Rolling bearing lubricating method and device

A technology for rolling bearings and lubricating devices, which is applied in the direction of engine lubrication, bearing components, shafts and bearings, and can solve problems such as increased stirring resistance and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

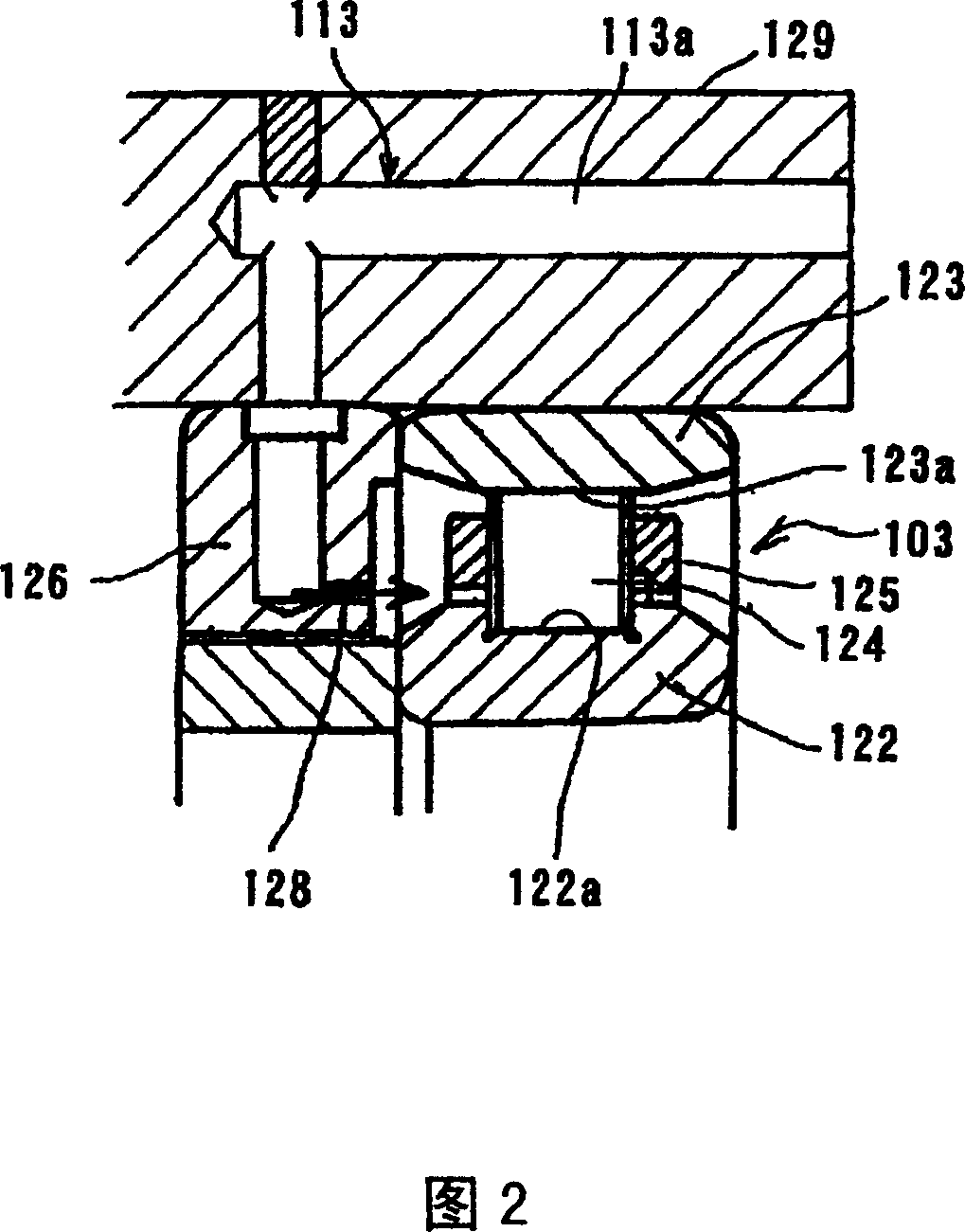

[0085] The method for lubricating a rolling bearing according to the first embodiment of the present invention will be described with reference to FIG. 1 and FIG. 2 . FIG. 1 shows the outline structure of a lubricating device used in this rolling bearing lubricating method. This lubricating device includes a lubricating oil supply mechanism 101 and a supply amount changing mechanism 102 . This lubricating oil supply mechanism 101 is a mechanism for supplying lubricating oil during operation of the rolling bearing 103 . The supply amount changing mechanism 102 is a mechanism for changing the supply amount of lubricating oil from the lubricating oil supply mechanism 101 in accordance with set conditions during the operation of the rolling bearing 103 .

[0086] The lubricating oil supply mechanism 101 intermittently injects air oil to the rolling bearing 103, and is configured as follows. The lubricating oil supply mechanism 101 includes a pump 105, which pressurizes the lubri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com