Hydraulic circumferential torque impact generator

A generator and hydraulic technology, which is used in drilling driving devices, drilling equipment, earth-moving drilling and other directions in the wellbore, can solve the problems of inconvenient installation and disassembly of the anti-drop device, and achieve improved service life and high service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

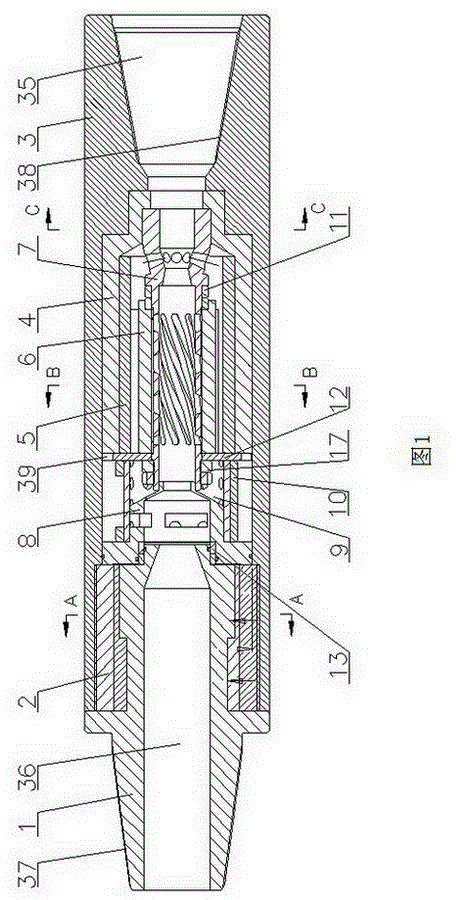

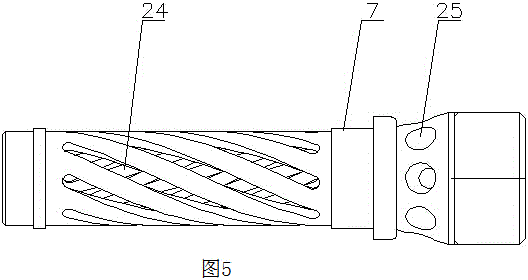

[0038] The hydraulic circumferential torque impact generator includes a casing head 1 , a casing 3 , a screen tube 7 , a circulation starter 6 and a throttle plug 8 . The housing 3 is provided with an assembly kit 4 . The assembly set 4 is in the shape of a cylinder, and the outer circumference of the assembly set 4 is symmetrically provided with a circulation starter rotating the diversion groove 28 clockwise and a circulation starter rotating the diversion groove 40 counterclockwise, and the circulation starter rotating the diversion groove 28 clockwise and circulation starter counterclockwise rotation diversion groove 40 is respectively provided with diversion holes 27; on the inner wall of the circumference of the assembly 4 is symmetrically provided with discharge grooves 26, and on the inner wall of the assembly 4 between the discharge grooves 26 is symmetrically shaped An impact hammer head groove 34 is provided.

[0039] The end of the housing 3 at one end of the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com