Design method for mixing proportion of self-compacting concrete mixture

A technology of self-compacting concrete and mix ratio design, applied in calculation, special data processing applications, instruments, etc., can solve the problems of unpredictable mixture performance, increased workload of trial mix adjustment, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] In this embodiment, the proportion design of the C50 self-compacting concrete mixture is taken as an example, and the method for designing the proportion of the self-compacting concrete mixture specifically includes the following steps.

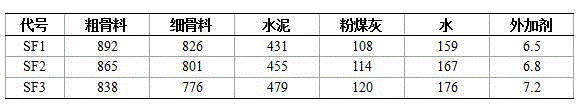

[0162] (1) Determine performance design goals

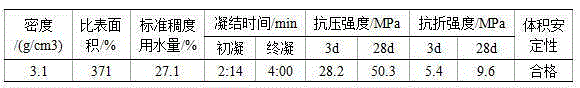

[0163] Specifically, this embodiment is a common reinforced concrete structure project, and the net distance between steel bars is 80-100 mm. Based on this, three kinds of mixtures of self-compacting performance levels are designed (the self-compacting performance of the mixture is expressed by the degree of slump expansion respectively The mix ratio of self-compacting concrete that reaches the three levels of SF1, SF2 and SF3), with the 28d compressive strength of 50MPa (standard cubic specimen) prepared with the same material as the standard, the strength level of self-compacting concrete is also required to reach 50MPa; at the same time, it is required to mix Good compound expansion ti...

Embodiment 2

[0301] In this example, the ratio of the self-compacting concrete mixture whose strength level is C60 is determined as an example. The raw materials are basically the same as in Example 1, except that the aggregate is determined according to five continuous grading curves calculated by the Fuller-Talbol formula. Firstly, the single-size particles obtained by sieving are combined to obtain the aggregate mixture satisfying five gradation curves, and then the aggregate gradation satisfying the closest packing state is determined through the bulk density test, and the mix ratio of the mixture is determined. Proceed as follows:

[0302] (1) Determine the preparation strength and water-binder ratio of self-compacting concrete

[0303] Calculation of Self-Compacting Concrete Preparation Strength f cu,0 : f cu,0 =1.15×6.0=69.0MPa;

[0304] The replacement rate of fly ash is still 20%, and the design strength of the cementitious material f b as follows:

[0305] ;

[0306] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com