Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "High yield production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

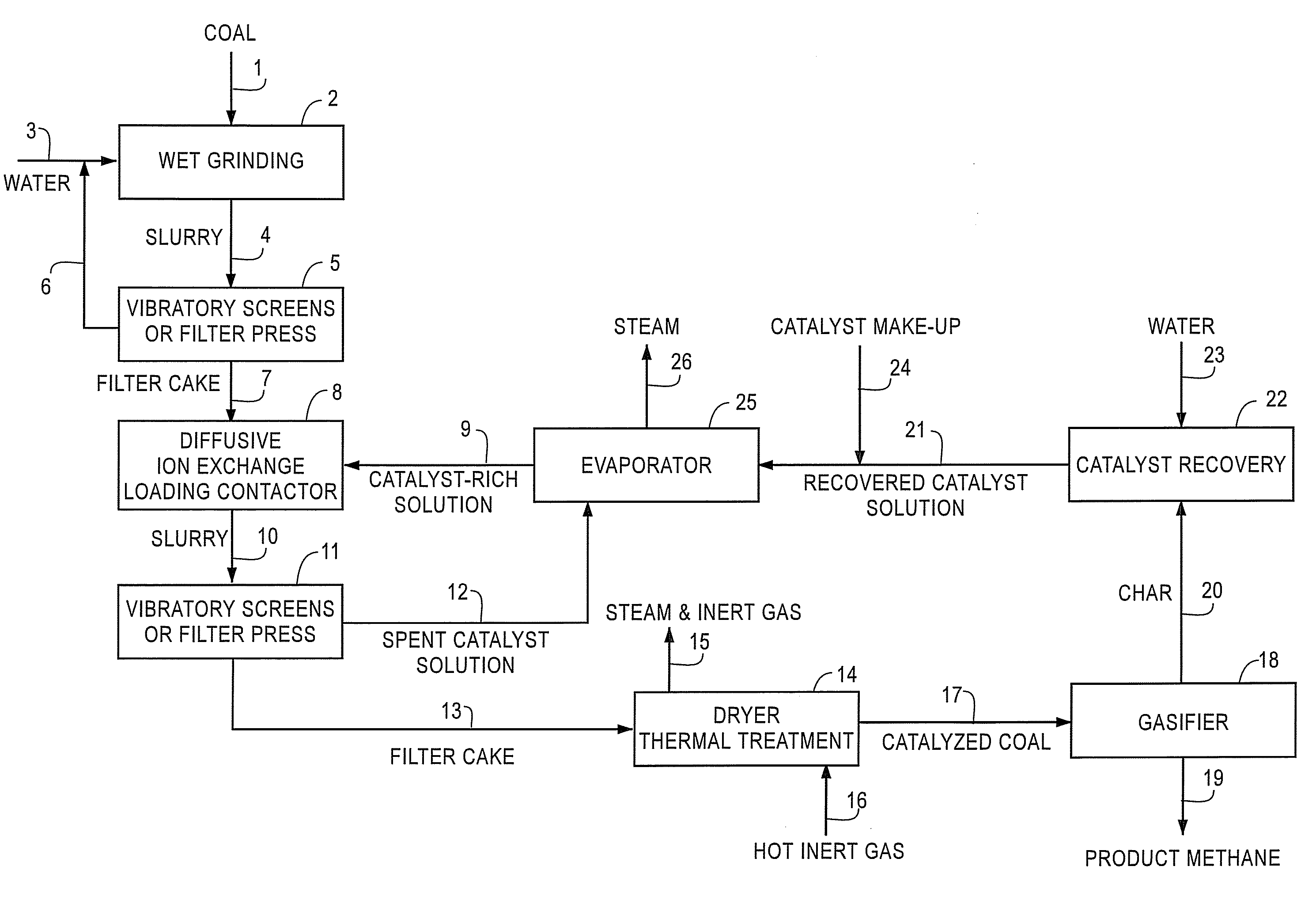

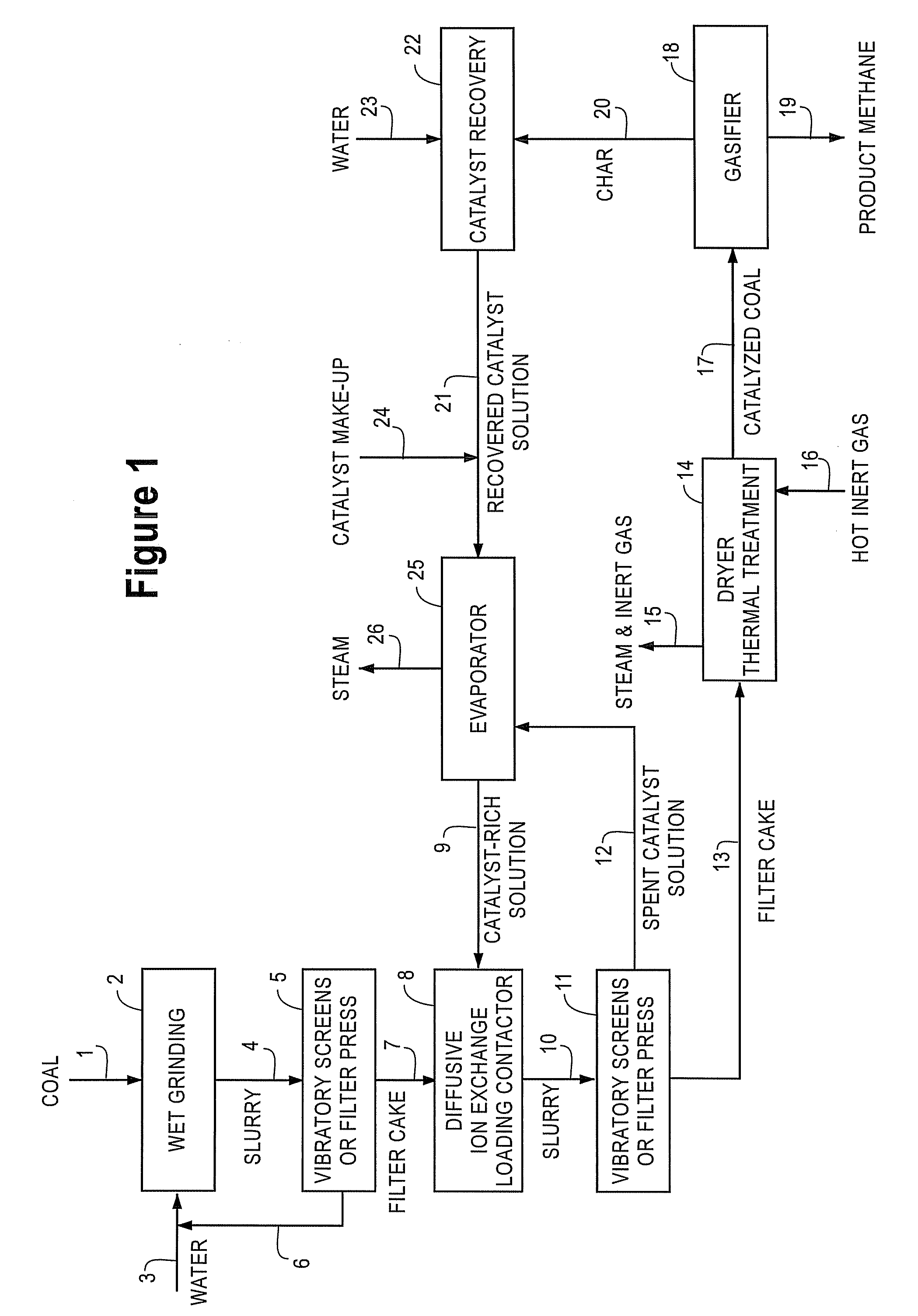

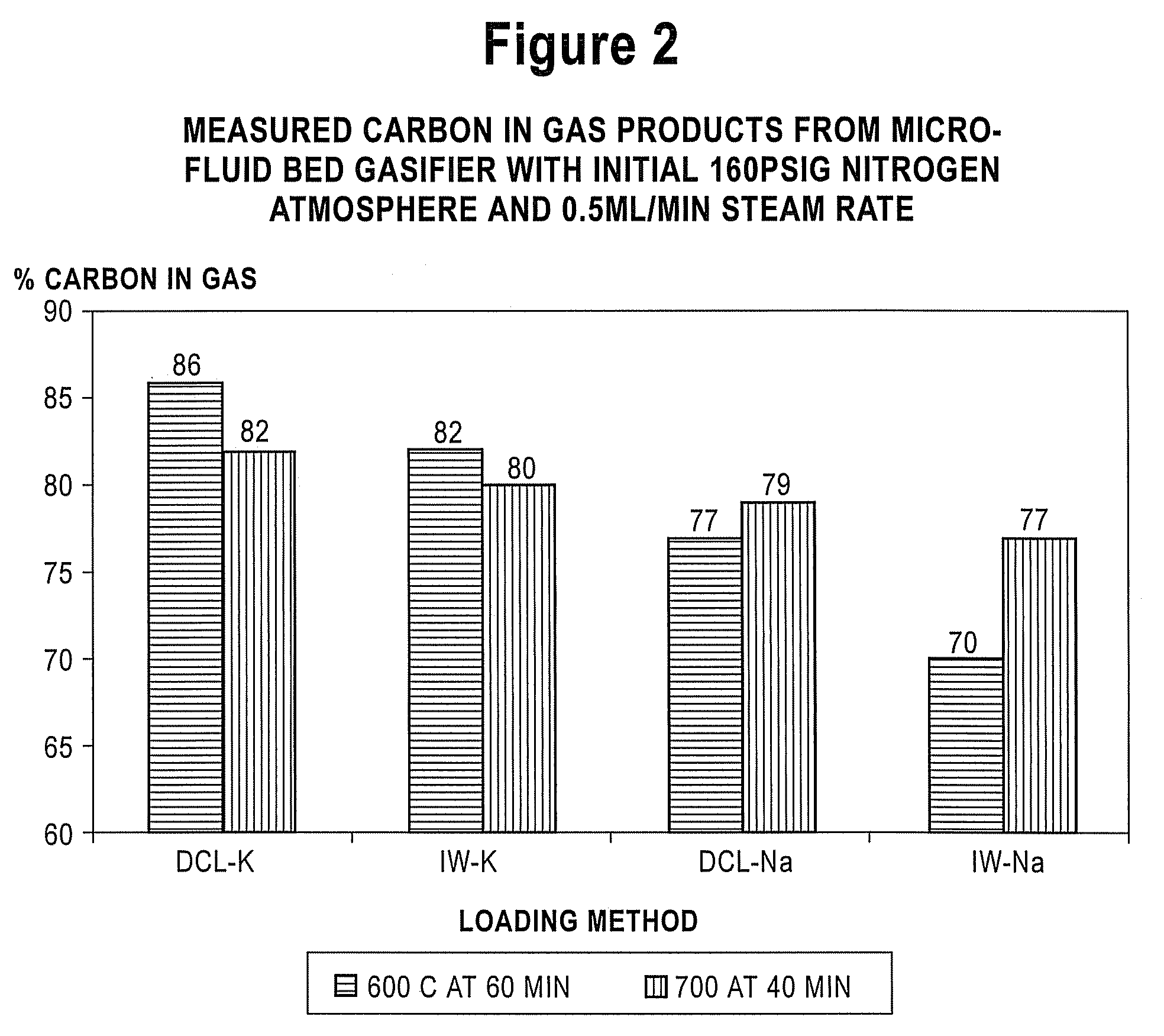

Catalyst-Loaded Coal Compositions, Methods of Making and Use

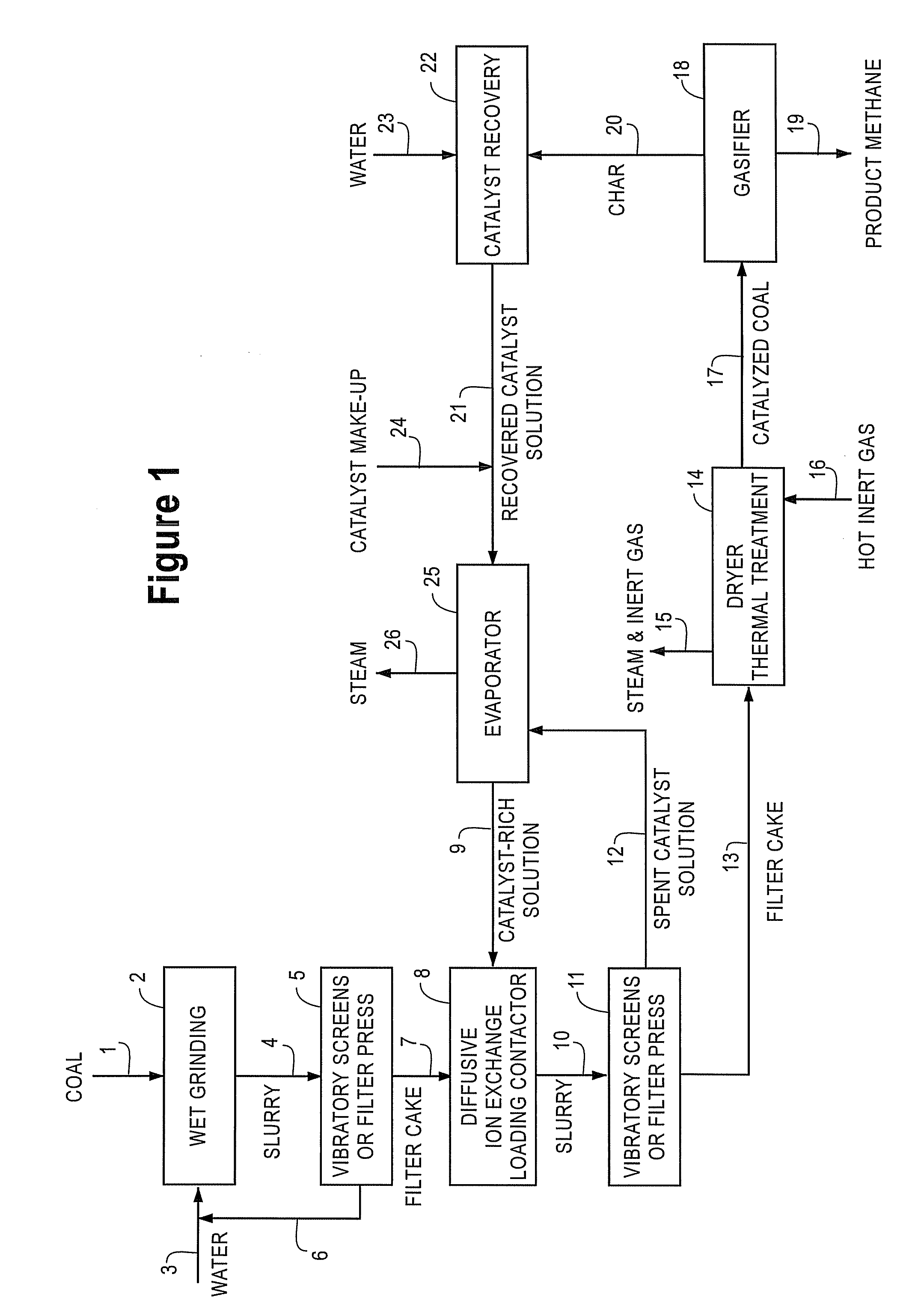

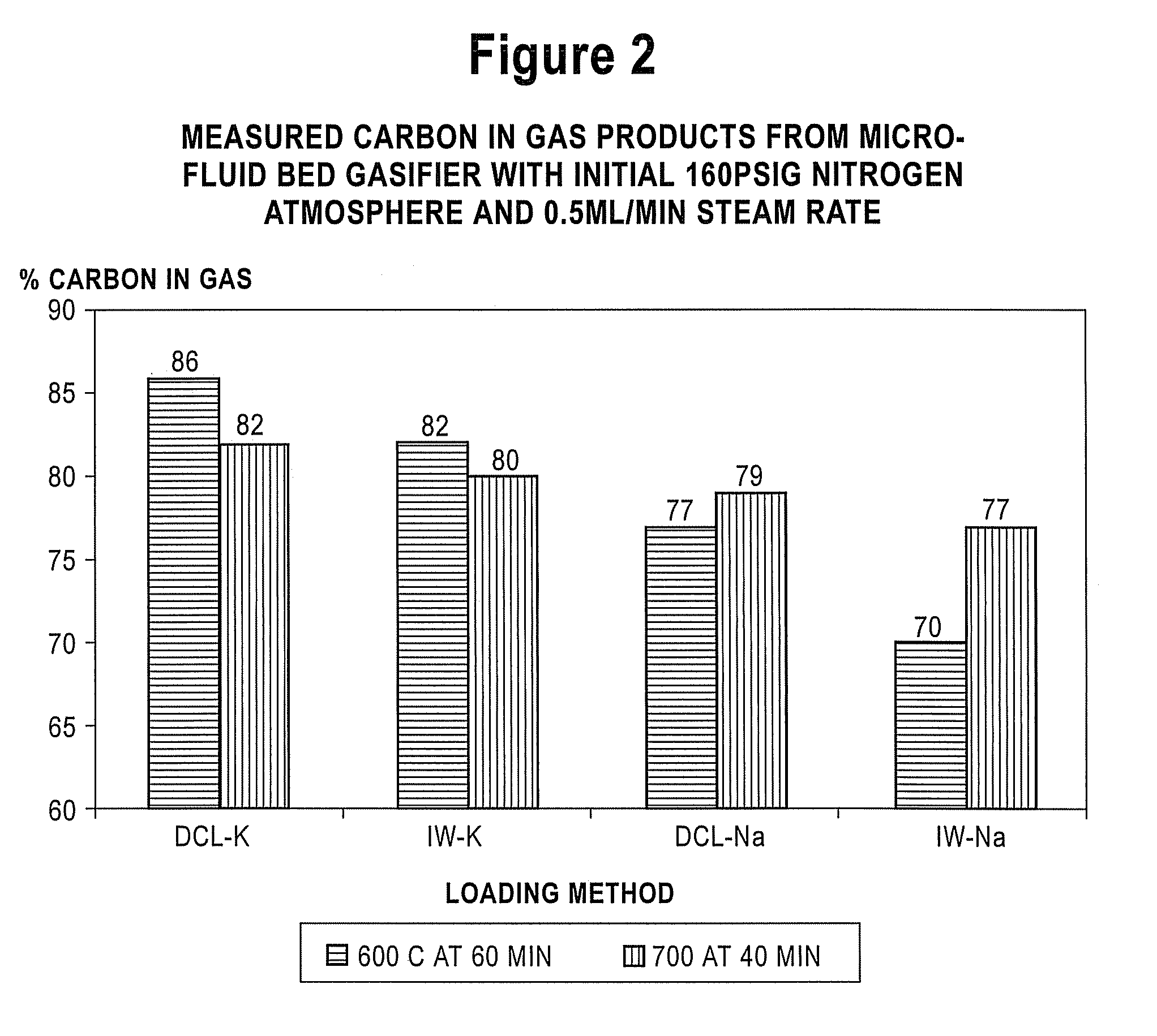

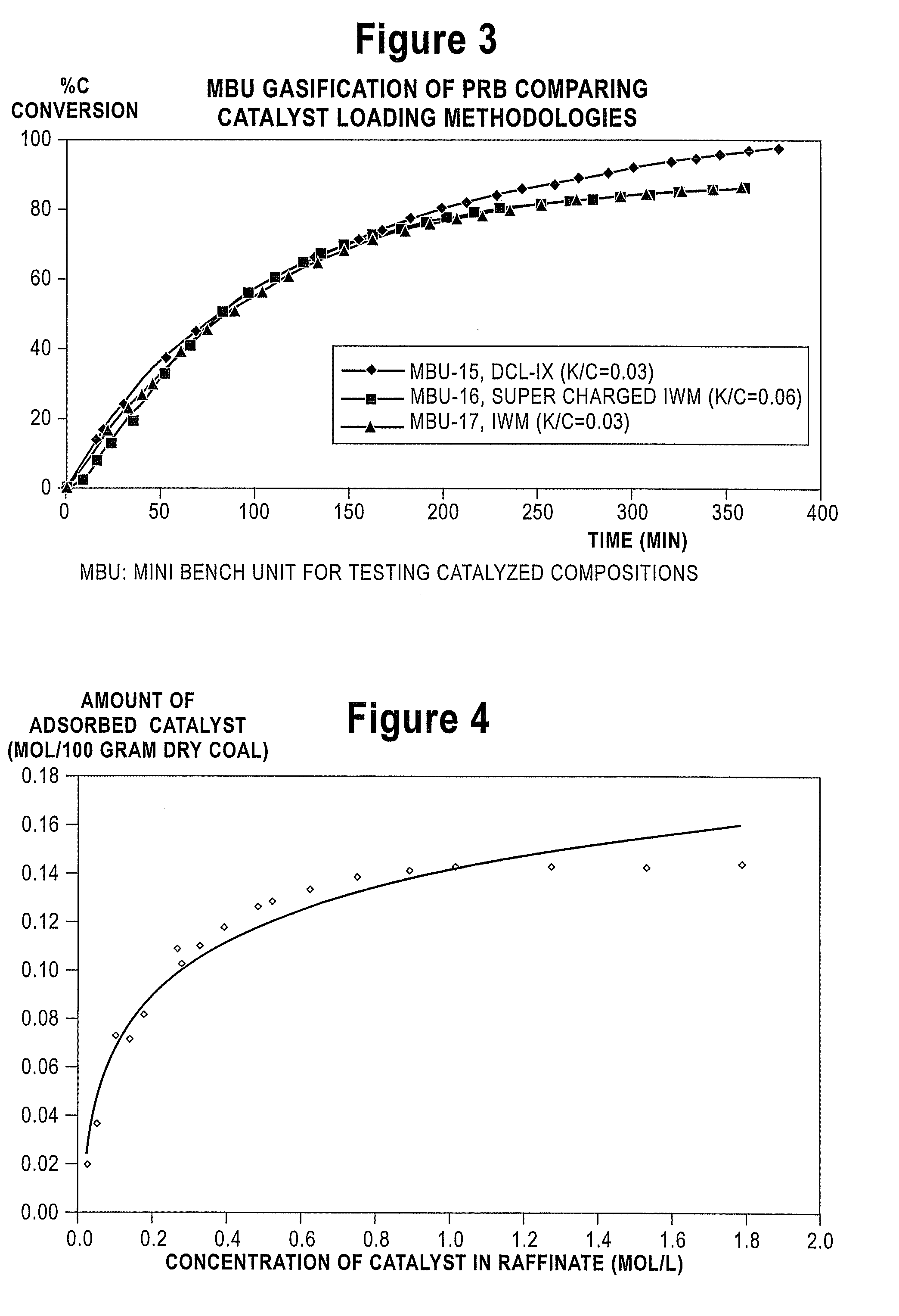

ActiveUS20090048476A1Efficient and high-yielding gasificationHigh yield productionCatalyst regeneration/reactivationSolid fuelsPtru catalystCoal matrix

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

Compositions for Catalytic Gasification of a Petroleum Coke

InactiveUS20090090056A1Cost-effective and high-yielding productionPromote gasificationHydrogenGaseous fuelsParticle compositionMethane gas

The present invention relates to particulate compositions of a lower ash type petroleum coke containing at least two preselected components (alkali metal and calcium) that exhibit an efficient, enhanced-yielding gasification to value added gaseous products, particularly when used in a steady-state integrated gasification process. The compositions of the present invention are particularly useful for catalytic gasification of petroleum coke at moderate temperatures ranging from about 450° C. to about 