Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Short baking time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft ceramic mud and preparation method thereof

The invention discloses a soft ceramic mud and method for preparation, which is prepared by polyvinylchloride pasty resin 15-40 parts by weight, dioctyl phthalate 20-55 parts by weight, calcium carbonate 15-35 parts by weight, plasticizer 0.1-0.4 parts by weight, toner 0.5-0.15 parts by weight, and trace moisture and impurity. The invention also discloses a method for preparation, which comprises steps as follows, each component is weighed proportionally and is placed into stirrer to stir until all components doesn't display nodular powder to be kneaded together evenly and the color is uniform, the evenly stirred mud is placed in the molder to squeeze and mould. The invention provides the soft ceramic mud which is hard and fine in texture under normal temperature, low in softening temperature to soften by hand temperature, low in toasting temperature and short in time, and the toasted material is as hard as ceramic without any odor, further protecting environment.

Owner:东莞市汇欣工贸有限公司

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

Quick roasting method of fresh grosvenor momordica

ActiveCN102100394AGuaranteed circulationExtend the baking timeFood preservationPharmaceutical product form changeTime rangeMicrowave oven

The invention discloses a quick roasting method of a fresh grosvenor momordica, which comprises the following steps: (1) classifying the ripe grosvenor momordica according to large, middle and small specifications and respectively placing into a special roasting tray used for a microwave oven; (2) placing the roasting tray filled with the grosvenor momordica into an intelligent microwave vacuum drying oven; and (3) determining the roasting time according to the weight of the grosvenor momordica and the power of the microwave oven and roasting, wherein the roasting temperature range is 20-40 DEG C, and the roasting time range is 30-150 minutes under the condition of vacuum degree less than -0.08MPa. In the method, the microwave technology for roasting is utilized, the roasting process is carried out at low temperature and constant temperature, the time consumption is short, the cost is low, and the fresh grosvenor momordica well keeps the bright yellow color and nutrition constituents and has good taste.

Owner:桂林普兰德生物科技有限公司

Tundish dry ribration material for continuous casting and its preparation method

InactiveCN1651352ANo irritating smellEasy constructionMelt-holding vesselsPolyvinyl alcoholRefractory

A lining material of tundish for conticasting is prepared from 6 primary raw materials including sintered magnesium sand, electrosmelted magnesium sand, forsterite, light forsterite, etc and 9 secondary raw materials including water glass, sodium tripolyphosphate, dextrin, starch, etc through proportionally mixing, stirring, loading in mould, vibrating, baking at 150-400 deg.C and demoulding.

Owner:WUHAN UNIV OF SCI & TECH

Iron-runner quick-drying casting material combined with silica sol

The invention relates to a fireproof material used in an iron runner of a blast furnace cast house, in particular to an iron-runner quick-drying casting material combined with silica sol, which comprises the following raw materials in percentage by weight: 67 percent of Al2O3, 24.8 percent of SiC, 3 percent of carbon element material, 0.2 percent of dispersant, 2 percent of antioxidant and 3 percent of expanding agent. The raw materials are prepared into bone powder and fine powder which are evenly stirred to obtain a finished product. When the iron-runner quick-drying casting material is used, the silica sol in 6-10 percent of the total casting material is added, stirred and cast in an iron-runner die to form a product, and the product is demoulded and roasted under a large fire for 3-4h to yield iron. The invention has the advantages of short trenching time, burst resistance, high construction quality, short roasting time, long service life of the casting material, lightened labor intensity of workers, castoff and waste utilization, energy saving, emission reduction, no environment pollution and environmental protection.

Owner:通化耐博耐火材料有限责任公司

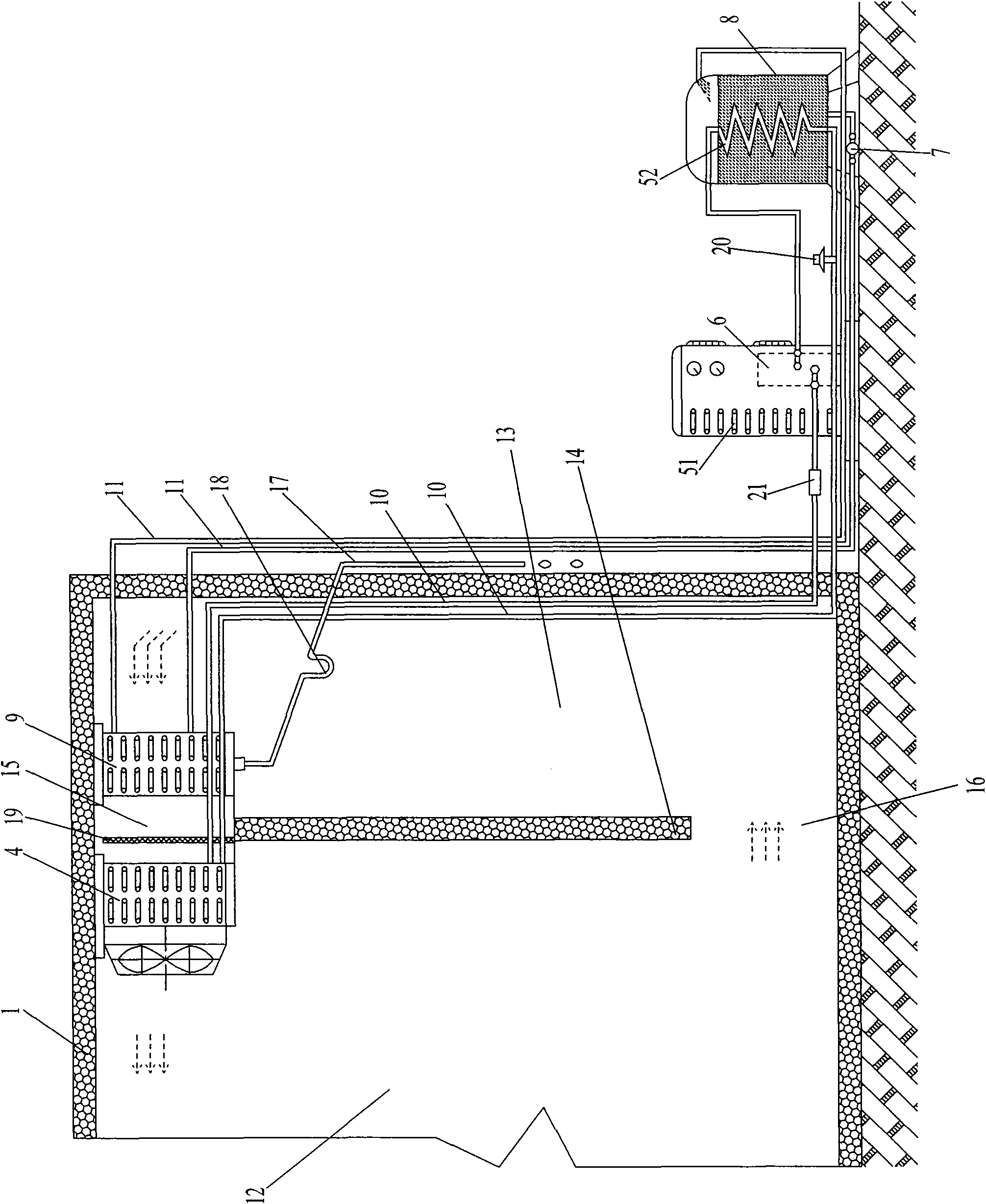

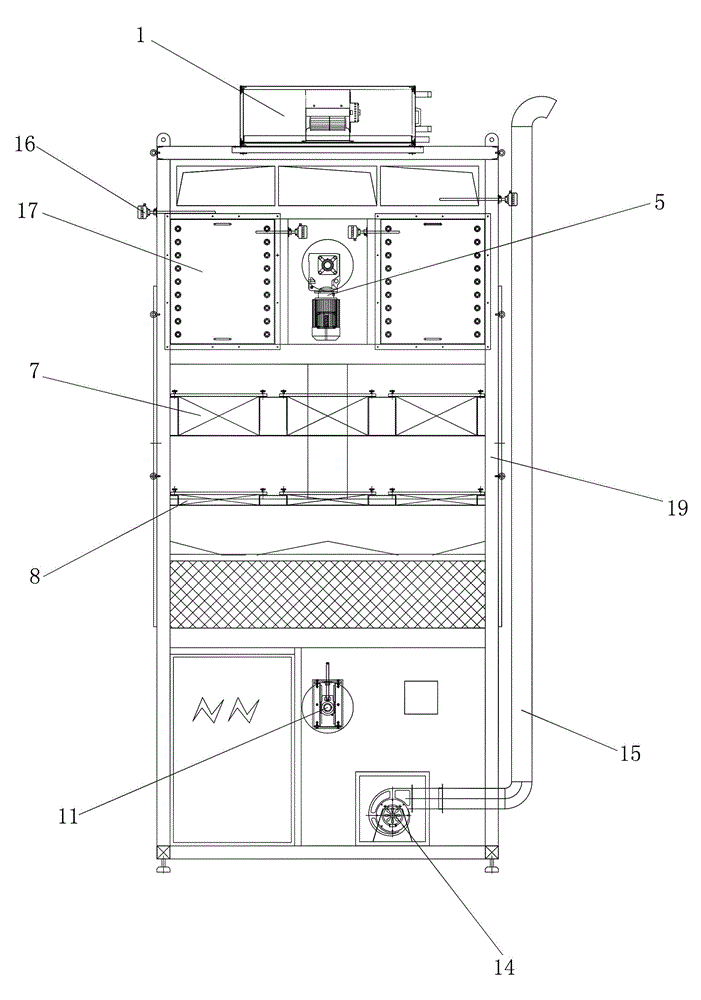

Heat pump cyclic medium dehumidification curing barn

InactiveCN101666576ANo pollutionShorten the timeDrying solid materials with heatDispersed particle separationHigh energyControl system

The invention discloses a heat pump cyclic medium dehumidification curing barn, comprising a heat insulation curing barn body, a control system, a heat pump heating system controlled by the control system, and a dehumidification system. The heat pump heating system comprises a condenser, an evaporator and a compressor which are circularly communicated by a refrigerant circulating pipeline; and thedehumidification system comprises a cold accumulation medium box exchanging heat with the evaporator and a dehumidification condenser circularly communicated with the cold accumulation medium box bya cold accumulation medium circulating pipeline. In the invention, the cold energy when refrigerant evaporates to absorb heat in the heat pump is stored and used for dehumidification work in the curing barn, thereby having good dehumidification effect, low running cost and high energy source use ratio, and being beneficial to energy saving and environment protection.

