Heat insulation exterior wall coating

A technology of exterior wall coatings and raw materials, applied in the field of coatings, can solve problems such as high indoor temperature and affect the service life of coatings, and achieve the effects of enhancing heat insulation performance, good UV resistance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

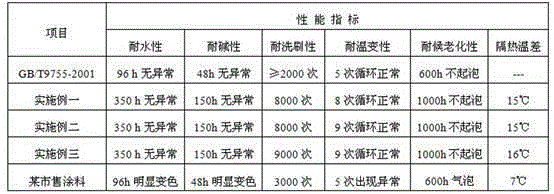

Examples

Embodiment 1

[0012] The heat-insulating exterior wall paint of the present invention includes the following raw materials in parts by weight: 30g of pure styrene-acrylic emulsion, 5g of ferric oxide, 5g of ferrous oxide, 10g of talc, 10g of heavy calcium carbonate, 30g of deionized water, Tween-8010g, anti-ultraviolet additive 1g, hydroxyethyl cellulose 1g, aluminum magnesium silicate 1g, nano zinc oxide 1g, nano flake aluminum powder 1g, nano flake zinc powder 1g.

Embodiment 2

[0014] The heat-insulating exterior wall paint of the present invention includes the following raw materials in parts by weight: 35g of pure styrene-acrylic emulsion, 7g of ferric oxide, 8g of ferrous oxide, 15g of talc, 15g of heavy calcium carbonate, 35g of deionized water, Tween-8015g, anti-ultraviolet additive 3g, hydroxyethyl cellulose 3g, aluminum magnesium silicate 2g, nano zinc oxide 3g, nano flake aluminum powder 2g, nano flake zinc powder 2g.

Embodiment 3

[0016] The heat-insulating exterior wall paint of the present invention includes the following raw materials in parts by weight: 40g of pure styrene-acrylic emulsion, 10g of ferric oxide, 10g of ferrous oxide, 20g of talc, 20g of heavy calcium carbonate, 40g of deionized water, Tween-8020g, anti-ultraviolet additive 5g, hydroxyethyl cellulose 5g, aluminum magnesium silicate 5g, nano zinc oxide 5g, nano flake aluminum powder 3g, nano flake zinc powder 3g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com