Resin plate multi-point hot forming uniform temperature controlling and loading method

A resin plate and thermoforming technology, applied in the field of mechanical engineering, can solve the problems of resin plate stress instability, wrinkling, and high forming cost of resin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

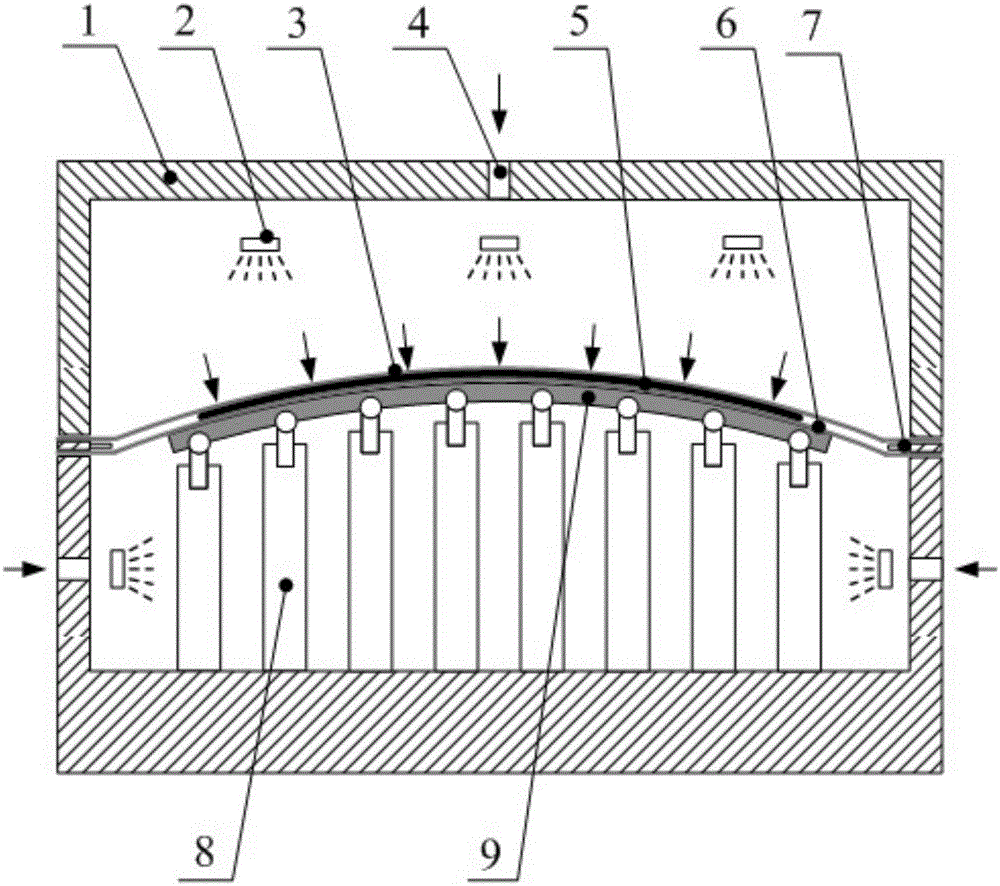

[0017] figure 1 It is a schematic diagram for explaining the multi-point thermal expansion uniform temperature control and loading method involved in an embodiment of the present invention, including five steps of multi-point mold shape adjustment, heating, pressurization, pressure holding and cooling; In the step of adjusting the shape of the multi-point mold, the multi-point basic body 8 and the polyurethane mold 9 are connected through a pin-hole structure, the height of the multi-point basic body 8 is controlled by the multi-point forming CAD / CAE / CAM software, and the regularly arranged polyurethane molds 9 are formed Discrete mold surface; in the heating step, the resin plate 5 is placed on the top of the polyurethane film 6, and the resin plate 5 is heated by the heater 2 arranged inside the thermal expansion box 1 and around the multi-point basic body 8, The temperature of the resin plate 5 is monitored by the thermocouple 7 until the target forming temperature; in the ...

