Impact disturbance surrounding rock testing equipment

A test equipment and surrounding rock technology, applied in the field of impact disturbance surrounding rock test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

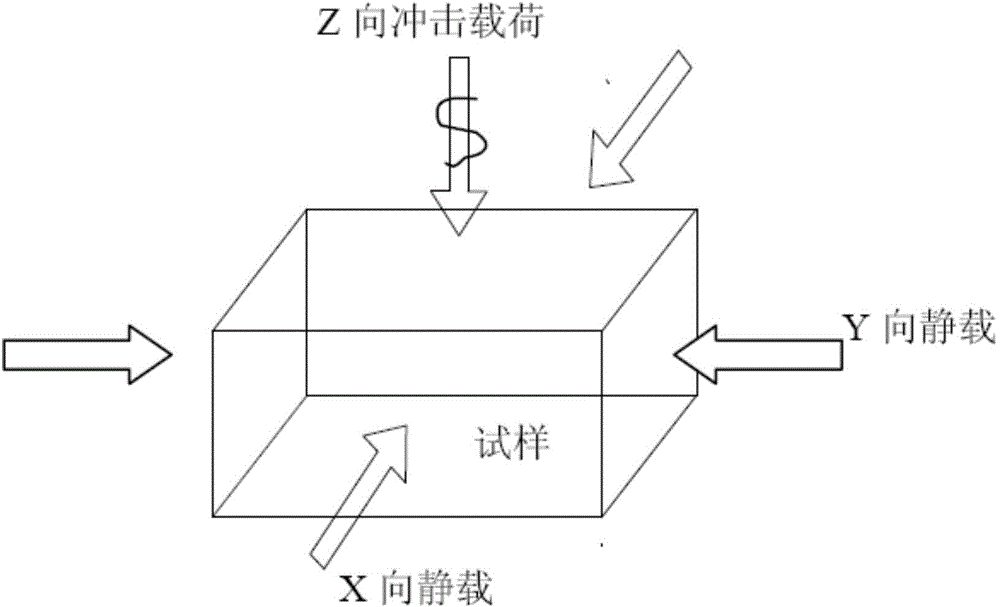

[0018] During the test, according to the size of the rock sample 7 to be tested, the positions of the loading splint 8 in the horizontal Y direction and the loading splint 10 in the horizontal X direction are adjusted, and the center of the rock sample 7 to be tested is aligned with the loading splint 8 in the horizontal Y direction and the loading splint 10 in the horizontal X direction. The center of the loading splint 10 is pre-clamped by the horizontal X-direction servo hydraulic cylinder 9 and the horizontal Y-direction servo hydraulic cylinder 12, and the pre-tightening load is applied to the rock sample 7 to be tested, and then the cylinder 14 is released, and the impact hammer head 13 is released. A vertical impact load is applied to the tested rock sample 7 to realize the combined effect of static load and impact load in the triaxial state. The static load-impact load schematic diagram of the tested rock sample 7 is shown in figure 2 shown.

Embodiment 2

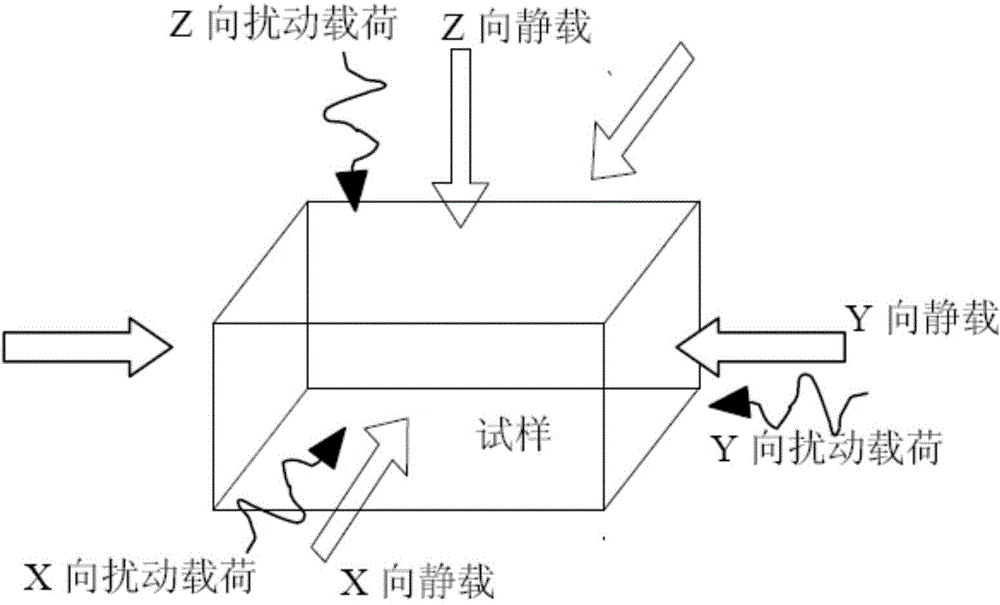

[0020] During the test, according to the size of the rock sample 7 to be tested, the positions of the loading splint 8 in the horizontal Y direction and the loading splint 10 in the horizontal X direction are adjusted, and the center of the rock sample 7 to be tested is aligned with the loading splint 8 in the horizontal Y direction and the loading splint 10 in the horizontal X direction. The center of the loading splint 10 is automatically adjusted by the computer according to the requirements of the experiment. The servo hydraulic system is applied to the three axial directions of the rock sample 7 by the servo hydraulic cylinders 9, 12, and 15. And it can realize the loading of curve loads such as half sine wave, triangular wave, square wave, etc., and realize the test effect of static load and dynamic disturbance load under the triaxial state. The static load-disturbance load schematic diagram of the tested rock sample 7 is as follows image 3 shown.

[0021] In the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com