Lithium ion battery electrode, preparation method thereof and lithium ion battery

A lithium-ion battery and electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of unguaranteed cycle performance, difficulty in infiltration of electrolytes, and uneven electrolytes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

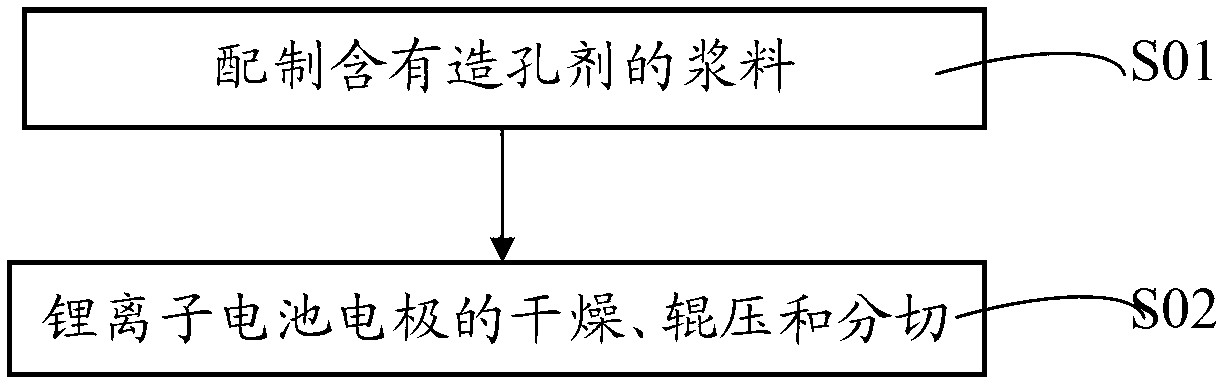

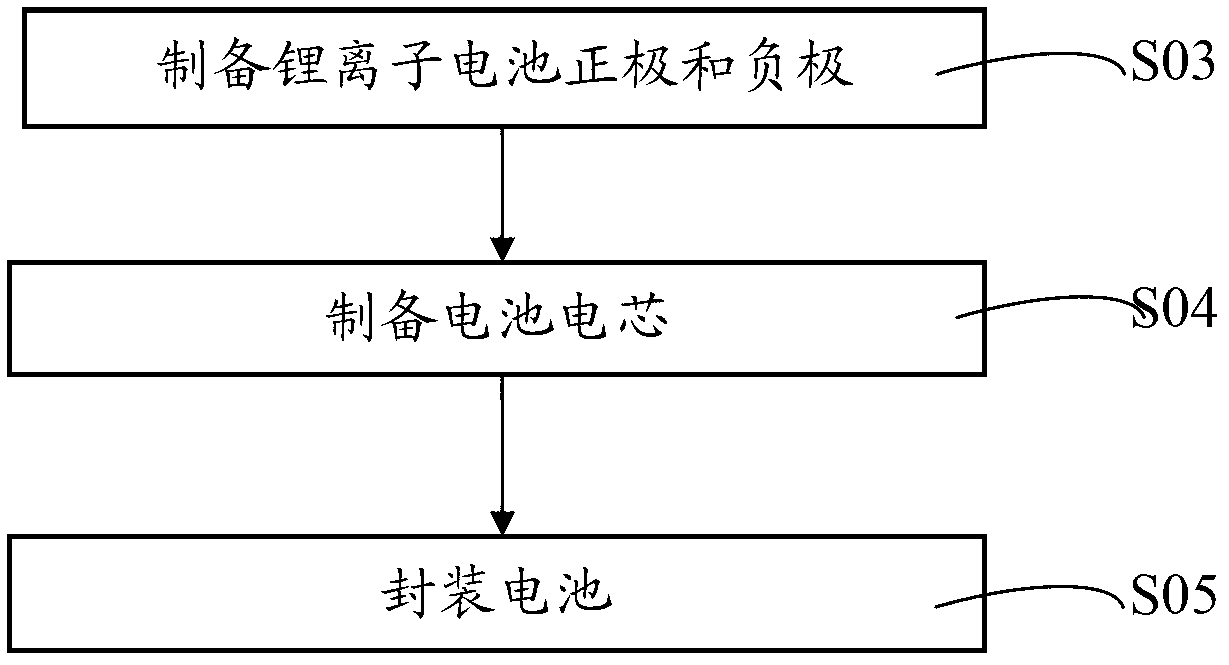

[0017] The example of the present invention provides a preparation method of a lithium-ion battery electrode with uniform pore distribution and high porosity. For the process flow of the electrode preparation method for lithium ion batteries, please refer to figure 1 described, including the following steps:

[0018] S01: Prepare a slurry containing a pore-forming agent: mix the positive electrode active material or negative electrode active material with a pore-forming agent, a conductive agent, a binder, and a solvent to prepare a slurry;

[0019] S02: Drying, rolling and slitting treatment of lithium-ion battery electrodes: Coat the slurry prepared in step S01 on the current collector, and place in a multi-stage temperature-controlled continuous oven at 40-45°C, 60-65°C, 85- 90°C, 75-80°C, drying treatment at a running speed of 4-15m / min. The specific running speed is adjusted and controlled based on the complete drying of the pole piece, rolling, and cutting to obtain lit...

Embodiment 1

[0045] A kind of preparation method of lithium ion battery:

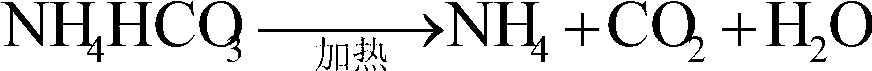

[0046] S11: First add 15g PVDF to 400g NMP and stir for 2 hours to obtain a colorless and transparent solution, then add 5g ammonium bicarbonate, continue stirring for 10 minutes, let it dissolve in the glue, then add 1000g LiCoO 2 The positive electrode active material and 15g of conductive agent acetylene black were first stirred slowly for 30 minutes, then stirred rapidly for 3 hours, and the viscosity was detected with a viscometer, and 20g NMP was added to adjust the viscosity at 8400cps; the mass percentage of solid matter was 71%;

[0047] S12: Coat the slurry prepared in step S11 on a 16 μm thick aluminum foil current collector, and continuously dry, roll, and strip at 40°C, 60°C, 85°C, and 80°C at a running speed of 8m / min. 56mm wide 18650 battery width required to obtain the lithium-ion battery positive pole piece;

[0048] S13: First add 18g CMC to 1100g pure water and stir for 2 hours to obtain a colorl...

Embodiment 2

[0052] A kind of preparation method of lithium ion battery:

[0053] S21: First add 12g PVDF to 390g NMP and stir for 2 hours to obtain a colorless and transparent solution, then add 10g ammonium bicarbonate, continue stirring for 10 minutes, let it dissolve in the glue, and then add 1000g of positive electrode active material LiCo 0.3 Ni 0.3 mn 0.3 o 2 With 10g of conductive agent acetylene black, first stir slowly for 30min, then stir rapidly for 3h, check the viscosity with a viscometer, if the viscosity is too high, add NMP to adjust, and finally adjust the viscosity of the slurry to 9300cps; the percentage of solid matter is 69.8%;

[0054] S22: Coat the slurry prepared in step S21 on a 15 μm thick aluminum foil current collector, and then dry, roll, and strip at 45°C, 60°C, 80°C, and 85°C at a running speed of 12m / min , obtaining the lithium-ion battery positive pole piece;

[0055] S23: First add 15g CMC to 950g pure water and stir for 2 hours to obtain a colorless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com