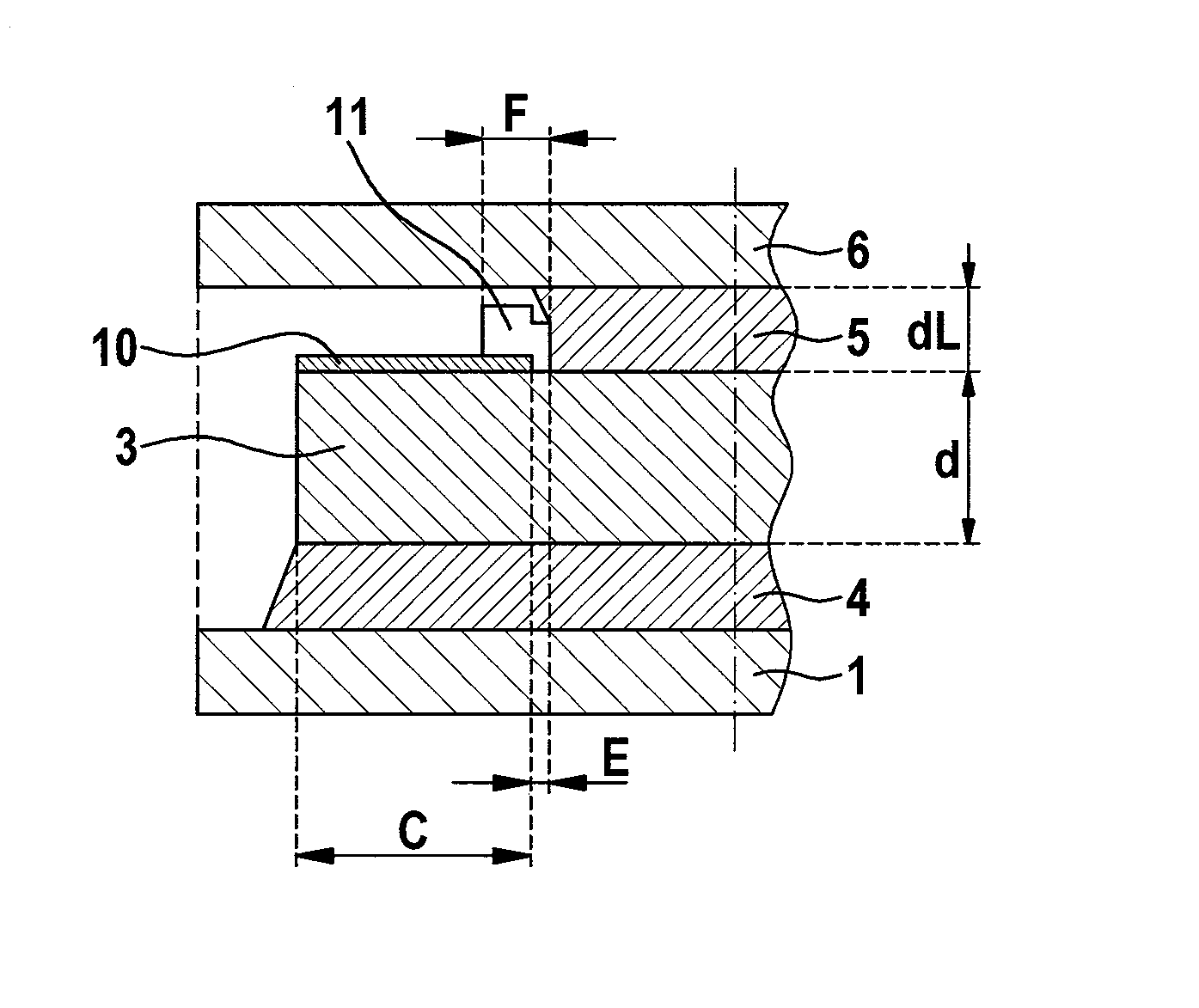

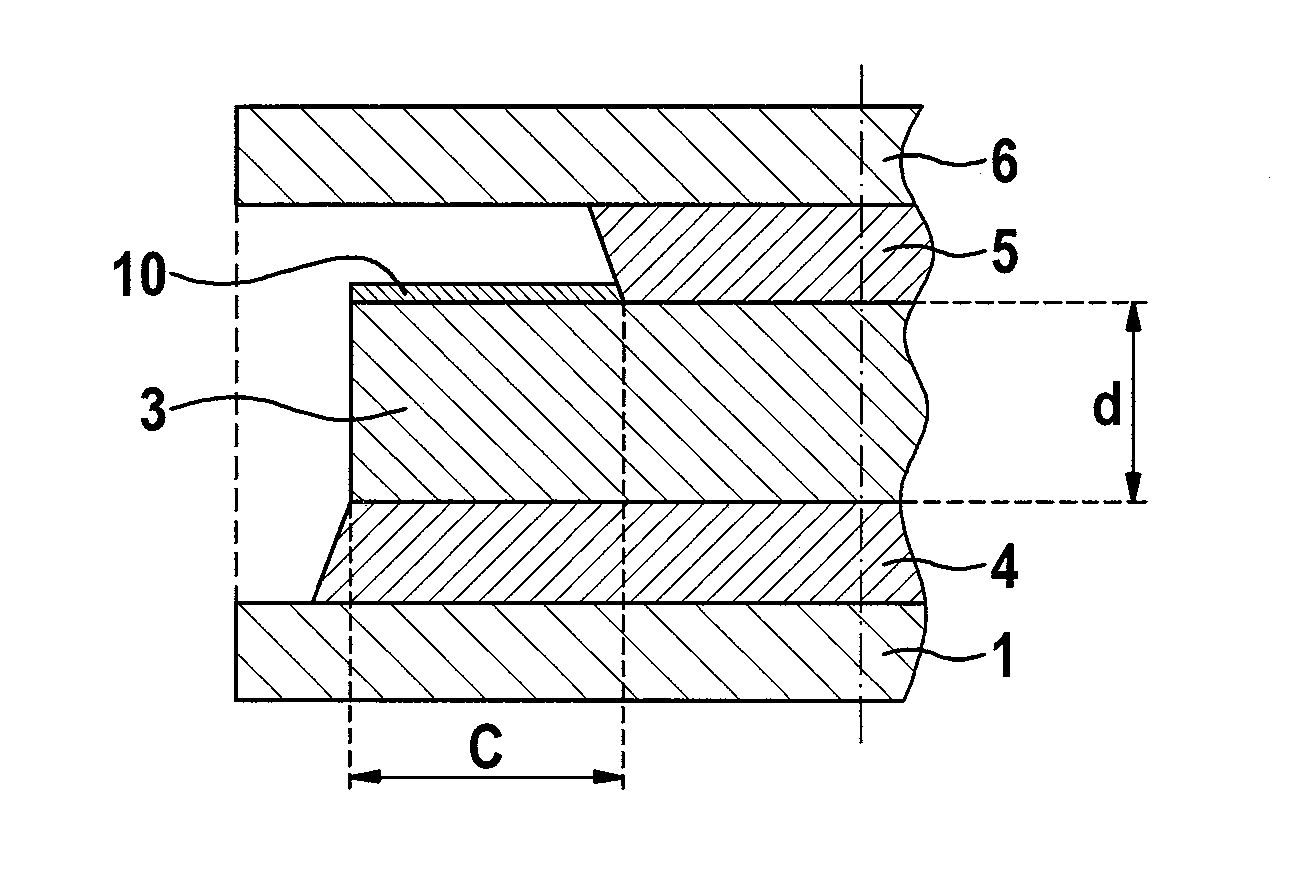

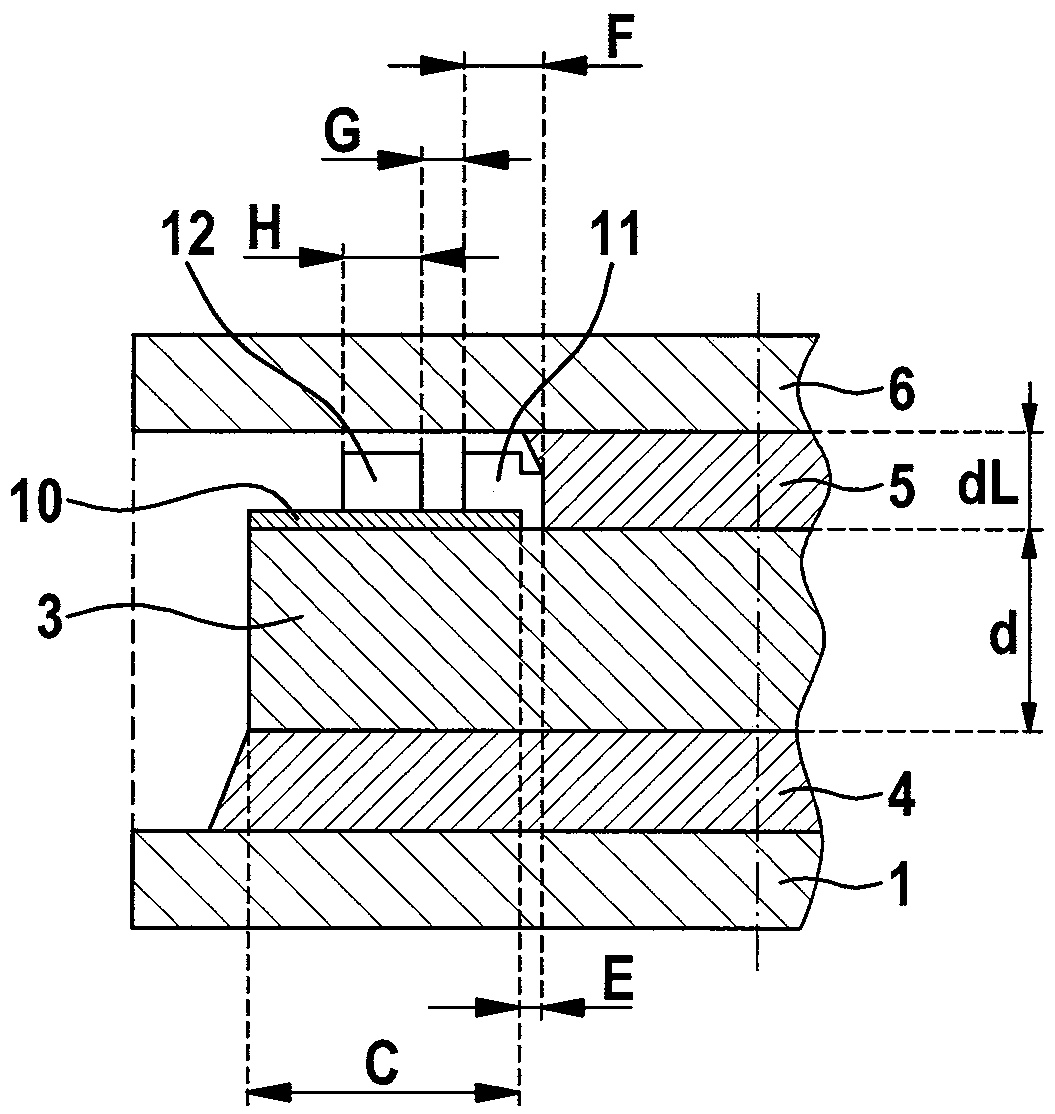

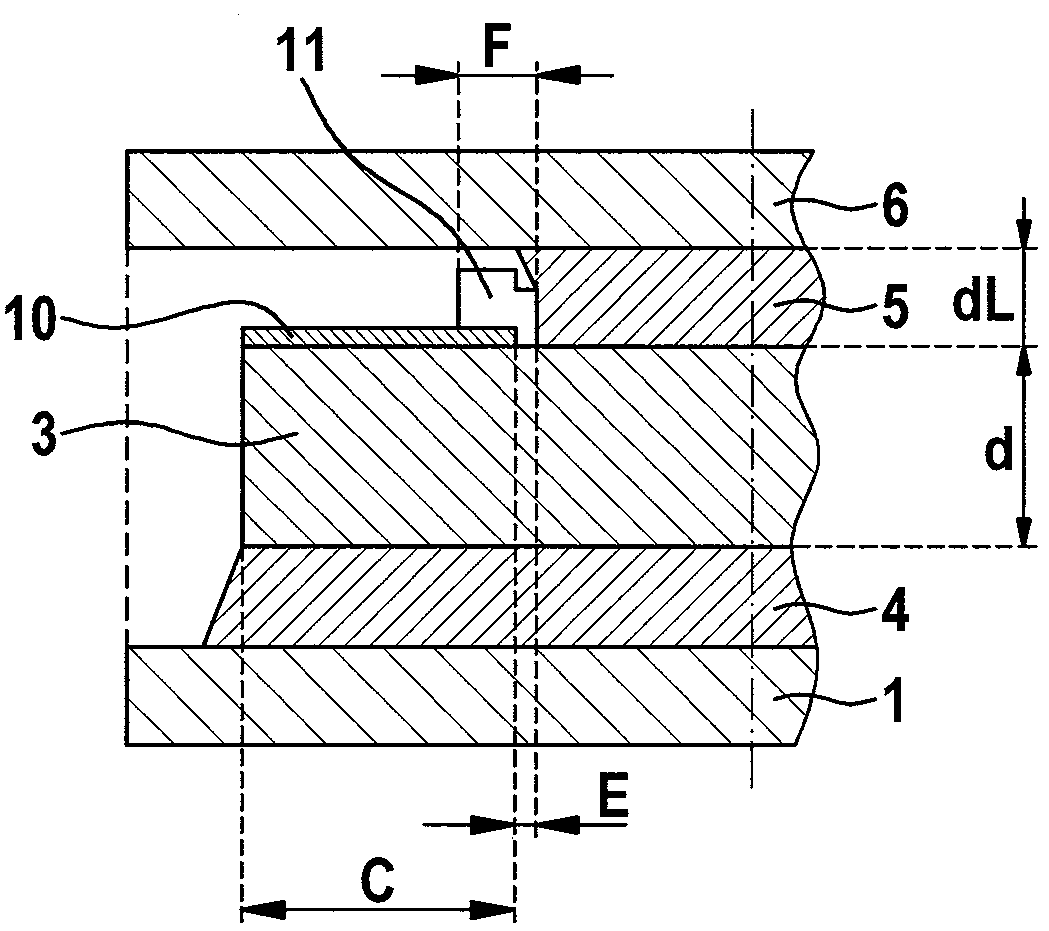

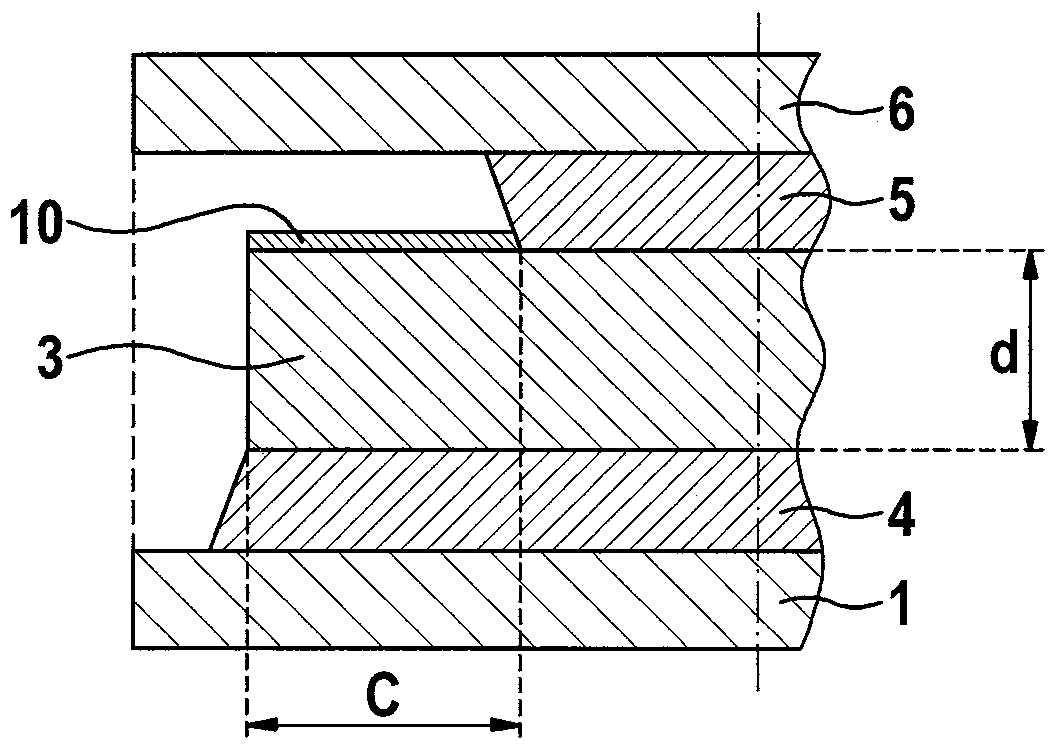

