Multidirectional hydraulic rock drilling machine with integrated drives

A technology that integrates driving and rock drilling rigs. It is used in earth-moving drilling, driving devices for rotary combined drilling, drill pipes, etc. It can solve the problems of small drilling operation range and poor adaptability of the working surface, and achieve compact structure and use. Low maintenance cost and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

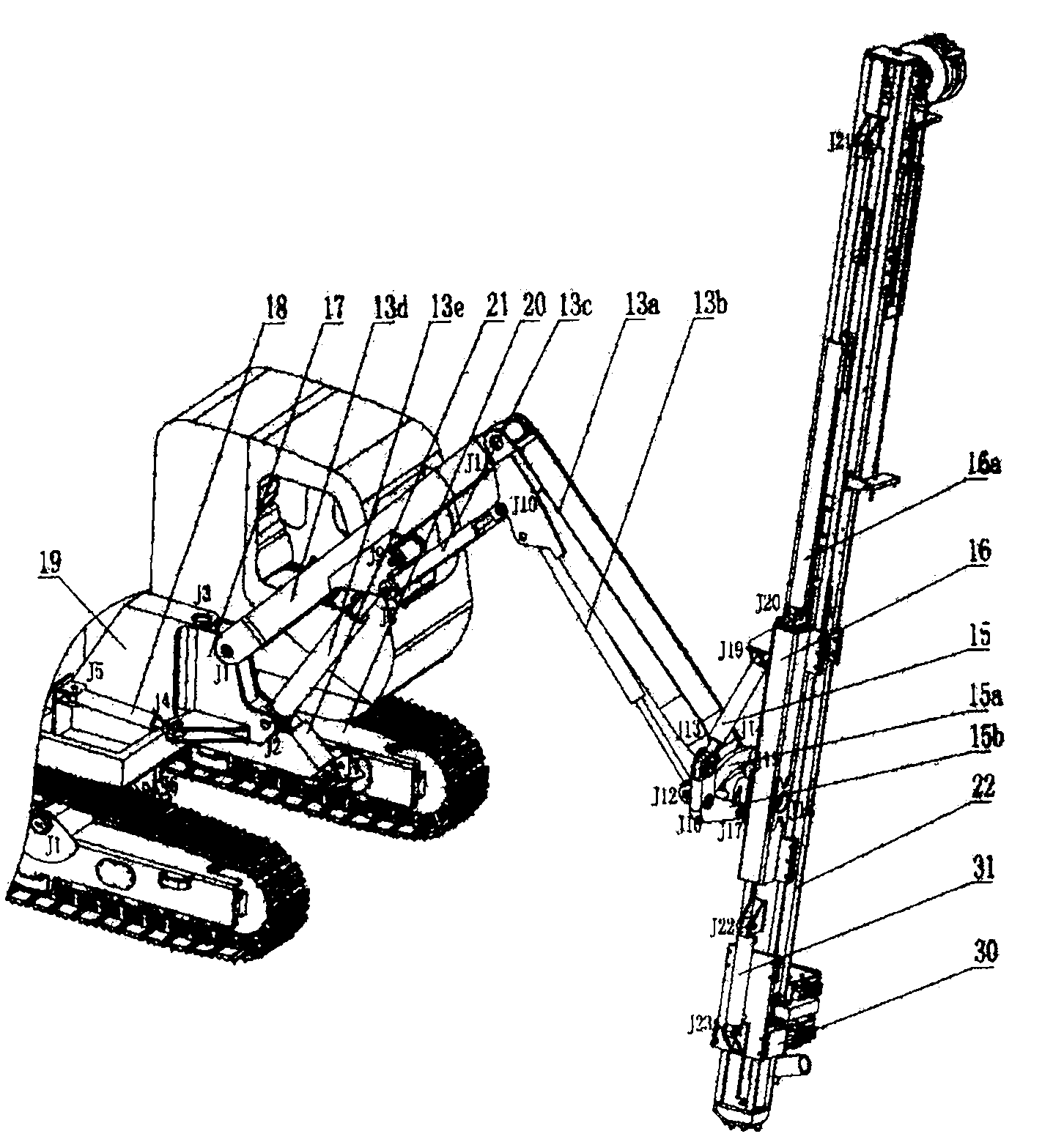