900° C. Advantageously, the compositions can be readily incorporated into fluidized bed gasification units, and can result in a cost-effective, high-yielding production of methane gas from petroleum coke.

Owner:SURE CHAMPION INVESTMENT LTD

Compositions for Catalytic Gasification of a Petroleum Coke

InactiveUS20090090055A1Improved gasification activityCost-effective and high-yielding productionHydrogenGaseous fuelsParticle compositionChemistry

The present invention relates to particulate compositions of a lower ash type petroleum coke containing at least two preselected components (alkali metal and iron) that exhibit an efficient, enhanced-yielding gasification to value added gaseous products, particularly when used in a steady-state integrated gasification process. The compositions of the present invention are particularly useful for catalytic gasification of petroleum coke at moderate temperatures ranging from about 450° C. to about 900° C. Advantageously, the compositions can be readily incorporated into fluidized bed gasification units, and can result in a cost-effective, high-yielding production of methane gas from petroleum coke.

Owner:SURE CHAMPION INVESTMENT LTD

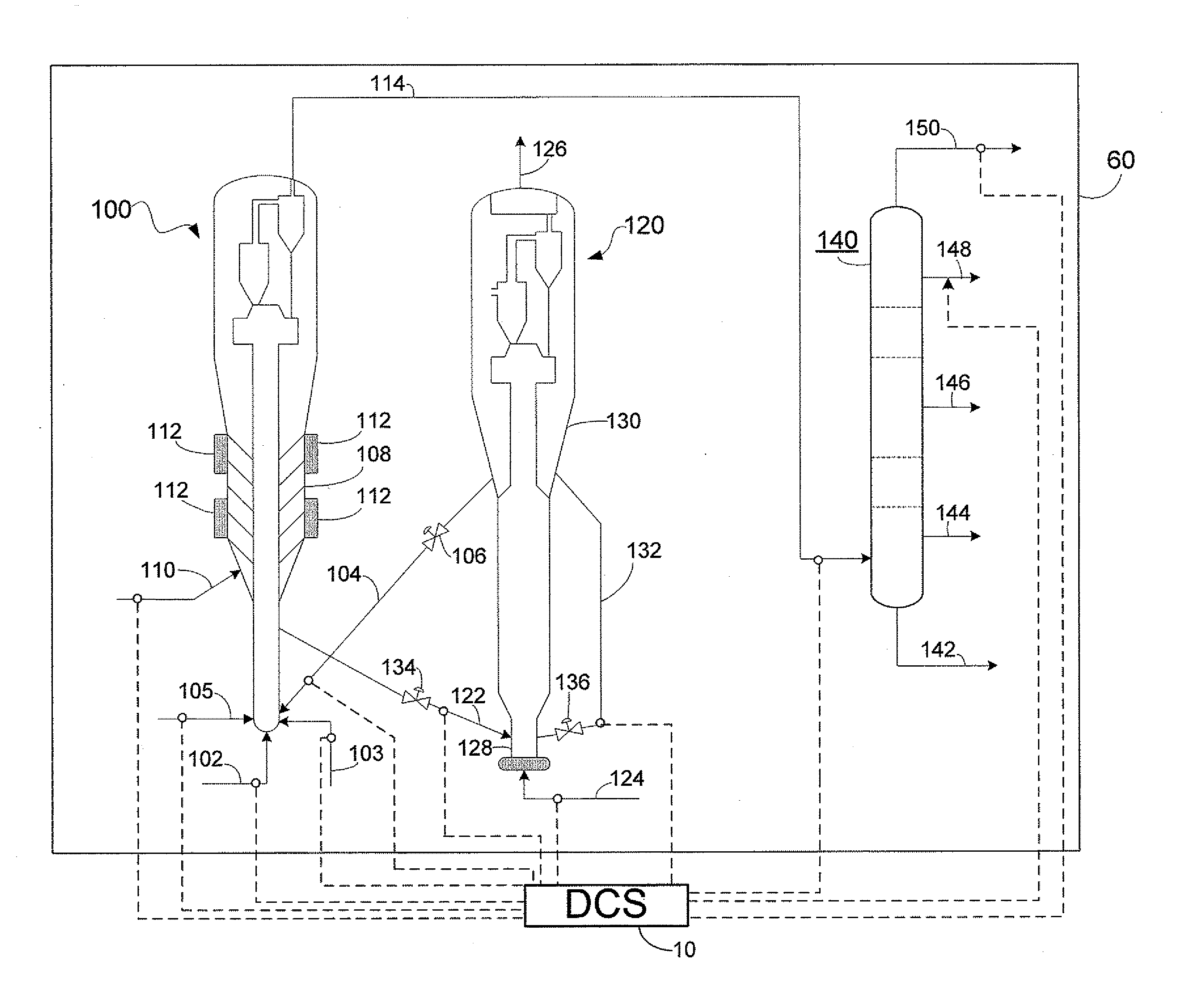

Control of Fluid Catalytic Cracking Process for Minimizing Additive Usage in the Desulfurization of Petroleum Feedstocks