High intensity temperature change-resistant crimping diode

ActiveCN103579374AImprove temperature resistance performancePrevent outflowSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipHigh intensity

The invention relates to a crimping diode provided with a semisonductor chip fixed between a pedestal and a top metal wire through a connecting layer; the connecting layer contracts at least on the front surface of the chip relative to the outer rim of the chip; an area without the connecting layer on the semiconductor chip is provided with surrounded and insulated first plastic layer; furthermore, a complete surrounded and insulated second plastic layer is employed to connect an end portion in a radial direction of the first plastic layer.

Owner:ROBERT BOSCH GMBH

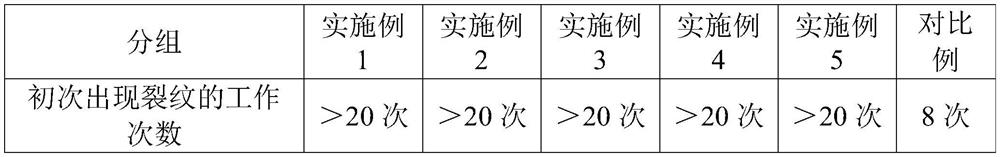

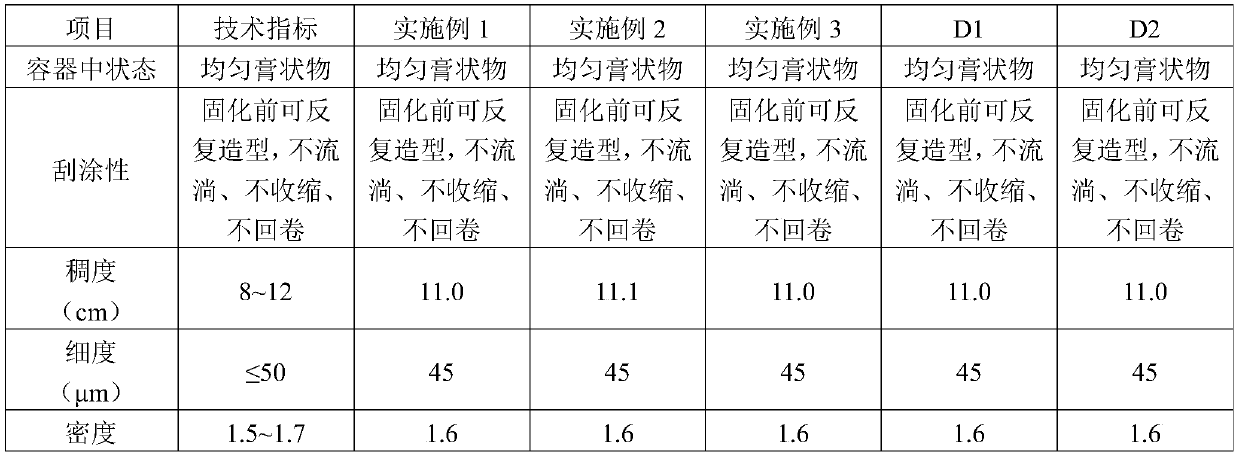

A special atomic ash for multiple trains and its preparation method and application