Embodiment approach 2

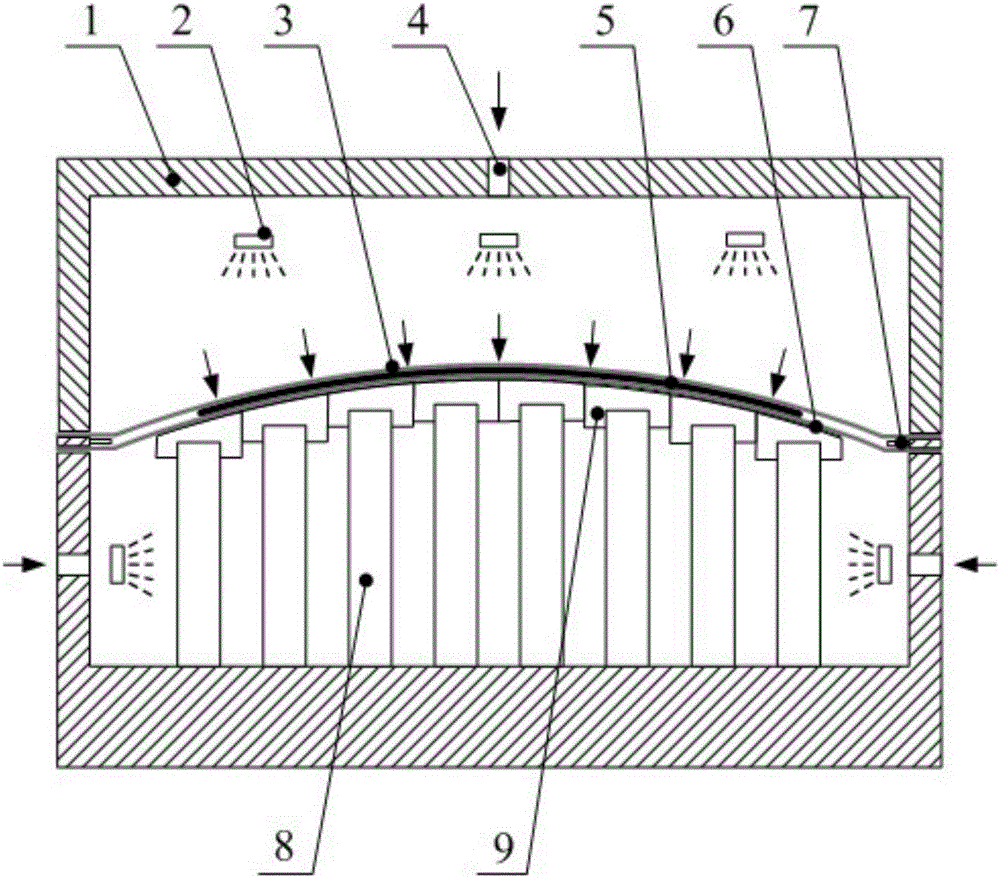

[0019] figure 2 It is a schematic diagram for explaining the multi-point thermal expansion uniform temperature control and loading method involved in another embodiment of the present invention, including five steps of multi-point mold shape adjustment, heating, pressurization, pressure holding and cooling; In the multi-point mold shape adjustment step, the multi-point basic body 8 and the polyurethane mold 9 are fixed by the multi-point support head, the multi-point basic body 8 and the support head are connected through a pin hole structure, and the polyurethane mold 9 and the support head are connected by a ball plug Into the hole connection, the height of the multi-point basic body 8 is controlled by the multi-point forming CAD / CAE / CAM software, and the change of the height of the multi-point basic body 8 drives the polyurethane mold 9 to form a continuous mold surface; in the heating step, the resin plate 5 Placed on the polyurethane film 6, the resin plate 5 is heated b...

Embodiment approach 3

[0021] image 3 It is a schematic diagram for explaining the multi-point thermal expansion uniform temperature control and loading method involved in another embodiment of the present invention, including five steps of multi-point mold shape adjustment, heating, pressurization, pressure holding and cooling; In the step of adjusting the shape of the multi-point mold, the multi-point basic body 8 and the polyurethane mold 9 are connected through a pin-hole structure, the height of the multi-point basic body 8 is controlled by multi-point forming CAD / CAE / CAM software, and the height of the multi-point basic body 9 is The change drives the height of the polyurethane mold 9 to change, and then the profile machine of the polyurethane mold 9 is added to the target curved surface; Heat the resin plate 5 with the heater 2 around the multi-point basic body 8, and monitor the temperature of the resin plate 5 through the thermocouple 7 until the target forming temperature; in the pressuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com