Track component and assembly method for constituting track

A crawler and crawler chain technology, applied in the field of conveying and transmission, can solve the problems of hidden safety hazards at the connection, unstable connection method, increased interference, etc., and achieve the effect of improving assembly accuracy and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

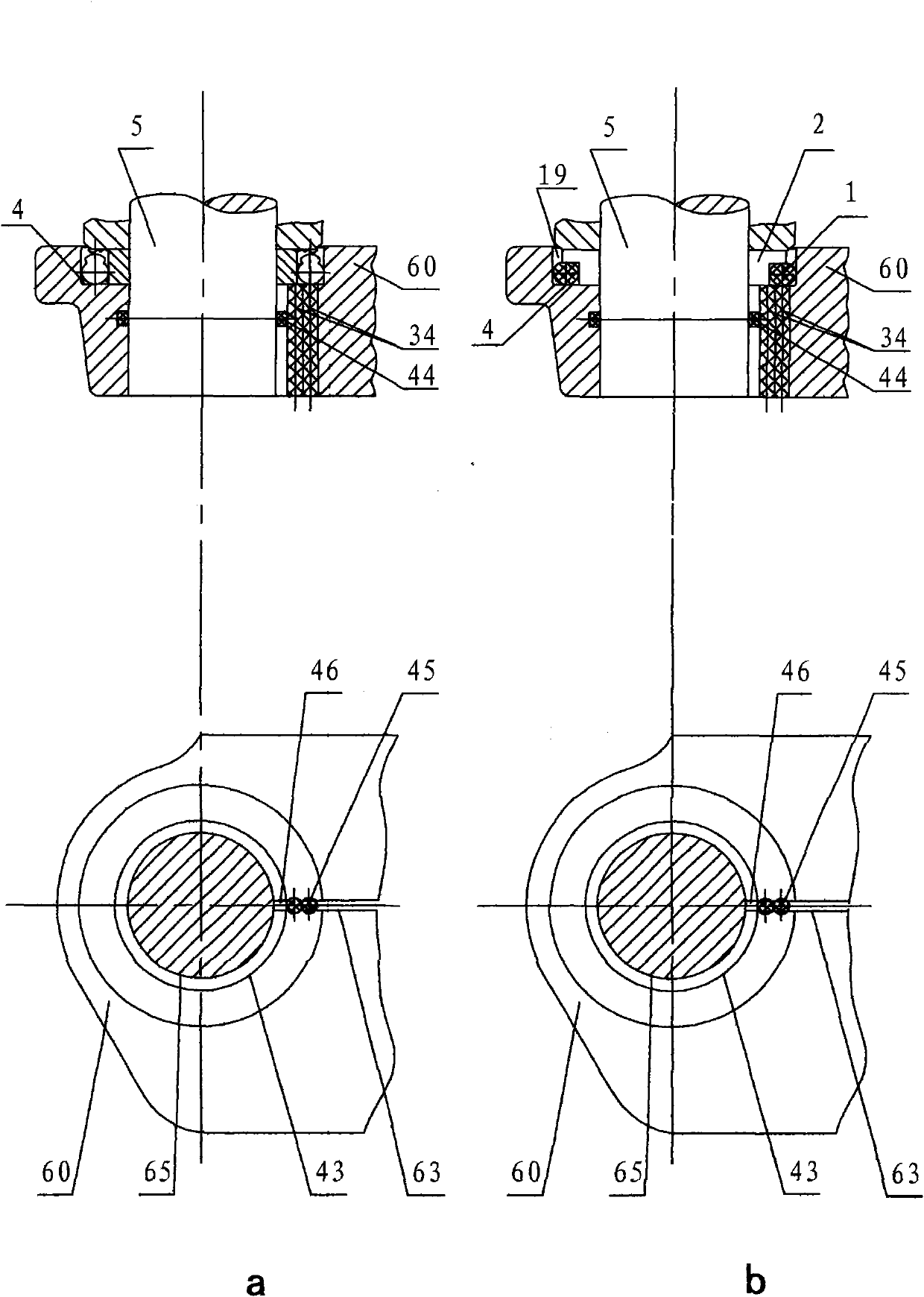

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0065] See figure 2 , the crawler pin sleeve 6 press-fit working surface and the crawler track chain link 8 press-fit the outer chamfered cone front section without any damage, and the only usable part of the inner dustproof is just on the pin sleeve 6 outer chamfered cone surface. Therefore, the outer chamfer of the end surface of the pin sleeve 6 is ≤45°, and the outer chamfer surface is a straight line segment, and a small rounded transition is used at both ends of the straight line segment to facilitate assembly. The end surface of the pin sleeve 6, the outer chamfer surface of the end surface is in contact with the seal, and the roughness Ra value is 0.4. The perpendicularity between the end surface of the pin sleeve 6 and the center line of the hole affects the sealing of the lubricating track, and the value should be controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com