Membrane performance tester and application thereof

A test device and performance technology, which is applied in the field of test devices for the performance of flat ultrafiltration membranes or reverse osmosis membranes, to achieve the effects of prolonging residence time, stabilizing temperature control, and reducing concentration polarization on the membrane surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

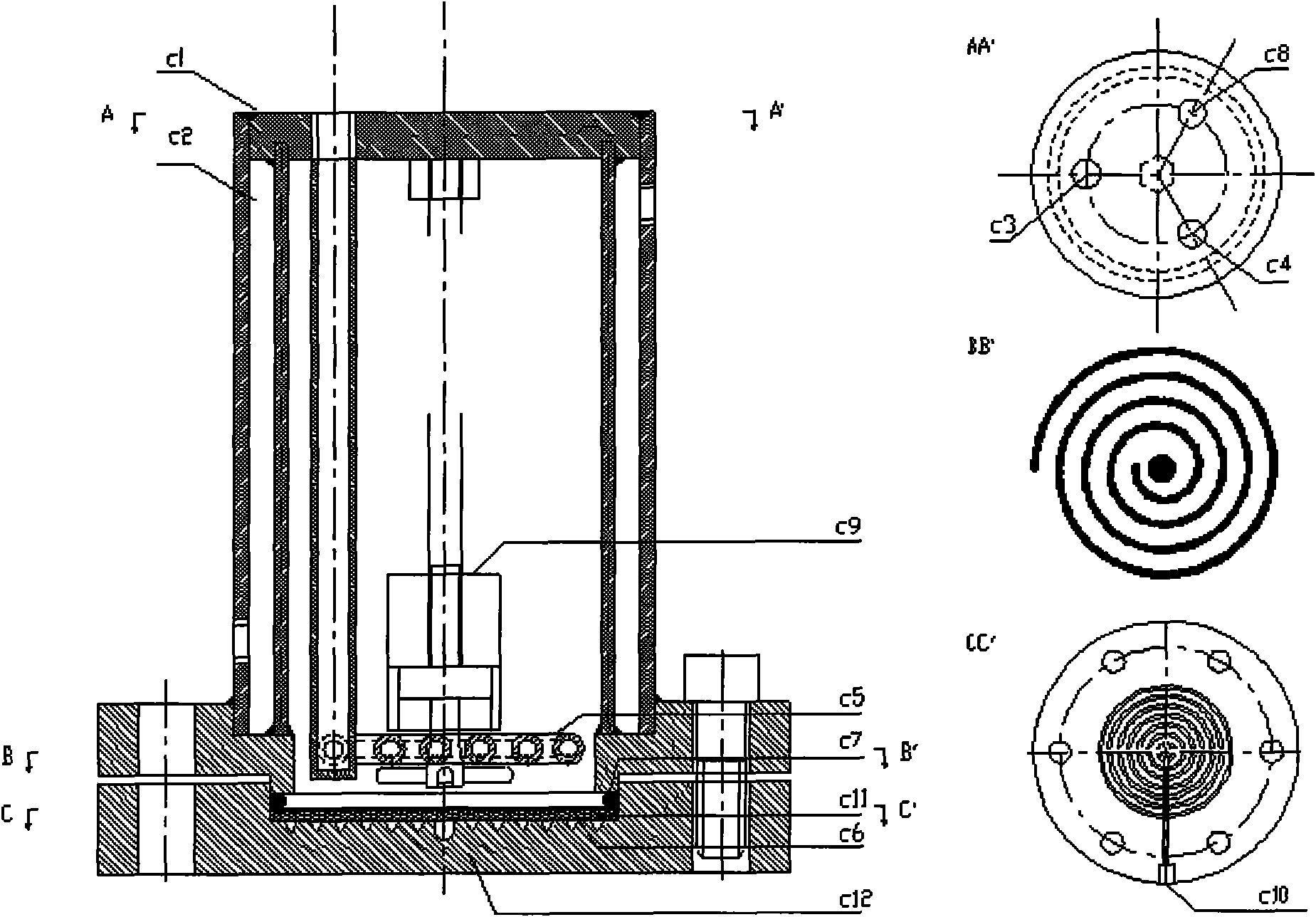

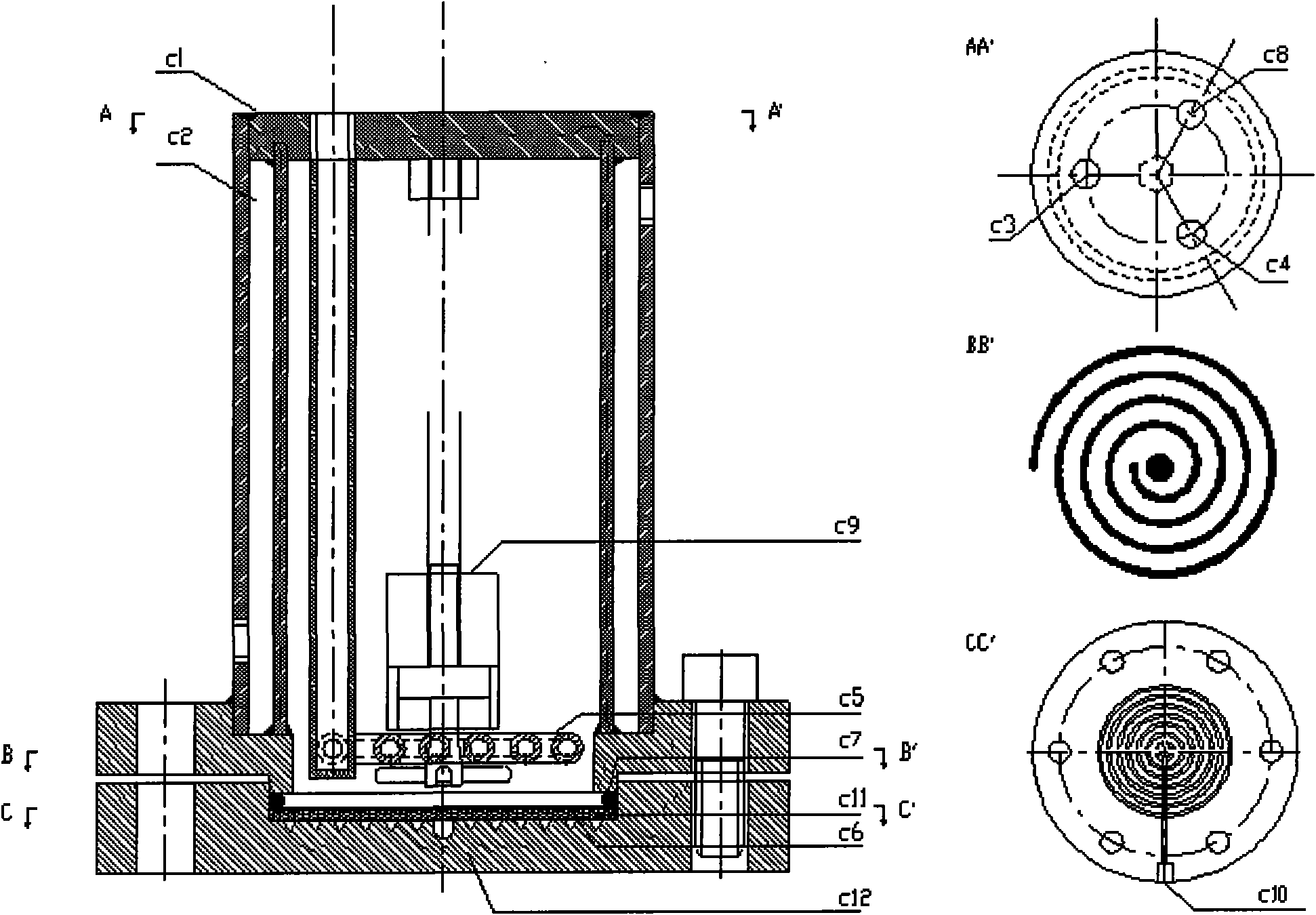

[0043] 1. Membrane test device

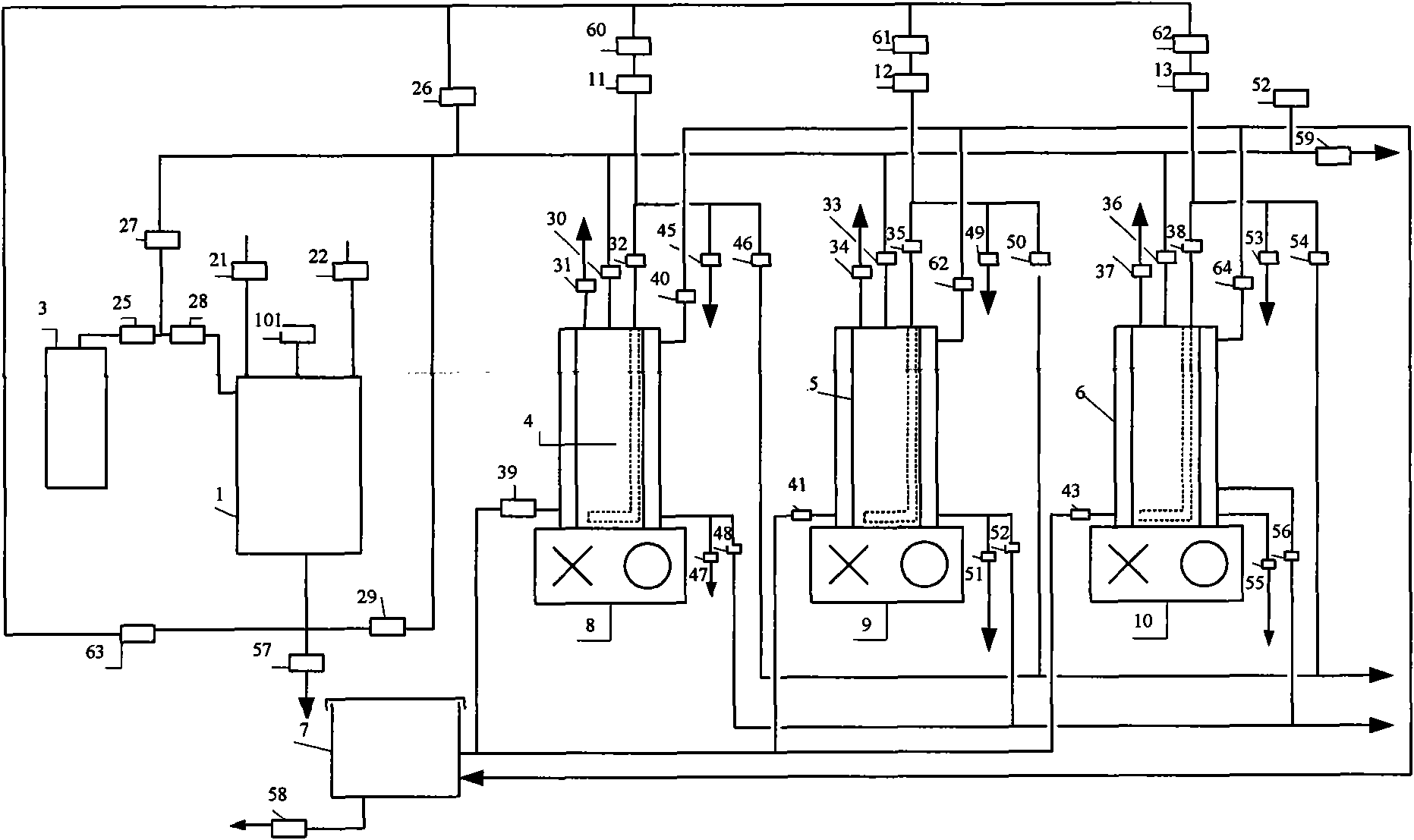

[0044] Membrane performance testing device, including 3 parallel permeation tanks, water supply unit, drainage unit, valves and measuring instruments;

[0045] in the attached figure 2 Among them, 1 is the feed liquid tank, 3 is the pressure supply device (nitrogen cylinder), 4, 5, and 6 are the permeation pools, 8, 9, and 10 are the magnetic stirring drives, and 7 is the constant temperature water bath; 30, 33, and 36 are the permeation pools 31, 34, 37 are exhaust valves for permeation tanks, 32, 35, 38 are concentrated water discharge valves for permeation tanks, 39, 41, 43 are water inlet valves for water