High temperature resistance lubrication mold release agent for glassware molding

A glassware and high temperature resistant technology, applied in the field of high temperature resistant release agent compositions, can solve the problems of poor adhesion, poor lubricity of metal molds, and many times of brushing, and achieve good high temperature resistance and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

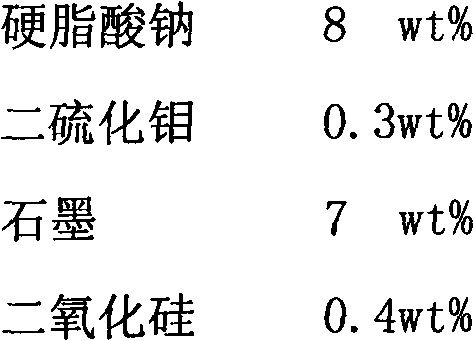

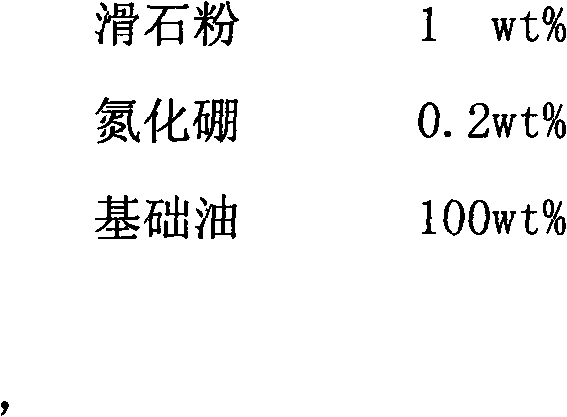

[0020] Example: Release agent composition for glassware molding

[0021] The first choice is to prepare the base oil of the release agent for glassware molding of the present invention. In a blending kettle with a stirrer, add 45wt% refined castor oil and 55wt% refined mineral oil, and add 3wt% viscosity index improver polyisoprene ethylene copolymer, stirred at 60-70°C for 1-2 hours to obtain the base oil of the present invention, and then blend the composition according to the following formula.

[0022]

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com