ActiveUS20100230324A1High yield productionLow and reduced usageThermal non-catalytic crackingCatalytic crackingChemistryPetroleum

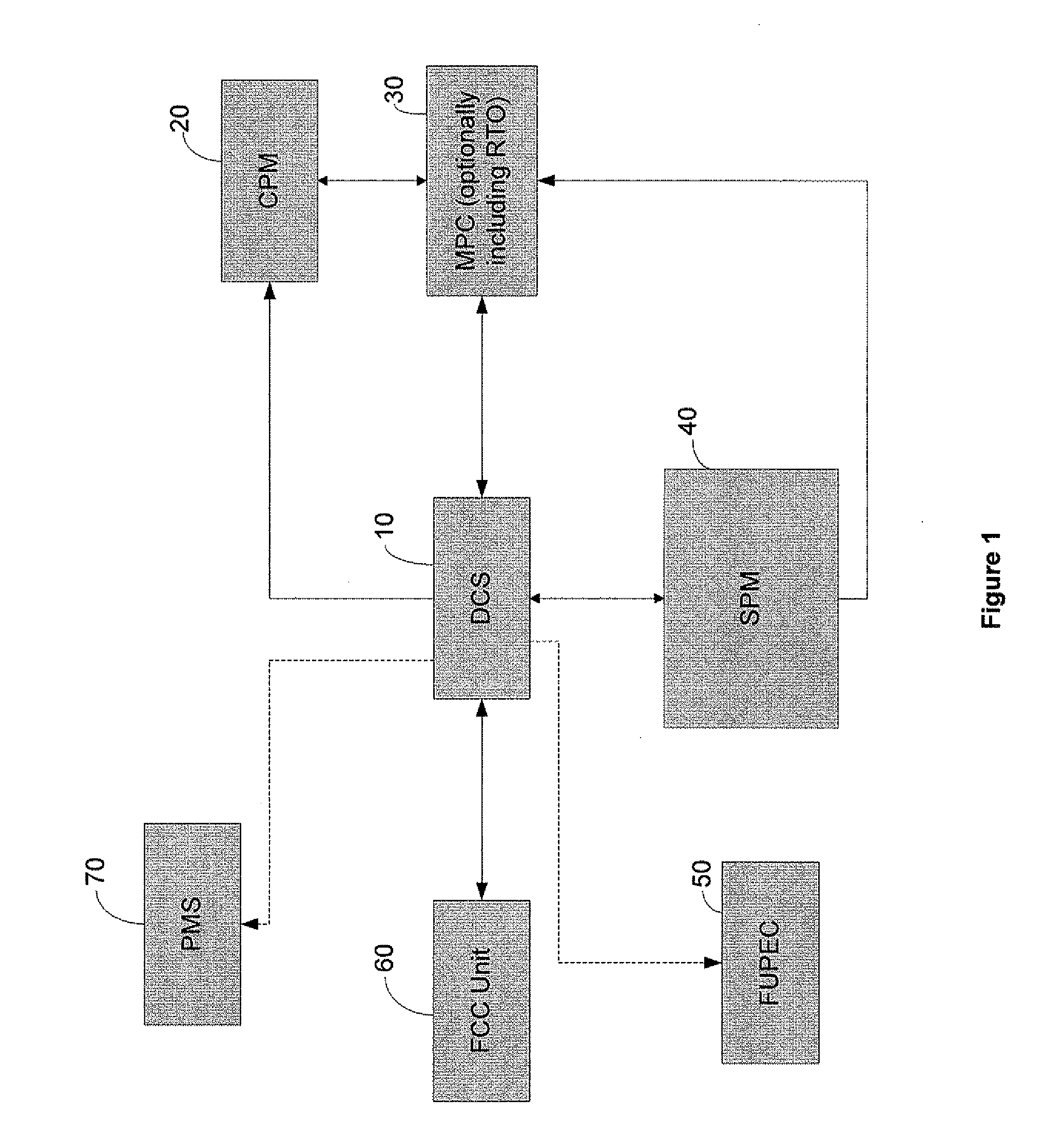

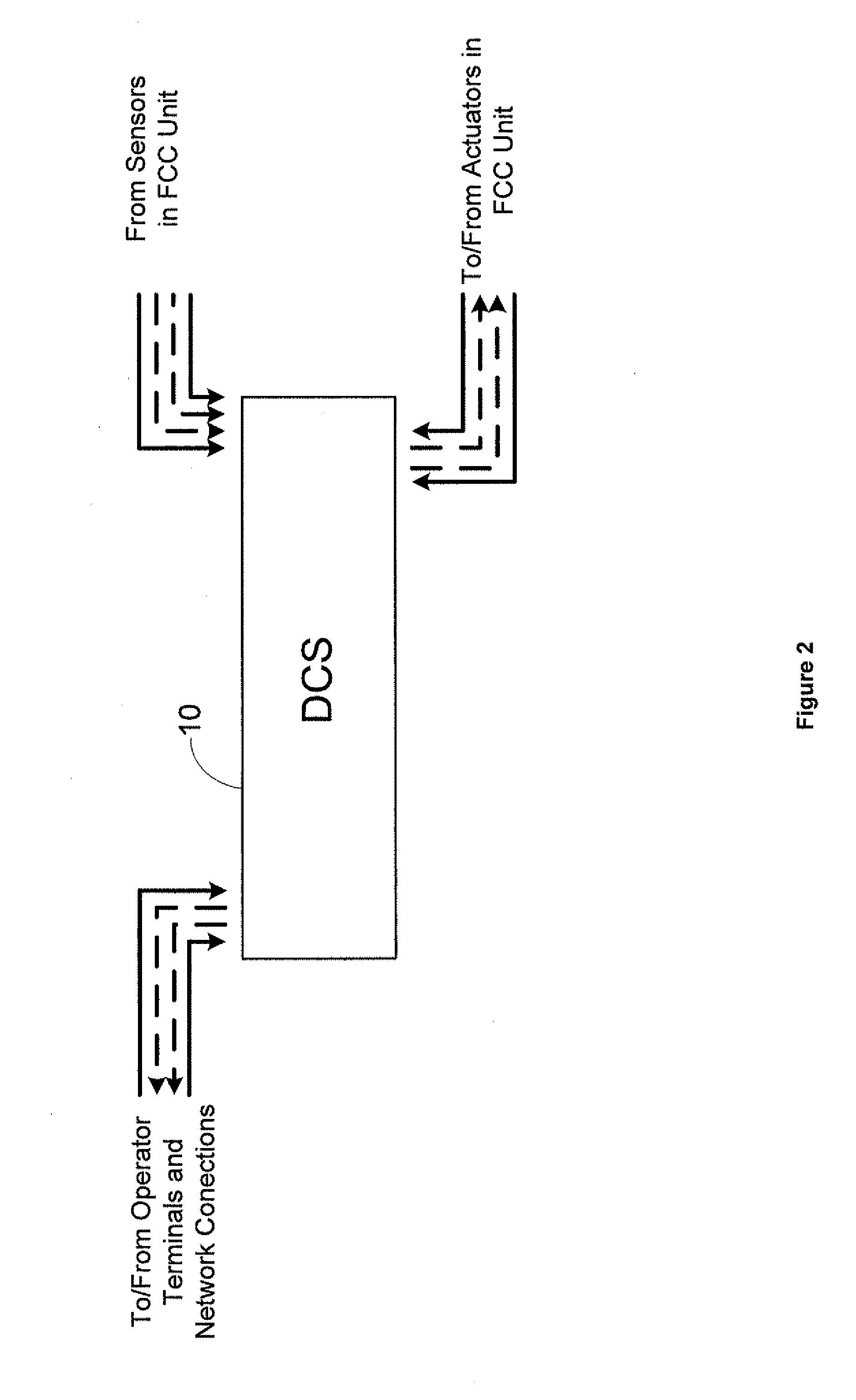

A method and apparatus for the cracking of a petroleum oil feedstock to produce a desulfurized full-range gasoline product. The petroleum oil feedstock is contacted with a base cracking catalyst and an FCC additive in an FCC unit, wherein the catalyst includes a stable Y-type zeolite and a rare-earth metal oxide and the additive includes a shape selective zeolite. The catalyst, additive and petroleum oil feedstock can be contacted in a down-flow or riser fluid catalytic cracking unit, that can also include a regeneration zone, a separation zone, and a stripping zone. The FCC unit includes an integrated control and monitoring system that monitors at least one parameter selected from FCC operating parameters, feed rate, feedstock properties, and product stream properties, and adjusts at least one parameter in response to the measured parameter to increase production of desulfurized products.