Owner:宜兴市泽利制冷设备有限公司 +1

Method for processing roasted mutton legs and roast mutton chops

InactiveCN101889690AEasy to operateKeep the flavorClimate change adaptationFood preparationMicrowave ovenFood flavor

The invention discloses a method for processing roasted mutton legs and roast mutton chops, which comprises the following steps of: processing qualified mutton legs or mutton chops serving as raw materials; preparing seasoning water or conditioning liquid; after injecting the conditioning liquid in an amount of 15 percent based on meat by using a saline injector, putting the mutton legs or the mutton chops into the seasoning water for salination; and precooking the conditioned mutton legs or mutton chops, and after roasting the mutton legs or the mutton chops in a microwave oven at the temperature of 220 DEG C for 15 minutes, taking the mutton legs or the mutton chops out, scattering sesame and cumin granules on the surfaces of the mutton legs or the mutton chops, sealing and packaging under vacuum, and sterilizing at a high temperature. The method has the advantages of simple operation, short roasting time, excellent roasting flavor and long storage period of products due to soft packages.

Owner:内蒙古草原兴发食品有限公司

Dried Momordica grosvenori and its processing method

InactiveCN1860920ARealize large-scale industrial productionReduce volatilityFood preservationSlurrySiraitia grosvenorii

Owner:杨赐福

Water-based PET (polyethylene terephthalate) undercoat paint, and preparation method and application thereof

The invention relates to a water-based PET (polyethylene terephthalate) undercoat paint for an UV (ultraviolet) photocuring ink undercoat, and a preparation method and application thereof. Every 100 parts by weight of paint comprises the following components in parts by weight: 40-75 parts of water-based polyester resin, 3-15 parts of cosolvent, 5-57 parts of deionized water and 0.1-0.5 part of defoamer. The product provided by the invention is low in volatile organic compound (VOC) content, and thus, is green and environment-friendly; and the manufacturing and use process is safe. The water-based polyester resin has favorable adhesive force with the PET film; and thus, when the surface tension of the PET film is greater than 40 dyne, the paint formula even does not need any curing agent or catalyst component, so that the required baking time of the paint is shorter, thereby obtaining higher production efficiency. The product provided by the invention has the advantages of high drying speed, no need of UV curing after being dried, simple production technique and high production efficiency.

Owner:广东新供销天保再生资源集团有限公司

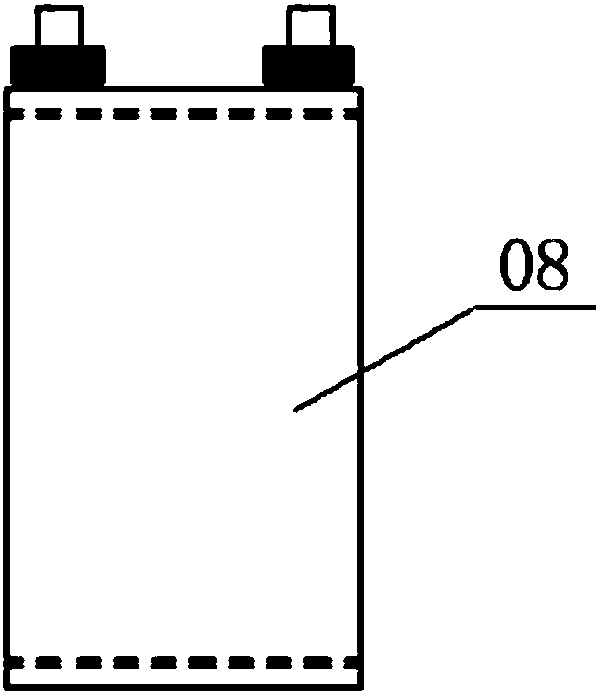

Lithium ion battery assembly method and lithium ion battery

InactiveCN110690506AImprove securityImprove cycle performanceFinal product manufactureElectrolyte accumulators manufacturePhysical chemistryBattery cell

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery assembly method which comprises the following steps: baking a positive plate, anegative plate and a diaphragm to obtain a baked positive plate, a baked negative plate and a baked diaphragm; laminating and / or winding the baked positive plate, the baked negative plate and the baked diaphragm; welding a tab to obtain a bare battery cell; soaking the bare battery cell in an electrolyte to obtain a battery cell soaked in the electrolyte; putting the battery cell soaked in the electrolyte into a shell, and performing packaging; and forming and re-packaging the packaged battery cell to obtain the lithium ion battery. According to the method, the bare battery cell is directly soaked in the electrolyte, so that the battery pole piece and the diaphragm are fully soaked by the electrolyte; then the liquid supplementing procedure is added according to the designed weight, so that the electrical consistency among battery batches can be ensured; and the standing time of a battery after liquid injection can be shortened, and the production efficiency is improved. The lithium ion battery prepared by the method disclosed by the invention is high in safety performance and good in cycle performance.

