Guide positioning method and positioning instrument for horizontal directional drilling

A technology of horizontal orientation and directional positioning, applied in directional drilling, earth-moving drilling, surveying, etc., can solve the problems of tens of seconds or even minutes, complexity and high cost, and achieve the improvement of intelligent level, controllable trajectory and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Introduce the present invention below in conjunction with accompanying drawing and embodiment.

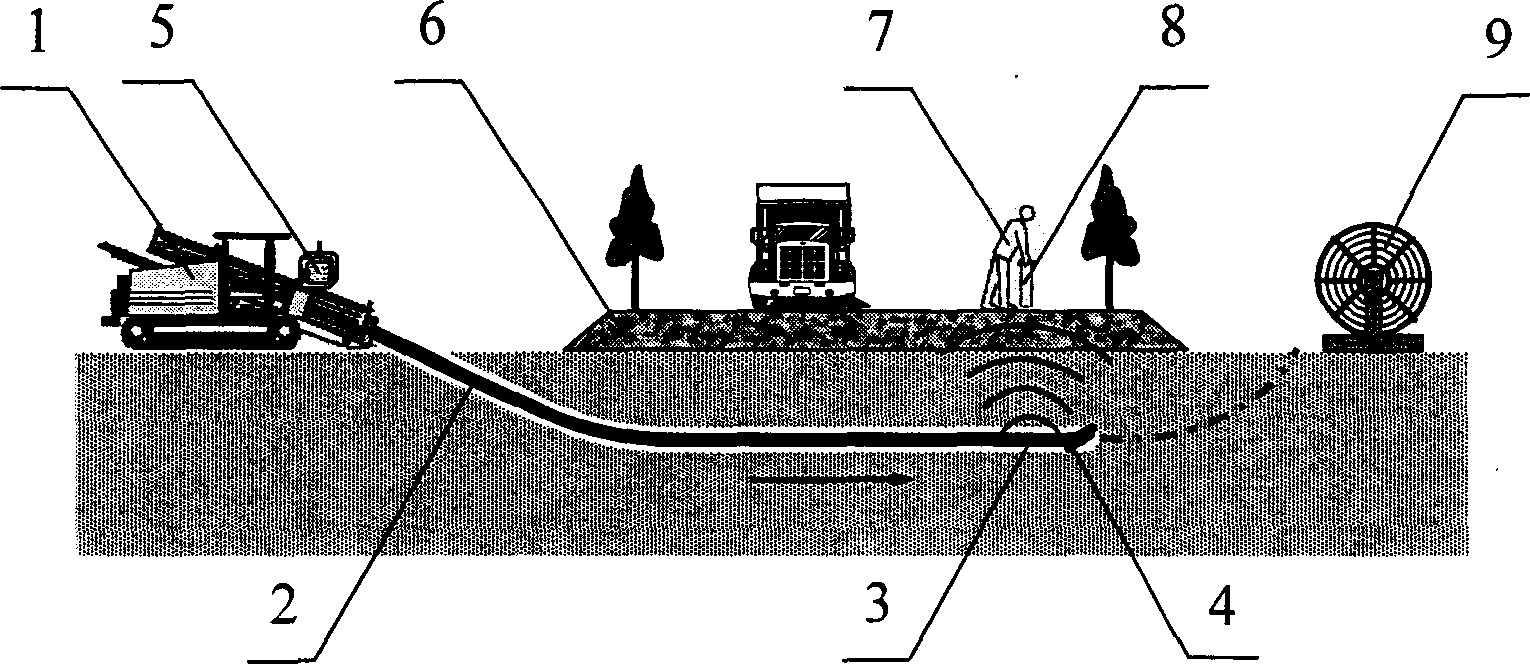

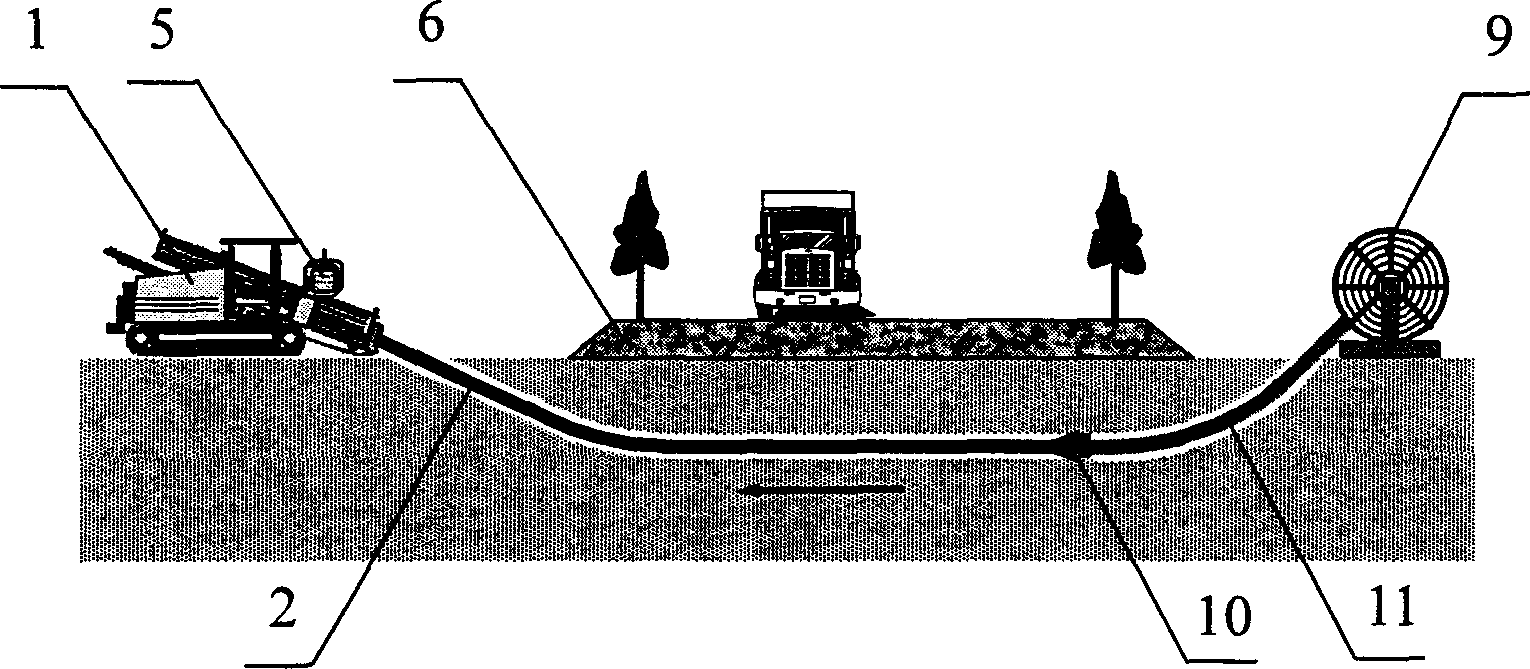

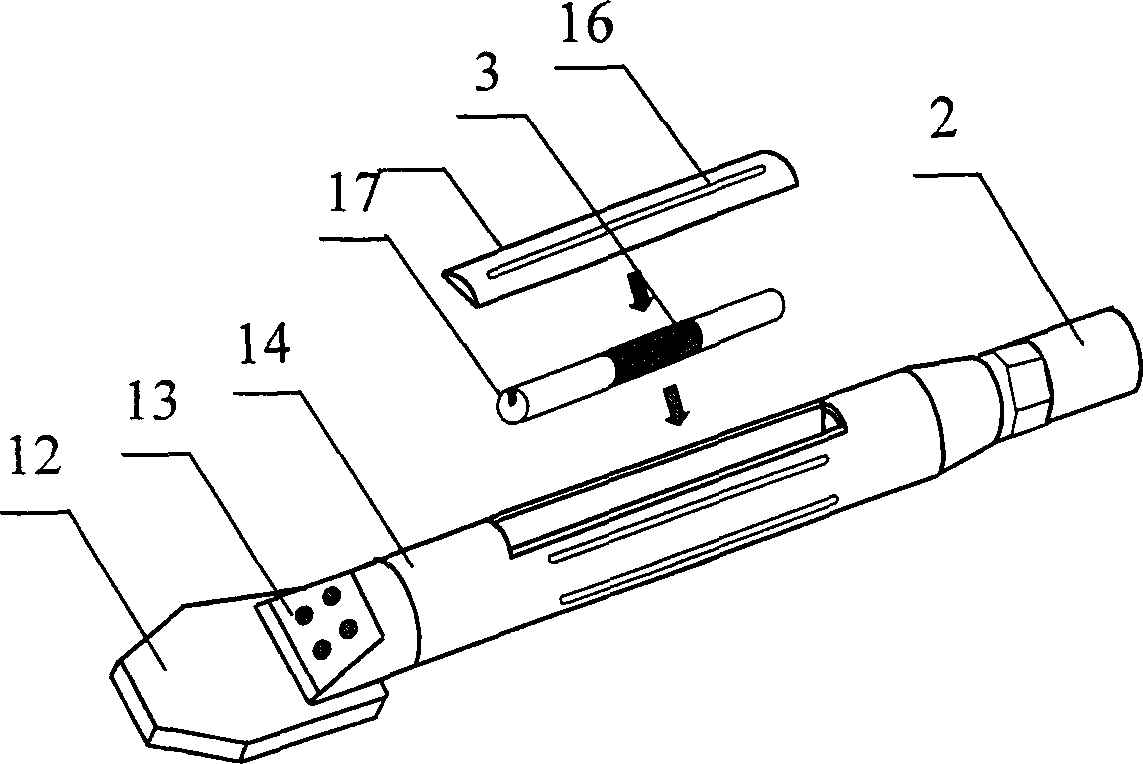

[0035] The invention belongs to a matching method and equipment for horizontal directional drilling. refer to figure 1 , 2 , during construction, first use the horizontal directional drilling machine 1 to drill a small-diameter pilot hole through the drill pipe 2 and the guide drilling tool 4 equipped with the sensing transmitter probe 3, and obtain the drilling tool’s temperature through the underground sensing transmitter probe 3 during the drilling process. status, and send the results to the ground receiver 8 in the form of wireless electromagnetic waves, and the ground positioning tracker 8 demodulates the transmitted parameter information, and at the same time locates and determines the depth according to the strength distribution of the signal, and then sends the measurement results Send to the monitor 5 at the horizontal directional drilling machine 1 to guide the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com