Owner:SAUDI ARABIAN OIL CO

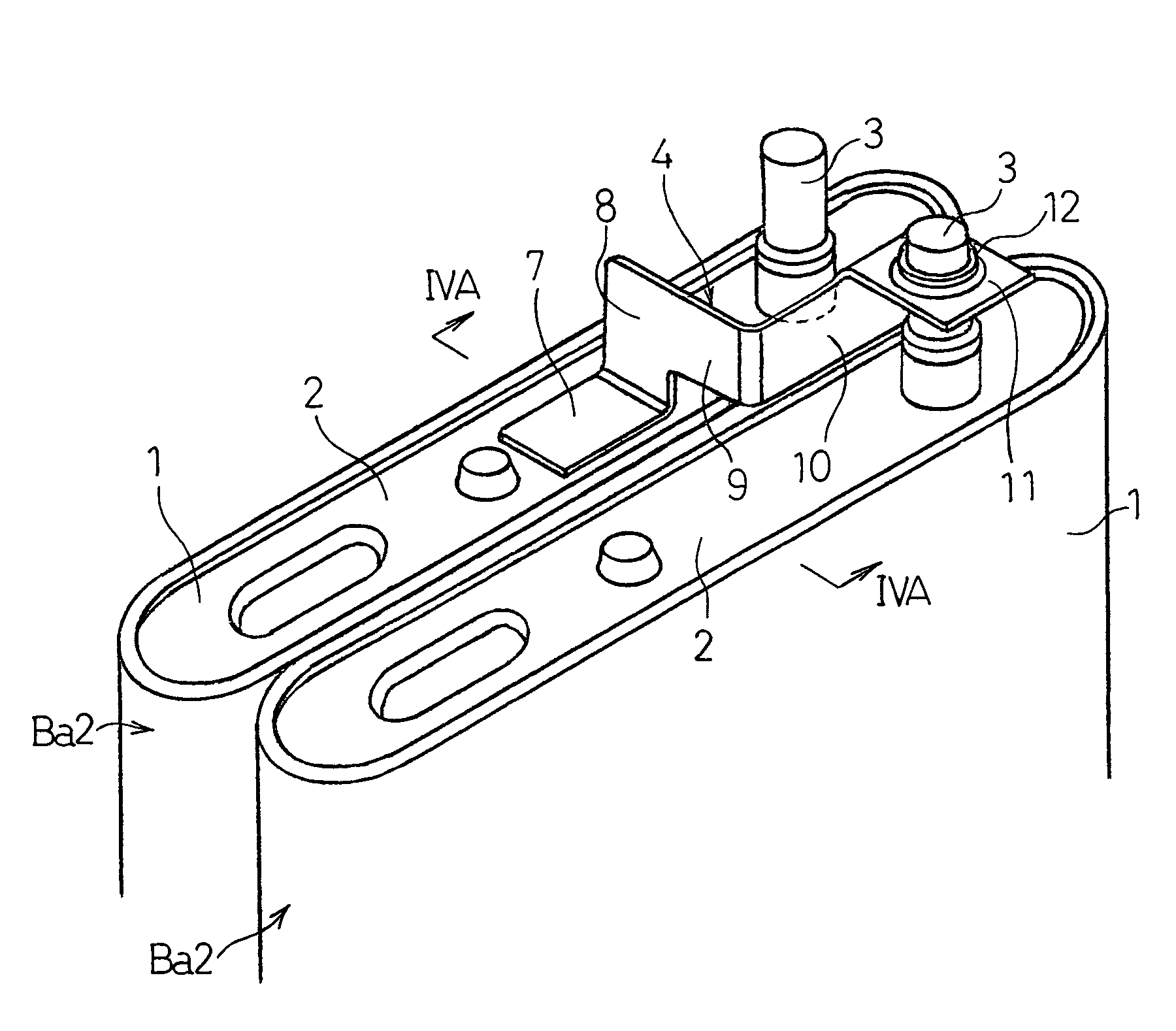

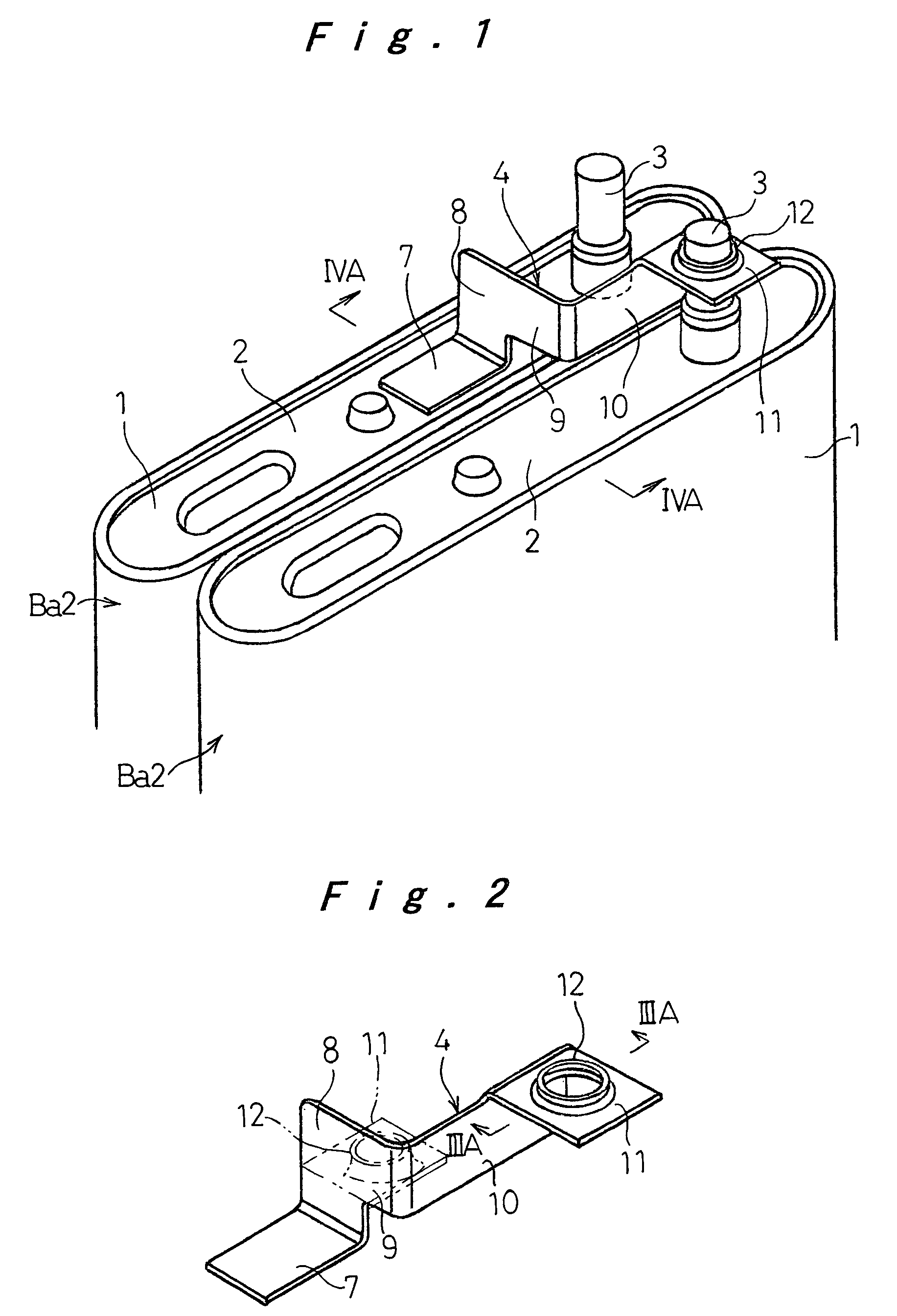

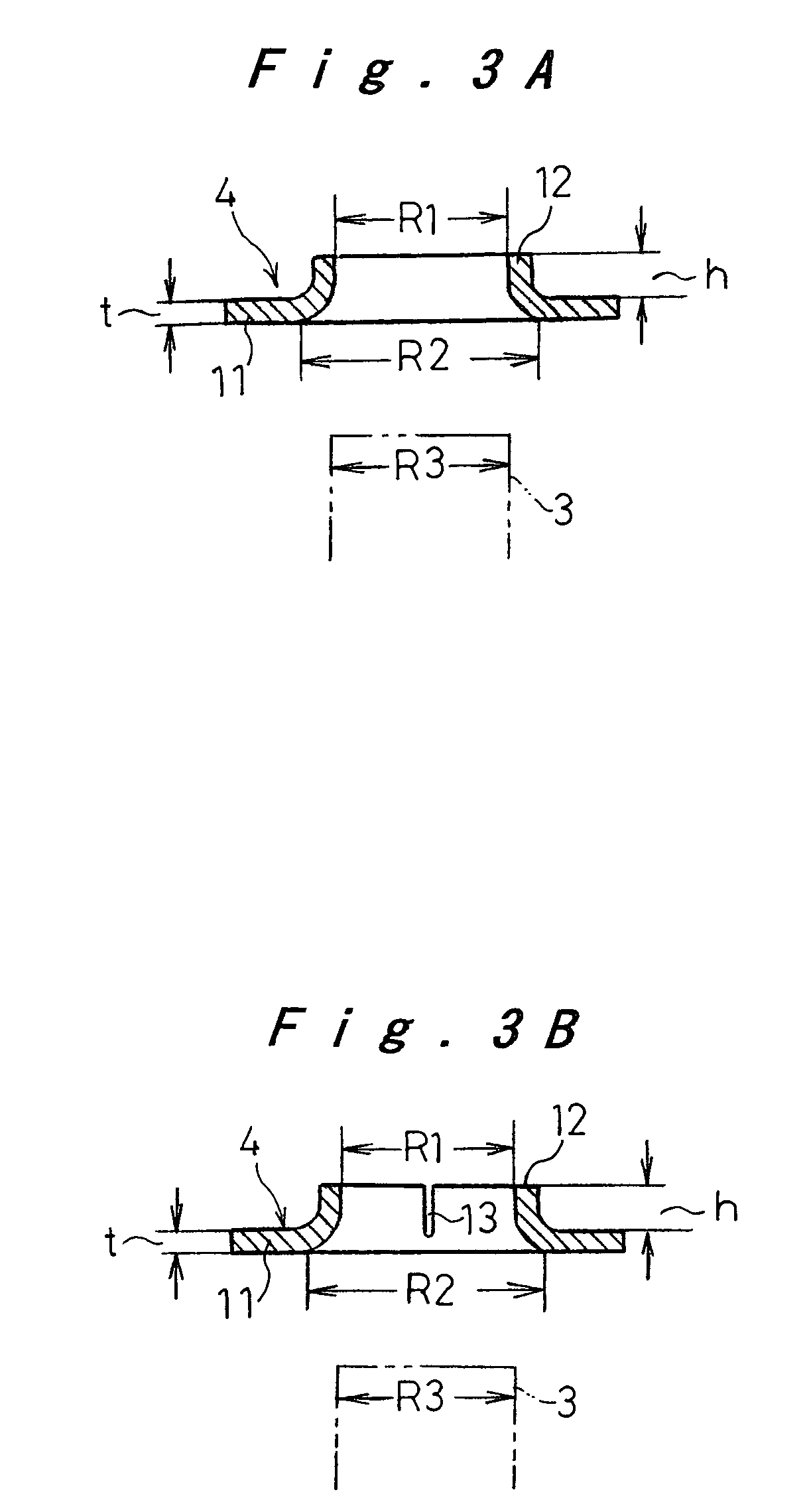

Battery pack

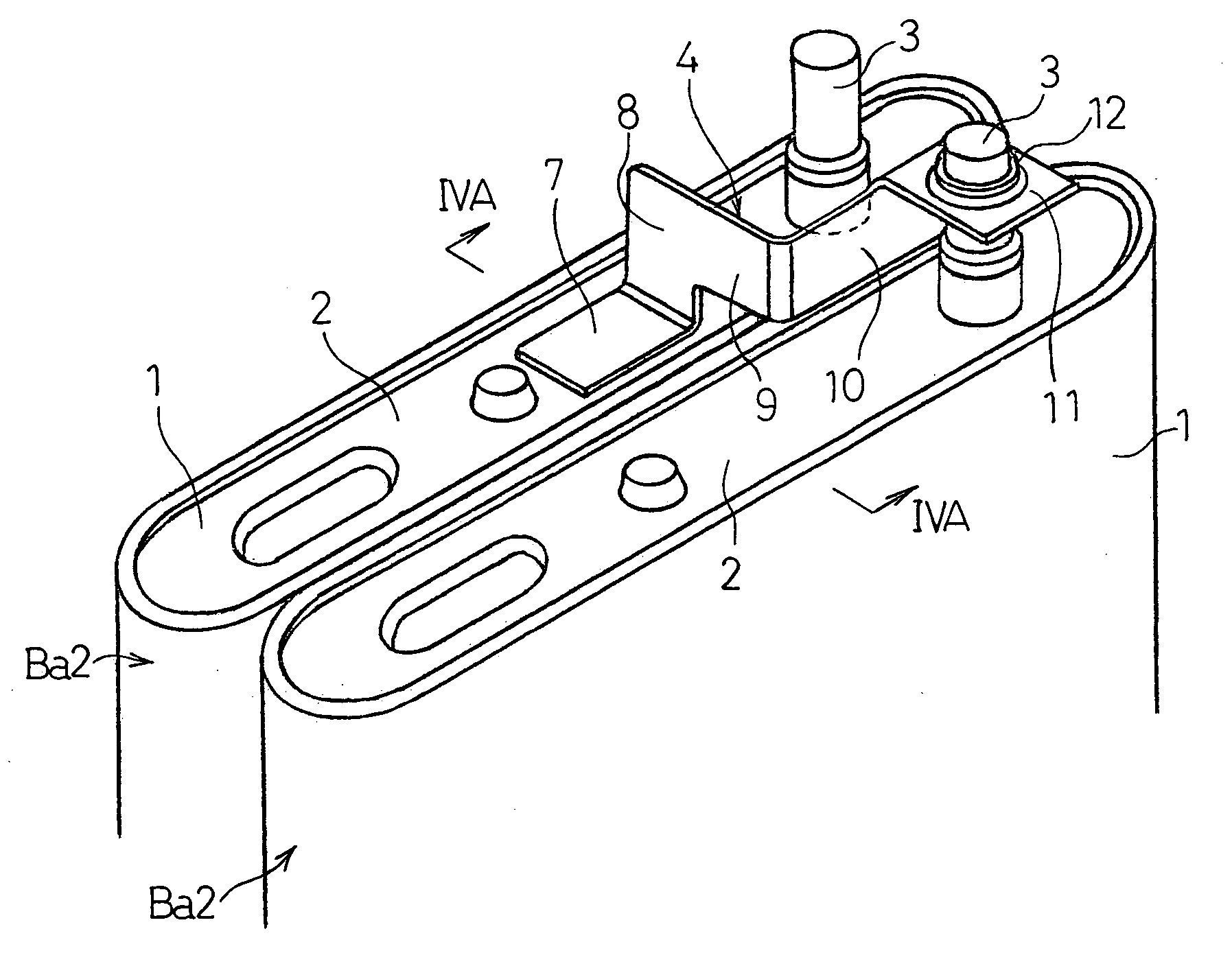

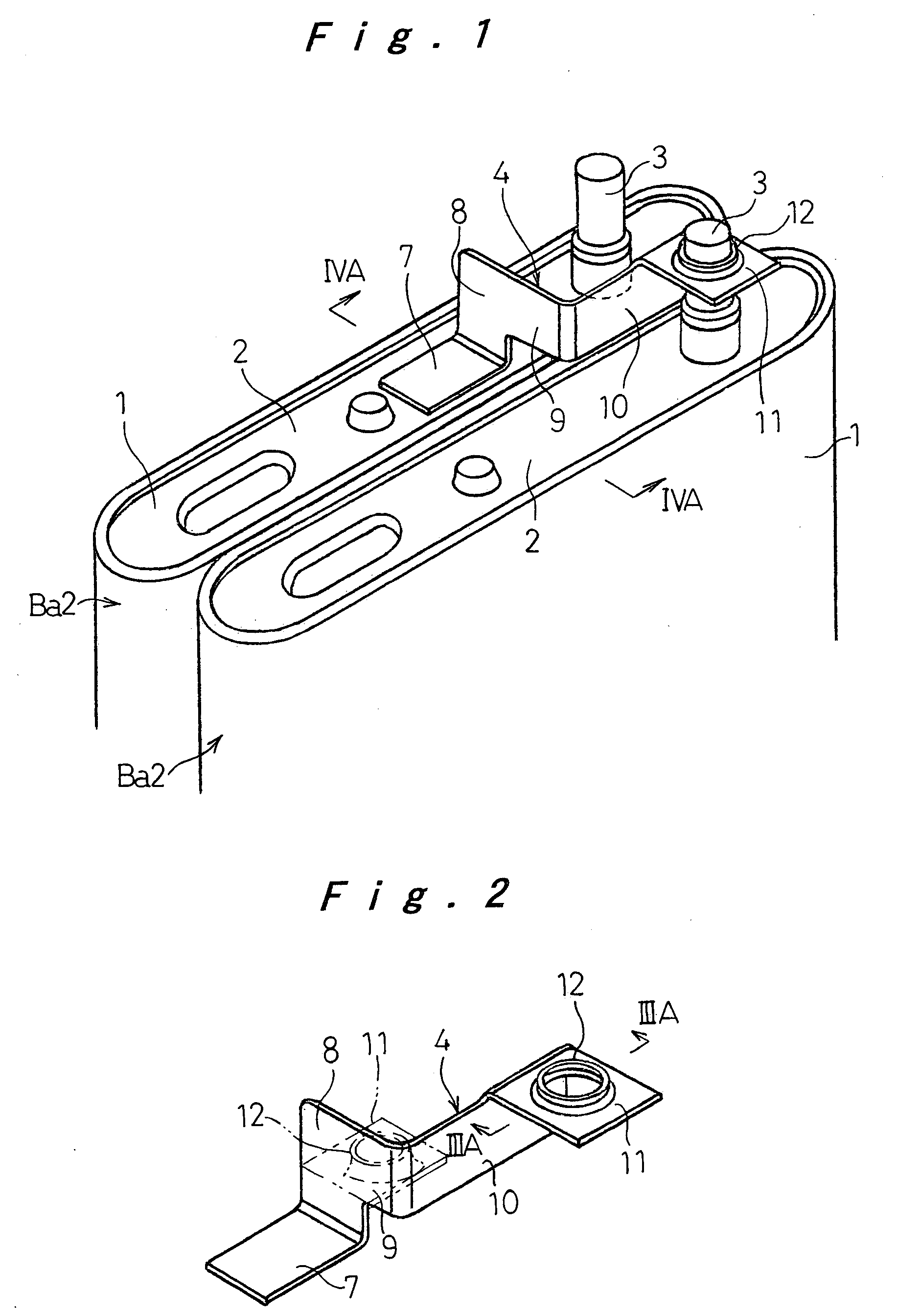

InactiveUS20070141458A1Reduce riskFirmly connectedPrimary cell to battery groupingSmall-sized cells cases/jacketsElectrical connectionBattery pack

