Heat pump cyclic medium dehumidification curing barn

A technology of heat pump circulation and baking room, applied in lighting and heating equipment, heating to dry solid materials, separation methods, etc., can solve problems such as low temperature and affecting baking operations, achieve good results, and do not pollute the environment. Baking time , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

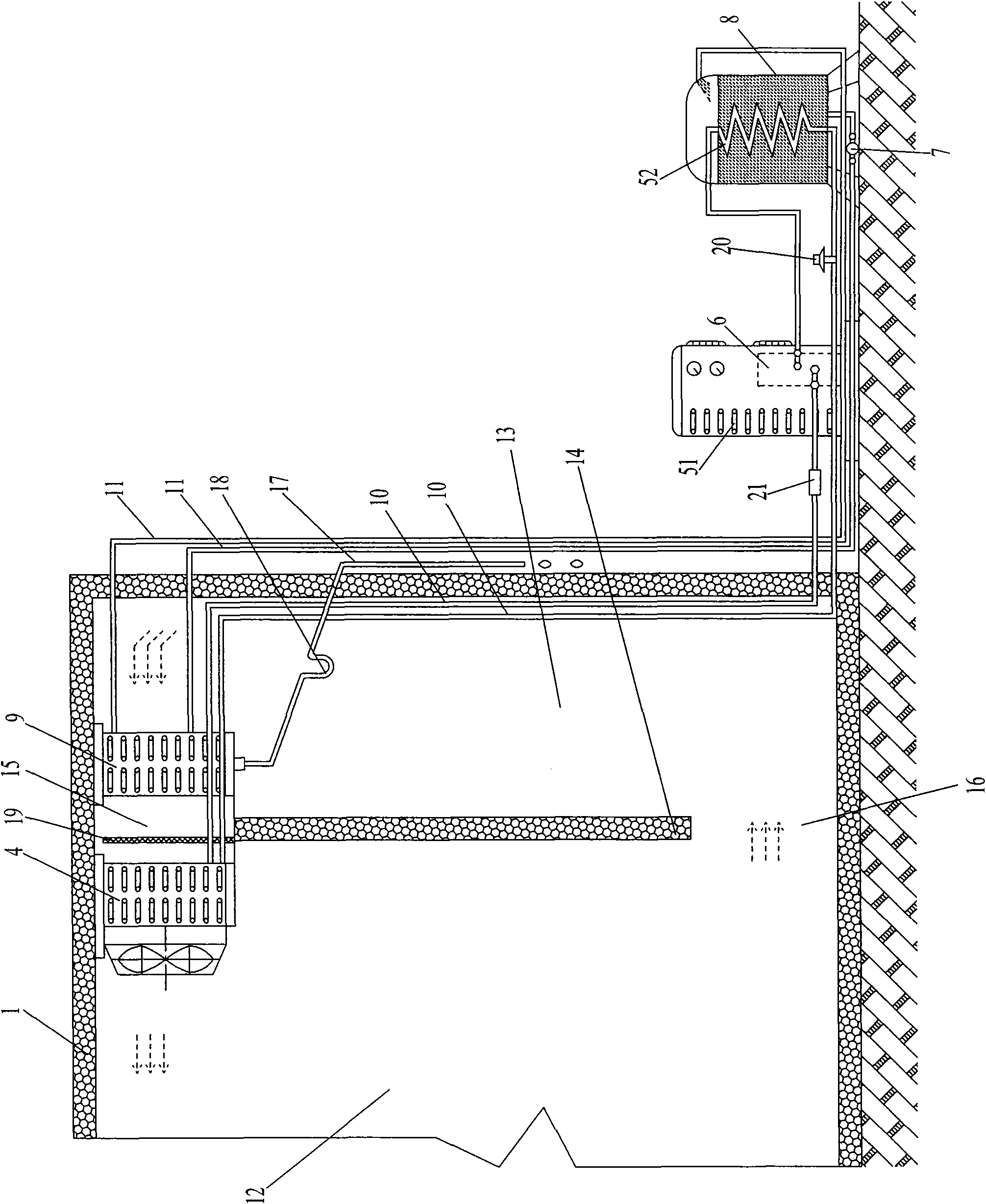

[0030] Example: such as Figure 1 to Figure 3 As shown, a heat pump circulating medium dehumidification barn includes a heat preservation barn body 1, a control system, and a heat pump heating system 2 and a dehumidification system 3 controlled by the control system. A condenser 4, an evaporator 5 and a compressor 6 communicated, the dehumidification system 3 includes a cold storage medium box 8 for heat exchange with the evaporator 5, and a dehumidification condensation unit that is circulated with the cold storage medium box 8 through a cold storage medium circulation pipeline 11 Device 9. A filter 21 is provided between the compressor 6 and the condenser 4 .

[0031] Wherein the barn body is made of six sides adopting EPS, XPS or rigid polyurethane Pu thermal insulation material to make thermal insulation wall, thermal insulation door, and is provided with baking shelf (not shown in the figure) in it.

[0032] figure 1 Shown in is the specific embodiment one, where there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com