bath jacket c2, 40, 62, 64 is the drain valve of water bath jacket c2, 46, 50, 54 are concentrated water discharge valves, 48, 52, 56 are product water discharge valves, 11, 12, 13 are cleaning gas flow meters, 60, 61, 62 are cleaning Gas shut-off valve.

[0046] The internal structures of the permeation tanks 4, 5 and 6 are the same a...

Embodiment 2

[0064] 1. Membrane test device

[0065] Same as Example 1.

[0066] 2. Membrane performance test and membrane cleaning (using a pressure-resistant tank and using three permeation tanks for testing)

[0067] (1) System feeding

[0068] Simultaneously open the feed valve 21 and the exhaust valve 22 on the top of the pressure-resistant material tank 1 and inject the feed liquid to be processed, then close the material valve 21 and the exhaust valve 22, open the pressure reducing valve of the compressed nitrogen cylinder 3 to perform rough adjustment of the required pressure, After fine-tuning the pressure through the pressure stabilizing valve 25, close the stabilizing valve 26 and the ball valve 27, open the intake valve 28 and start to pressurize the feed liquid in the pressure-resistant material tank 1, and wait for the pressure gauge 101 on the pressure-resistant material tank 1 to pressurize. After the reading reaches a certain value, open the main valve 29 on the discharg...

Embodiment 3

[0079] 1. Membrane test device

[0080] Same as Example 1.

[0081] 2. Membrane performance test and membrane cleaning (do not use a pressure tank, use a single permeation tank for testing)

[0082] (1) System feeding

[0083] Open the exhaust valves 31 and 59 above the permeation tank 4, close the concentrate discharge valve 32 of the permeation tank 4, manually feed the permeation tank 4, and close the exhaust valves 31 and 59 after the feeding is completed.

[0084] (2) Material constant temperature

[0085] Open the water inlet valve 39 and the drain valve 40 of the water bath jacket c2 pipeline connected to the constant temperature water bath 7, open the magnetic stirring driver 8 and set a certain stirring speed, and stir while heating the liquid to be measured in the osmosis tank 4 to prevent The temperature distribution of the liquid to be tested is uneven.

[0086] (3) Test system operation

[0087] After the feed liquid temperature in the permeation tank 4 reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com