Bionic bulletproof insert plate capable of changing direction of bullet

A bionic bulletproof and plug-in technology, used in protective equipment, armor plate structure, offensive equipment, etc., can solve the problems of heavy overall weight and poor protective performance, reduce damage, reduce impact force and speed, and facilitate consumption. scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

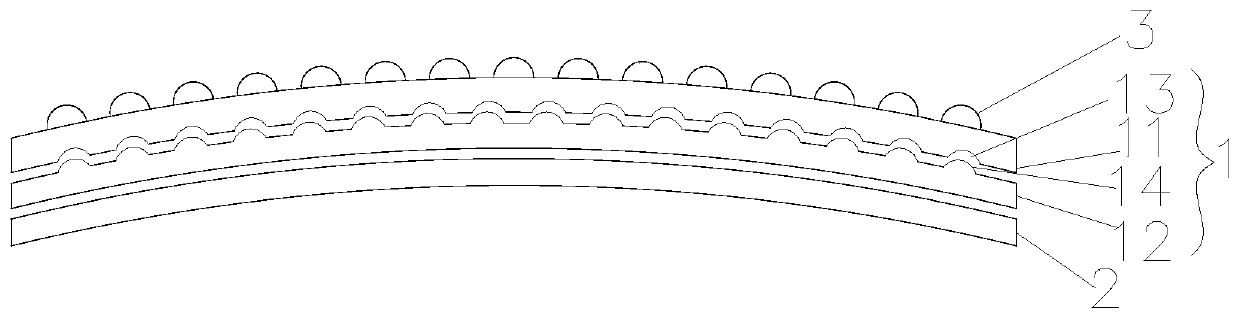

[0032] Such as Figure 1-3 As shown in the figure, a bionic bullet-proof board that can change the direction of the warhead includes an upper board 1 made of hard ceramics and a lower board 2 made of high-performance fibers;

[0033] In this embodiment, the dimensions of the upper plate 1 and the lower plate 2 are both 250mm*300mm, and the material of the upper plate 1 is hard ceramics, and the hard ceramics are aluminum oxide, boron carbide or silicon carbide. One, wherein boron carbide has the best performance in all aspects, but the price of boron carbide is very expensive, while the price of silicon carbide is relatively moderate, and its density and hardness are not much different from boron carbide, so the upper layer in this embodiment adopts Made of silicon carbide ceramics. The strength of the silicon carbide ceramic plate is very large, and it will be broken instantly when it is hit by a bullet. It relies on the cracks generated by the fragmentation to disperse the ...

