Extracting method of camellia oleosa seed oil

An extraction method and camellia seed oil technology are applied in the directions of oil/fat production, fat production, etc., which can solve the problems of low oil extraction rate and difficulty in grinding, and achieve the improvement of clear oil yield, short baking time, and improved oil extraction. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

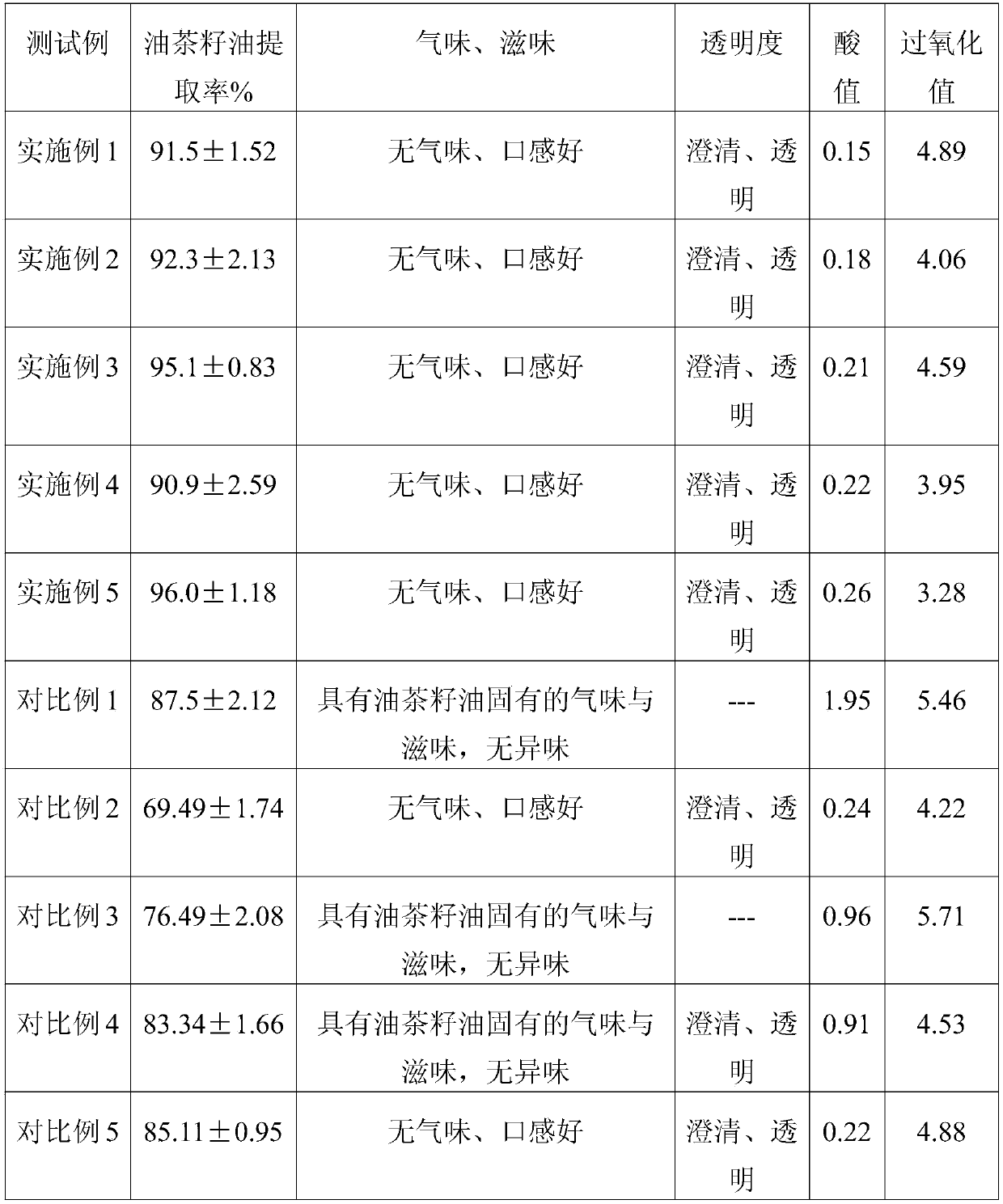

Embodiment 1

[0022] A method for extracting camellia oleifera seed oil, comprising the following steps:

[0023] (1) Steam explosion: After the shelled camellia seeds are heated and baked by far infrared, the baking temperature is 180°C, the baking time is 5min, under 2.4Mpa, the pulp is exploded after maintaining pressure for 180s, and the slurry is obtained .

[0024] (2) Adjust the pH value: Mix the slurry and water uniformly according to the ratio of solid to liquid 1:3.5, and then adjust the pH value to 8 with sodium hydroxide.

[0025] (3) Extraction by water substitution method: perform vibration extraction on the slurry after adjusting the pH value. The vibration extraction is performed at a rotation speed of 160r / min for 150min at an extraction temperature of 75°C. After vibration extraction, stand still for 120min and centrifuge For the oil layer, emulsified layer and residue, the centrifugation speed is 4000r / min, and the centrifugation time is 10min.

[0026] (4) Demulsificat...

Embodiment 2

[0028] A method for extracting camellia oleifera seed oil, comprising the following steps:

[0029] (1) Steam explosion: After the shelled camellia seeds are heated and roasted by far infrared, the roasting temperature is 190°C, the roasting time is 8min, under 2.4Mpa, the maintenance pressure is 210s, and the pulp is exploded to obtain the slurry .

[0030] (2) Adjust the pH value: mix the slurry and water according to the ratio of solid to liquid 1:4.5, and then adjust the pH value to 10 with sodium hydroxide.

[0031] (3) Extraction by water substitution method: perform vibration extraction on the slurry after adjusting the pH value. The vibration extraction is carried out at a rotation speed of 150r / min for 180min at an extraction temperature of 95°C. After vibration extraction, stand still for 120min and centrifuge For the oil layer, emulsified layer and residue, the centrifugation speed is 5000r / min, and the centrifugation time is 10min.

[0032] (4) Demulsification: t...

Embodiment 3

[0034] A method for extracting camellia oleifera seed oil, comprising the following steps:

[0035] (1) Steam explosion: After the shelled camellia seeds are heated and roasted by far infrared, the roasting temperature is 200°C, the roasting time is 11min, under 2.6Mpa, the maintenance pressure is 180s, and the pulp is exploded to obtain the slurry .

[0036] (2) Adjust the pH value: Mix the slurry and water uniformly according to the ratio of solid to liquid 1:3.8, then adjust the pH value to 9 with sodium hydroxide.

[0037] (3) Extraction by water substitution method: perform vibration extraction on the slurry after adjusting the pH value. The vibration extraction is carried out at a rotation speed of 160r / min for 210min at an extraction temperature of 85°C. After vibration extraction, stand still for 120min and centrifuge For the oil layer, emulsified layer and residue, the centrifugation speed is 4000r / min, and the centrifugation time is 10min.

[0038] (4) Demulsificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com