Owner:汇洋世纪新能源科技有限公司

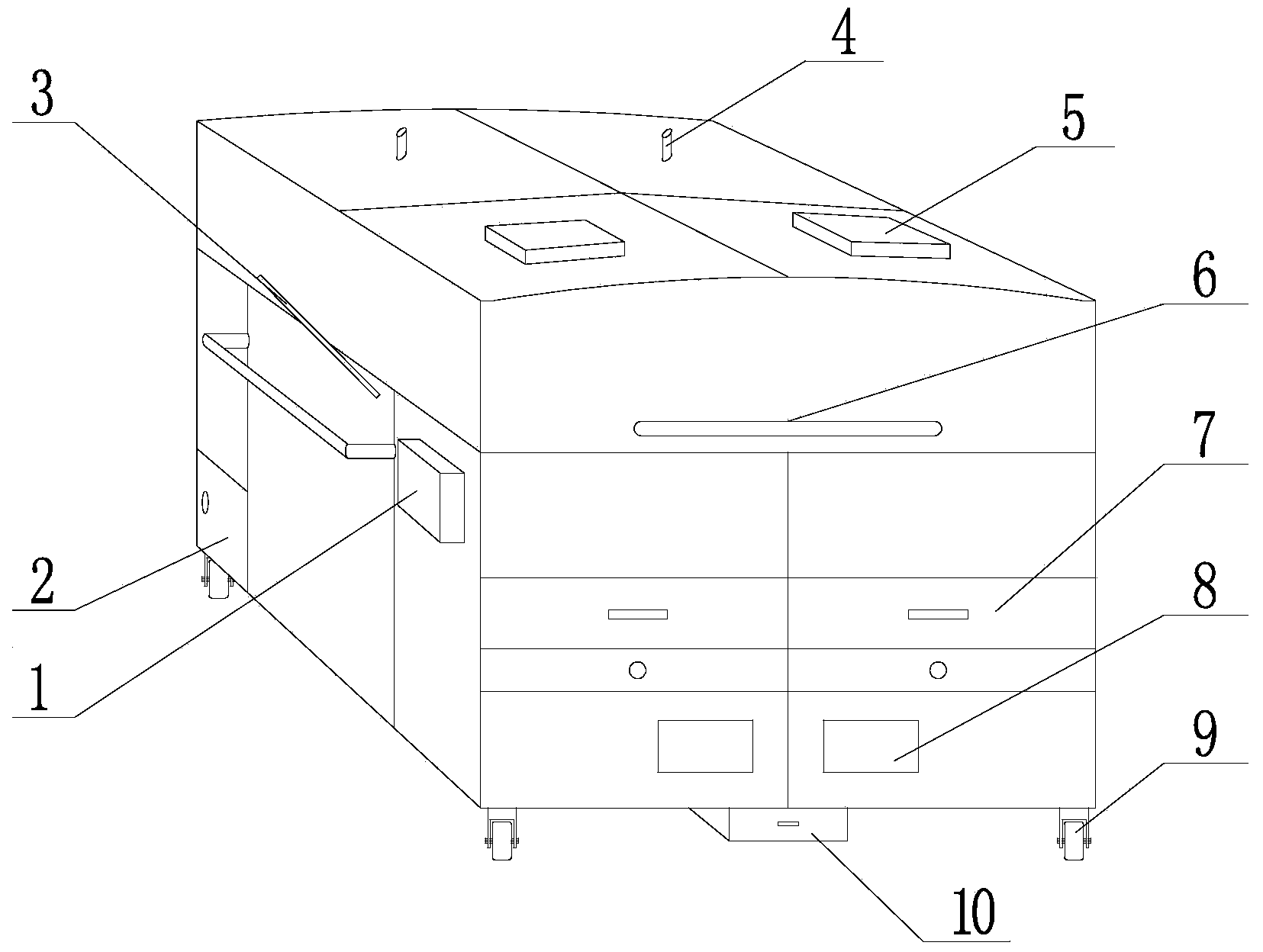

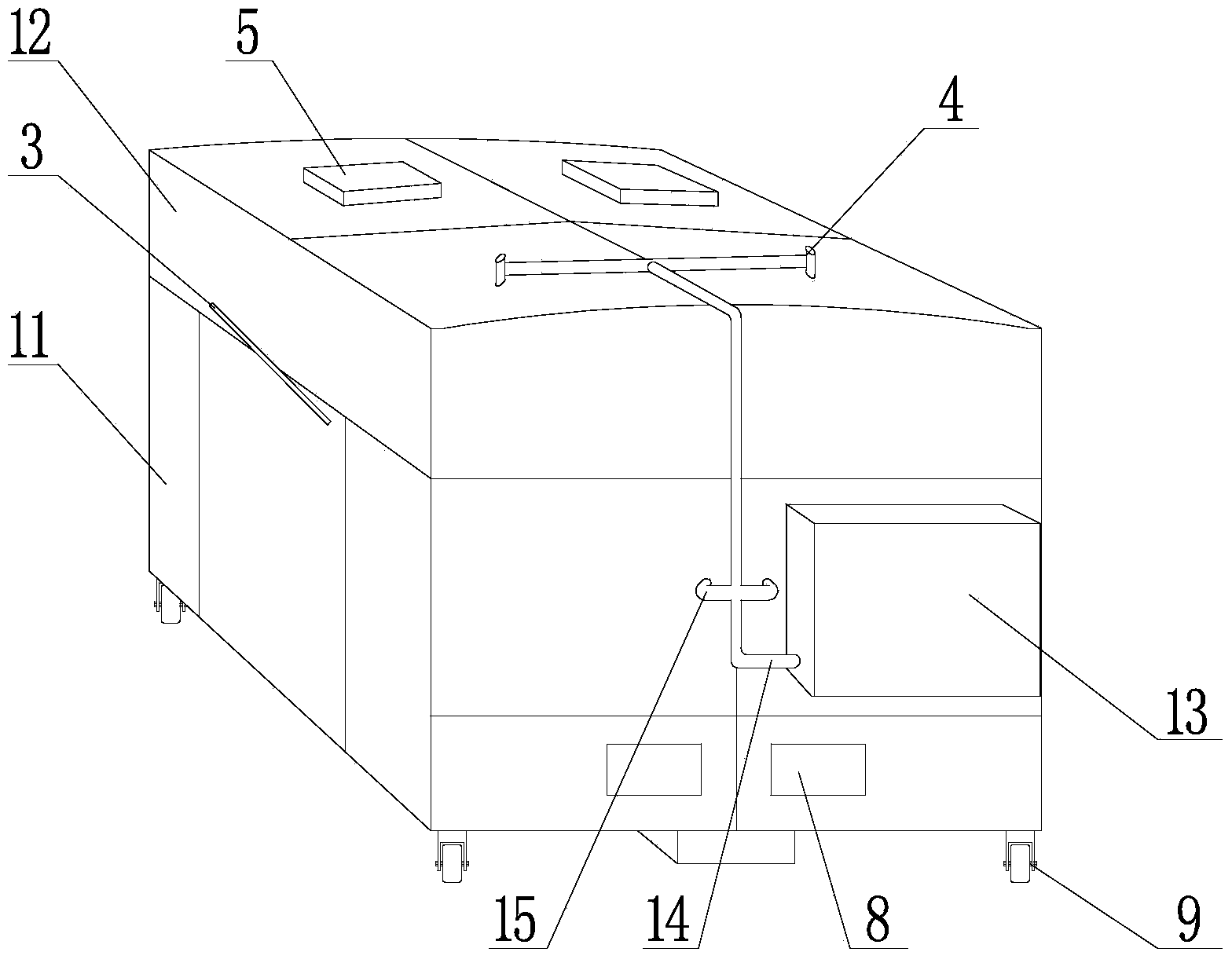

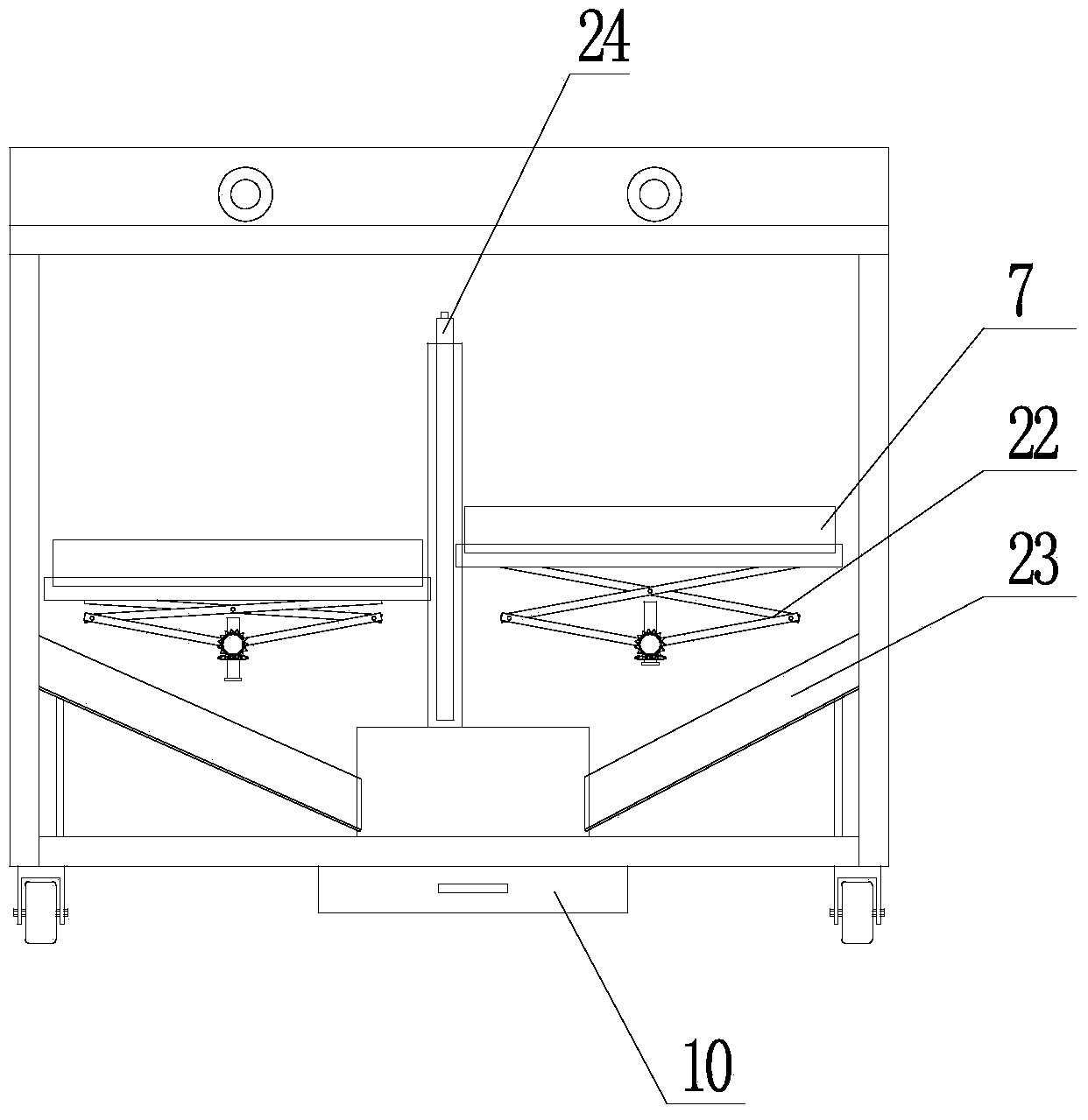

Automatic charcoal-fire sheep roasting machine

InactiveCN103651646AGuaranteed tasteKeep fresh tasteSpecial goods bakingAutomatic controlComputer module

The invention provides an automatic charcoal-fire sheep roasting machine. The automatic charcoal-fire sheep roasting machine comprises an oven, a grill, charcoal fire chambers and a control unit; the oven comprises a box body, and coaxial shaft sleeves are arranged at the upper end of the box body in pairs; a rotary shaft is arranged on the grill, the shaft head at one end of the rotary shaft is fixedly connected with a transmission device which is connected with a driving device, and the driving device is connected with the control unit; air holes are formed in the bottoms of the charcoal fire chambers which are arranged inside the box body and below the grill, and ventilation openings are formed in the positions, below the charcoal fire chambers, of the box body; the control unit comprises a rotary-shaft forward and reverse rotation motion control module, a forward and reverse rotation number control module and a master switch. The automatic charcoal-fire sheep roasting machine achieves uniform roasting heating, saves manpower, is capable of automatically controlling roasting time and short in roasting time, achieves good mouthfeel, is capable of being used for roasting multiple sheep, achieves batch roasting, saves energy, is beneficial to environmental protection, improves efficiency, reduces the number of carcinogenic substances adhering to the surfaces of the roasted sheep, guarantees cleanliness of waste gas, and has the advantages of being simple in structure, convenient to operate and low in cost.

