Pneumatic crawler hydraulic jumbo

A hydraulic drilling rig and crawler type technology, applied in rotary drilling rigs, drilling equipment, earth-moving drilling and other directions, can solve the problems of sparks generated by electrical equipment, small rotation angle of drilling rigs and inappropriateness, etc., to avoid electric sparks, reduce The effect of labor intensity, safety and reliability of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention is described in further detail:

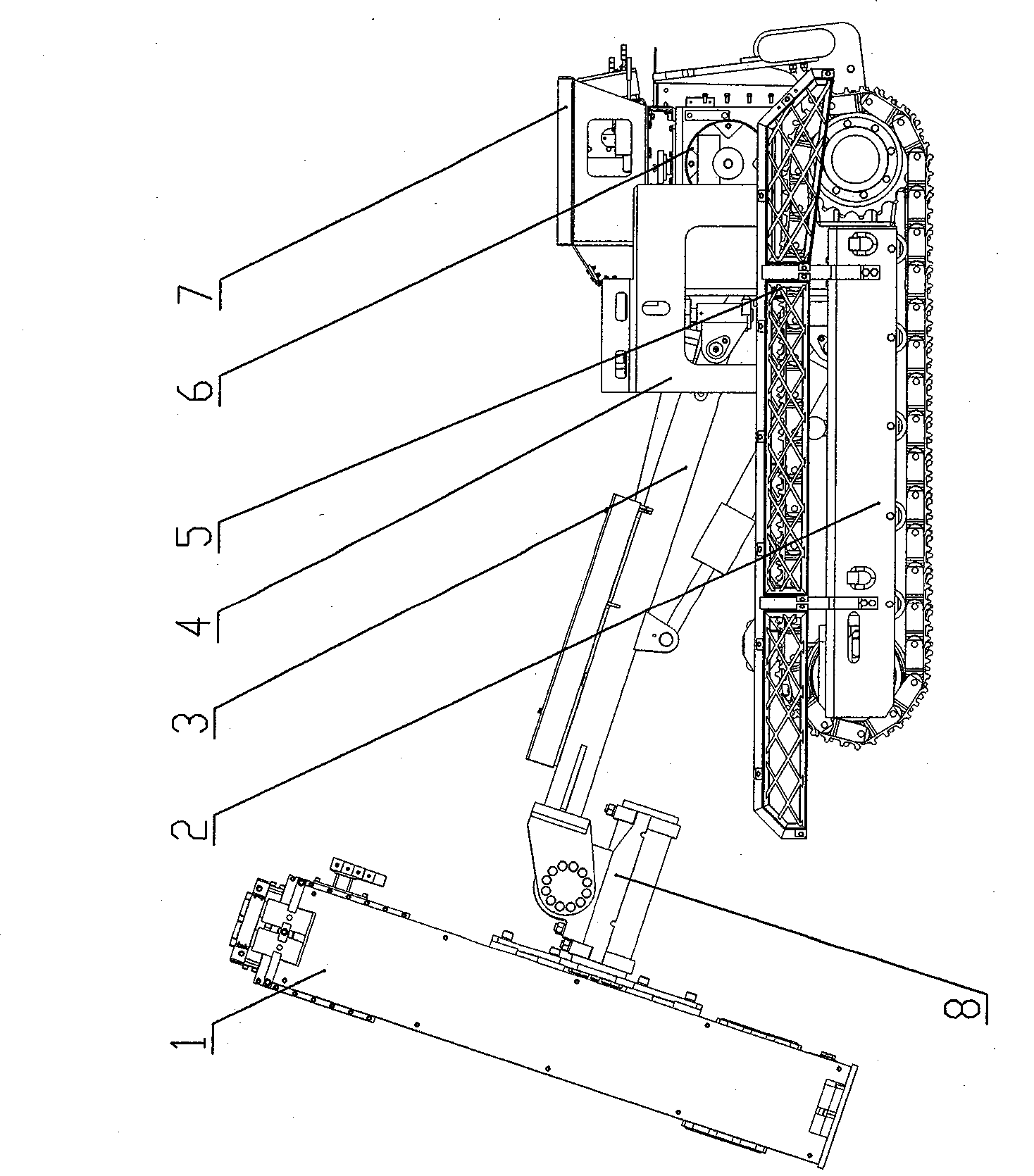

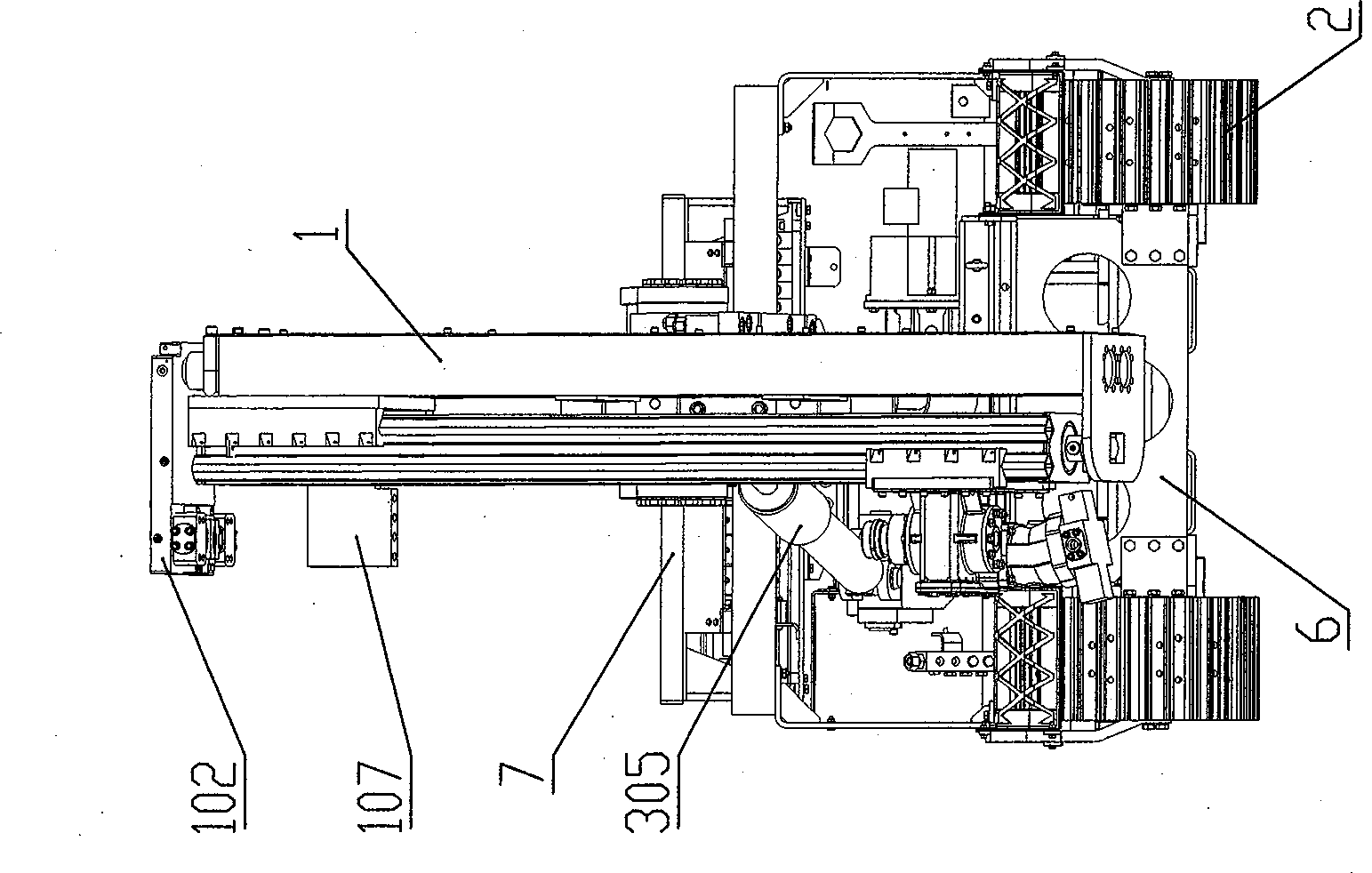

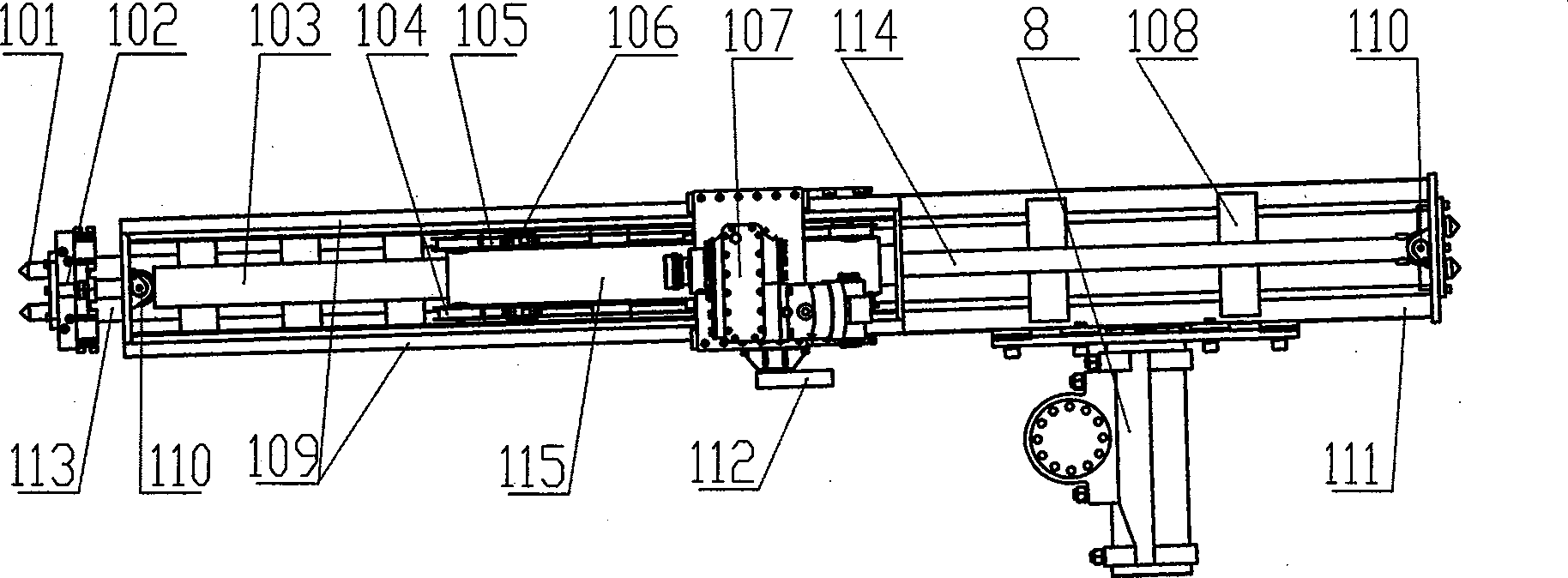

[0047] The pneumatic crawler hydraulic drilling rig of the present invention mainly includes a car body 6, a traveling device 2, a drilling device 1 connected to the car body, a hydraulic system for driving each device, and an operating device. The car body 6 is a central part connecting each part, and it includes a vehicle frame 602 , the two sides of the vehicle frame 602 are crawler belt connecting plates 601 , and the crawler type running gear is connected on the crawler belt connecting plates 601 . A hydraulic system and an operating device are installed on the vehicle frame 602 . The hydraulic system includes various hydraulic control valves and an oil tank 610. The oil tank 610 is provided with a motor connection plate 611. The motor connection plate 611 is connected to the air motor 626 and the hydraulic pump in the oil tank 610. The air motor 626 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com