A battery pack is made up of a plurality of flat prismatic batteries arranged face to face, each battery having one electrode terminal protruding from one end face in the height direction of the battery case and this end face or a side face of the battery serving as the other electrode terminal. The connector for electrically connecting adjacent prismatic batteries includes a flat part that is welded to one electrode terminal of one prismatic battery of the adjacent prismatic batteries, and a cylindrical part that is fitted onto and welded to the other electrode terminal of the other prismatic battery. The cylindrical part is formed in an attachment part that extends from the flat part through an upright part in the direction in which the batteries are aligned. The connector enables reliable electrical connection of the prismatic batteries despite possible variation in height of the electrode terminals.

Owner:PANASONIC CORP

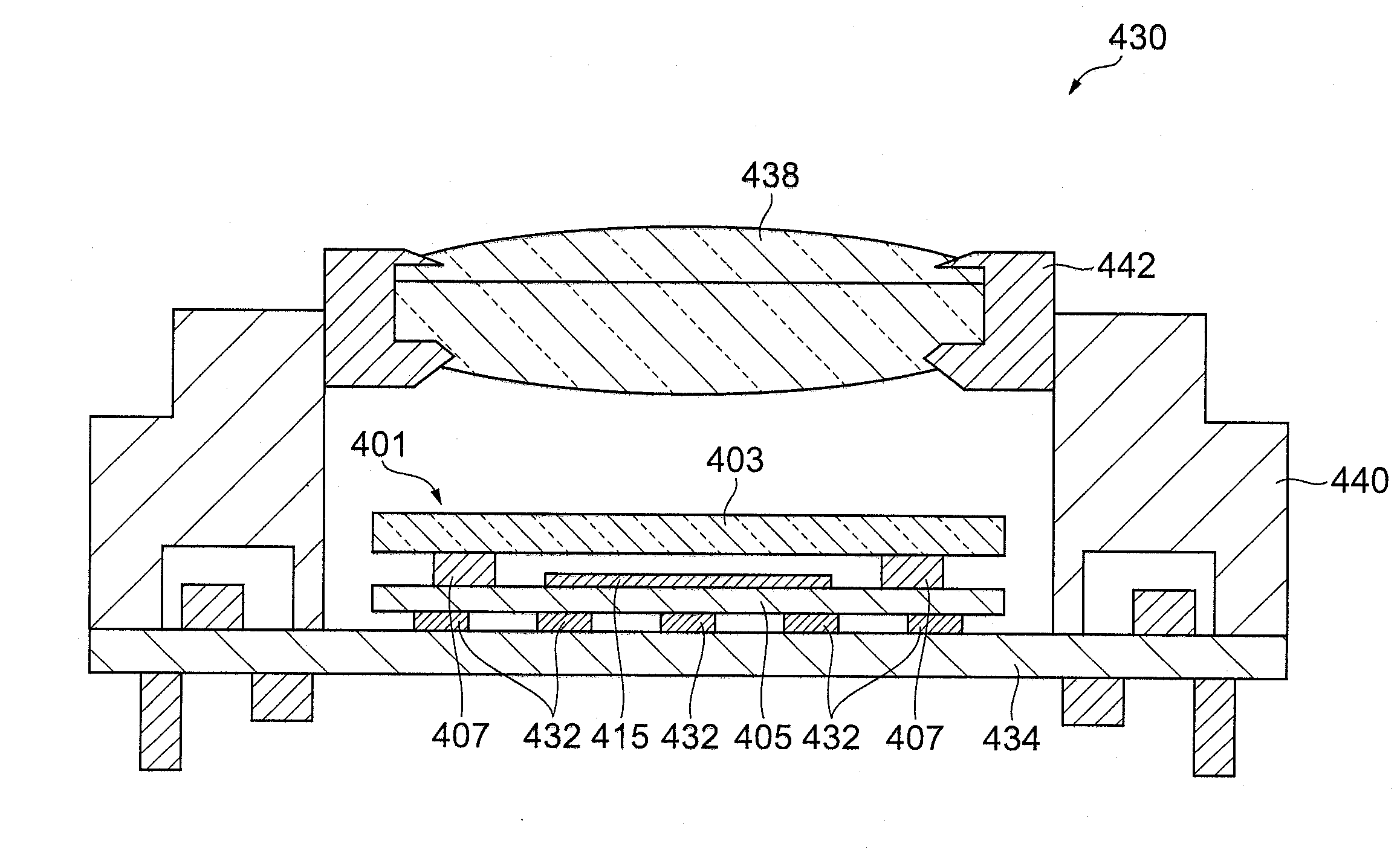

Photosensitive adhesive composition, photosensitive film adhesive, adhesive pattern, semiconductor wafer with adhesive, semiconductor device and electronic component

InactiveUS20110159238A1High yield productionPhotosensitive materialsSolid-state devicesPolymer scienceWafering

A photosensitive adhesive composition that can form an adhesive layer on an adherend and allows an adhesive pattern to be formed by exposure treatment with radiation and developing treatment with a developing solution, the photosensitive adhesive composition having solubility and developability, and the film thickness T1 (μm) of the adhesive pattern formed after development satisfying the conditions represented by the following expression (1).(T1 / T0)×100≧90 (1)[In expression (1), T0 represents the film thickness (μm) of the adhesive layer before developing treatment.]