Owner:刘文山

Process for preparing low temperature baking silver mirror back lacquer

InactiveCN1900189ALow baking temperatureShort baking timeInstrumentsPolyester coatingsOrganic solventLacquer

The lower temperature baked silver mirror back lacquer consists of priming lacquer and finishing paint. The priming lacquer consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, and organic solvent in certain weight proportion. The finishing paint consists of inorganic cross-linking agent, talc powder, barium sulfate, modified alkyd resin, coloring pigment, antiskimming agent, drying agent, leveling agent and organic solvent in certain weight proportion. The present invention has silver mirror back lacquer with baking temperature lowered to 100 deg.c, raised adhesion, high wet head resistance, high temperature change tolerance, high salt fog resistance, high salt water resistance, high corrosion resistance and good post finishing property.

Owner:SHANGHAI JIAO TONG UNIV

Magnesium-calcium tundish dry vibrating material and preparation method thereof

The invention relates to a magnesium-calcium tundish dry vibrating material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of: mixing 68-80 percent by weight of magnesium-calcium sand, 9-16 percent by weight of magnesium sand fine powder and 4-17 percent by weight of hydrated sodium metasilicate; uniformly stirring the mixture; performing vibratory compaction on a tire membrane; baking at the temperature of 100-300 DEG C for 2-12 hours; and demolding, wherein the content of CaO of the magnesium-calcium sand is less than or equal to 60 percent by weight, the particle composition is 45-70 percent by weight when the particle size is 3-1 millimeter and 30-55 percent by weight when the particle size is less than or equal to 1 millimeter, the particle size of magnesium sand fine powder is less than 0.088 millimeter, the magnesium sand fine powder is more than one of sintered magnesium sand and electrically-molten magnesium sand, and the hydrated sodium metasilicate is more than one of sodium metasilicate pentahydrate and metasilicate nonahydrate. The vibrating material has a simple process, is environmentally-friendly and can be baked quickly. A prepared working lining has the characteristics of high intensity, high erosion resistance and long service life, and particularly has good heat preserving and molten steel purifying functions. The development requirement for clean steel smelting is met.

Owner:WUHAN UNIV OF SCI & TECH

Production process of cake

The present invention discloses a production process of a cake, and belongs to the field of food processing. The production process of the cake comprises steps of processing hericium erinaceus, common yam rhizome, pumpkin, Chinese chestnut, foxtail millet, jobstears seed and wheat, carrying out drying and cooling, performing screening with a sieve, preparing a slurry material, loading the slurry material into molds, and carrying out baking, demolding, metal detecting and culling, and packaging. `In the whole production process of the cake, no water is added so as to maximally integrate various health-care and nutritional substances, thereby enduing the cake with delicious taste as well as multiple efficacy of enhancing immunity, nourishing stomach, protecting blood vessels, supplementing fibers and proteins, and the like.

Owner:胡积松

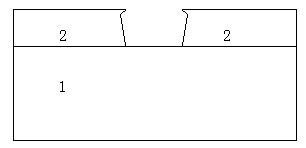

Single-layered positive photoresist photoetching method applied to metal stripping

InactiveCN103293850ALow baking temperatureShort baking timePhotomechanical exposure apparatusPhotosensitive material processingSolventChemistry

The invention provides a single-layered positive photoresist photoetching method applied to metal stripping. The single-layered positive photoresist photoetching method comprises the following steps of: (1) coating a positive photoresist layer 2 on a semiconductor base plate 1; (2) after gelatinizing of the photoresist layer 2, carrying out baking treatment to remove a part of a solvent; (3) carrying out positive photoresist developing solution treatment on the photoresist layer 2; (4) exposing the photoresist layer 2; (5) exposing the photoresist layer 2 and carrying out the baking treatment; (6) developing the photoresist layer 2, wherein a developing solution is a positive photoresist developing solution; and (7) after the photoresist layer 2 is developed, carrying out the baking treatment. The single-layered positive photoresist photoetching method disclosed by the invention has the advantages that a photoetching profile pattern with an olecranon-shaped opening is obtained so as to prevent metal of a photoresist surface layer from being connected with metal at the bottom of a photoresist pattern in an evaporation process, thereby being good for the metal stripping. Compared with a process of adopting a plurality of layers of glue to realize the metal stripping, the single-layered positive photoresist photoetching method is simple; meanwhile, the single-layered positive photoresist photoetching method has better pattern resolution than using negative photoresist, and can realize a small-line-width image stripping process.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

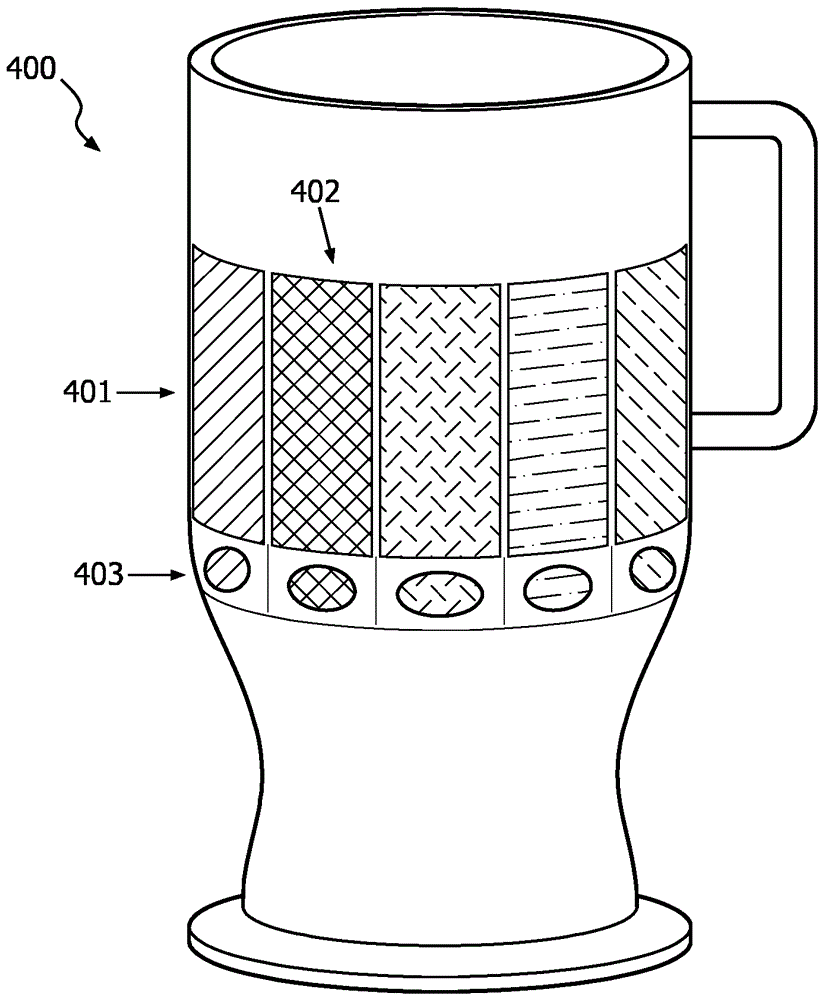

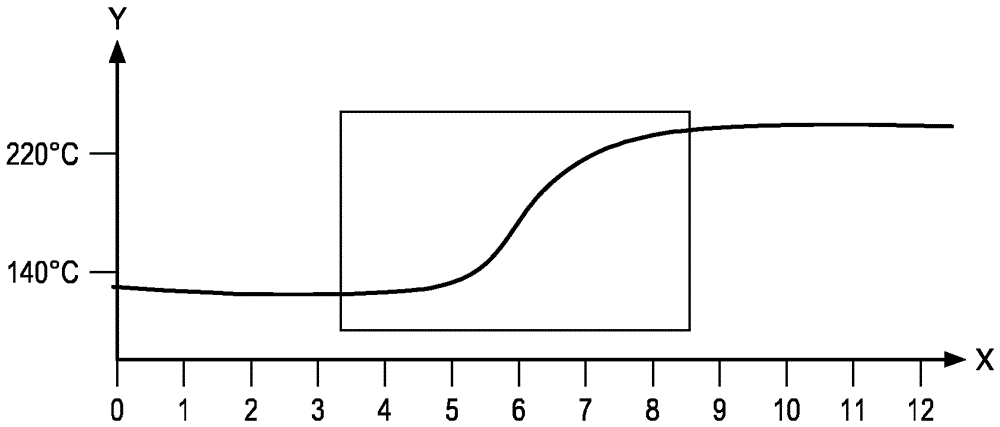

Method and device for roasting partially roasted coffee beans

ActiveCN105939643AEasy to storeEvenly bakedBeverage vesselsCoffee roasting methodsEngineeringCoffee bean

The present invention relates to a roasting method of roasting partially roasted coffee beans; the roasting method comprises the steps of: obtaining a roast level of the partially roasted coffee beans; determining a roasting profile for roasting based on at least the roast level of the partially roasted coffee beans prior to roasting; and roasting the partially roasted coffee beans according to the determined roasting profile. The present invention also proposes a method of making coffee, a roasting device and a coffee machine providing a segmented roasting solution.

