Process for producing ordered porous anodic alumina form

A technology of porous anode and aluminum oxide film, which is applied in anodic oxidation and other directions, can solve the problems of inaccessibility and long nanopores, and achieve the effects of increased porosity, stable properties and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

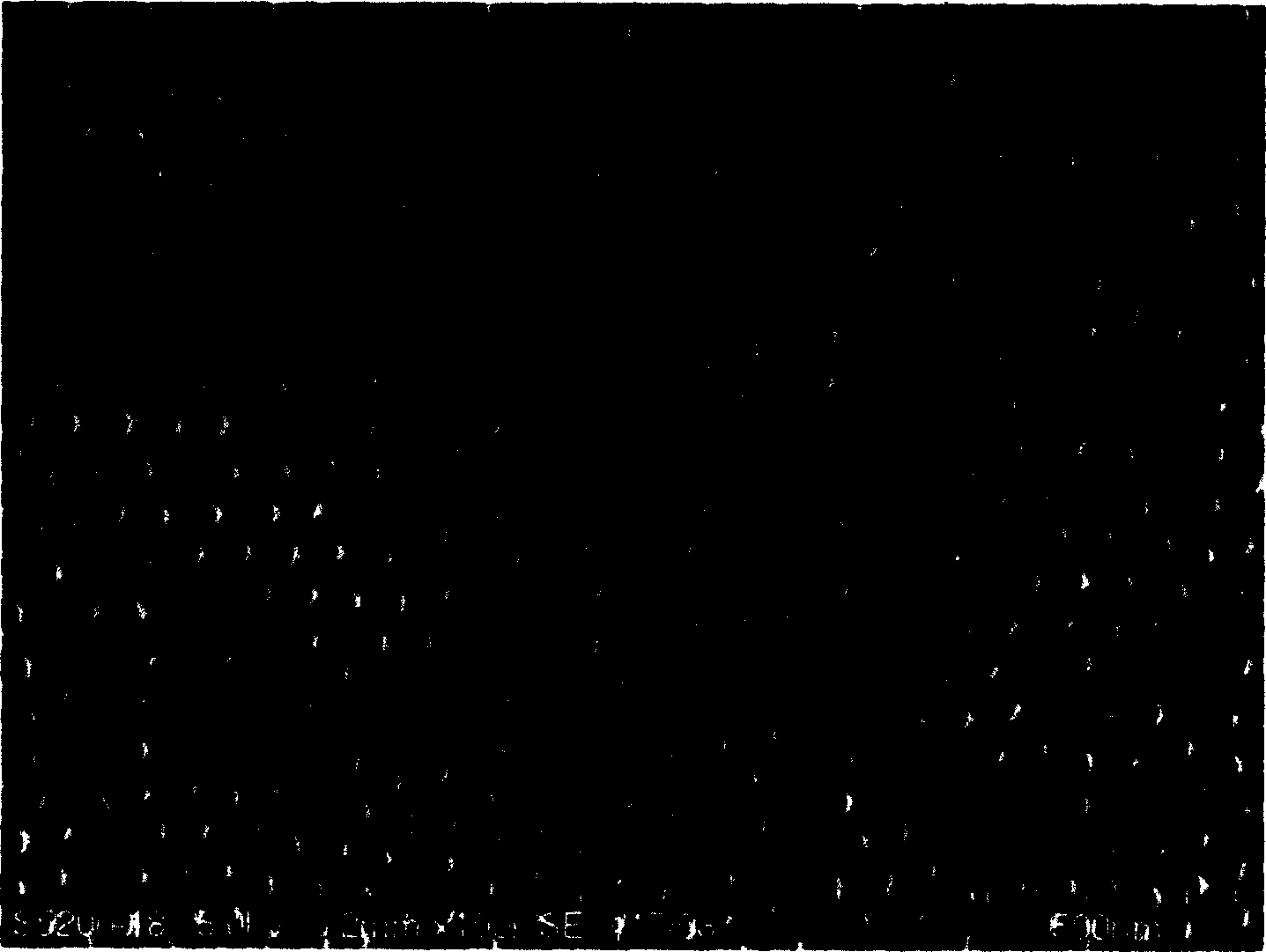

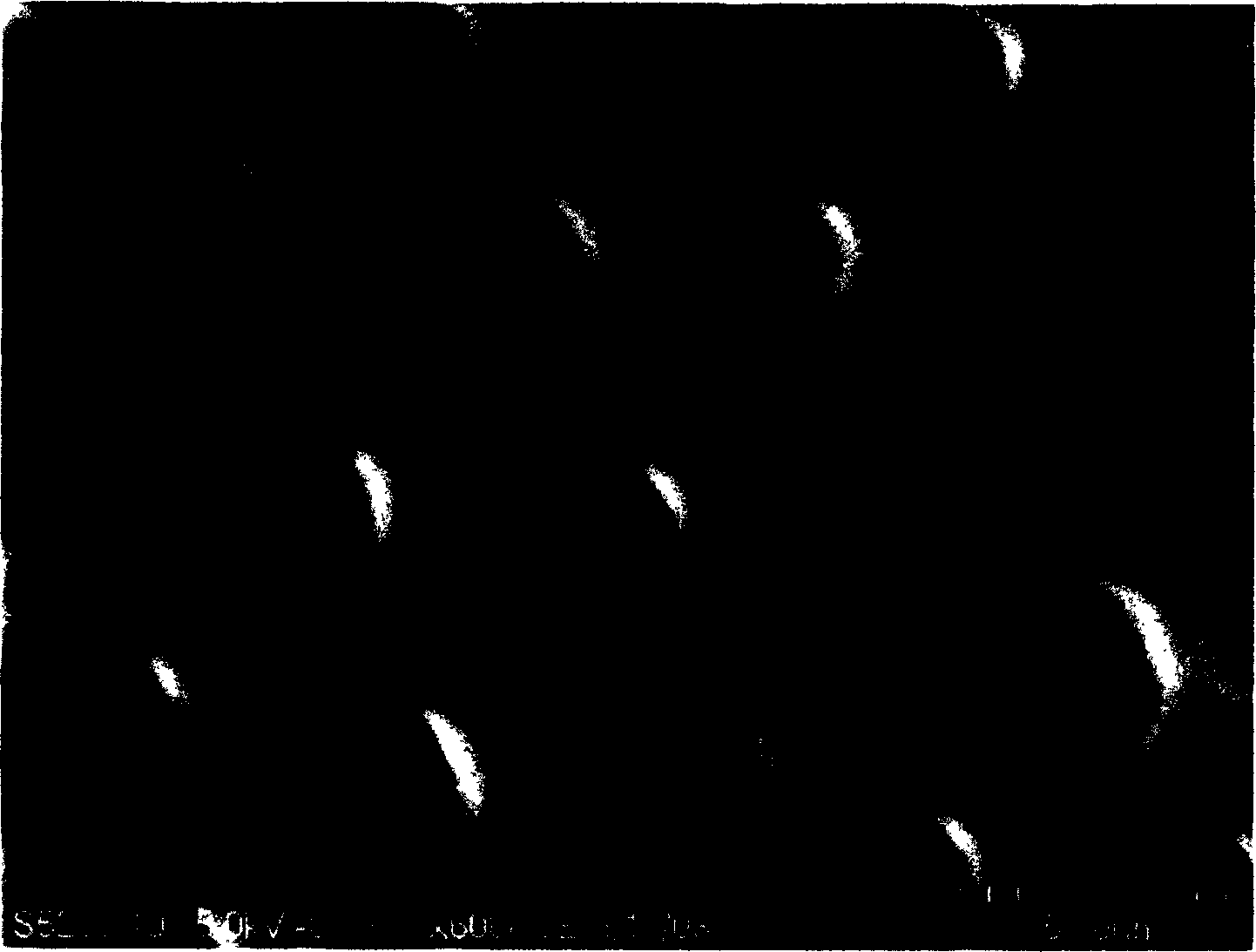

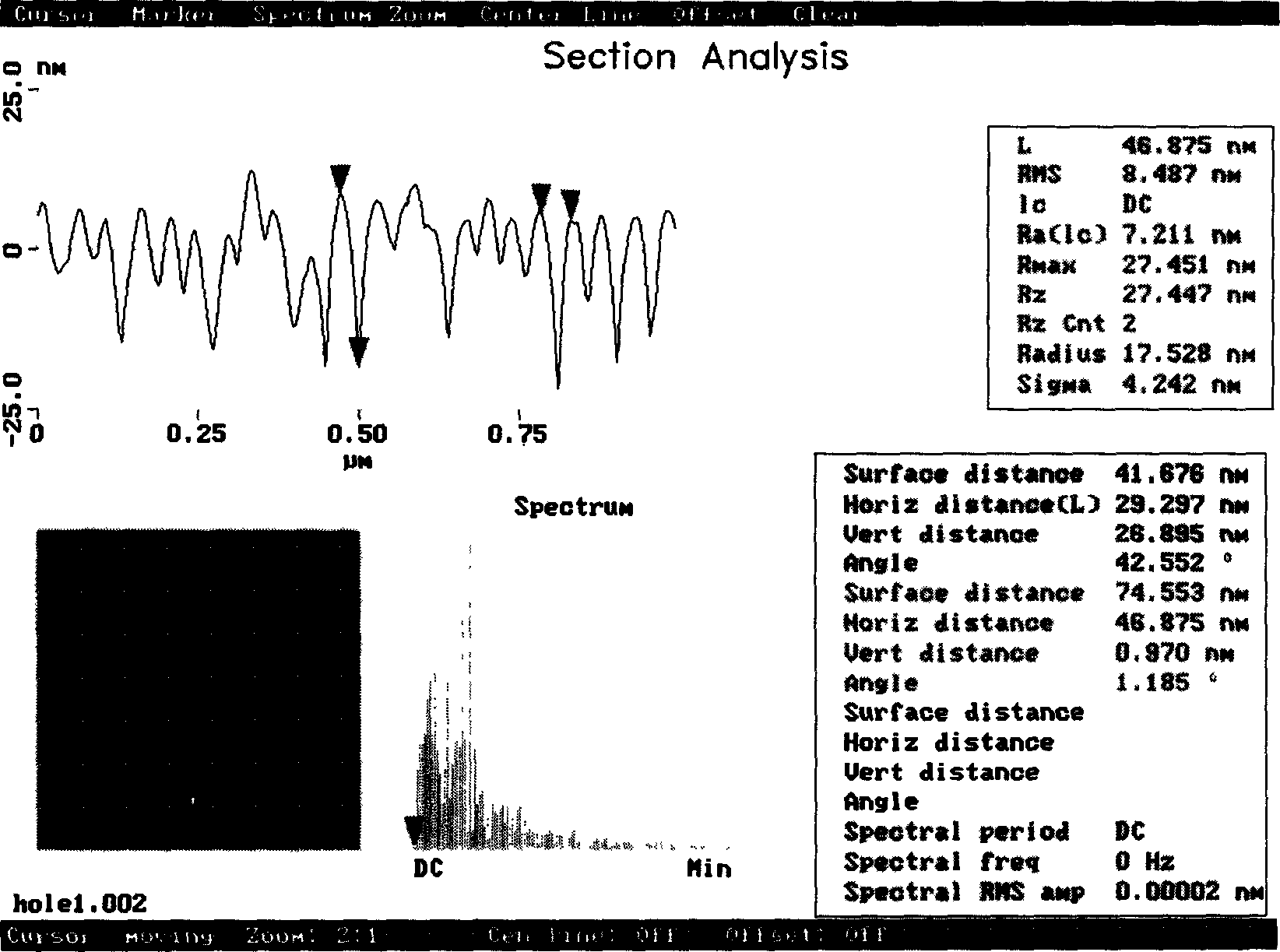

Method used

Image

Examples

Embodiment 1

[0024] 1. Polish the aluminum sheet with a mixture of 70% perchloric acid and absolute ethanol (volume ratio 1:4) at 5°C for 10 minutes, and the voltage is 20V;

[0025] 2. After the aluminum sheet is washed with secondary water, it is first oxidized in 1.0mol / L sulfuric acid at a voltage of 20V for 2 hours, and a stainless steel plate is used as the counter electrode;

[0026] 3. Wash the aluminum sheet with 6% phosphoric acid and 1.8% chromic acid mixed washing solution at 60℃ for half an hour to remove the oxide film;