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

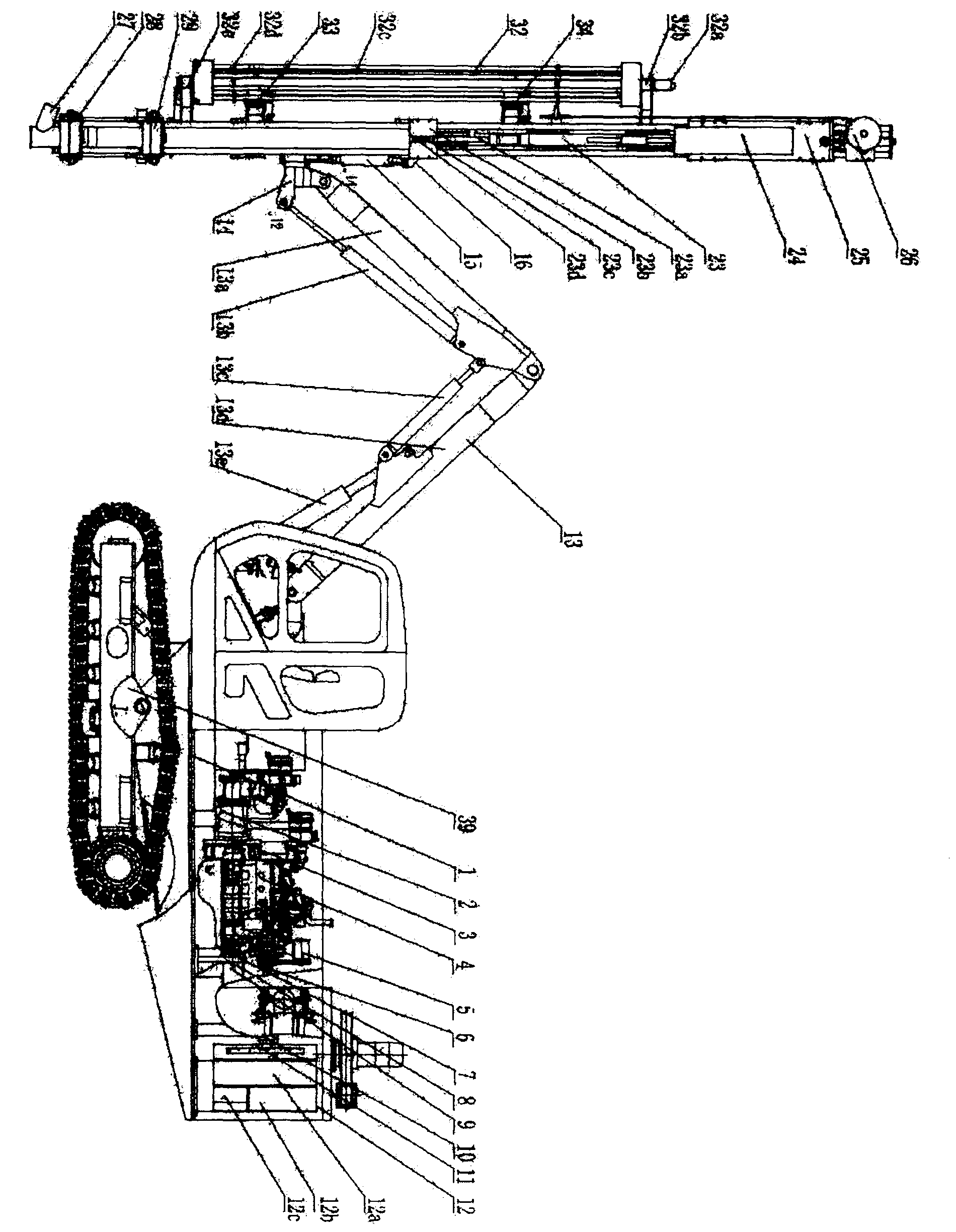

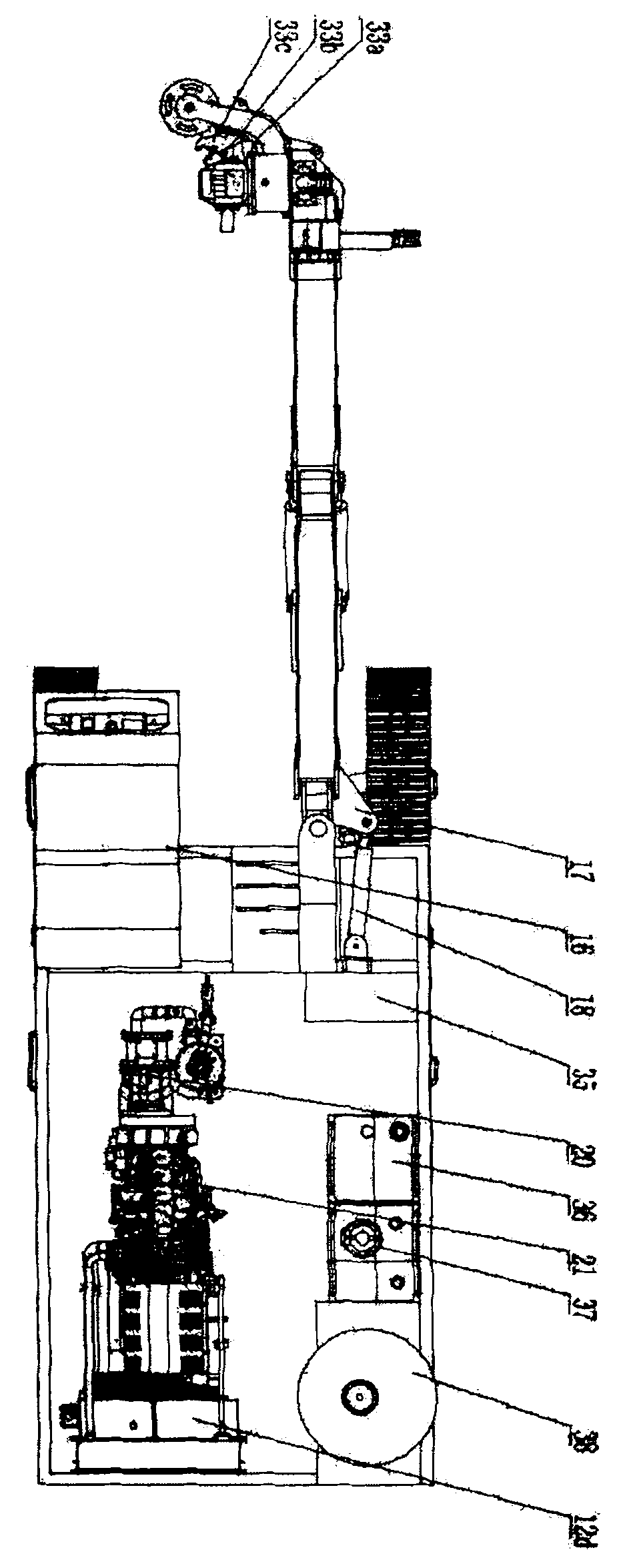

[0030] see figure 1 and figure 2 The integrated drive multi-directional hydraulic rock drilling rig, the engine 4 is installed on the frame 1, the air compressor 2 is installed on the flywheel housing of the engine, and is connected with the main shaft of the engine 4 through the coupling 3, and the hydraulic pump group 9 is installed on the rear support of the engine On the seat 8, it is connected to one end of the main shaft of the engine 4 through a coupling 7; the fan blade 10 of the integrated radiator 12 (including the engine radiator 12a, the air compressor radiator 12b, the air conditioner radiator 12c, and the hydraulic oil radiator 12d) Connect with the output shaft of the engine through the coupling 6, and the fan end of the couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com