Owner:FANSONE HLDG LTD

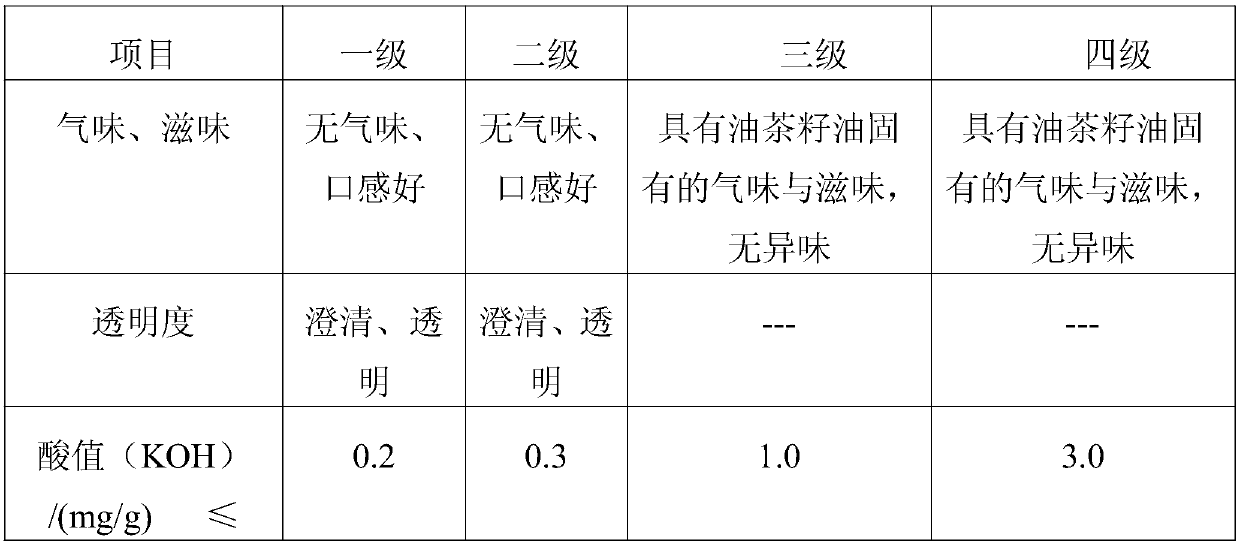

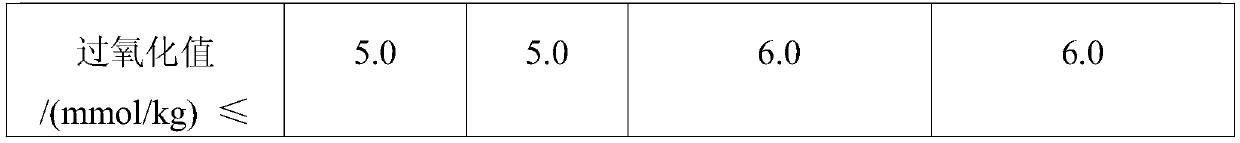

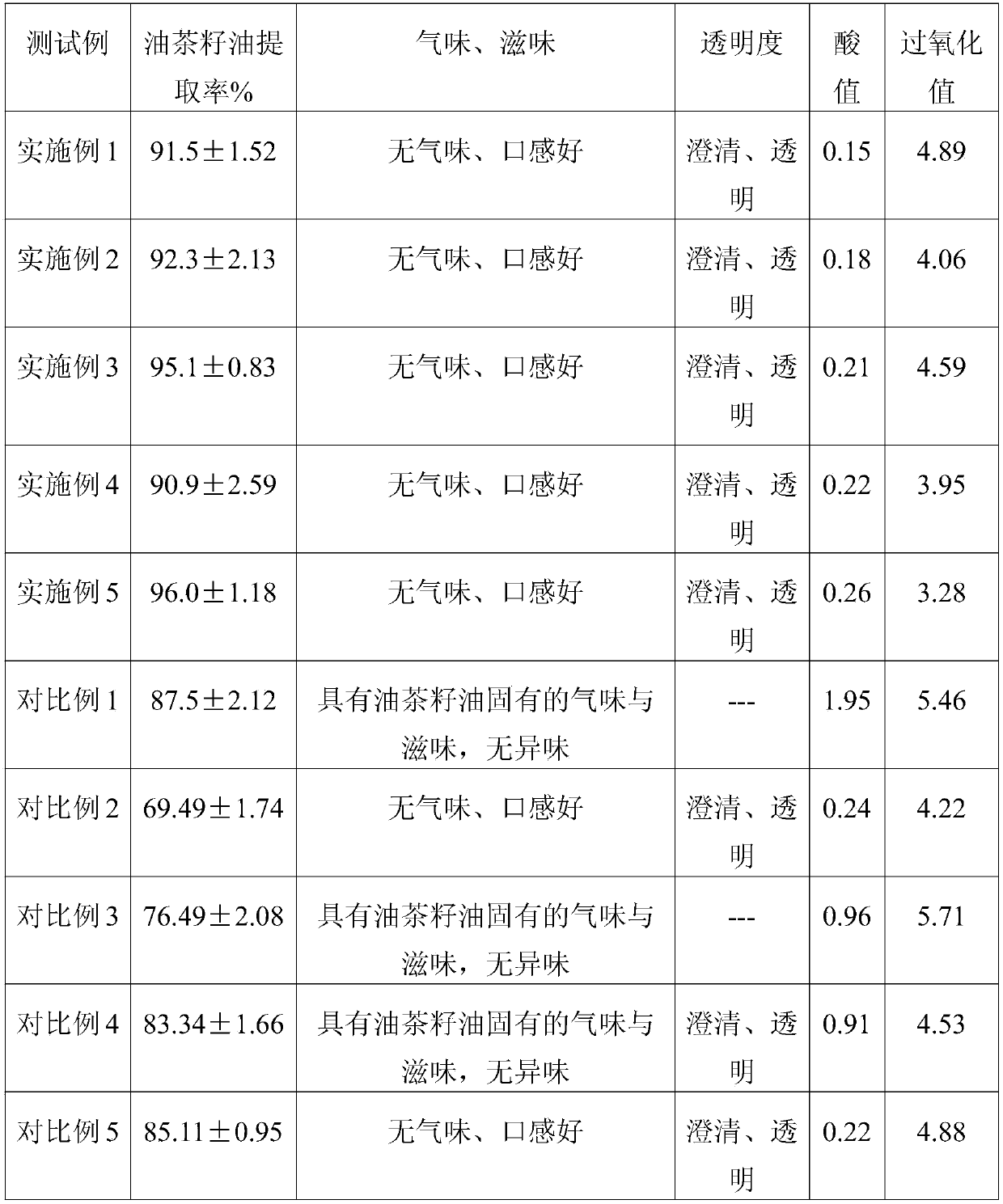

Extracting method of camellia oleosa seed oil

The invention provides an extracting method of camellia oleosa seed oil. The extracting method comprises the following steps: (1) steam explosion; (2) regulation of pH value; (3) extracting with an aqueous extraction process; (4) emulsion breaking. The method provided by the invention solves the problems of difficult grinding and low oil extraction rate in traditional aqueous extraction process; through the steam explosion, the cellulose and hemicellulose in the cell walls of camellia oleosa seeds are degraded, the cell walls are effectively damaged, and oil is separated from a lipid complex,thus the oil in the cells is quickly released, and the oil extraction rate is effectively increased. The emulsion breaking is performed in an alkaline condition, and the glycosidic bond of tea saponinis hydrolyzed so as to lose the surface activity and increase the clear oil yield.