ActiveCN107641365BGood flexibilityImprove bending performanceFilling pastesCopper naphthenateNaphthoquinone

The invention discloses poly putty specially used for a multiple unit train. The poly putty comprises main putty and a curing agent, wherein the main putty comprises the following components in partsby weight: 38-42 parts of unsaturated polyester resin, 0.7-0.8 part of cobalt isooctanoate with a weight fraction of 8%, 2-5 parts of styrene, 0.2-0.5 part of a composite auxiliary agent, 5-8 parts offumed silica, 5-10 parts of titanium dioxide, 25-30 parts of talcum powder with 325 meshes, and 8-15 parts of talcum powder with 600 meshes; and the composite auxiliary agent is composed of TBC, 1,4-naphthoquinone, antioxidant 264, copper naphthenate, and methyl ethyl ketoxime. The poly putty provided by the invention has the characteristics of high flexibility, high bendability, high impact resistance and very good temperature variation resistance, and the poly putty can withstand long-term high-low temperature change, is not easy to crack or fall, and fully meets the long-term operating requirements of the multiple unit train in areas with a high temperature difference.

Owner:河北新盾合成材料有限公司

Exterior wall coating

InactiveCN105001692AImprove performanceImproves UV resistanceAntifouling/underwater paintsPaints with biocidesActive agentAluminum silicate

The invention discloses an exterior wall coating and belongs to the technical field of building materials. The exterior wall coating comprises, by weight, 30-40 parts of silicone-modified acrylic emulsion, 30-40 parts of filler, 10-20 parts of pigment, 30-40 parts of deionized water, 1-10 parts of cationic surface active agent, 1-10 parts of non-ionic surface active agent, 1-10 parts of substituted acrylate, 1-10 parts of hydroxyethyl cellulose, 1-10 parts of magnesium aluminum silicate, 1-10 parts of magnesium oxide, 1-10 parts of silicone emulsion, 1-10 parts of mineral oil preservative and bactericide and 1-10 parts of texanol ester alcohol. Hybrid dispersant is adopted, under the effects of the hydroxyethyl cellulose, the magnesium aluminum silicate, the magnesium oxide, the silicone emulsion and the mineral oil preservative and bactericide, the performance of the exterior wall coating is enhanced, the ultraviolet resistance, aging resistance, weather resistance, chemical resistance and scrubbing resistance of the exterior wall coating are greatly improved, and the decoration performance of a building is enhanced.

Owner:QINGDAO WINCHANCE TECH

High-strength temperature-resistant crimp diode

ActiveCN103579374BImprove temperature resistance performancePrevent outflowSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsSemiconductor chip

The invention relates to a crimp diode with a semiconductor chip fixed between a base and a top wire by a connection layer. The connection layer is set back circumferentially relative to the chip outer edge at least on the chip front side. A surrounding, insulating first plastic layer is present on the region of the semiconductor chip free of the connection layer. Furthermore, a completely surrounding, insulating second plastic layer is provided which overlaps the radially inner end region of the first plastic layer.

Owner:ROBERT BOSCH GMBH

Preparation method of metal colored transparent high-temperature-yellowing-resistant coating

InactiveCN111560202AGuaranteed textureImprove fullnessFireproof paintsIn situ polymerizationFirming agent

The invention discloses a preparation method of a metal colored transparent high-temperature-yellowing-resistant coating, belonging to the technical field of protective coatings. The invention aims toovercome the problems of poor temperature change resistance, low adhesive force, difficulty in realizing colored transparent coating and the like of traditional anti-fingerprint metal plate at present. According to the preparation method, high-temperature-resistant organosilicone modified acrylate resin is prepared by blocking flexible organosilicone small molecules onto an acrylate main chain through in-situ polymerization, so the temperature change resistance of basic resin is improved; and then an epoxy resin curing agent, nanometer inorganic color paste and an auxiliary agent are subjected to mixing and ball-milling to prepare a coating, and the surface of a metal substrate is uniformly coated with the coating through a rotary spraying device to obtain the colored transparent high-temperature-yellowing-resistant coating. The color of the obtained coating does not cover the original color and texture of metal, metal texture can be integrally kept, and the coating is suitable for protection and decoration of surfaces of various household appliance panels, building boards, environment-friendly equipment and the like and has wide market application prospects.

