Double-rotation wheel hot spinning necking method for large-diameter seamless gas cylinder

A technology of seamless gas cylinders and large diameters, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem that the outer diameter of the largest gas cylinder has not yet been broken through, so as to save spinning time, reduce production costs, and improve the finished product. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment, and following embodiment is explanation of the present invention and the present invention is not limited to following example.

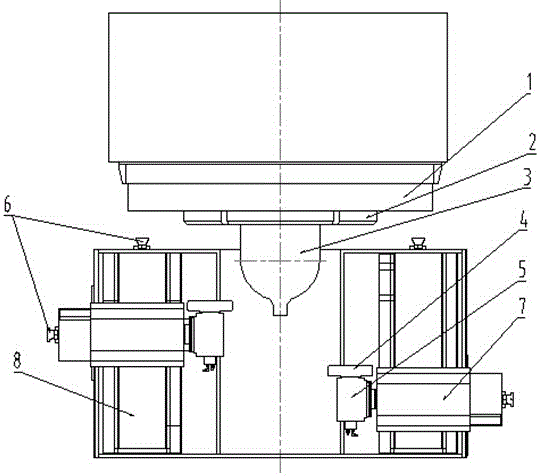

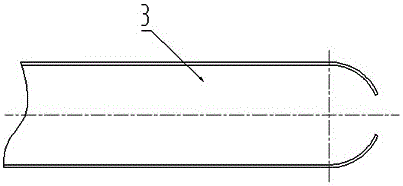

[0031] like figure 1 As shown, the spinning machine implementing the method of the present invention is composed of a clamping head 1, a spindle claw 2, a rotary wheel 4, a rotary wheel seat 5, a lateral feed system 8 and a longitudinal feed system 7, and the spindle claw 2 clamps The outer wall of the seamless steel pipe 3, at the same time, with the cooperation of the hydraulic system 6, the rotary wheel 4 installed on the rotary wheel seat 5 can be driven by the horizontal feed system 8 and the longitudinal feed system 7 according to the set The shape trajectory of the steel pipe 3 is spun and closed.

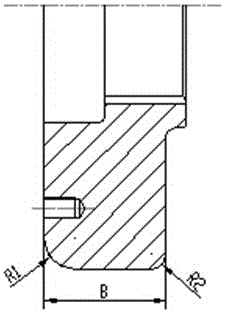

[0032] like figure 2 As shown, the structural parameters of the front wheel and the back wheel are: wheel width B=12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com