Micropore forming method

A forming method and microporous technology, applied in the field of instrumentation (analytical instruments), can solve the problems of reducing processing accuracy, human injury, and damage to tool life, etc., and achieve the effect of easy implementation, simple method, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

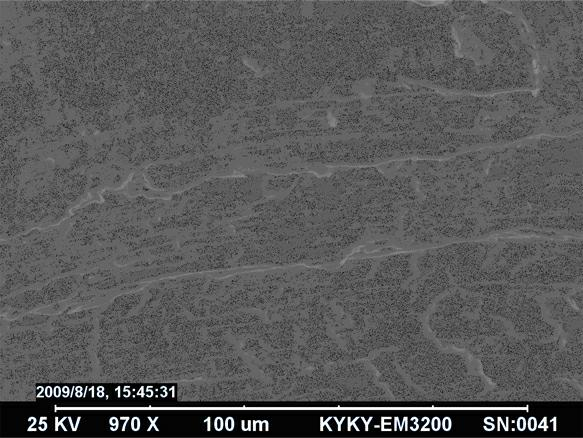

Image

Examples

Embodiment 1

[0046] Such as Figure 3-4 As shown, it is a schematic diagram of a molybdenum sheet 2 as an electron microscope suction pole. The design diameter of the molybdenum sheet 2 is Ф30mm, and the design thickness is 0.5mm, and a diameter of Ф0 should be formed at the center of the molybdenum sheet 2. .38mm, roundness of 0.01mm, and surface roughness of Ra0.1 micropore 5, that is, the extremely small hole for suction.

[0047] In the present invention, the so-called "design diameter of the molybdenum flake 2" refers to the diameter requirement that the molybdenum flake as the electron microscope extractor should meet. The so-called "design thickness of the molybdenum sheet 2" refers to the thickness requirement that the molybdenum sheet used as the electron microscope extraction electrode should meet.

[0048] The processing steps of forming the micropores 5 on the molybdenum sheet 2 using the micropore forming method provided by the present invention include:

[0049] ① Turn the ...

Embodiment 2

[0061] Compared with Embodiment 1, the processing steps of forming micropores 5 on the molybdenum sheet 2 in the present embodiment include:

[0062] ① The workpiece is fixed, and the molybdenum sheet 2 is fixed on the workbench of the processing equipment. In this embodiment, the processing equipment is a processing center with a series of common processing machine tools such as lathes and drilling machines.

[0063] ② micropore forming, forming the micropore 5 with a diameter of Ф0.38mm, a roundness of 0.01mm, and a surface roughness of Ra0.1 at the predetermined position of the molybdenum sheet 2. In this embodiment, the The predetermined position is the center position of the molybdenum sheet 2 . The specific steps are as follows:

[0064] a. Utilize a positioning drill to form a positioning hole on the predetermined position of the molybdenum sheet 2;

[0065] b. Using a drill bit with a diameter of Ф0.28 mm to Ф0.32 mm, forming a pre-drilled hole along the thickness d...

Embodiment 3

[0069] The difference between this embodiment and Embodiment 1 is: in the step c of the 5th step, the rotating speed of the reaming drill is 5000 revolutions / min, the feed rate is 5mm / min, and the number of cycle drilling times is 12 times, and increase the supply of cutting fluid and the amount of grease lubricant applied.

[0070] The molding method provided by the invention can appropriately reduce the requirements on processing equipment and avoid extra equipment investment. For example, when using some relatively old or low-precision processing equipment for micro-hole processing, since these processing equipment may not be able to reach a high speed such as 7500 rpm, it is also impossible to control the reaming drill to stabilize at a low speed of 3mm / min. Feed, then at this time, the speed of the reaming drill can be appropriately reduced and the feed speed can be increased. Although, lower rotational speed and faster feed rate are not conducive to the formation of mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com