Impact screw drilling tool

A screw drilling tool and percussion technology, which is applied in the direction of drilling tools, drilling equipment, earthwork drilling, etc., can solve the problems of easy damage and short service life of cutting teeth, and achieve the effect of improving service life, improving efficiency and realizing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

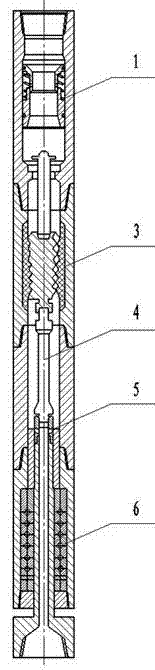

[0070] like figure 1 As shown, the impact screw drilling tool includes a bypass valve assembly 1, a motor assembly 3, a cardan shaft assembly 4 and a drive shaft assembly 6 connected in sequence, wherein the bypass valve assembly is mainly composed of a valve body , valve core, spring and sieve plate, the motor assembly is mainly composed of the stator housing and the rotor, the cardan shaft assembly is mainly composed of the cardan shaft housing and the cardan shaft, and the transmission shaft assembly is mainly composed of the transmission shaft housing , a hollow transmission shaft, a thrust bearing group and a radial bearing group; a flow adjustment assembly 5 is arranged between the transmission shaft assembly 6 and the cardan shaft assembly 4, and the upper end of the flow adjustment assembly is in contact with the universal joint The shaft is connected, and the lower end is connected with the transmission shaft.

[0071] like figure 2 and image 3 As shown, the flow...

Embodiment 2

[0074] like Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that a hydraulic pressurization assembly 2 is provided between the bypass valve assembly 1 and the motor assembly 3, and the hydraulic pressurization assembly is in the form of the upward movement of the piston, mainly composed of a hollow Mandrel 21, upper and lower shell 22, sealing ring 23, disc spring group 24 and pipe plug 25; the upper end of the mandrel is threaded and the lower end of the bypass valve assembly is threaded, and the lower part is located in the shell and the middle Cooperate with the inner side of the upper part of the shell, there is a shoulder between the lower part and the middle part outside the mandrel, and the wall thickness of the lower part is 1 / 3~1 / 2 of the wall thickness of the middle part, and the lower end is connected with the pipe plug through threads, and the disc spring assembly The lower part of the mandrel is sleeved between the pip...

Embodiment 3

[0077] like Image 6 As shown, the difference between this embodiment and embodiment 2 is that the hydraulic pressurization assembly 2 is arranged on the upper end of the bypass valve assembly 1, the lower end of the casing is connected with the upper end of the bypass valve assembly through threads, and the thread at the upper end of the mandrel is used for Connect with external agencies. This setting method is used for deep drilling. Since the position of the hydraulic pressurization assembly is high, it can reduce the impact of the damaged rock formation on it, and increase the impact force generated by the drilling fluid in the screw drilling tool, and then Improve the rock-breaking effect and prolong the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com