Long-acting protective coating for furnace wall of gas nitriding furnace and preparation method thereof

A gas nitriding and protective coating technology, applied in the field of material science, can solve the problems of decreased adhesion between coating and metal layer, easy oxidation of metal, poor bonding ability, etc., to improve high temperature resistance performance and chemical stability, guarantee The effect of long-term continuous use and improved temperature difference resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

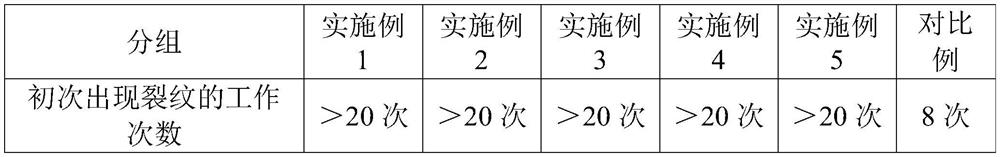

Examples

Embodiment 1

[0023] Weigh 15kg sodium silicate, 36kg silicon dioxide, 35kg boric anhydride, 10kg calcium oxide, 2kg copper oxide, 1kg potassium fluoroborate and 1kg potassium carbonate respectively, add 100kg water after mixing, mix and stir to obtain a mixed slurry, mix the mixed slurry The material is sprayed on the inner wall surface of the nitriding furnace with an average thickness of 0.3 mm, and a protective coating is obtained after drying.

Embodiment 2

[0025] Weigh 35kg of sodium silicate, 31kg of silicon dioxide, 20kg of boric anhydride, 5kg of calcium oxide, 5kg of copper oxide, 2kg of potassium fluoroborate, 2kg of potassium carbonate and 150kg of silicon carbide, mix and add 250kg of water, mix and stir to obtain a mixed slurry , spray the mixed slurry on the inner wall surface of the nitriding furnace, the average thickness of the spray is 0.4mm, and obtain a protective coating after drying.

Embodiment 3

[0027] Weigh 28kg sodium silicate, 30kg silicon dioxide, 30kg boric anhydride, 6kg calcium oxide, 4kg copper oxide, 2kg potassium fluoroborate, 100kg aluminum oxide, 50kg silicon carbide and 50kg tin powder, mix and add 300kg water, mix and stir The mixed slurry is obtained, and the mixed slurry is sprayed on the inner wall surface of the nitriding furnace with an average thickness of 0.5 mm, and the protective coating is obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com