Owner:HITACHI CHEM CO LTD

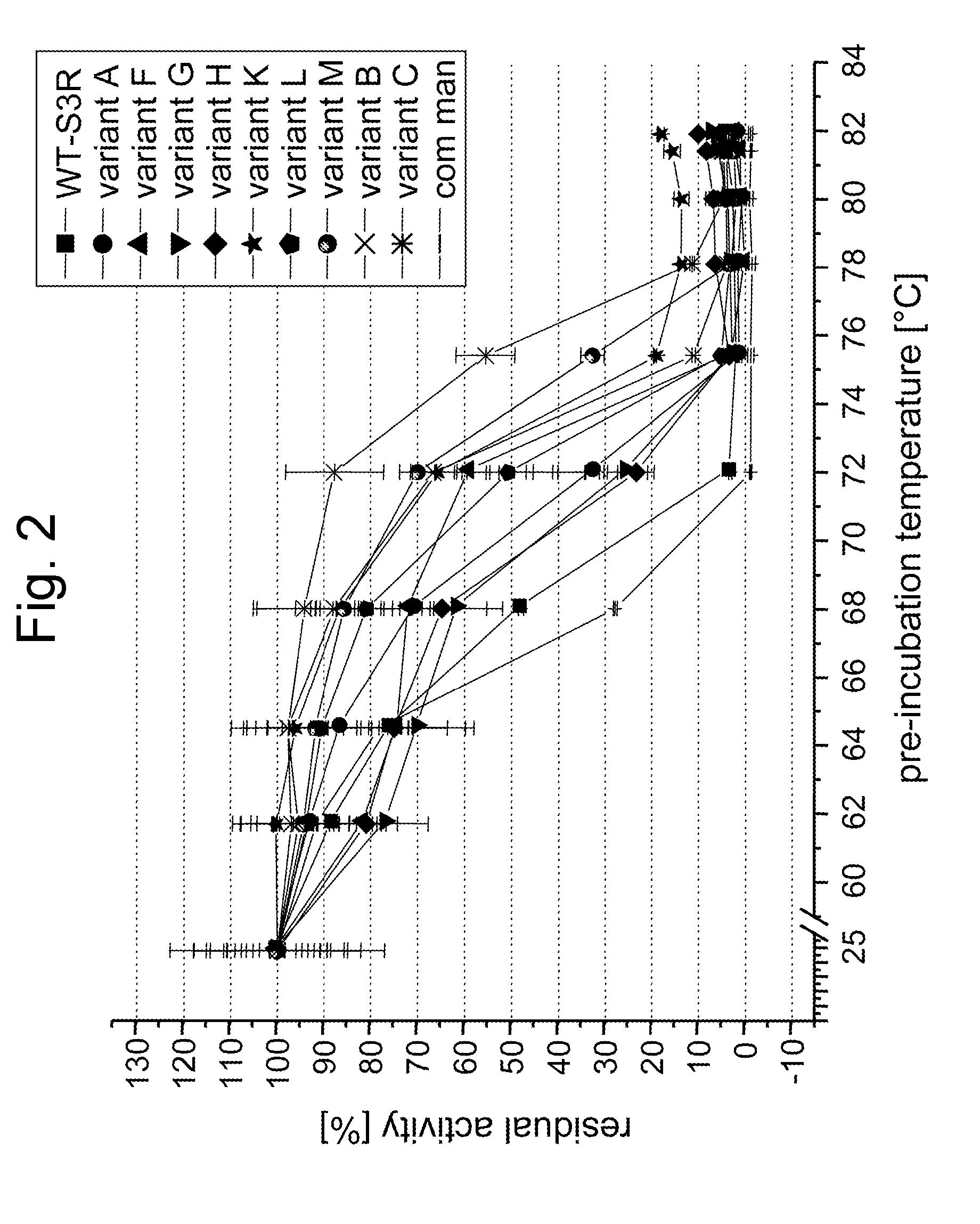

Mannanases

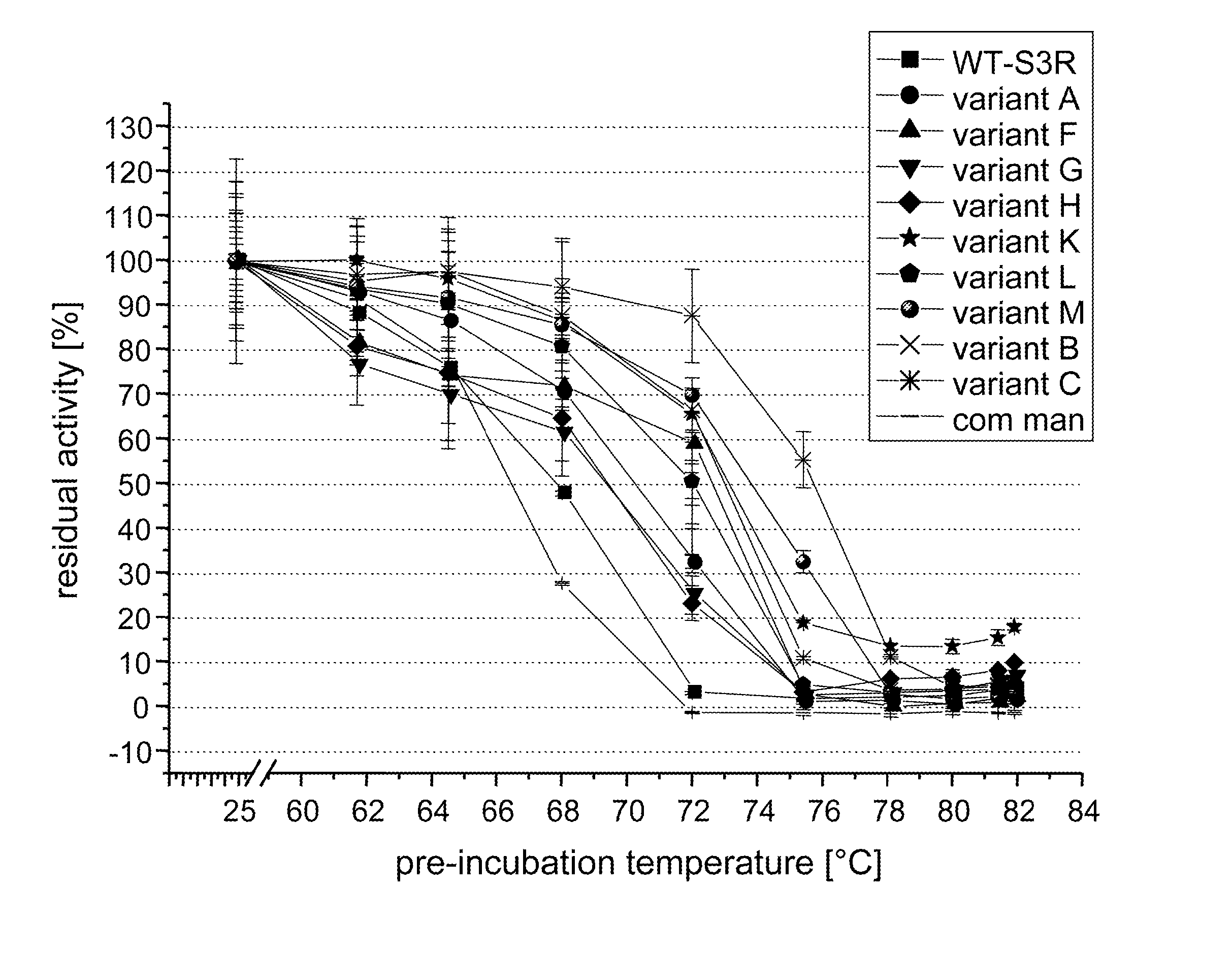

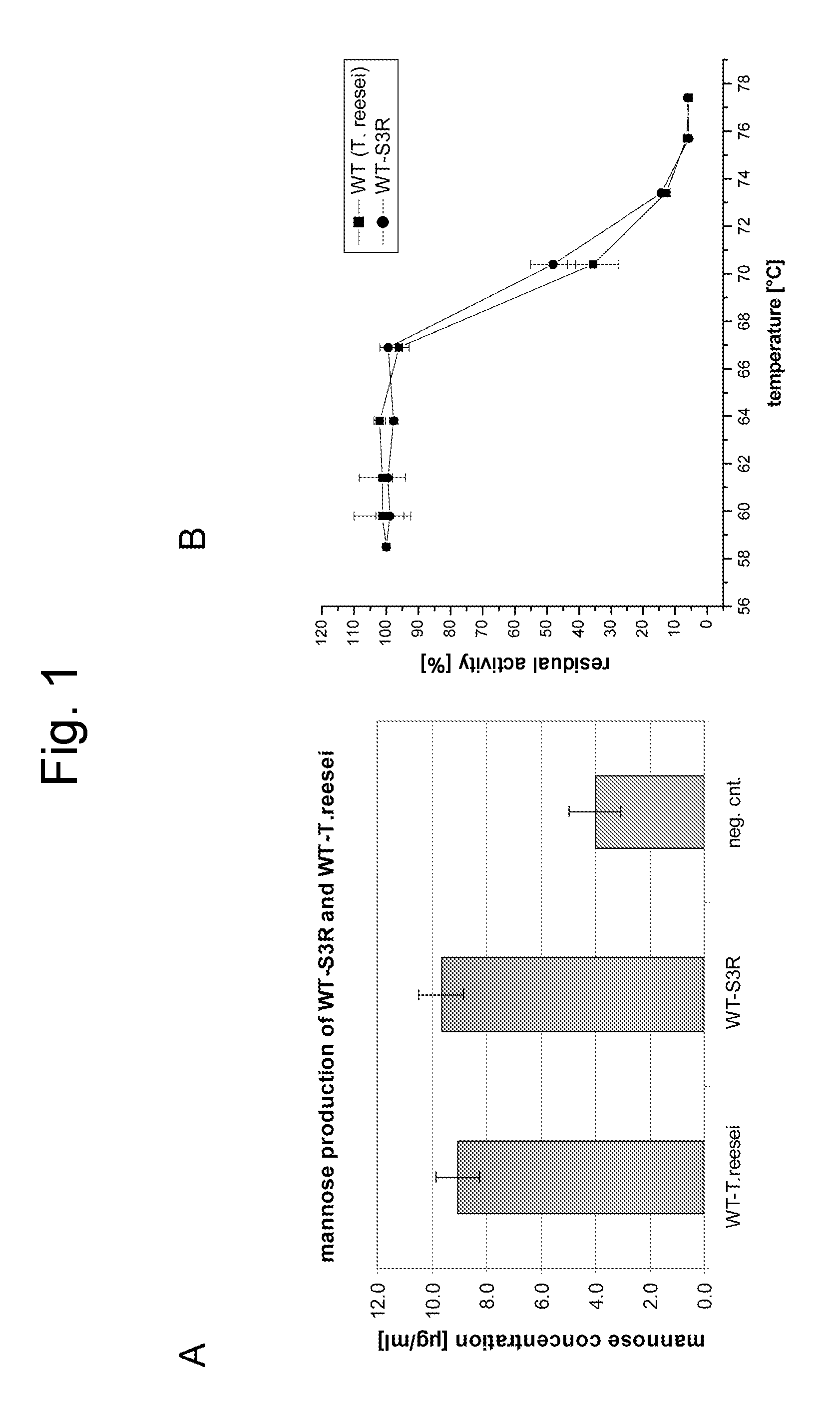

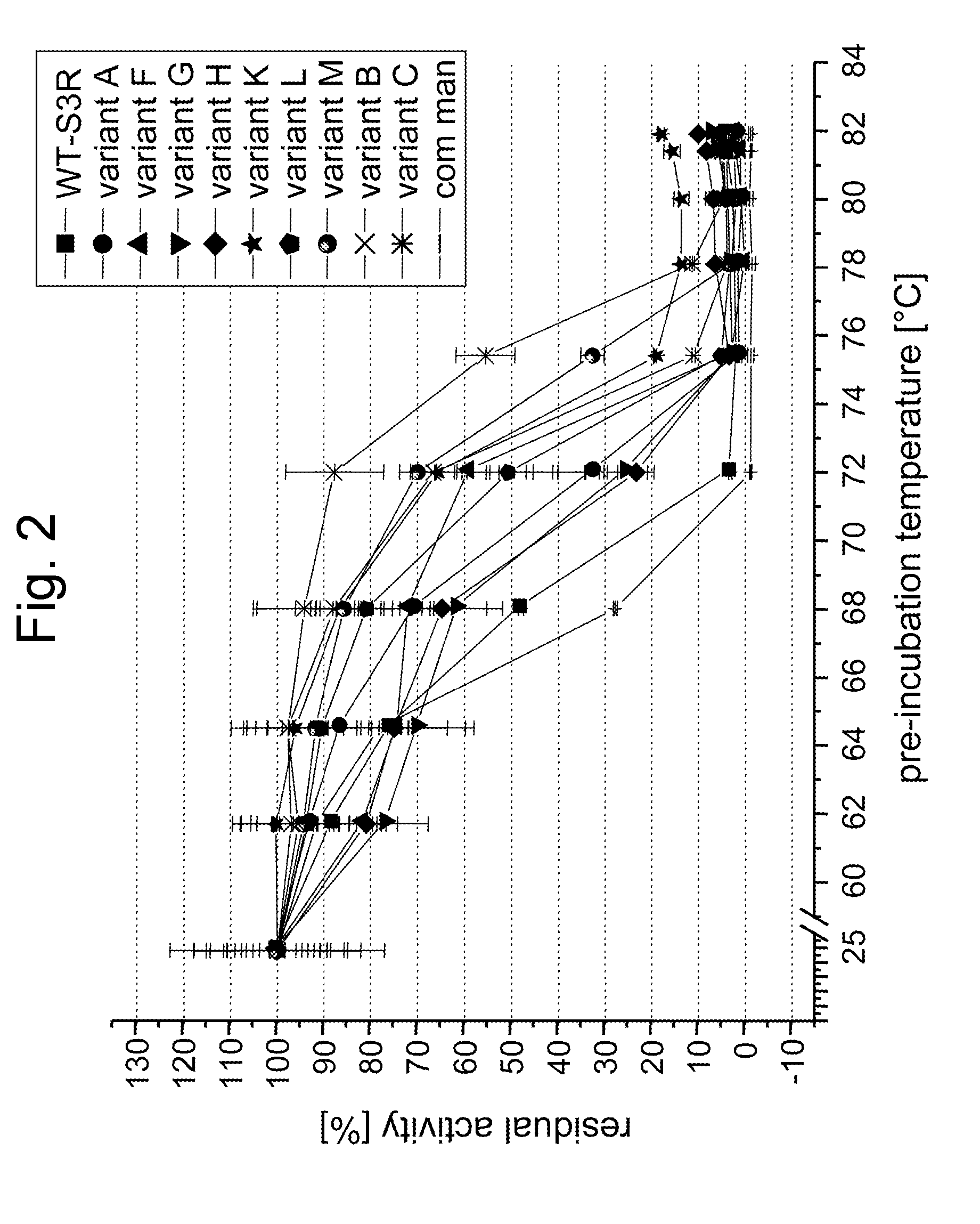

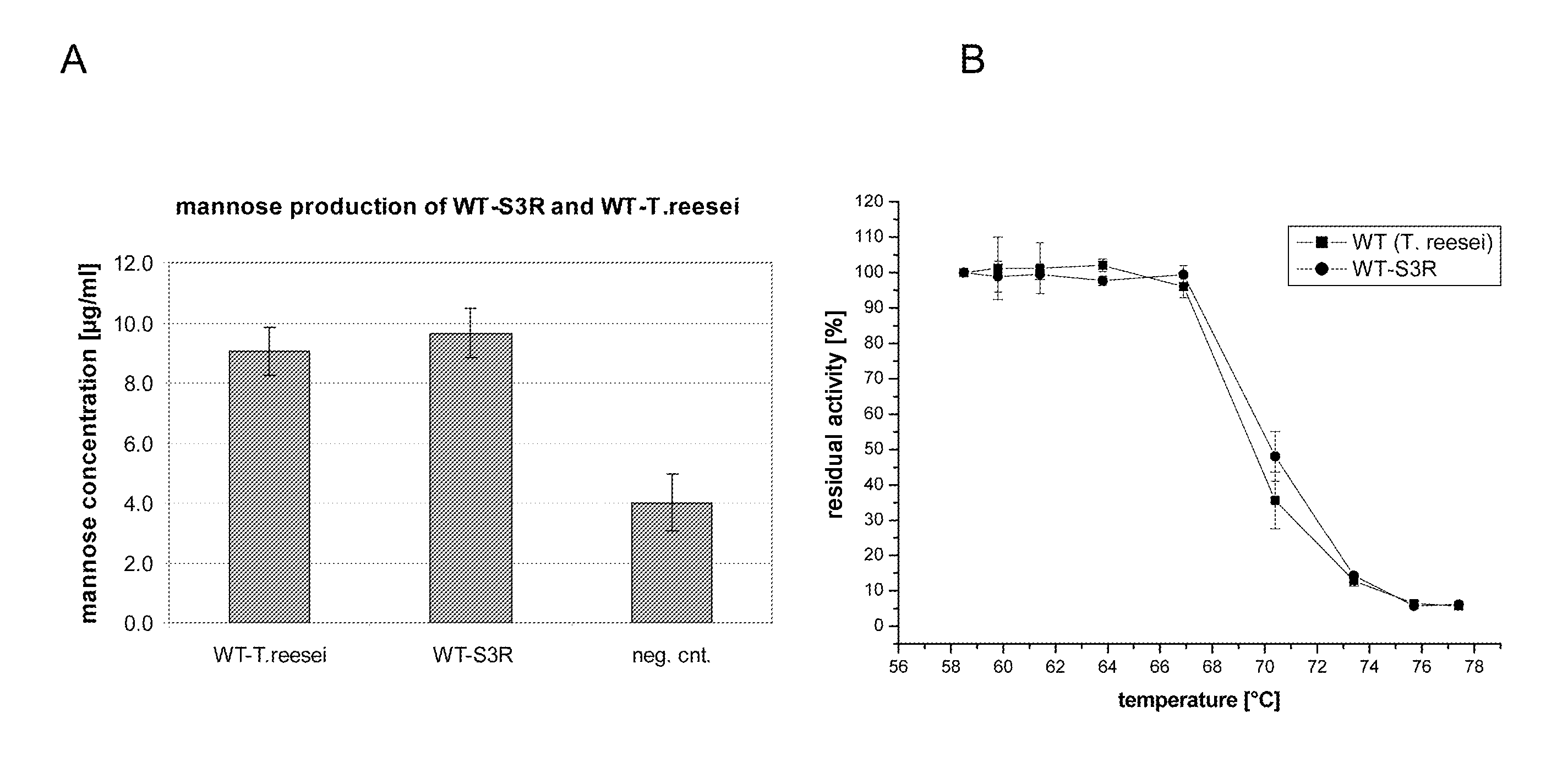

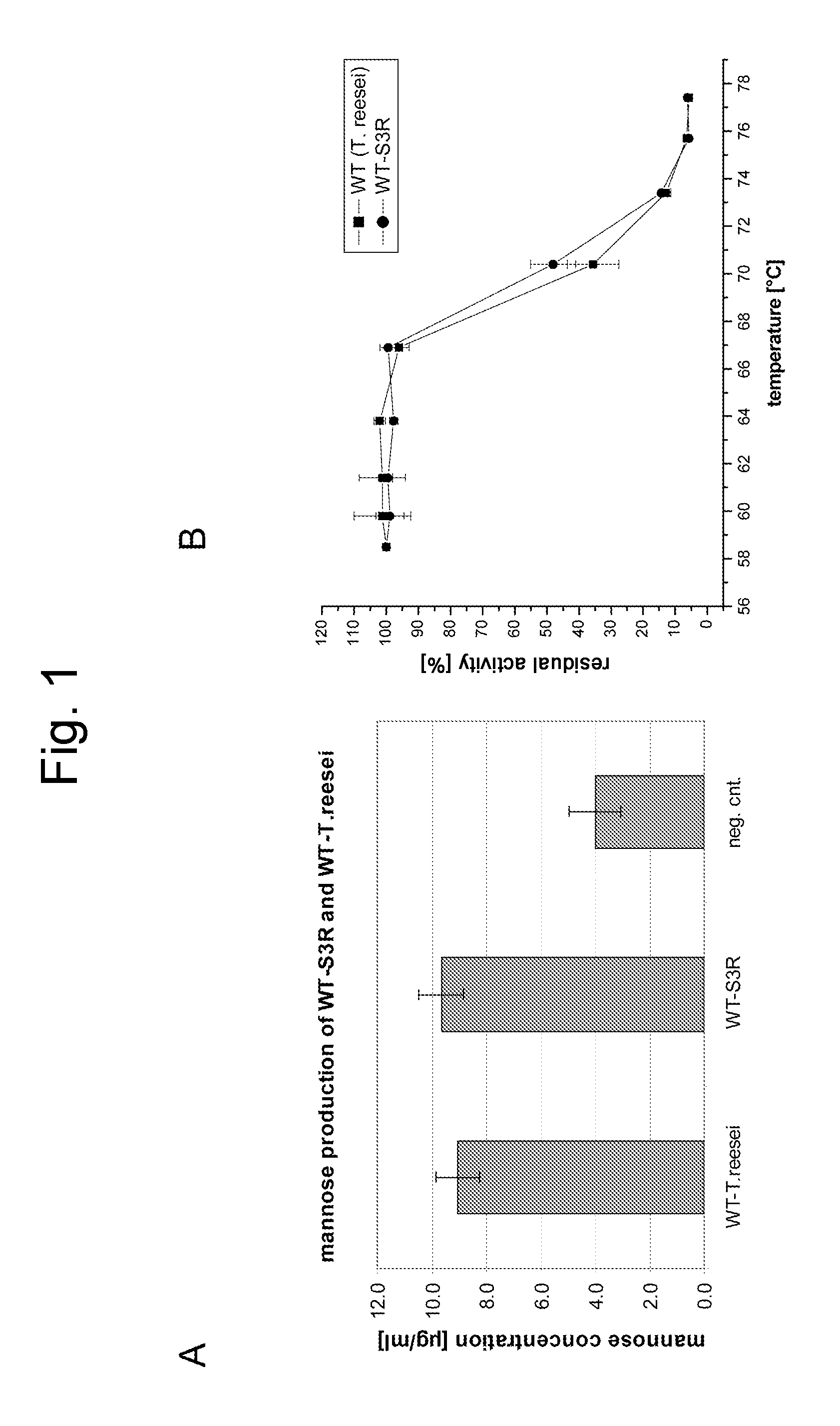

ActiveUS20080064064A1Precise and reproducible enzyme dosagePrevent steppingTissue cultureFlushingBleachWild type

The present invention provides an insertion, deletion and / or substitution mutein of wild-type Trichoderma reesei β-mannanase having enhanced thermostability, proteolytic stability, specific activity and / or stability at low pH, a nucleic acid molecule encoding said mannanase mutein, a composition comprising said mannanase mutein; a method for its preparation, and its use for food and feed processing, for coffee extraction and the processing of coffee waste, as a supplement to food and feed, for enzyme aided bleaching of paper pulps, as bleaching and / or desizing agent in textile industry, for oil and gas well stimulation by hydraulic fracturing, as detergent, for removal of biofilms and in delivery systems, or for the processing of renewable resources intended for the production of biological fuels.

