Methods and Apparatus for Wireline Drilling On Coiled Tubing

a wireline and wireline technology, applied in the direction of drilling drives, drilling pipes, borehole/well accessories, etc., can solve the problems of low efficiency in the conversion of hydraulic power to drilling footage, limited reach of ct drilling, etc., and achieve the effect of improving the transportation of cuttings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

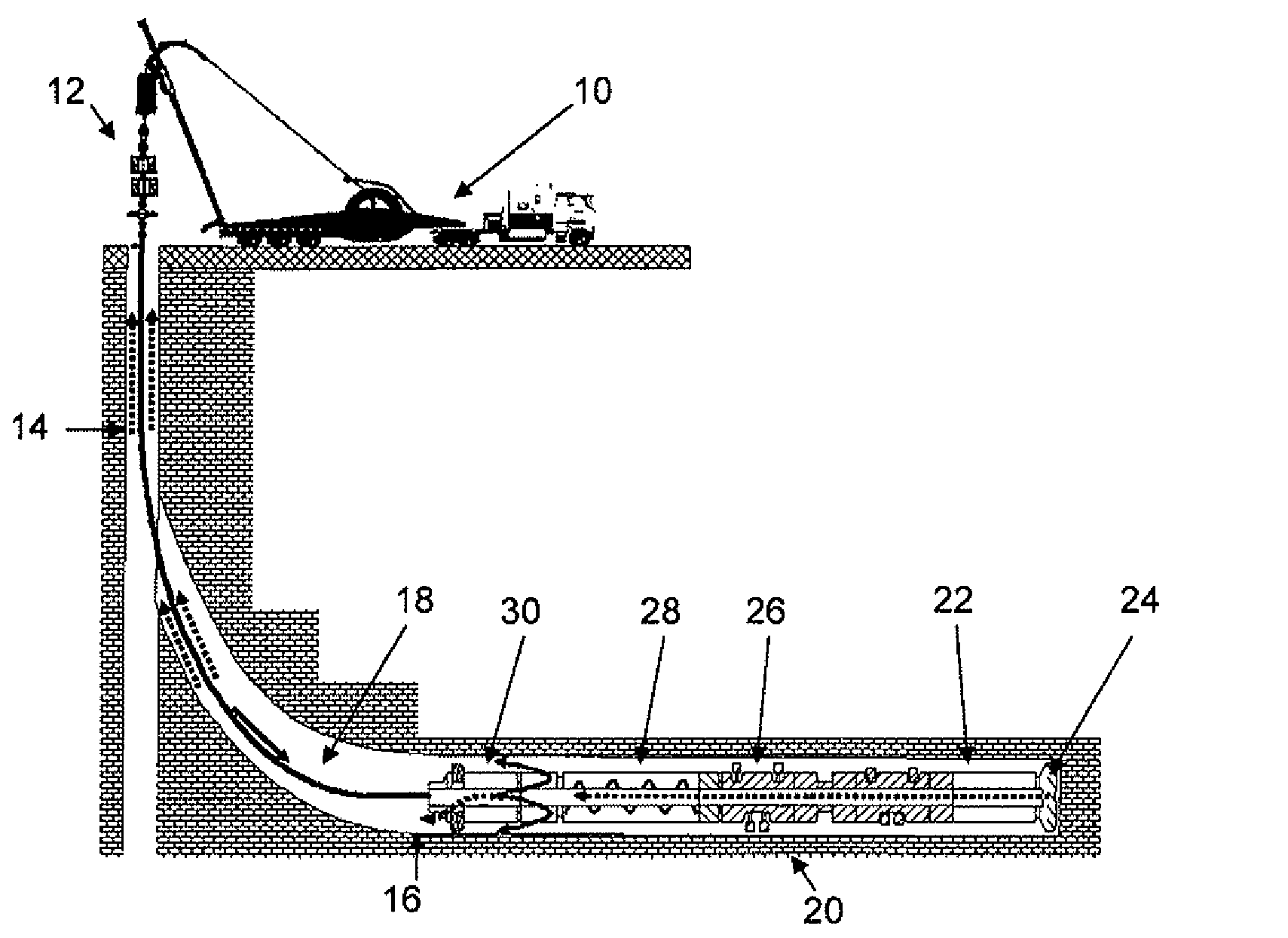

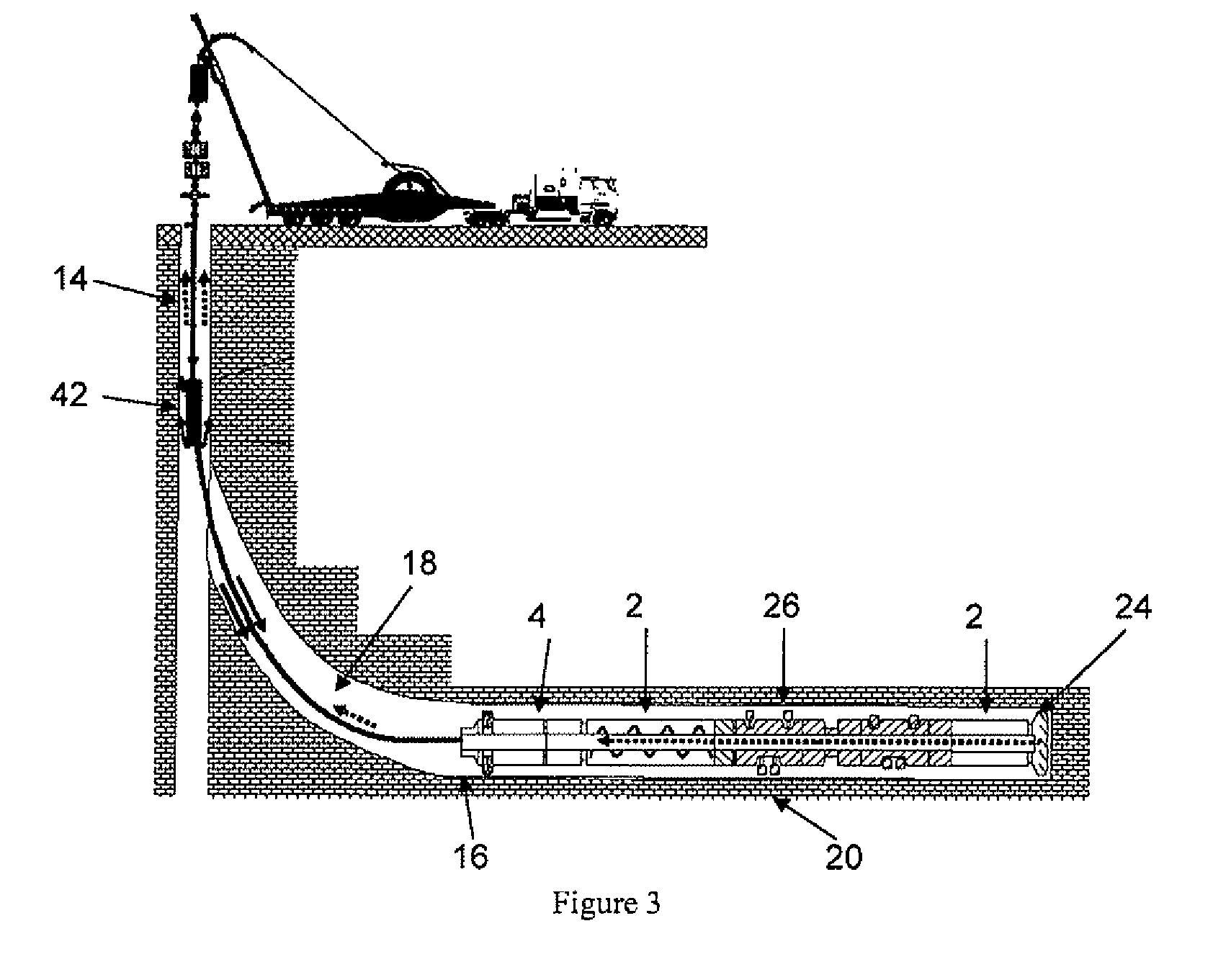

[0036]The drilling operation shown in FIG. 1 is conducted using a conventional CT unit 10 and injector / pressure control setup 12 at the surface of the well 14 and is being used to drill a lateral well 16 extending away from the main well 14. The lateral well 16 has been started in the usual manner by milling a window in the casing and drilling laterally using a whipstock to provide deviation in drilling direction. The drilling apparatus comprises a CT conveyance system 18 carrying a drilling assembly 20 at its lower end. The conveyance system 18 comprises a CT having an electric cable running inside from the surface. The weight of the tool is carried by the CT 18, so the electric cable only needs to be able to support its weight. A drilling fluid supply forms part of the CT unit 10 at the surface and pumps drilling fluid down the inside of the CT.

