Sharpening method for drill tip back knife face of fully screw face drill

A drill tip and flank technology, which is applied in drilling/drilling equipment, components of boring machines/drilling machines, twist drills, etc., can solve the problems of low precision and complex motion relationship, and achieve less sharpening error sources. , Overcome the effect of complex and simple motion relations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

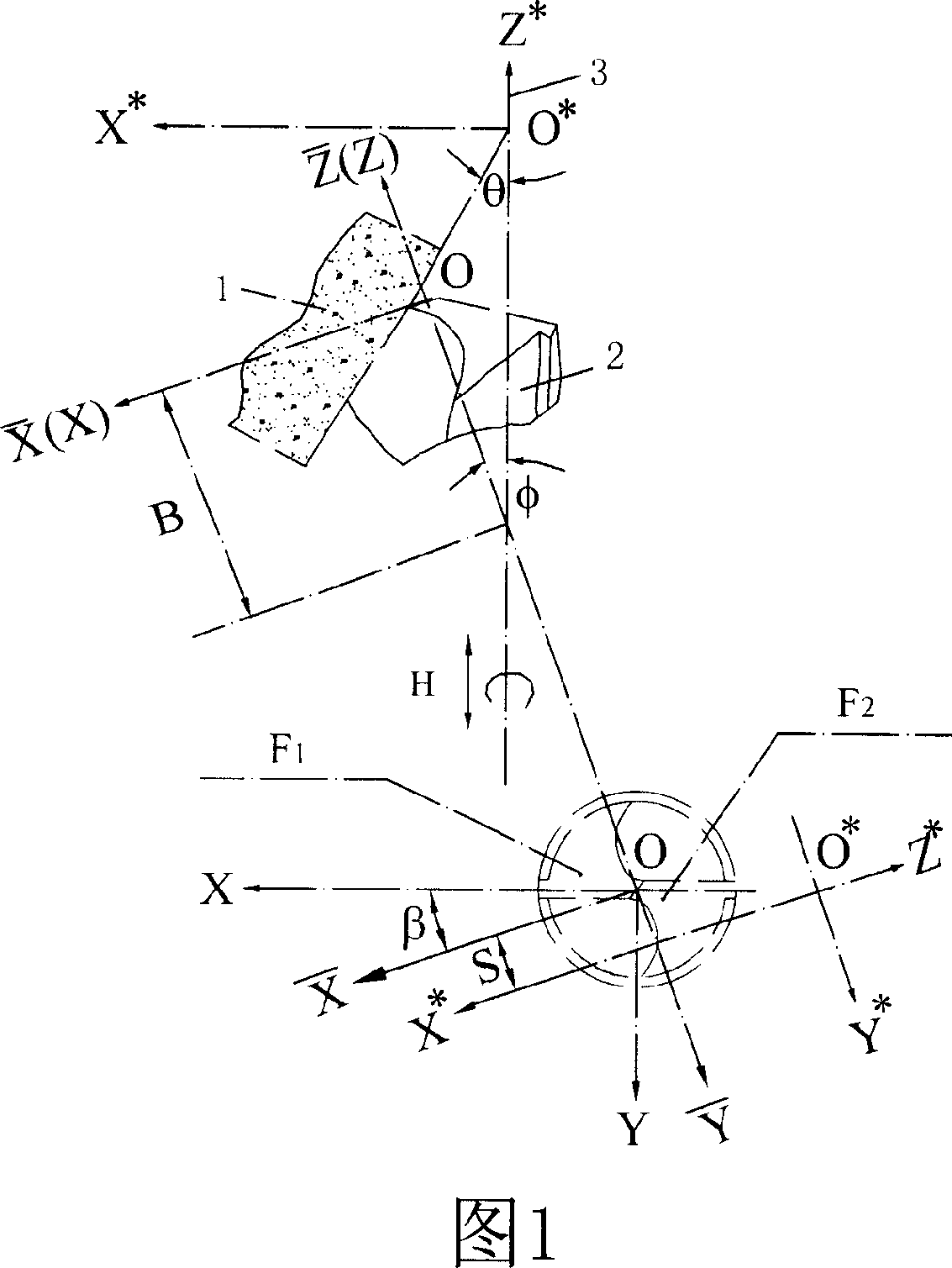

[0014] The flank face of the full helical drill bit is a continuous helical surface, which is ground by the relative helical feed motion of the grinding wheel and the drill bit. Referring to Fig. 1, the position of the grinding wheel 1 is fixed, and the drill bit 2 performs a helical feed movement with a pitch H around the machine tool spindle 3 to form a full helical flank flank drill tip. f 1 and F 2 It is the helicoid flank, when one flank F 1 After the sharpening is completed, the drill rotates 180° around its own axis relative to the starting position of the sharpening and grinds a symmetrical flank F with the same sharpening parameters 2 .

[0015] See Figure 1, X * Y * Z * , XYZ and X Y Z respectively represent the machine tool coordinate system, drill coordinate system and transition coordinate system when sharpening the flank, where X Y Z is defined by the machine tool coordinate system X * Z * plane around Y * Rotate the axis by an angle Φ, and move the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com