Temperature control unit based on shape memory alloy

A memory alloy, temperature control unit technology, applied in thermal switch parts and other directions, can solve the problems of difficult heat preservation, low control accuracy, easy to be affected by ambient temperature, etc., to achieve fast response speed, high stability, and high control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto. Unless otherwise specified, the materials and processing methods used in the present invention are conventional materials and processing methods in the technical field.

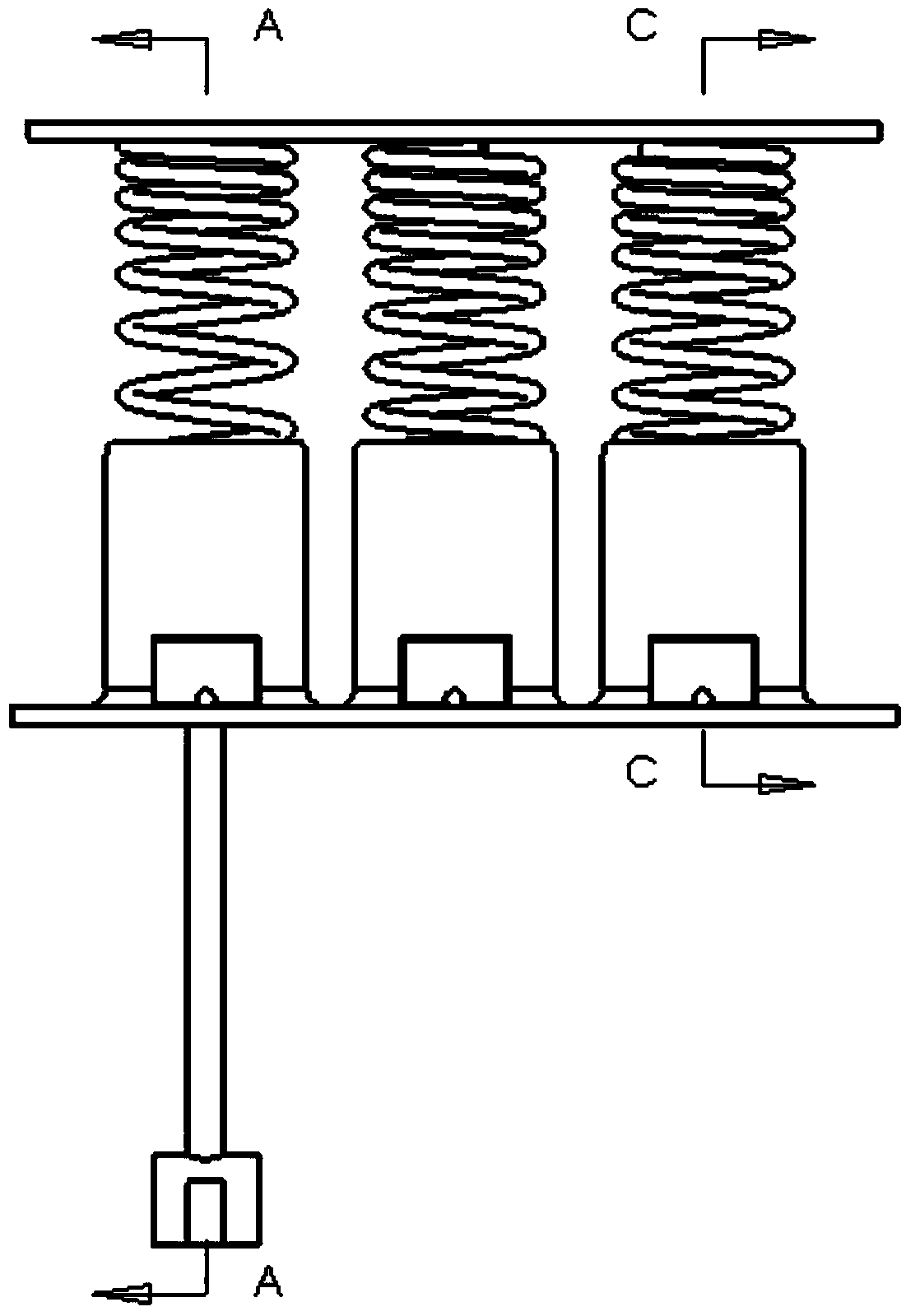

[0029] Such as figure 1 As shown, a temperature control unit based on a shape memory alloy includes a temperature control switch and a basic circuit; the temperature control switch is mainly composed of a temperature limiter 9, a first insulator 10 and a second insulator 11; the basic circuit is mainly composed of a heating Device 12, main switch 13, first current limiting resistor R1, second current limiting resistor R2, heating indicator light H2, heat preservation indicator light H1 and fuse FU. The first current-limiting resistor R1 is connected in parallel with the heater 12; one end of the parallel connection is connected with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com