Owner:NANTONG UNIVERSITY +2

A flame retardant for paper with good film-forming performance and preparation method thereof

ActiveCN108978341BGood film formingEvenly distributedPaper/cardboardIgnifugeants additionPolymer scienceEmulsion

The invention discloses a paper flame retardant with high film-forming property and a preparation method thereof, and aims to solve the problems of non-uniform distribution, poor film-forming propertyand susceptibility to aging and fracturing of a flame retardant in the prior art. The paper flame retardant with high film-forming property is prepared from the following raw materials in parts by weight: 10 to 30 parts of ammonium polyphosphate, 40 to 100 parts of decabromodiphenyl ethane and 200 to 500 parts of modified vinyl acetate copolymer emulsion. The preparation method comprises the following steps: adding other raw materials into the modified vinyl acetate copolymer emulsion served as a dispersion liquid; mixing uniformly; discharging. The paper flame retardant has the advantages ofhigh film-forming property, uniform distribution of the flame retardant is realized, high mechanical performance is achieved, and the aging and fracturing are not easy to occur.

Owner:NEIJIANG NORMAL UNIV

Nano-modified anticorrosive coating for power transmission and transformation lines and preparation method thereof

InactiveCN110713793AGood adhesionGood high and low temperature resistanceAnti-corrosive paintsWeather resistanceAluminum silicate

The invention discloses nano-modified anticorrosive coating for power transmission and transformation lines and a preparation method thereof, and belongs to the technical field of electric power corrosion prevention. The coating is prepared from the following raw materials in parts by weight: 50-80 parts of epoxy modified organosilicon resin, 5-10 parts of nano magnesium oxide, 5-15 parts of a coupling agent, 5-12 parts of a curing agent, 30-50 parts of a compound diluent, 4-10 parts of red lead, 2-5 parts of aluminum silicate and 1-6 parts of an auxiliary agent. The coating is good in temperature change resistance and weather resistance.

Owner:国网河南省电力公司内乡县供电公司

Material for fireproof sealing of cable entry

ActiveCN110408276BImprove hydrophobicityHigh closed cell rateFireproof paintsElectrically-conductive paintsPolymer scienceEngineering

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +1

Nanometer fence paint

InactiveCN105153771AImprove performanceGood UV resistanceAnti-corrosive paintsAluminum magnesium silicateWeather resistance

The invention discloses a nanometer fence paint, and belong to the field of paint technology. The nanometer fence paint of the present invention comprises the following raw materials in parts by weight: 30-40 parts of acrylic acid emulsion, 5-10 parts of ferric oxide, 5-10 parts of ferrous oxide, 10-20 parts of talcum powder, 10-20 parts of heavy calcium carbonate, 30-40 parts of deionized water, 10-20 parts of tween-80, 10-20 parts of span-80, 1-5 parts of substituted acrylic acid ester, 1-5 parts of hydroxyethyl cellulose, 1-5 parts of magnesium aluminum silicate, 1-5 parts of nanometer zinc oxide, 1-3 parts of nanometer sheet shaped aluminium powder and 1-3 parts of nanometer sheet shaped copper powder. Tween-80 and span-80 are used, hydroxyethyl cellulose and magnesium aluminum silicate are combined, substituted acrylic acid ester and nanometer additives are added, and thereby performance of the nanometer fence paint is enhanced, and surface brightness of the cement fence is increased; the nanometer fence paint has the advantages of good ultraviolet resistance capability, aging resistance, weatherability, chemical corrosivity resistance and scrubbing resistance.

Owner:QINGDAO WINCHANCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com