Owner:BASF AG

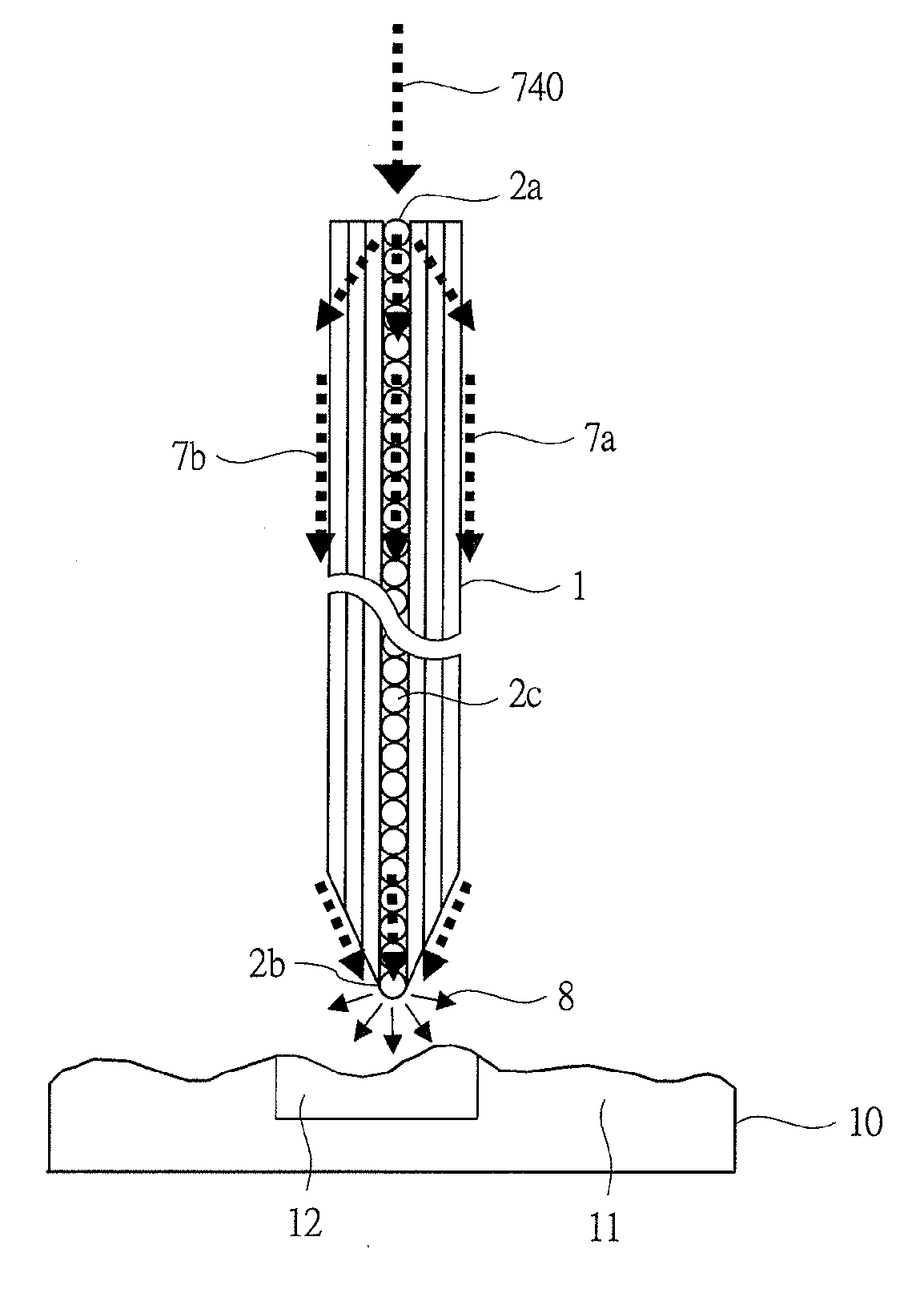

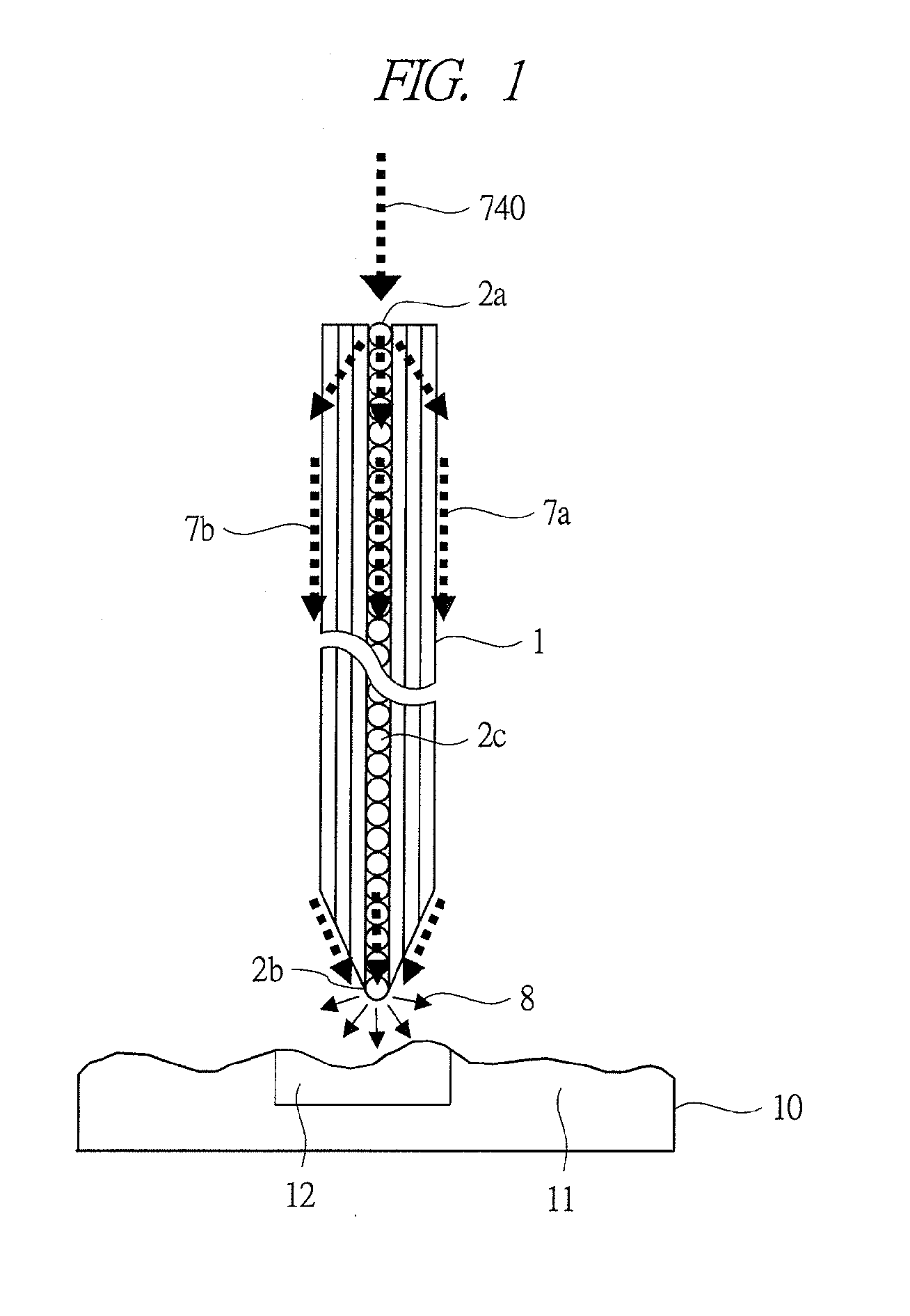

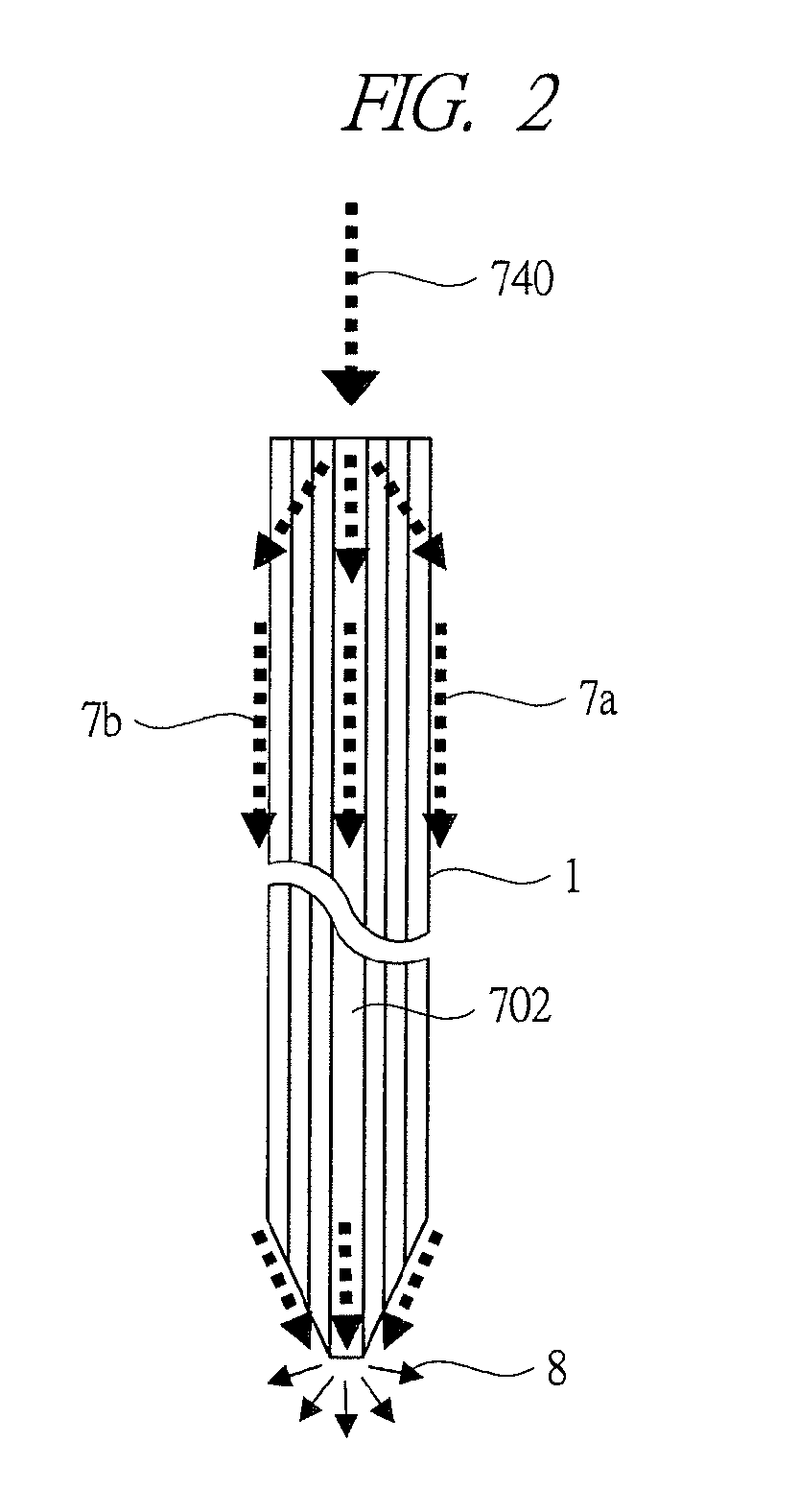

Scanning probe microscope and method of observing sample using the same

ActiveUS20100218287A1Reduced measurement reproducibilityReduce resolutionNanoopticsNanosensorsImage resolutionMeasurement point

In a scanning probe microscope, a nanotube and metal nano-particles are combined together to configure a plasmon-enhanced near-field probe having an optical resolution on the order of nanometers as a measuring probe in which a metal structure is embedded, and this plasmon-enhanced near-field probe is installed in a highly-efficient plasmon exciting unit to repeat approaching to and retracting from each measuring point on a sample with a low contact force, so that optical information and profile information of the surface of the sample are measured with a resolution on the order of nanometers, a high S / N ratio, and high reproducibility without damaging both of the probe and the sample.