[0027] 4. After the aluminum sheet is washed with secondary water, anodize for 5 hours with the same voltage as in step 2;

[0028] 5. Strip the aluminum substrate with saturated stannous oxide, expand the pores with 5% phosphoric acid for 15 minutes, and store in secondary water at last.

Embodiment 2

[0030] 1. Polish the aluminum sheet with a mixture of 70% perchloric acid and absolute ethanol (volume ratio 1:4) at 0°C for 10 minutes, and the voltage is 20V;

[0031] 2. The aluminum sheet is first oxidized in 0.3mol / L oxalic acid at a voltage of 40V for 2 hours after being washed with secondary water, and a stainless steel plate is used as the counter electrode;

[0032] 3. Wash the aluminum sheet with 6% phosphoric acid and 1.8% chromic acid mixed washing solution at 60℃ for half an hour to remove the oxide film;

[0033] 4. After the aluminum sheet is washed with secondary water, anodize for 8 hours with the same voltage as in step 2;

[0034] 5. Strip the aluminum substrate with saturated stannous oxide, expand the pores with 5% phosphoric acid for 20 minutes, and store in secondary water at last.

Embodiment 3

[0036] 1. Polish the aluminum sheet with a mixture of 70% perchloric acid and absolute ethanol (volume ratio 1:4) at 3°C for 10 minutes, and the voltage is 20V;

[0037] 2. After the aluminum sheet is washed with secondary water, it is first oxidized in 0.6mol / L phosphoric acid at a voltage of 110V for 1.5 hours, and a stainless steel plate is used as the counter electrode;

[0038] 3. Wash the aluminum sheet with 6% phosphoric acid and 1.8% chromic acid mixed washing solution at 60℃ for half an hour to remove the oxide film;

[0039] 4. After the aluminum sheet is washed with secondary water, anodize for 8 hours with the same voltage as in step 2;

[0040] 5. Strip the aluminum matrix with saturated stannous oxide, expand the hole with 5% sulfuric acid for 10 minutes, and store it in secondary water at last.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com