Ultra-low nitrogen gas burner

A gas burner, ultra-low nitrogen technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problem of large NOx emissions, and achieve the effect of sufficient fuel combustion, low noise and stable emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

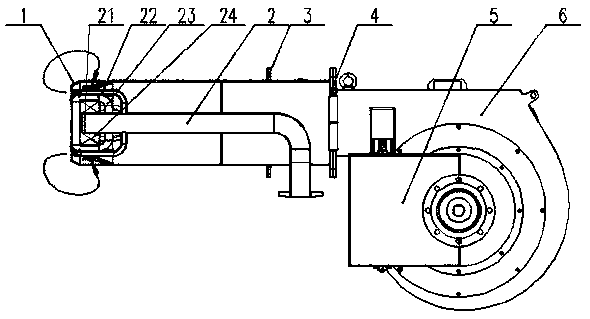

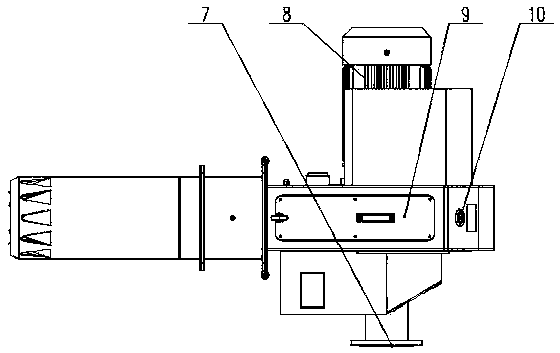

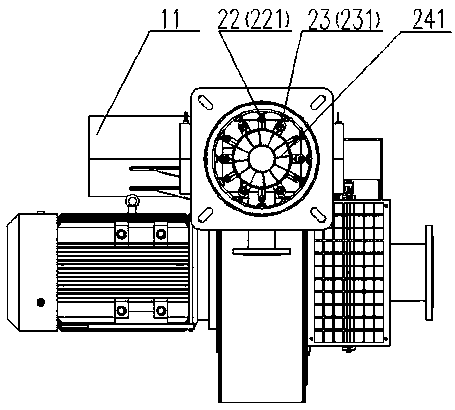

[0028] Such as figure 1 , figure 2 with image 3 As shown, an ultra-low nitrogen gas burner includes a combustion cylinder 1, a housing 6 and a motor 8 connected by a rotating positioning pin 4, the combustion cylinder 1 is arranged at the front end of the housing 6, and the motor 8 is arranged at The tail part of the housing 6; the combustion tube 1 is a shrinking combustion tube, and the front end of the combustion tube 1 is also provided with a flue gas internal circulation channel, and the smoke gas is sucked into this channel and mixed with the combustion-supporting air; the inside of the housing 6 is also Equipped with a fan impeller and a draft hood, the motor 8 prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com