Rotary impact type rock drilling machine and double-layer drilling rod mechanism

A technology of rock drilling rig and double-layer drill pipe, which is applied in the direction of impact drilling, reciprocating drilling rig, drill pipe, etc. The effect of shock energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

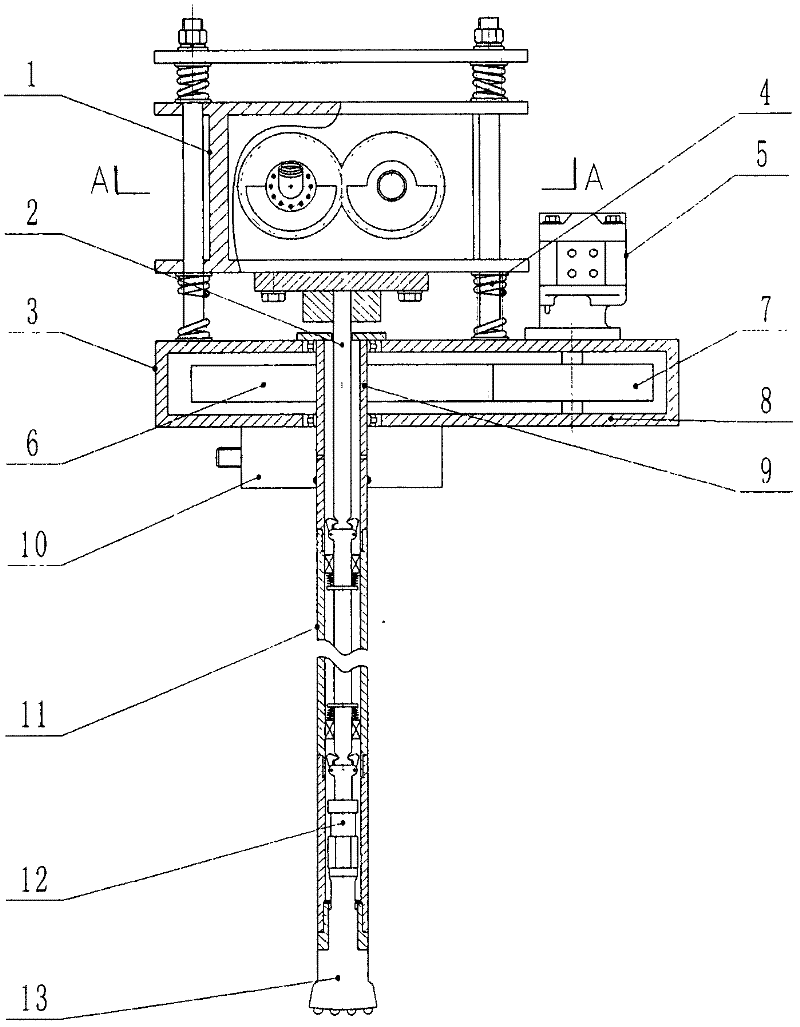

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

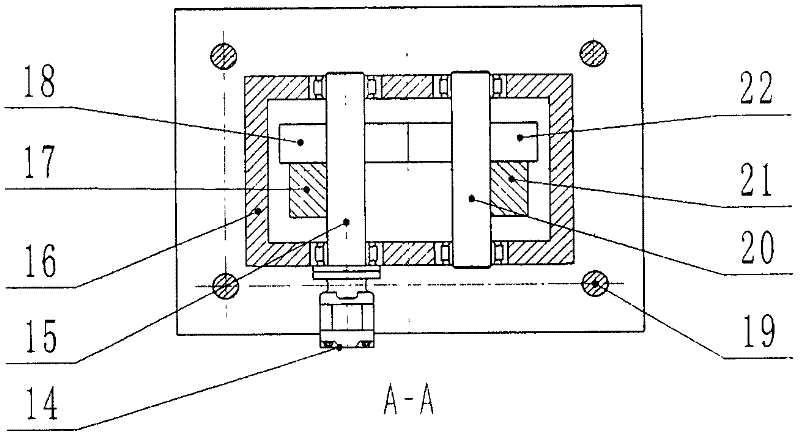

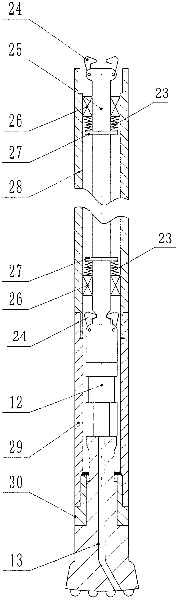

[0016] The vibration excitation mechanism 1 adopted in the present invention can adopt the impact mechanism involved in the Chinese patent application number 201010596120.4 and the title of the invention "a kind of impact hydraulic rock drill". The vibration mechanism 1 adopted in this embodiment consists of a first hydraulic motor 14, an excitation box 16, a first active eccentric shaft 15, a first driving gear 18, a first driven gear 22, a first eccentric block 17, a second The eccentric block 21, the second eccentric shaft 20 and the connecting rod 2 are formed, and two or four or more paired eccentric shafts and eccentric blocks can also be installed as required. In the excitation mechanism, two identical eccentric shafts are arranged side by side on the excitation box to form an eccentric group. The same eccentric block and gear are installed on the eccentric shaft. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com