Nano-modified anticorrosive coating for power transmission and transformation lines and preparation method thereof

An anti-corrosion coating, power transmission and transformation line technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of weather resistance to be improved, power tower anti-corrosion coatings have poor temperature change resistance and other problems, achieve good mechanical properties, improve anti-corrosion performance, the effect of improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

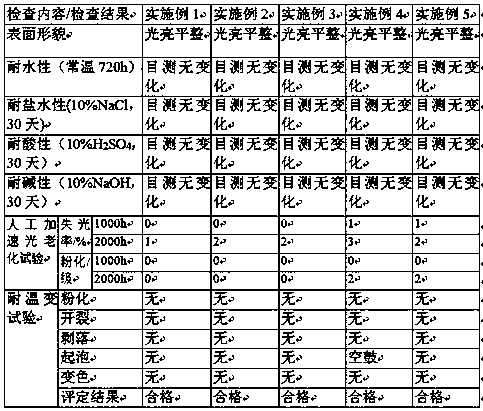

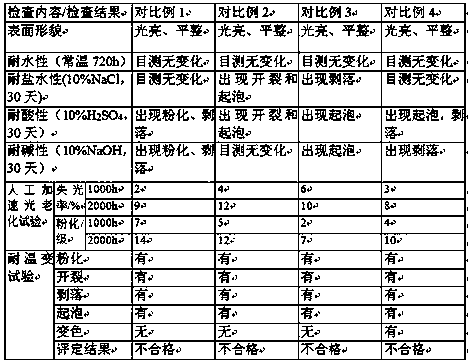

Examples

Embodiment 1

[0028] A nano-modified anti-corrosion coating for power transmission and transformation lines, which is composed of the following raw materials in parts by weight: 65 parts of epoxy-modified silicone resin, 7 parts of nano-magnesium oxide, 10 parts of coupling agent, 8 parts of curing agent, Prepare 40 parts of thinner, 7 parts of red lead, 3 parts of aluminum silicate and 3 parts of additives.

[0029] Among them: the coupling agent is titanate coupling agent TC-2, the curing agent is a combination of polyamide curing agent and diethylenetriamine, and the weight ratio of polyamide curing agent and diethylenetriamine is 2.7:1.

[0030] The compounded diluent is a composition of tetraethyl orthosilicate and n-butanol, and the mass ratio of tetraethyl orthosilicate and n-butanol is (1.2-2.5):1.

[0031]Auxiliary agent is the composition of xanthan gum, fatty acid polyethylene glycol ester, defoamer and leveling agent, and the mass ratio of xanthan gum, fatty acid polyethylene gl...

Embodiment 2

[0039] A nano-modified anti-corrosion coating for power transmission and transformation lines, which is composed of the following raw materials in parts by weight: 60-70 parts of epoxy-modified silicone resin, 6-8 parts of nano-magnesium oxide, 8-12 parts of coupling agent, 6-8 parts of curing agent, 35-45 parts of compound diluent, 6-8 parts of red lead, 3-4 parts of aluminum silicate and 2-4 parts of auxiliary agent.

[0040] Wherein, the curing agent is a composition of a polyamide curing agent and diethylenetriamine, and the weight ratio of the polyamide curing agent to diethylenetriamine is 2.0:1.

[0041] The compound diluent is a composition of tetraethyl orthosilicate and n-butanol, and the mass ratio of tetraethyl orthosilicate and n-butanol is 1.2:1.

[0042] Auxiliary agent is the composition of xanthan gum, fatty acid polyethylene glycol ester, defoamer and leveling agent, and the mass ratio of described xanthan gum, fatty acid polyethylene glycol ester, defoamer a...

Embodiment 3

[0050] A nano-modified anti-corrosion coating for power transmission and transformation lines, which is composed of the following raw materials in parts by weight: 60-70 parts of epoxy-modified silicone resin, 6-8 parts of nano-magnesium oxide, 8-12 parts of coupling agent, 6-8 parts of curing agent, 35-45 parts of compound diluent, 6-8 parts of red lead, 3-4 parts of aluminum silicate and 2-4 parts of auxiliary agent.

[0051] Wherein, the curing agent is a composition of polyamide curing agent and diethylenetriamine, and the weight ratio of polyamide curing agent and diethylenetriamine is 3.5:1.

[0052] The compound diluent is a composition of tetraethyl orthosilicate and n-butanol, and the mass ratio of tetraethyl orthosilicate and n-butanol is 2.5:1.

[0053] Auxiliary agent is the composition of xanthan gum, fatty acid polyethylene glycol ester, defoamer and leveling agent, and the mass ratio of described xanthan gum, fatty acid polyethylene glycol ester, defoamer and le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com