Drop hammer impact testing machine

A drop hammer impact test and column technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of high labor intensity, time-consuming, low efficiency, etc., and achieve the goal of improving work efficiency, saving test time, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the description of the drawings and the specific embodiments:

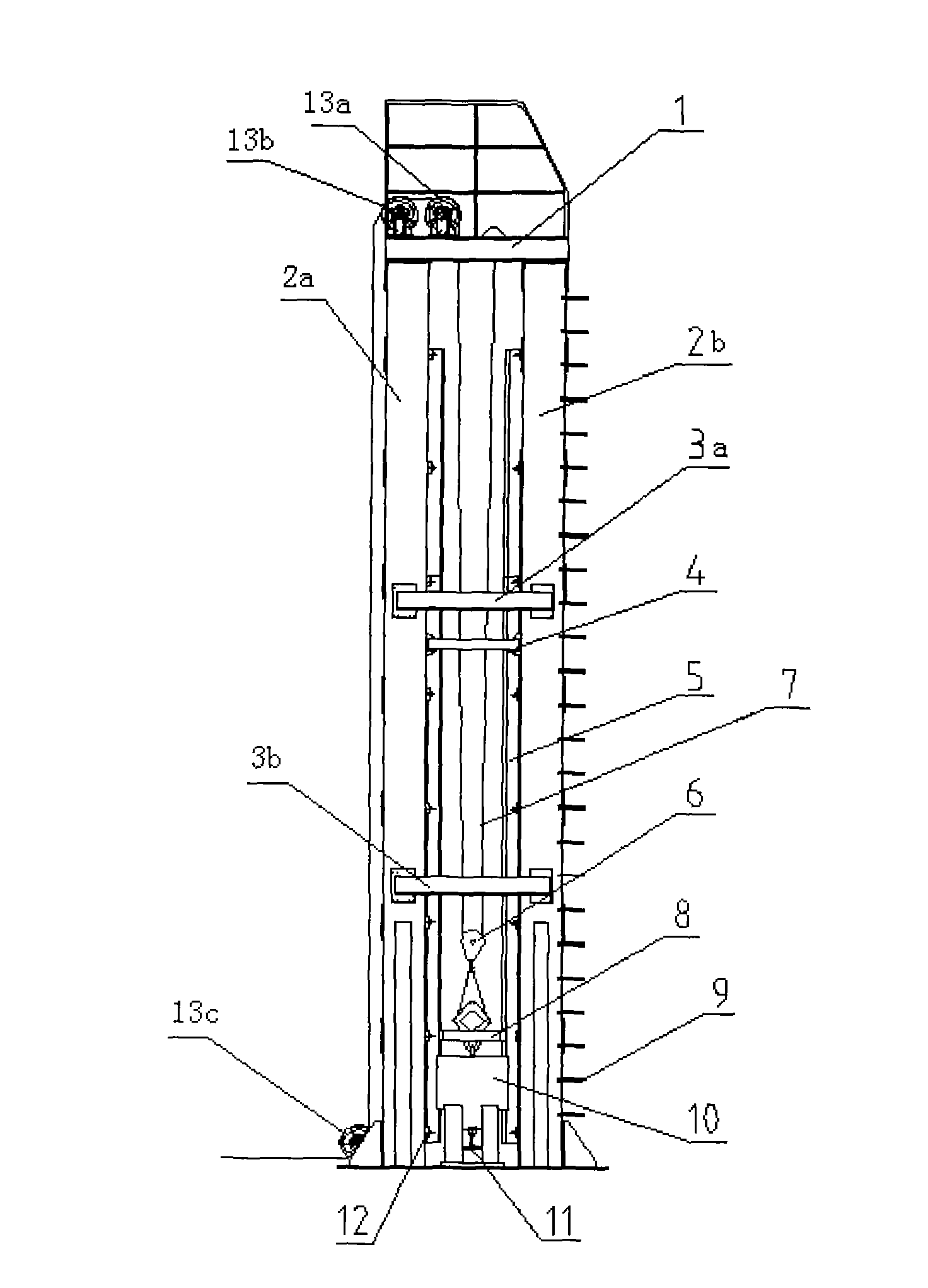

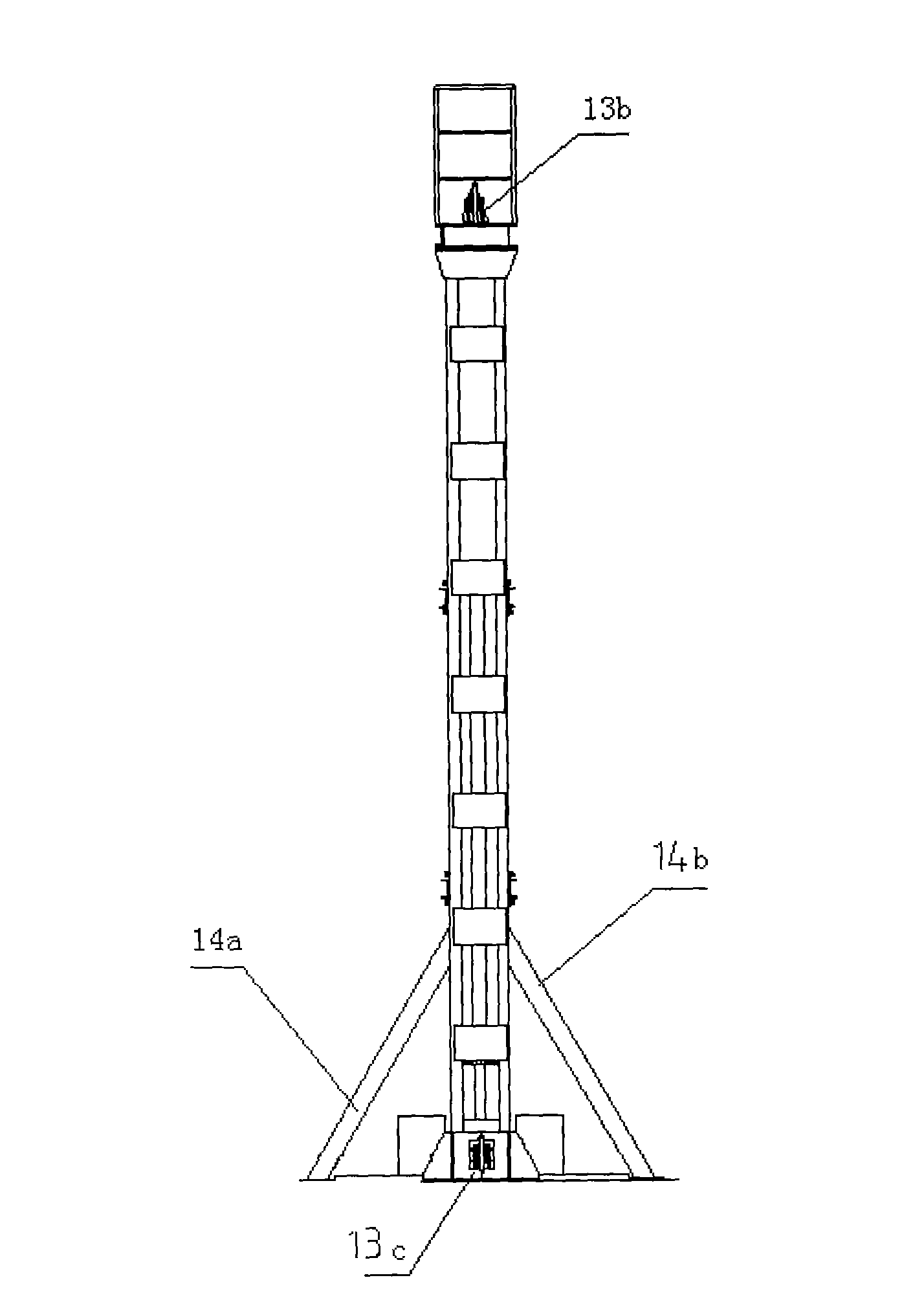

[0025] A drop-weight impact testing machine, including the following components:

[0026] Cross beam 1, first column 2a, second column 2b, first cross brace 3a, second cross brace 3b, iron stop 4, steel rail 5, hook (with insurance card) 6, wire rope 7, grapple device 8, iron Ladder 9, impact hammer 10, rail clamping device 11, pressing plate 12, first pulley 13a, second pulley 13b, third pulley 13c, first support 14a, second support 14b.