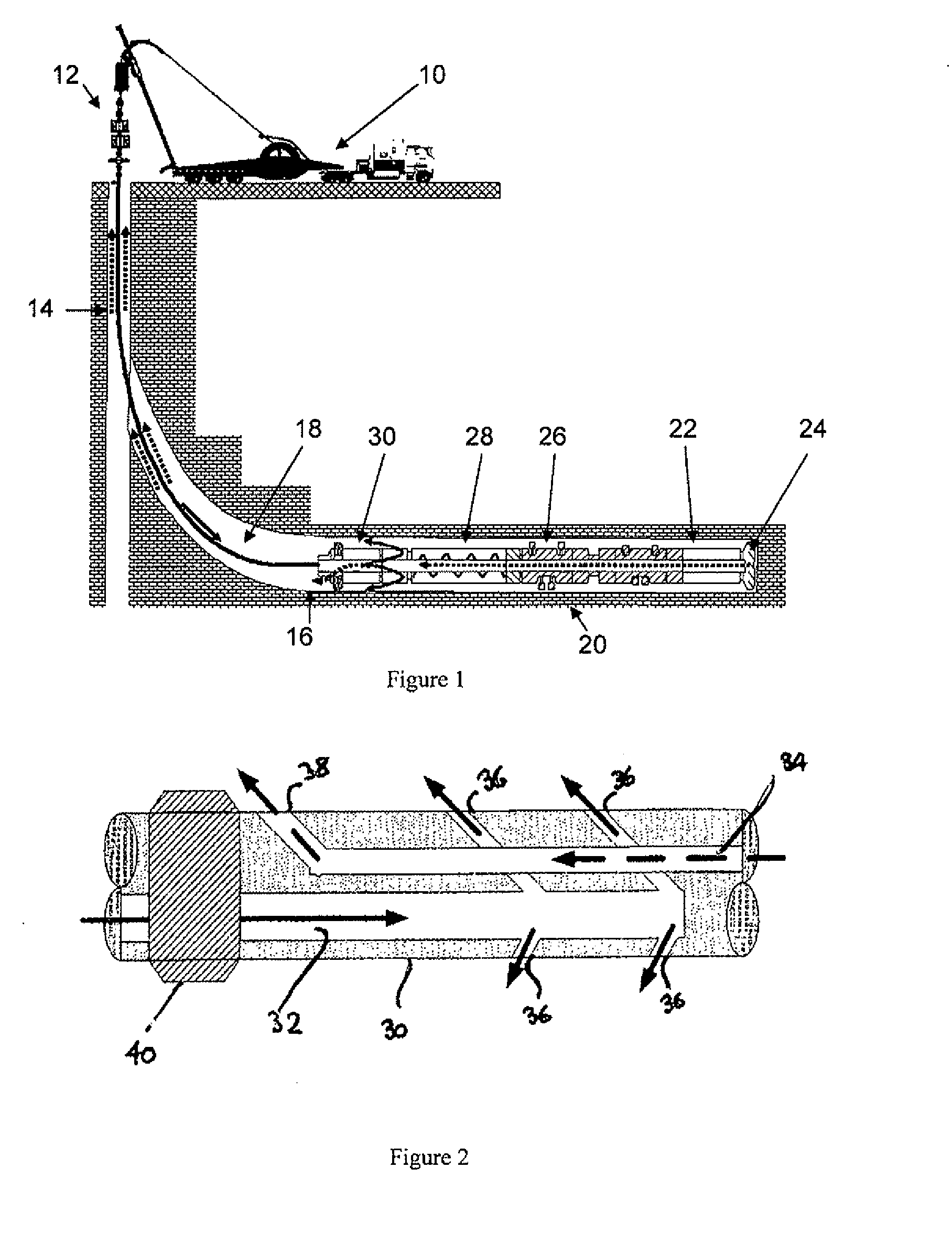

[0037]The drilling assembly 20 comprises a motor section 22 including an electric motor providing rotary drive to a drill bit 24. Immediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com