Owner:HAIKOU EXPERIMENTAL STATION CHINESE ACAD OF TROPICAL AGRI SCI

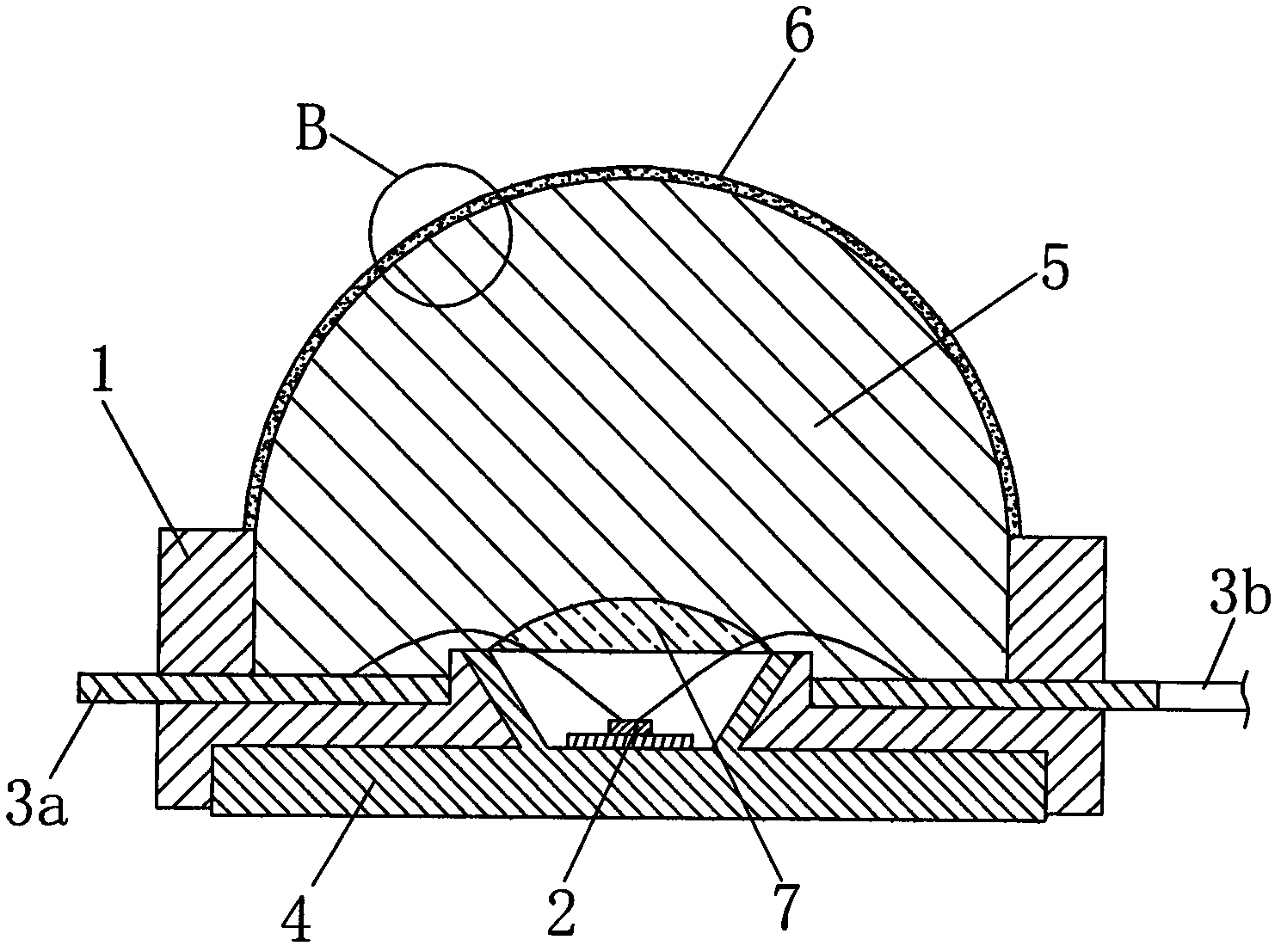

Novel LED packaging structure

InactiveCN102306698AControl shapeControl thicknessSolid-state devicesSemiconductor devicesElectricityPhosphor

The invention discloses a novel light emitting diode (LED) packaging structure. The structure comprises: a pedestal; a recessed cavity, which is formed in the pedestal; a heat sink, which is fixed in the recessed cavity; a cup bowl, which is formed on the heat sink; and an LED chip, which is fixed in the cup bowl. Besides, a pair of conductive feet are extended and are fixed in the pedestal; the LED chip is electrically connected with the conductive feet; a lens is formed on the pedestal and enables the LED chip and a part of conductive feet to be sealedly capped; and an external surface of the lens are provided with a layer of phosphor coating. According to the LED packaging structure provided in the invention, a traditional LED packaging mode is broken; a phosphor coating is directly transferred from an original chip surface to a surface of a lens, so that the phosphor coating is thoroughly far away from an LED chip and a luminous decay is substantially reduced; moreover, a shape and a thickness of the phosphor coating can be controlled accurately and an excitation area of the phosphor coating can be enlarged, so that an occurrence of a yellow ring can be avoided, a light extraction efficiency is improved and color temperatures of the phosphor coating are highly consistent.

Owner:SHENZHEN GLORY SKY OPTOELECTRONICS CO LTD

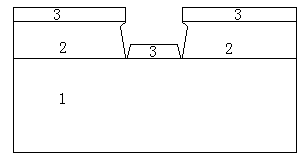

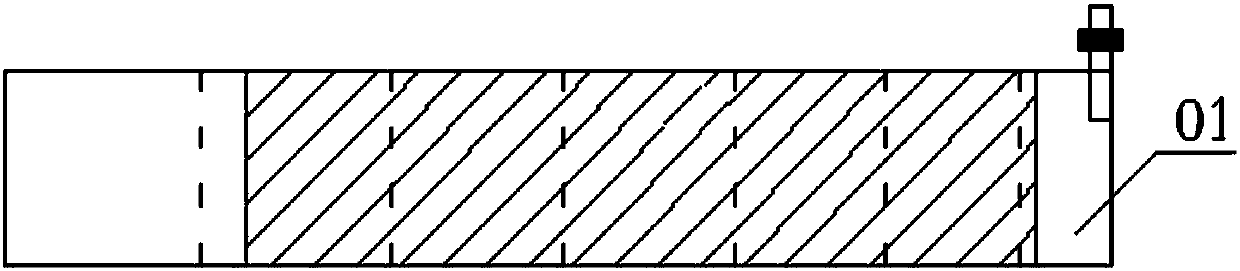

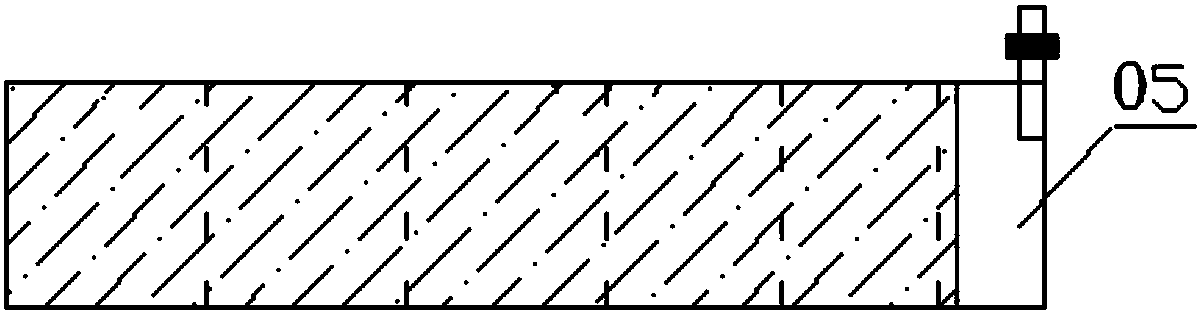

Coiled lithium ion battery, coiled core and manufacturing method of coiled lithium ion battery

PendingCN107768598ASimple pathShort baking timeFinal product manufactureSecondary cellsCooking & bakingEngineering

The invention discloses a coiled lithium ion battery coiled core, a coiled lithium ion battery and a manufacturing method of the coiled lithium ion battery. The coiled lithium ion battery coiled corecomprises a coiled core body, wherein the coiled core body comprises a positive plate and a negative plate which are coiled with each other in a matching way; the positive plate is provided with positive plate openings; the negative plate is provided with negative plate openings; the positive plate openings and the negative plate openings are arranged in a staggered way along a radial direction toform channels passing through the coiled core body; at least two channels are formed; on the same channel, the areas of the positive plate openings are larger than the areas of the negative plate openings. In the coiled core, the positive plate is provided with the positive plate openings, the negative electrode plate is provided with the negative plate openings, and specific channels are formedon the coiled core body after coiling, so that coiled core body gas can smoothly pass through and be discharged from a battery system during baking, and the baking time can be shortened; meanwhile, apath from electrolyte infiltration to the coiled core body can be shortened through the channels, so that the infiltration effect is improved.

