Filled 0-degree carbon fiber prepreg preforming tooling and preforming process

A carbon fiber prepreg and preforming technology, applied in the field of composite material forming, can solve problems such as the influence of the strength and mechanical properties of the long truss, the bending deformation of the fiber, and the uncontrollable shape of the blank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

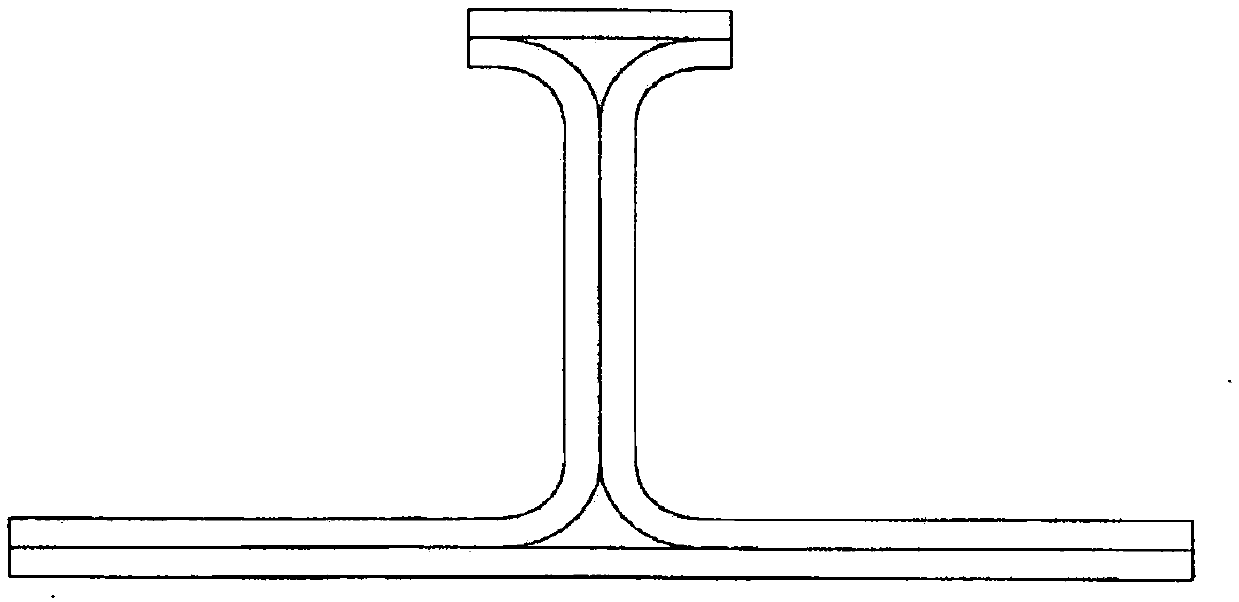

[0018] See attached figure 1 , the figure shows a typical I-shaped long truss structure made of composite materials, with figure 2 It shows the manufacturing components of the I-shaped long truss made of composite materials, and the filling 0° carbon fiber prepreg 1 is rolled on the heating platform according to the previous process method;

[0019] see image 3 In order to calculate the amount of carbon fiber prepreg filled with 0°, the following formula is used for calculation:

[0020] b=[2r*r-(πr 2 / 2)] / h

[0021] b is the width of a single layer of prepreg;

[0022] r is the outer R angle of the stringer;

[0023] π is a constant;

[0024] h is the cured thickness of a single layer of prepreg.

[0025] see Figure 4 , is the form of preforming tooling for filling 0° carbon fiber prepreg material, including forming press plate 2, forming mandrel 3, base plate 4 and limit stopper 5, several forming mandrels 3 are closely arranged in parallel, and are located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com