High intensity temperature change-resistant crimping diode

A technology of diodes and Schottky diodes, which is applied in the field of crimping diodes and can solve problems such as plastic deformation of solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

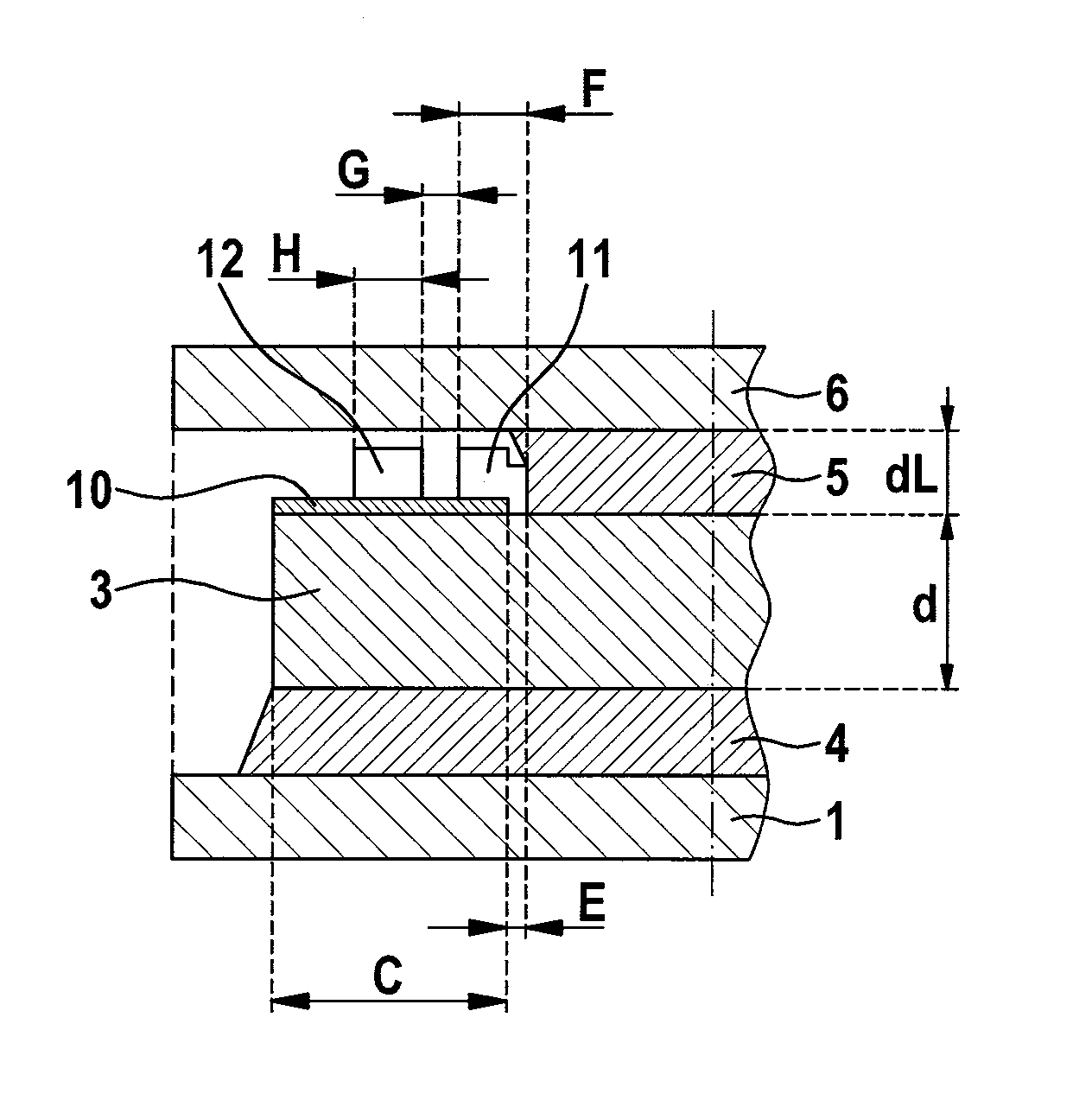

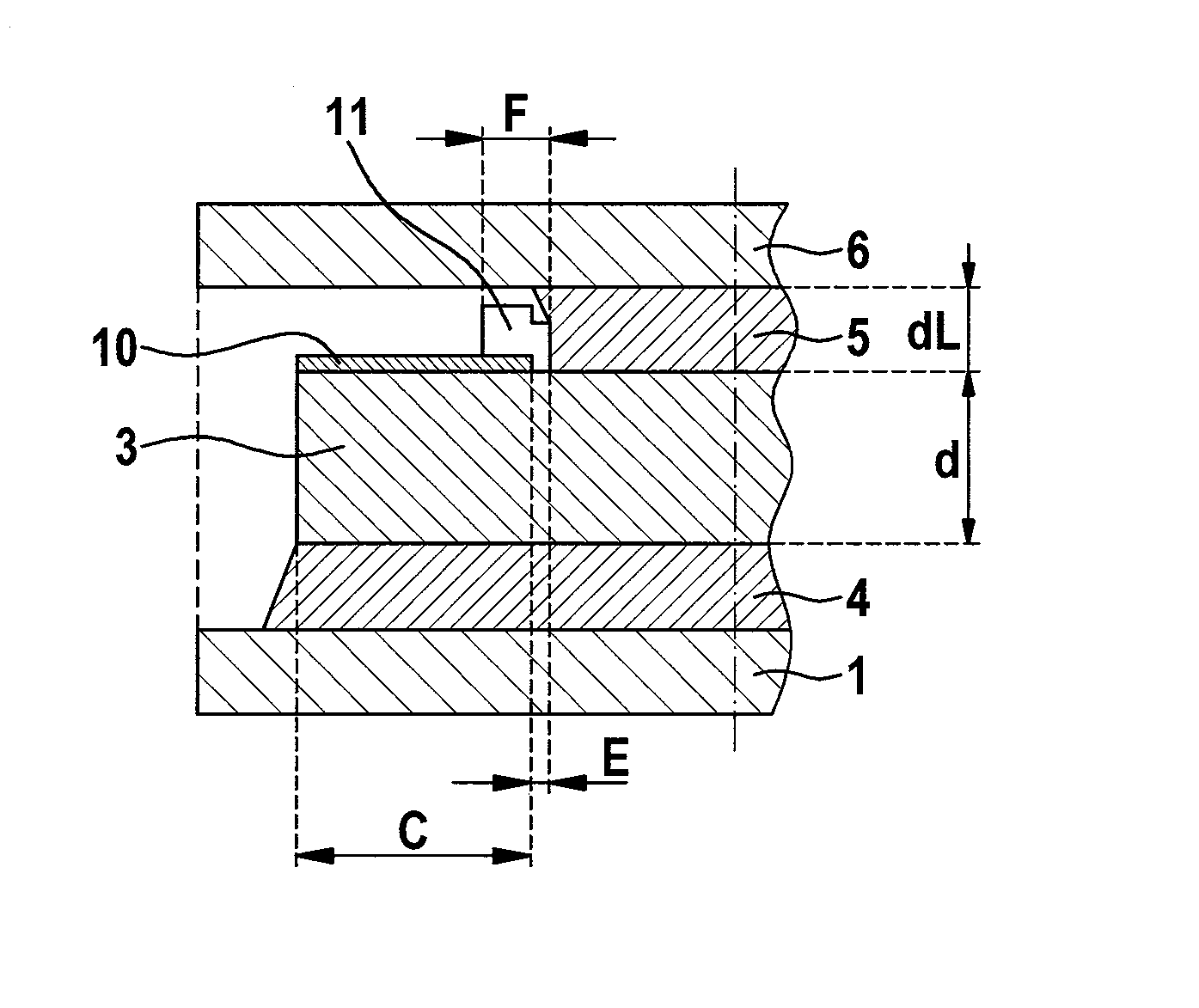

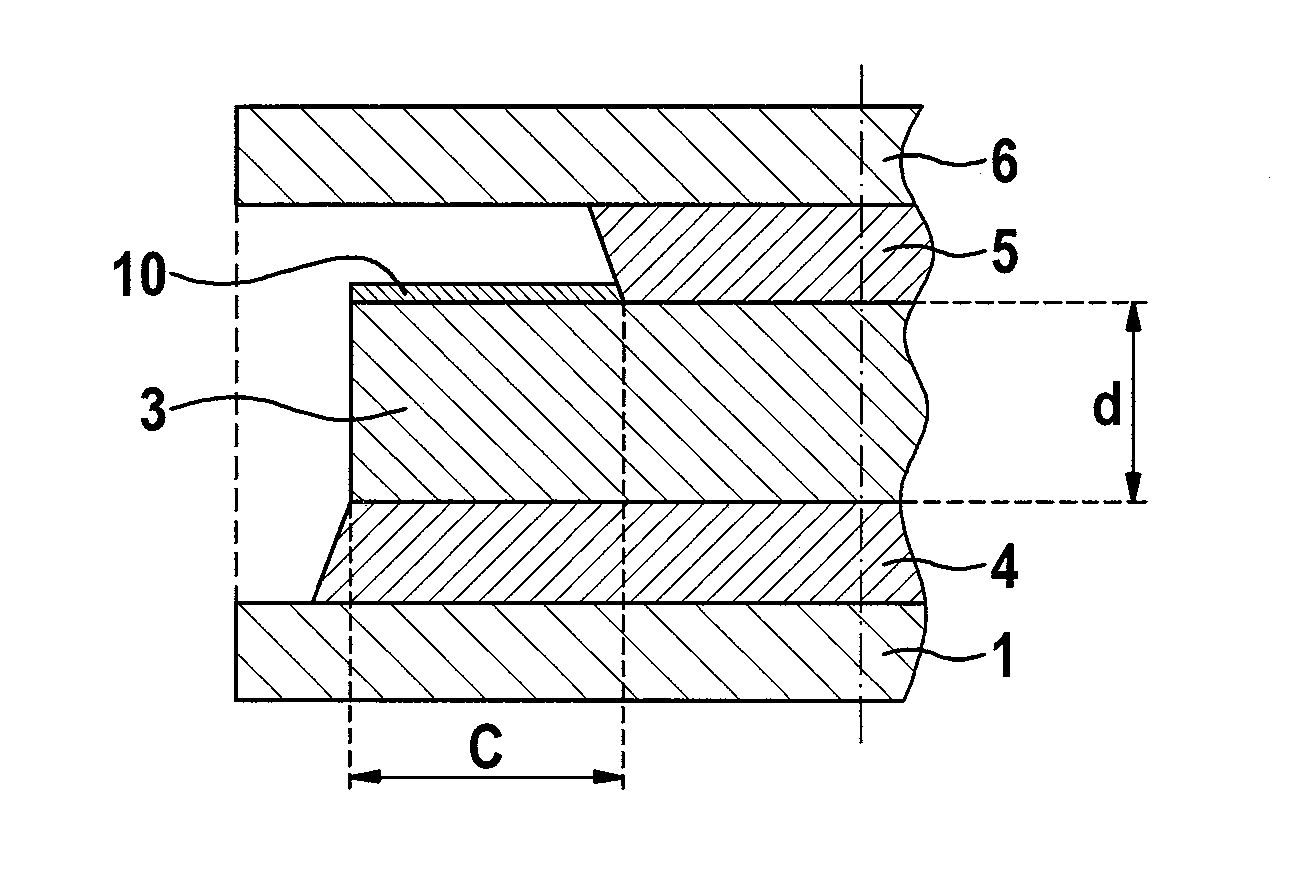

[0020] The inventors have recognized that when making crimped diodes, as in image 3 As can be seen in , the solder layer 5 is squeezed through the insulating layer 10 . this is in Figure 4 shown in the Figure 4 It can be seen that the flux layer 5 has overlapped the insulating layer 10 by a distance (C-D) after the soldering process, where C is the creep distance of the flux without overlapping and D is the The creeping distance of the flux in the case of connection. As a result of the overlap, a reduction of the creeping path occurs, by which reduction the temperature resistance of known crimp diodes is reduced.

[0021] The overlapping of the solder layer 5 on the insulating layer 10 can be traced to various causes. Among the causes are, for example, the pressure exerted on the top wire during soldering, deviations during the soldering process (Streuungen), the base 1 or the top wire 6 (cf. figure 1 ) of the surface quality fluctuations. Furthermore, there is the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com