Owner:HANGZHOU FUTURE POWER TECH

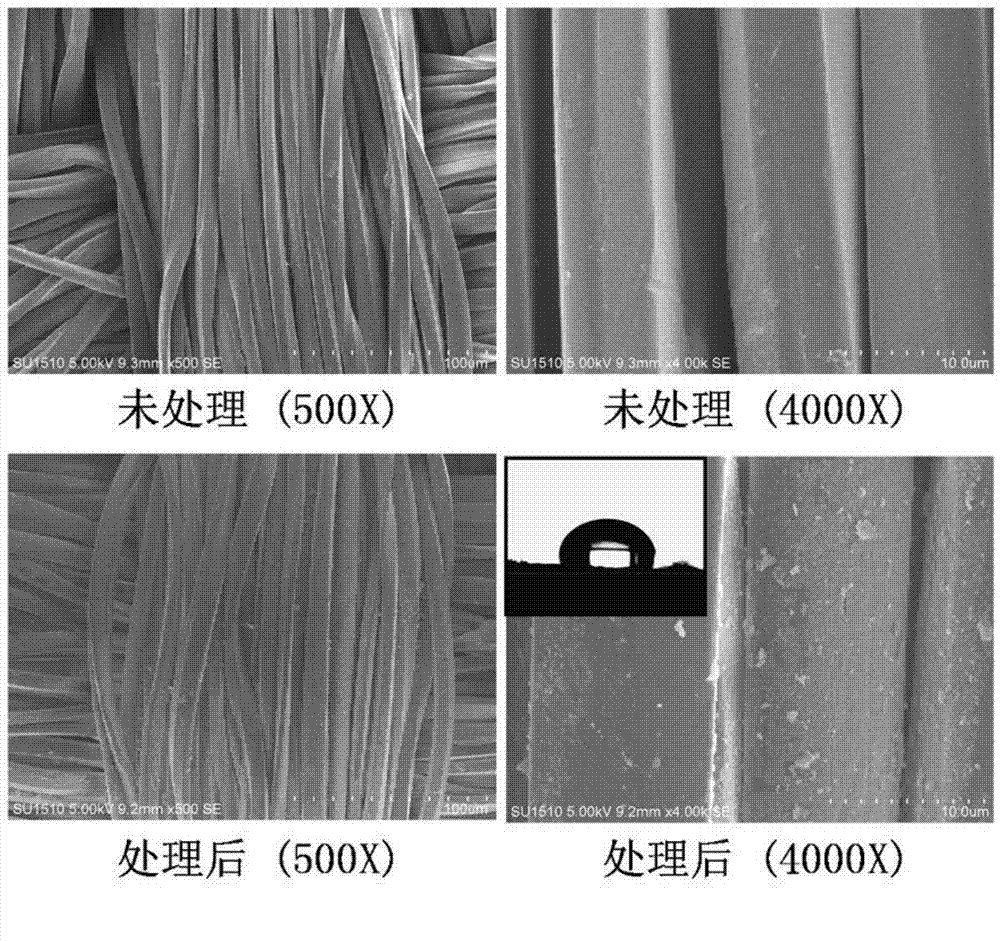

PAA-TEOS-OA combined treatment-based finishing method for polyester or polyamide hydrophobic fabric

The invention discloses a PAA-TEOS-OA combined treatment-based finishing method for a polyester or polyamide hydrophobic fabric, and belongs to the technical field of functional textiles. A fabric is subjected to pretreatment by utilizing polyacrylic acid, so that the capability of the fabric in the aspect of reacting with a subsequent chemical reagent is improved, and a bridge function is achieved; tetraethyl orthosilicate is hydrolyzed and polycondensed under an acid or alkali condition, and particular matters are formed on the surface of the fabric, so that a function of roughening the fabric is achieved; long-chain alkane type octadecylamine can effectively reduce surface energy of the fabric, and meanwhile, the environment problem caused by perfluoronic compounds is avoided; in the finishing treatment, traditional soaking, rolling, baking and roasting processes are utilized, so that the homogeneity and the repeatability of products are good, and the cost is low; the polyacrylic acid, the tetraethyl orthosilicate and the octadecylamine, which are utilized in the whole finishing process, need to be utilized under weak acid and weak alkali conditions, and the baking temperature is low, so that the damage to the fabric is small; the finishing method can be applied to finishing a hydrophobic function of the polyester or polyamide fabric.

Owner:高青如意纺织有限公司

Freeze-drying method of sliced fresh momordica grosvenori

InactiveCN104273213AGood lookingGreat tasteFruit and vegetables preservationTea substituesFreeze-dryingEngineering

The invention discloses a freeze-drying method of fresh fructus momordicae slices, which comprises the following steps: slicing selected high-quality mature fresh fructus momordicae while controlling the thickness of the slices at 1-2 cm; killing out the sliced fresh fructus momordicae in a microwave killing-out machine for 3-5 minutes; and carrying out freeze-drying on the killed-out fructus momordicae slices in a freeze-drying device, and carrying out vacuum seal packaging to obtain the finished product. By quickly baking the fructus momordicae at low temperature, the method maximally maintains the nutrient contents in the fresh fructus momordicae, and is convenient for the fructus momordicae to be a substitute for tea.

Owner:桂林普兰德生物科技有限公司

Dry breezed chicken and making technology thereof

The invention discloses a dry breezed chicken and a making technology thereof. The dry breezed chicken comprise, by weight, 800-1200 parts of chicken, 20-30 parts of white granulated sugar, 25-35 parts of monosodium glutamate, 0.1-0.3 parts of sodium nitrite, 90-120 parts of salt, and 40-65 parts of a bittern material; and the bittern material comprises Beautiful Galangal Fruit, Illicium verum, Kaempferia galanga L., cardamom, Fructus Foeniculi, Alpinia officinarum Hance, sage, Fructus Amomi, Myristica fragrans, dahurian angelica root, Chinese prickly ash, Cinnamon Bark, dried orange peel, Syzygium aromaticum, Fructus Tsaoko, lily magnolia and mature ginger. The making technology of the dry breezed chicken comprises the following steps: processing live chicken, cleaning, marinating and baking. The dry breezed chicken is made by using laying hens and Bashan native chicken which have been or will be knocked out, and has the characteristics of unique taste, deliciousness, tender meat and high nutrition values; and the making technology has the advantages of simple flow, convenient preparation, and suitableness for factory large-scale production.

Owner:SICHUAN PROVINCE BASHANWA FOOD DEV CO LTD

Rapid baking method for sweet osmanthus

InactiveCN103006787AOvercomingEvenly heatedDigestive systemRespiratory disorderTime rangeAdditive ingredient

The invention discloses a rapid baking method for sweet osmanthus. The rapid baking method comprises the steps as follows: firstly fresh sweet osmanthus is cleaned, impurities are removed, the sweet osmanthus is dried in the air and placed in a microwave machine, the temperature is controlled in a range from 110 DEG C to 115 DEG C, and water removing is performed for 2-3minutes; the sweet osmanthus subjected to water removing is placed into a vacuum microwave baking chamber to be baked, under the condition that the vacuum degree is smaller than 0.08 Mpa below zero, the baking temperature ranges from 45 DEG C to 50 DEG C, the baking time ranges from 60 minutes to 90 minutes, and then the dried sweet osmanthus is weighed, bag-dispensed and packaged. According to the rapid baking method for the sweet osmanthus, the fresh sweet osmanthus is rapidly baked under the conditions of the low and constant temperature, so that the energy and time are saved, further, the original colors, fragrances, shapes, taste and nutritional ingredients of the sweet osmanthus can be maintained, the operation is simple, and the cost is low.

Owner:桂林普兰德生物科技有限公司 +1

Operation method for baking scrap steel in converter

InactiveCN112280927AReduce harmShort baking timeManufacturing convertersProcess efficiency improvementProcess engineeringIndustrial engineering

The invention discloses an operation method for baking scrap steel in a converter. The method includes the following processing steps that preparation work is performed, specifically, the converter, scrap steel and a coal oxygen lance are prepared; Step 1, the coal oxygen lance is moved to a working position, igniting is performed in an ever-burning fire position of an oxygen lance opening, and then descending to a waiting position is performed; Step 2, two troughs of the scrap steel are added to the converter, the converter is shaken back and forth for 3-5 times to uniformly distribute the scrap steel, and then the furnace is shaken right, the opening degrees of coal gas and oxygen are adjusted to specified parameters, and it is judged that flames are normal. According to the method, thescrap steel is used in the converter special steel workshop, the specially-made coal oxygen lance is used, the purposes of short baking time, much scrap steel ratio increase, furnace lining damage reduction, baking efficiency improvement, consumption reduction and the like can be achieved, the opening degree change parameters, process lance position change and the like of a process adjusting valveare defined, through the baking method, the scrap steel ratio can be increased to 30% or above, the scrap steel baking time can be controlled within 10 min, efficient baking is achieved, and the process production rhythm is basically not affected.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Baked caramel treats

ActiveCN103651685AMaintain propertiesPure tasteDough treatmentBakery productsNutritive valuesCooking & baking

The invention relates to baked caramel treats, and belongs to the field of food. The baked caramel treats are composed of, by weight, 40 parts to 42 parts of malt syrups, 30 parts to 32 parts of wheat flour, 15 parts to 17 parts of palm oil, 13 parts to 15 parts of eggs and 2 parts to 3 parts of sesames. According to the baked caramel treats, nature, nutrition and health are emphatically taken into consideration, natural and high-quality raw materials are selected for manufacturing, no food additives or food antiseptics are added to a product, and the baked caramel treats are pure, loose, soft, sweet and crispy in taste and low in sweetness. Meanwhile, a traditional frying method is abandoned in the production method, the vacuum dough kneading process, the extrusion process and the baking process are adopted, the characteristics of the raw materials are ensured, and higher nutritive value is bestowed on the product.

