Combined directional and impact drilling motor

a directional drilling and impact technology, applied in the direction of directional drilling, earth drilling, drilling machines and methods, etc., can solve the problems of limited access to the benefits of directional drilling, unsuitable or too expensive rotor-stator technology for air hammer drilling tools, and limited access to directional drilling by the air hammer drilling industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Before explaining the disclosed embodiment of the present invention in detail it is to be understood that the invention is not limited in its application to the details of the particular arrangement shown, since the invention is capable of other embodiments. Also, the terminology used herein is for the purpose of description and not of limitation.

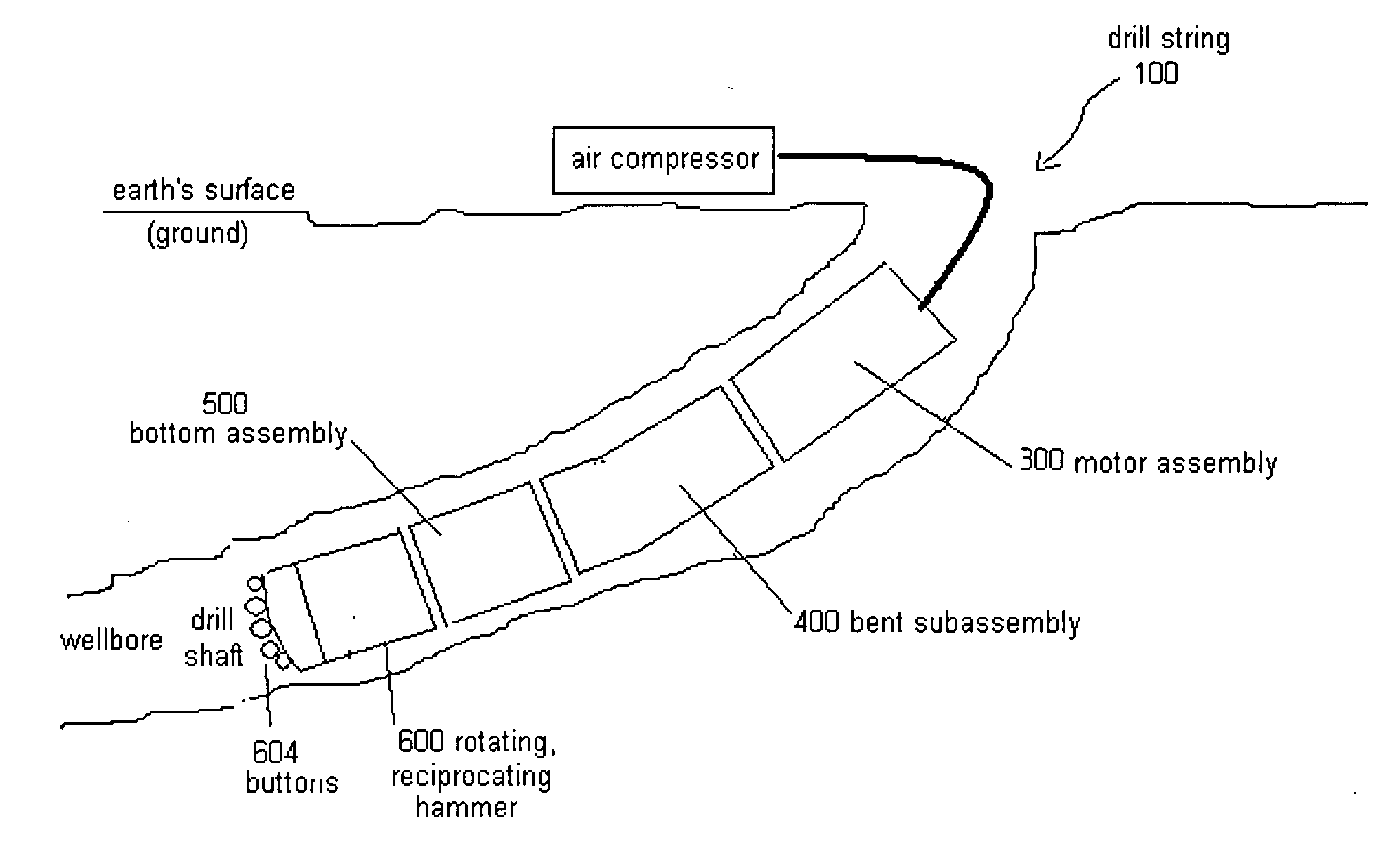

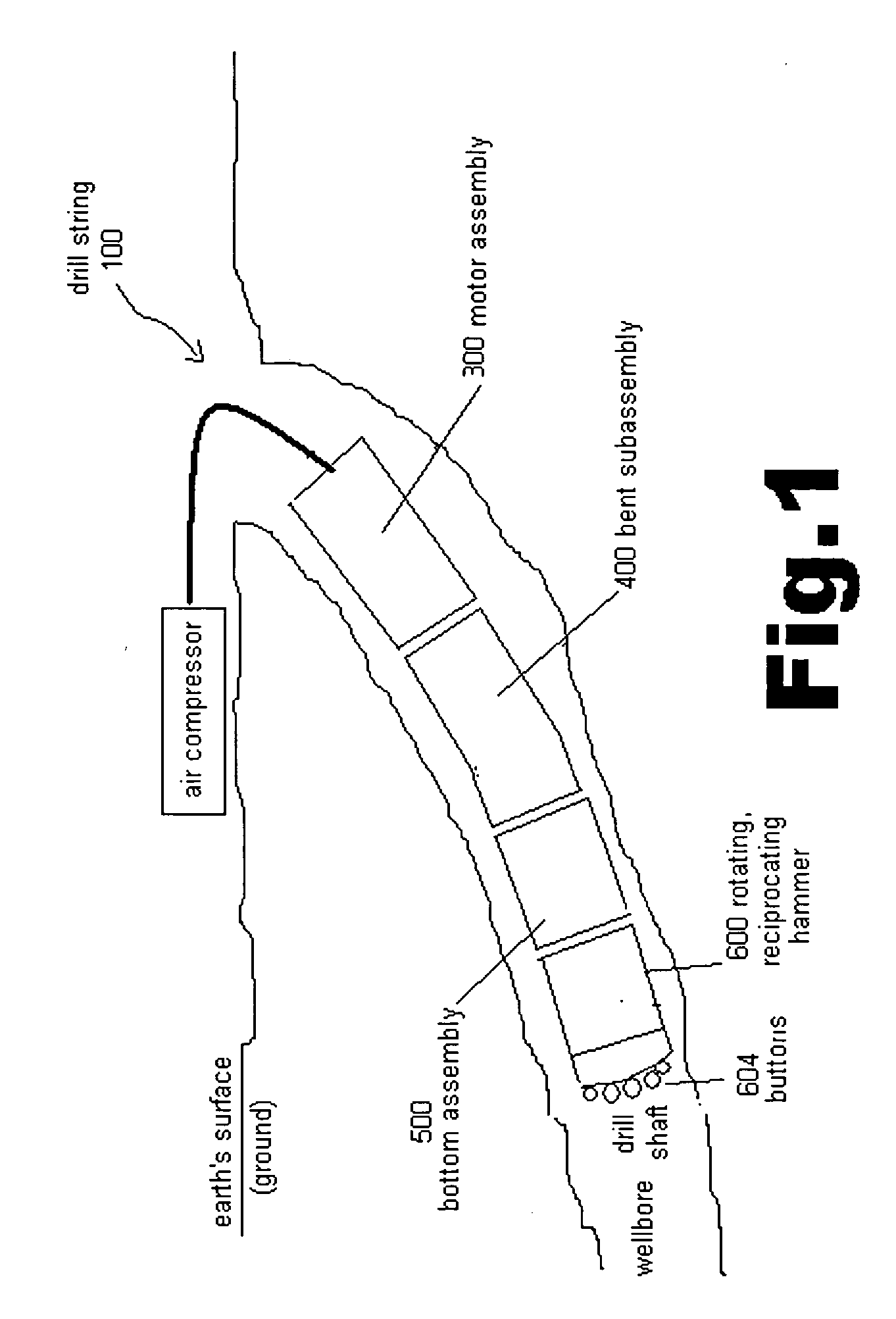

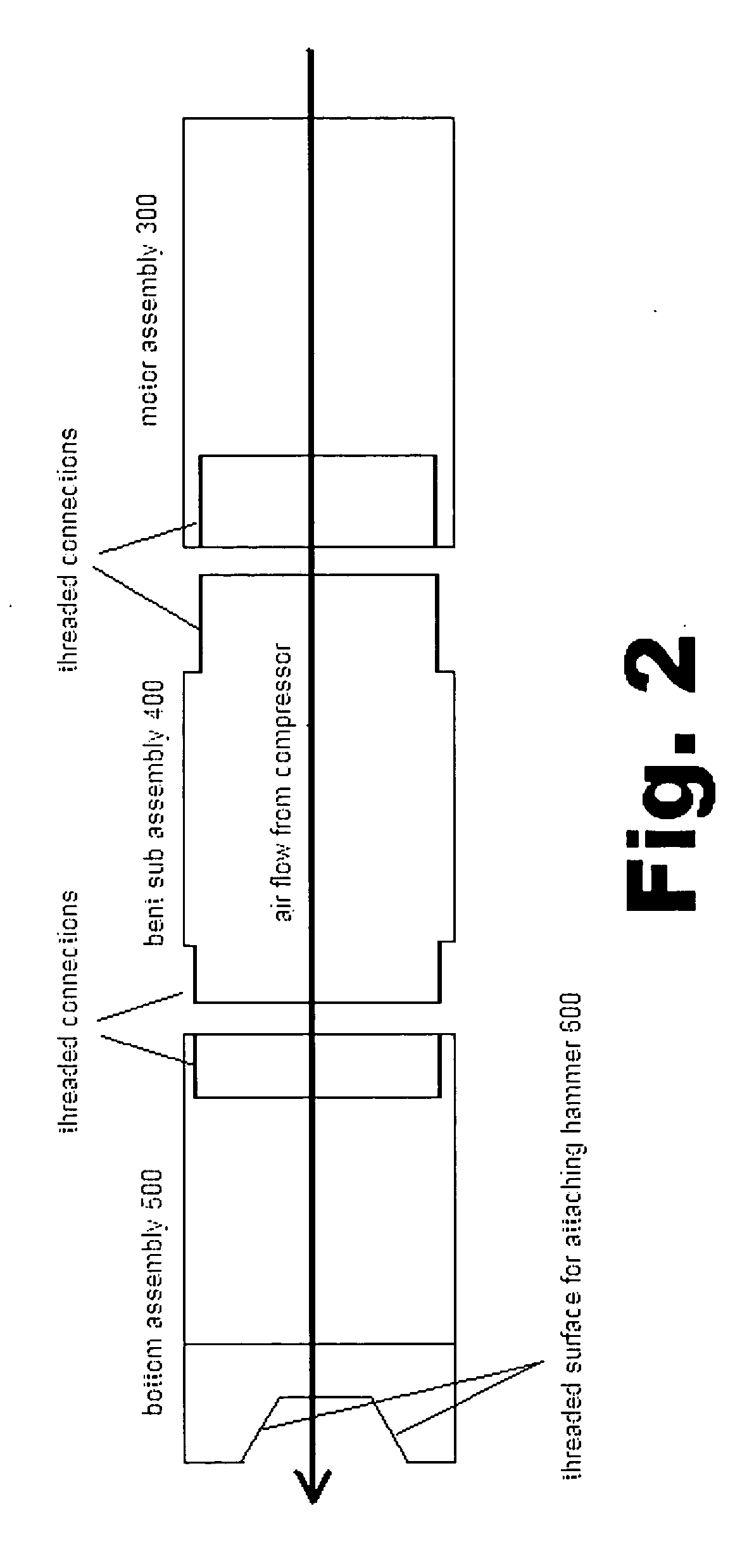

[0013] The present invention uses standard air hammer drilling tools and utilizes them in the directional drilling process. Existing hammer tools can be used without modification. In addition, the present invention generates enough torque to use conventional drill bits in some applications. The present invention achieves this by operating a drilling motor rotation device that uses compressed air from an above-ground compressor to rotate down-hole percussive or hammer drills in oil and gas well drilling, or other down-hole drilling applications.

[0014] As will be shown in more detail below, the present invention incorporates a commer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com