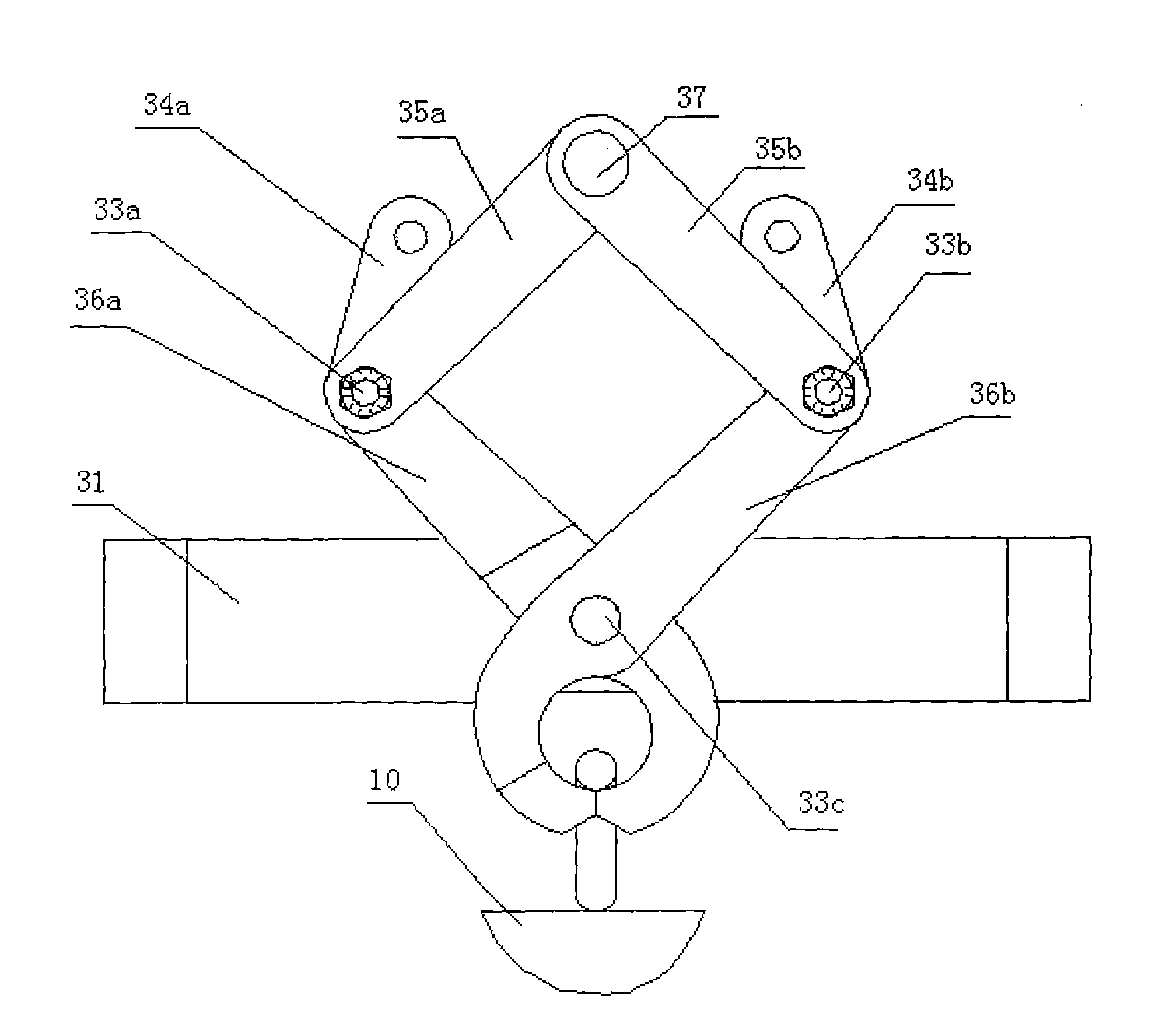

[0027] Among them, the grappling hook device 8 includes:

[0028] Guide frame 31, first shaft 33a, second shaft 33b, third shaft 33c, first hanging plate 34a, second hanging plate 34b, first link 35a, second link 35b, first clamp arm 36a, first The second clamp arm 36b, the block shaft 37.

[0029] The rail clamping device 11 includes:

[0030] The anvil 38, the first stopper 39a, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com