Owner:麦肯嘉顿(江苏)食品有限公司

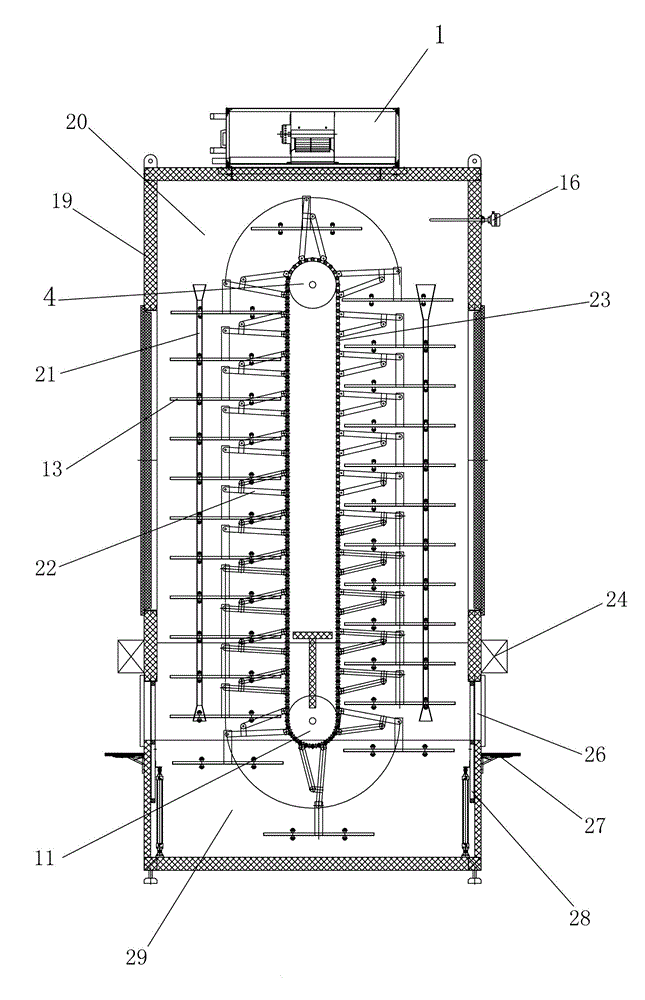

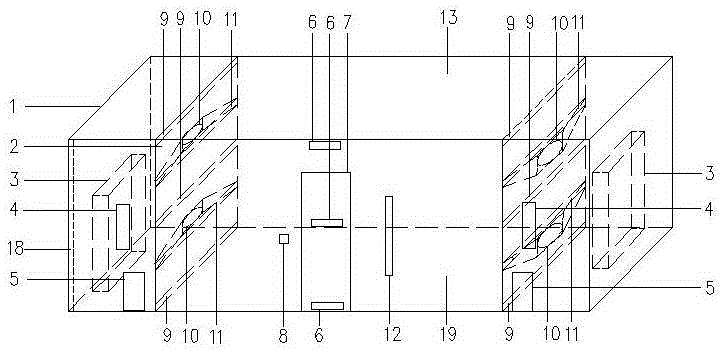

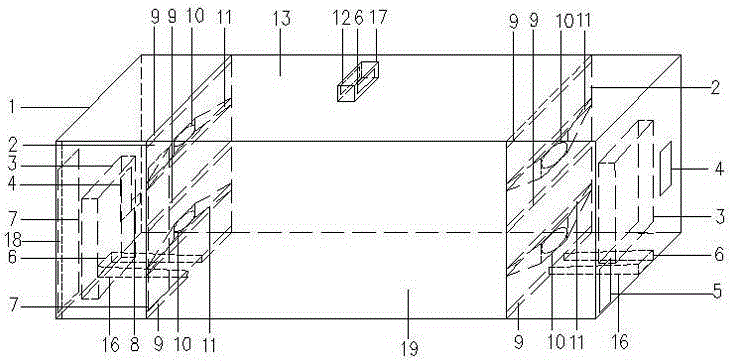

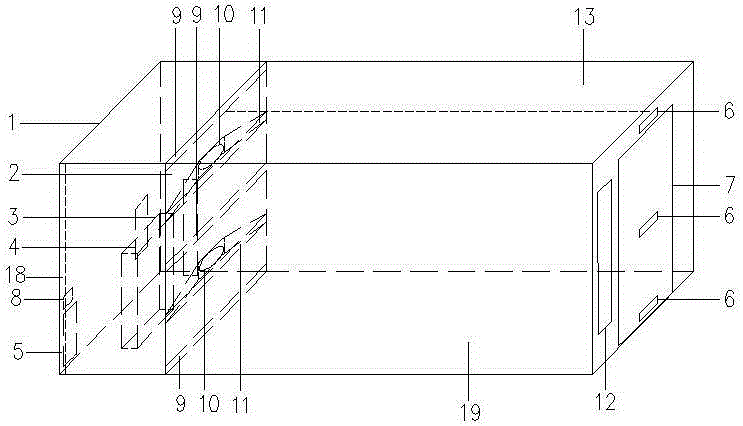

Vertical continuous tempering furnace

ActiveCN104480276AReduce installation spacingIncrease productivityFurnace typesHeat treatment furnacesHanging basketDrive motor

The invention discloses a vertical continuous tempering furnace which comprises a furnace body, wherein a heating zone and a cooling zone are arranged in the furnace body; charging and discharging ports are formed between the heating zone and the cooling zone; an air supply channel is formed in the inner side wall of the heating zone; heating pipes, a circulating fan and filters are arranged on the furnace body; a drive sprocket and a tensioner sprocket are arranged in the furnace body; the drive sprocket is connected with a drive motor; a circulating chain is connected between the drive sprocket and the tensioner sprocket; hanging baskets are connected onto the circulating chain; an air conditioning refrigeration unit is arranged at the top of the furnace body and communicated with a cooling air inlet; and a cooling exhaust fan is arranged on the cooling zone. The vertical continuous tempering furnace is energy-saving; the temperature uniformity and stability are good with adoption of an upper feeding and lower returning type air supply structure on the furnace body, a one-way cycle operation manner is adopted, and the equipment occupation area is reduced due to height increase; and meanwhile, an air conditioning is adopted to cool a workpiece, the workpiece temperature is reduced to be lower than 40 DEG C during workpiece discharging, and the workpiece temperature during workpiece taking is reduced.

Owner:WENTON IND EQUIP JIANGSU

Layer cakes with flavor of fruits and making method of layer cakes

The invention discloses layer cakes with flavor of fruits. The layer cakes are prepared from crusts and fillings and are characterized in that the crusts are prepared from the following raw materials in parts by weight: 60-80 parts of graham flour, 10-20 parts of fresh egg white, 4-8 parts of black sesame seeds, 5-10 parts of honey, 3-6 parts of fresh-squeezed orange juice, 4-6 parts of corn germ oil, 2-4 parts of a traditional Chinese medicine extracting solution, 0.05-0.15 part of isomaltooligosacharide, 0.05-0.15 part of potassium hydrogen tartrate, 0.5-1.5 parts of baking soda powder, and 5-10 parts of water; the fillings are prepared from the following raw materials in parts by weight: 10-20 parts of fresh yolk, 5-9 parts of fresh fruit flesh, 2-4 parts of soy protein isolate, 1-2 parts of white granulated sugar, 0.02-0.1 part of potassium sorbate, and 0.5-1.5 parts of a sweetening agent. The invention further provides a making method of the layer cakes with the flavor of fruits. Because the technical scheme is adopted, the prepared layer cakes disclosed by the invention are crisp in crusts, smooth and tender in fillings, good in mouth feel, and easy to absorb, and have the efficacies of loosening bowel to relieve constipation, maintaining beauty, keeping young and delaying aging.

Owner:孙菁

Weather-resistant electrophoretic wood grain aluminum profile production process and aluminum profile prepared through same

InactiveCN110438544AProtection cleanImprove surface adhesionAnodisationNatural patternsAcid etchingElectrophoresis

The invention discloses a weather-resistant electrophoretic wood grain aluminum profile production process and an aluminum profile prepared through the same. The process comprises the following stepsof a pretreatment procedure, an electrophoresis procedure and a heat transfer printing procedure, wherein the pretreatment procedure comprises the following treatment of oil removing, acid etching, alkali etching, neutralization, oxidation, coloring, hole sealing, hot water soaking and the like on the aluminum profile. According to the process and the aluminum profile, the anti-erosion abilities of the acid resistance, the alkali resistance and the like of the aluminum profile are effectively improved; and moreover, the surface of a film is flat, smooth, uniform and consistent, and a bright metal surface is obtained.

Owner:湖南金牛铝业有限公司

Tobacco curing kiln and tobacco curing process

ActiveCN105192871AHigh proportion of smokeHigh average priceTobacco preparationBiotechnologyEngineering

The invention provides a tobacco curing kiln and a tobacco curing process. An inner wall is provided with a plurality of air return openings and a plurality of air outlets, the air return openings and the air outlets are formed in a cross mode at the interval of a layer of tobacco leaves, circulating fans are arranged in air flues between heaters and the inner wall, and the two ends of the position between an outer wall and the inner wall are each provided with a heater. The tobacco curing process conducted through the tobacco curing kiln includes the steps that after heating is conducted, the temperature is raised to 36 DEG C at the speed of 1-2 DEG C per hour, and the dryness and humidity difference ranges from 2 DEG C to 4 DEG C; when tobacco leaves reach 20%-30% in the yellowing degree, the temperature is raised to 38 DEG C at the speed of 1 DEG C per hour, and the dryness and humidity difference ranges from 3 DEG C to 6 DEG C; when the tobacco leaves reach 70%-80% in the yellowing degree, the temperature is raised to 43 DEG C at the speed of 1 DEG C per hour, and the dryness and humidity difference ranges from 5 DEG C to 7 DEG C; when the tobacco leaves reach 95%-100% in the yellowing degree and the water loss ranges from 50%-60%, the temperature is raised to 53 DEG C at the speed of 1 DEG C per hour, it is guaranteed that all tobacco leaves are dried, and the wet bulb temperature ranges from 37 DEG C to 40 DEG C; then the temperature is raised to 65 DEG C-70 DEG C at the speed of 1 DEG C per hour, the wet bulb temperature ranges from 40 DEG C to 43 DEG C, temperature stabilizing is conducted for 2-8 hours, and drying is ended.

Owner:贵州贵三烟叶烘烤科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com