Embodiment 2

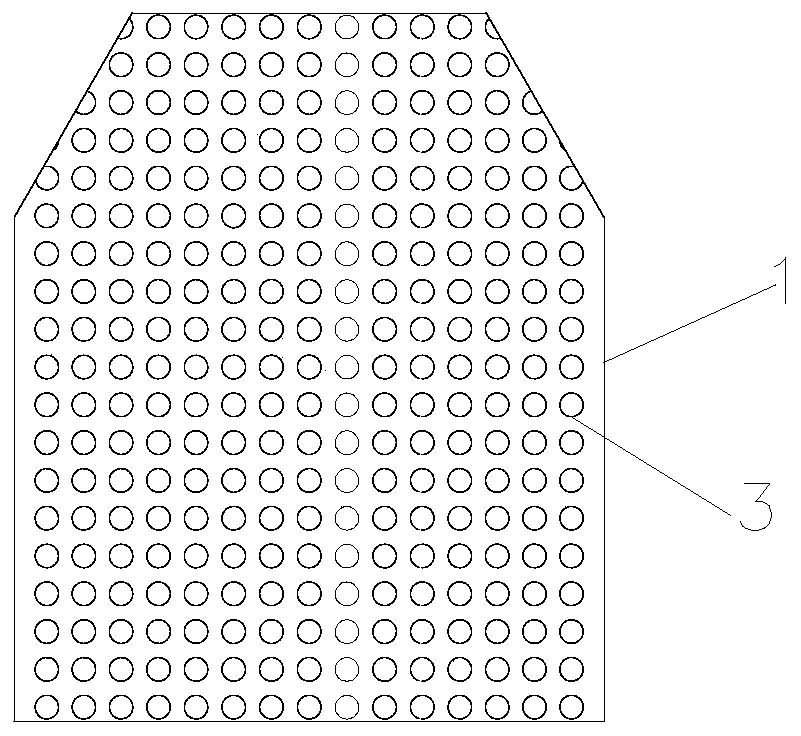

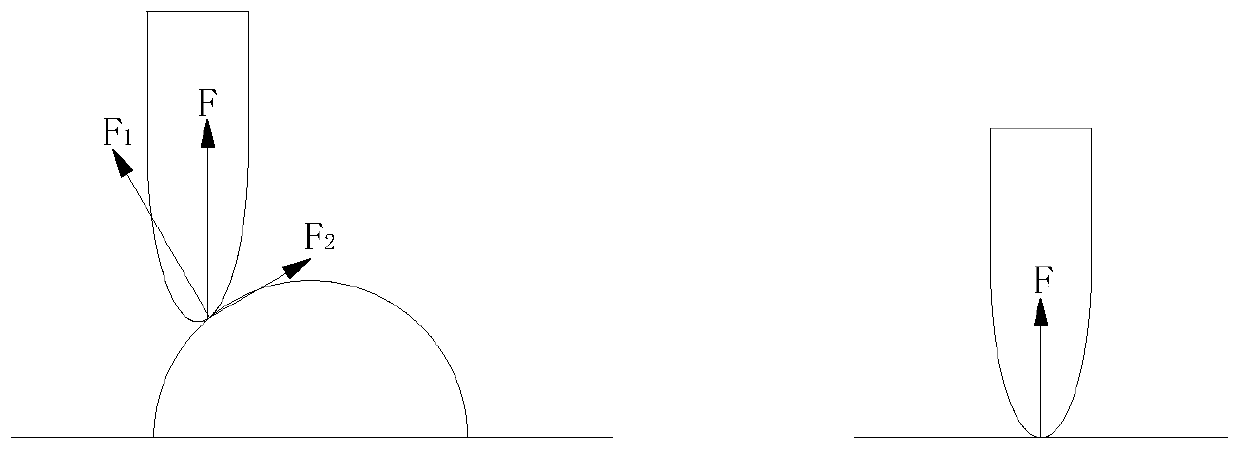

[0050] The shape of the first convex hull 3 is a hemisphere, the side of the upper plate 1 away from the lower plate 2 is the upper surface, and the radius of the first convex hull 3 is 4mm; the upper surface of the upper plate 1 The first convex hull 3 changes the angle of incidence of bullets injected into the bulletproof plate, reducing the impact of bullets on the plate. The size of the first convex hull 3 has a direct impact on the angle of incidence of the bullet. The first convex hull 3 is too large or too small relative to the caliber of the bullet, which is not conducive to the direction change of the bullet. Multiple first convex hulls 3 are arranged in a rectangular array. , the gap between adjacent first convex hulls 3 is 2 mm; the gap between adjacent first convex hulls 3 should be smaller than the caliber of bullets, which can effectively prevent bullets from entering the board from the gap.

[0051] Wherein, the second convex hull 14 is a one-third sphere, and t...

Embodiment 3

[0054] The shape of the first convex hull 3 is a hemisphere, the side of the upper plate 1 away from the lower plate 2 is the upper surface, and the radius of the first convex hull 3 is 6 mm; the upper surface of the upper plate 1 The first convex hull 3 changes the angle of incidence of bullets injected into the bulletproof plate, reducing the impact of bullets on the plate. The size of the first convex hull 3 has a direct impact on the angle of incidence of the bullet. The first convex hull 3 is too large or too small relative to the caliber of the bullet, which is not conducive to the direction change of the bullet. Multiple first convex hulls 3 are arranged in a rectangular array. , the gap between adjacent first convex hulls 3 is 2 mm; the gap between adjacent first convex hulls 3 should be smaller than the caliber of bullets, which can effectively prevent bullets from entering the board from the gap.

[0055] Wherein, the second convex hull 14 is one-third of a sphere, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com