Owner:HITACHI LTD

Nanotubes and nanowires based electronic devices and method of fabrication thereof

InactiveUS20090162927A1Easy to produceLow yieldBioreactor/fermenter combinationsMaterial nanotechnologyNanowireBioadhesive

An electronic device is presented comprising at least one electrically conductive element coupled to an elongated carbon or inorganic semiconductor based nanostructure, by a biological binder.

Owner:YEDA RES & DEV CO LTD

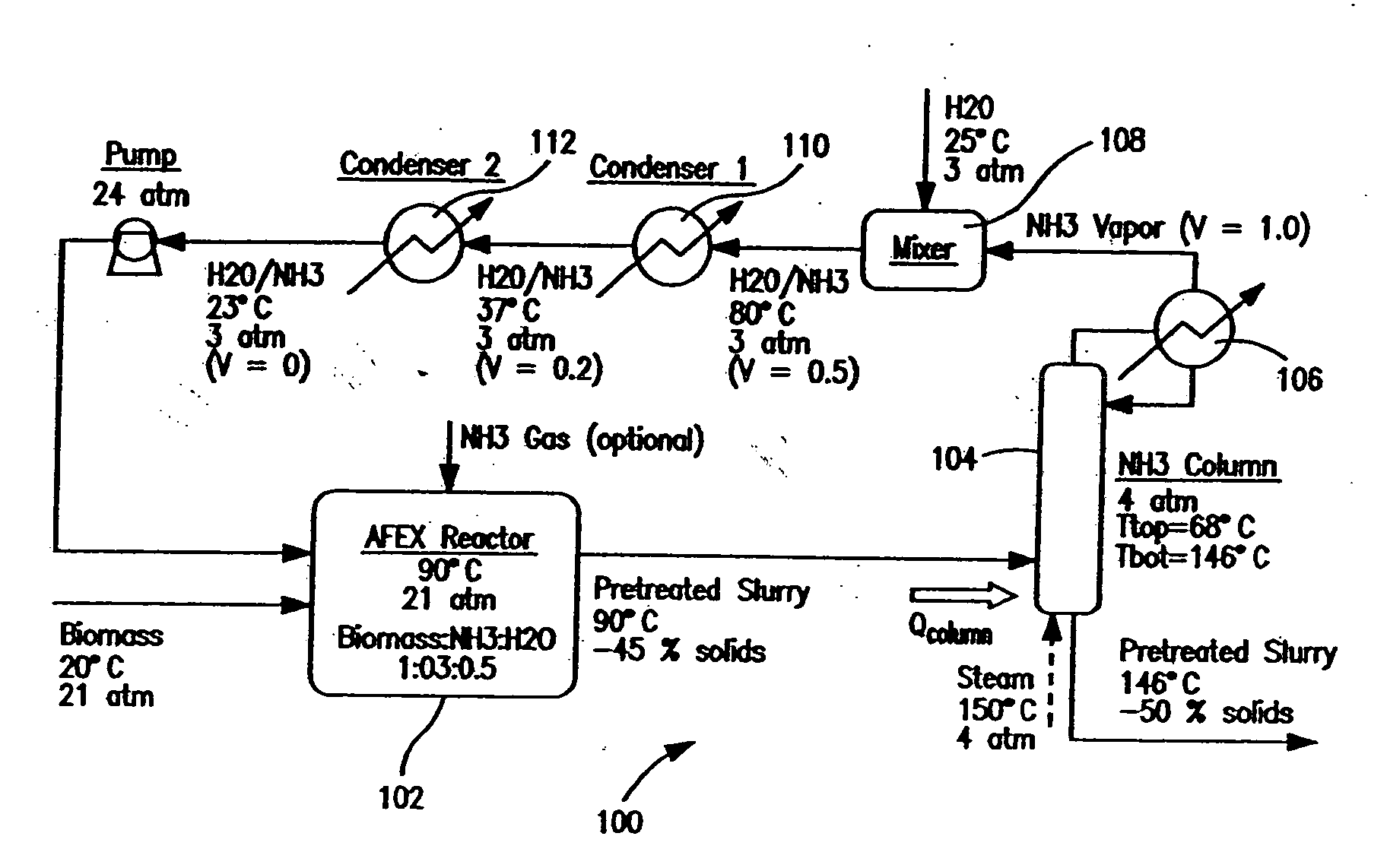

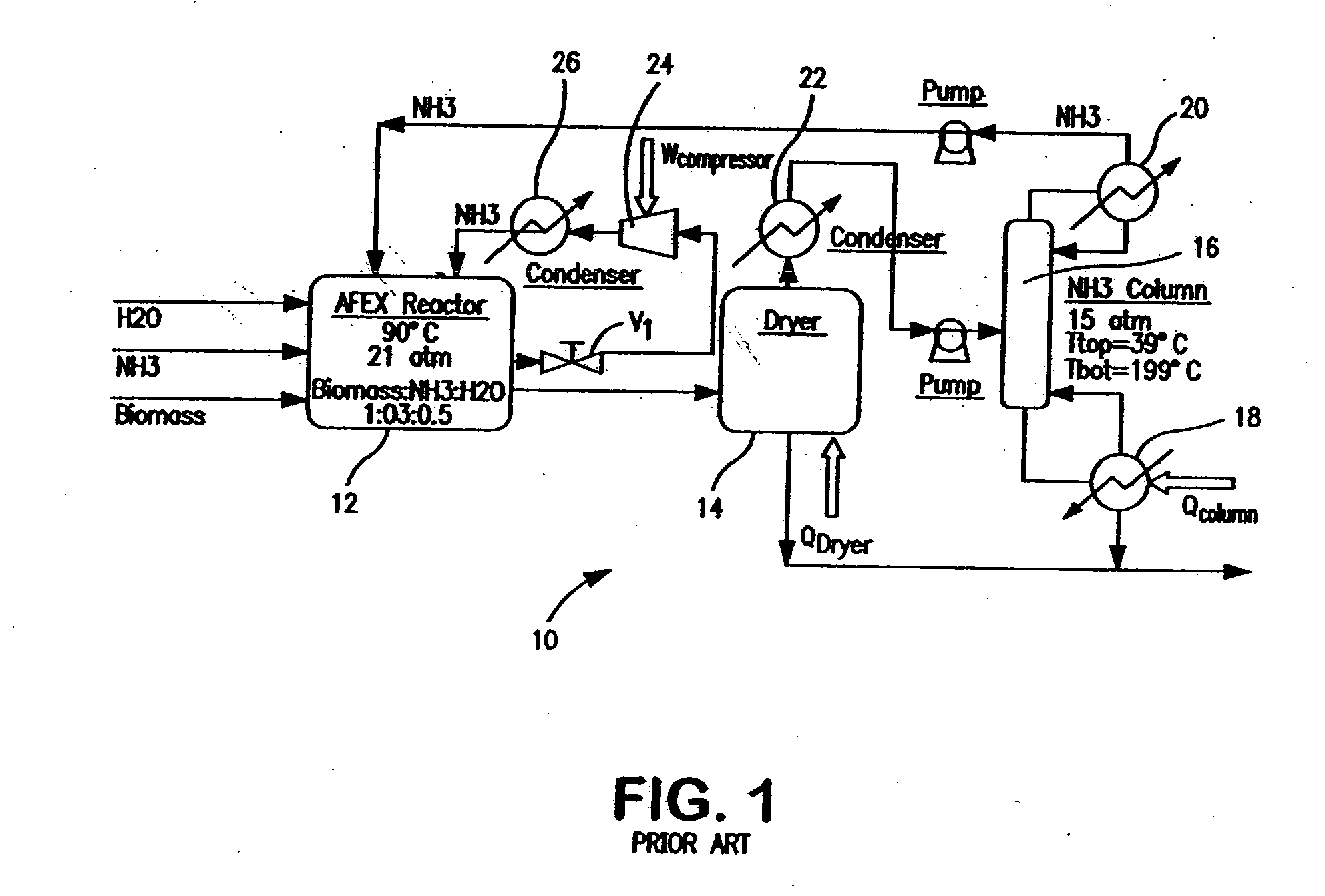

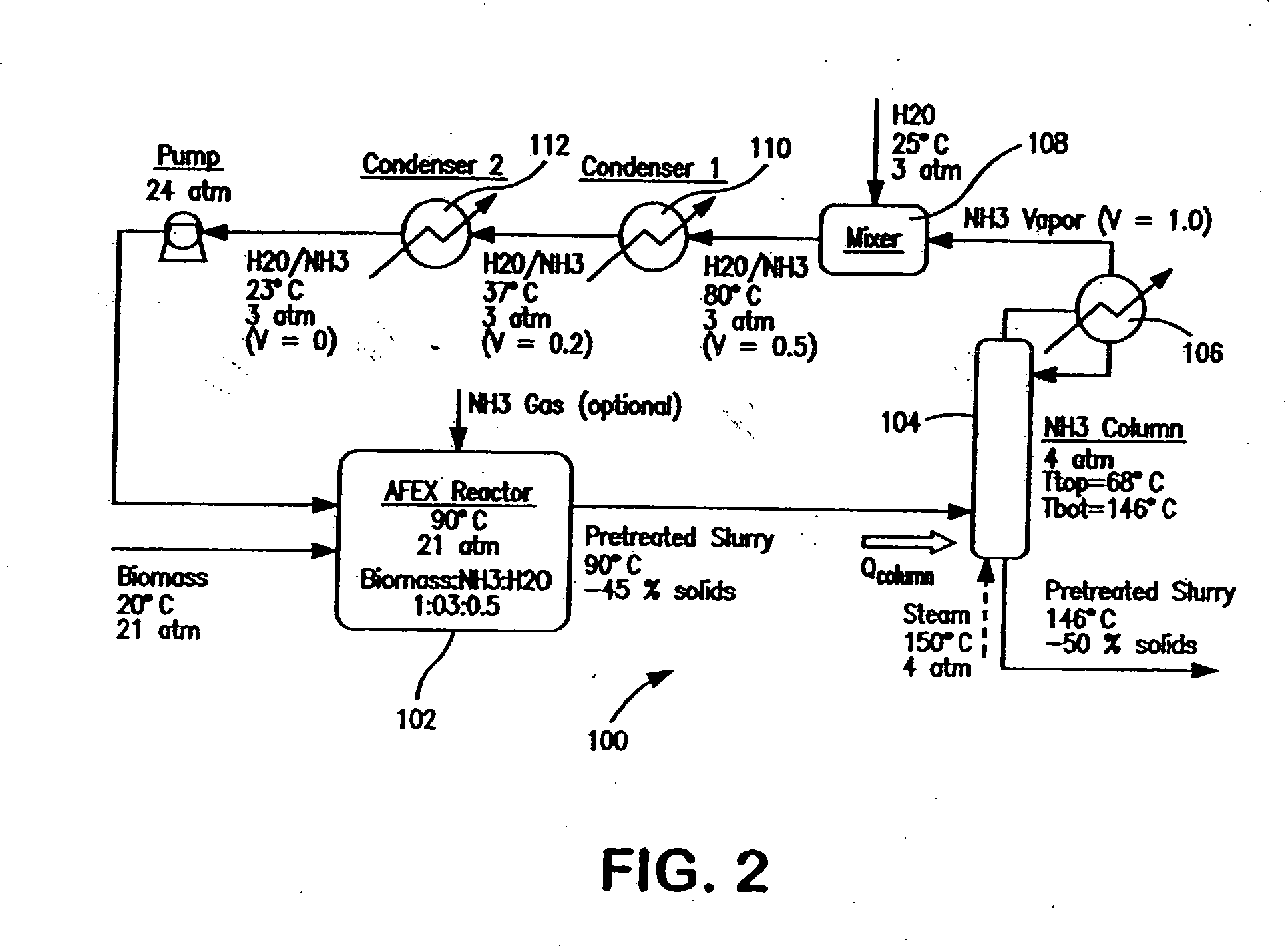

Process for the Treatment of Lignocellulosic Biomass

A process for the treatment of biomass to render structural carbohydrates more accessible and / or digestible using concentrated ammonium hydroxide with or without anhydrous ammonia addition, is described. The process preferably uses steam to strip ammonia from the biomass for recycling. The process yields of monosaccharides from the structural carbohydrates are good, particularly as measured by the enzymatic hydrolysis of the structural carbohydrates. The monosaccharides are used as animal feeds and energy sources for ethanol production.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

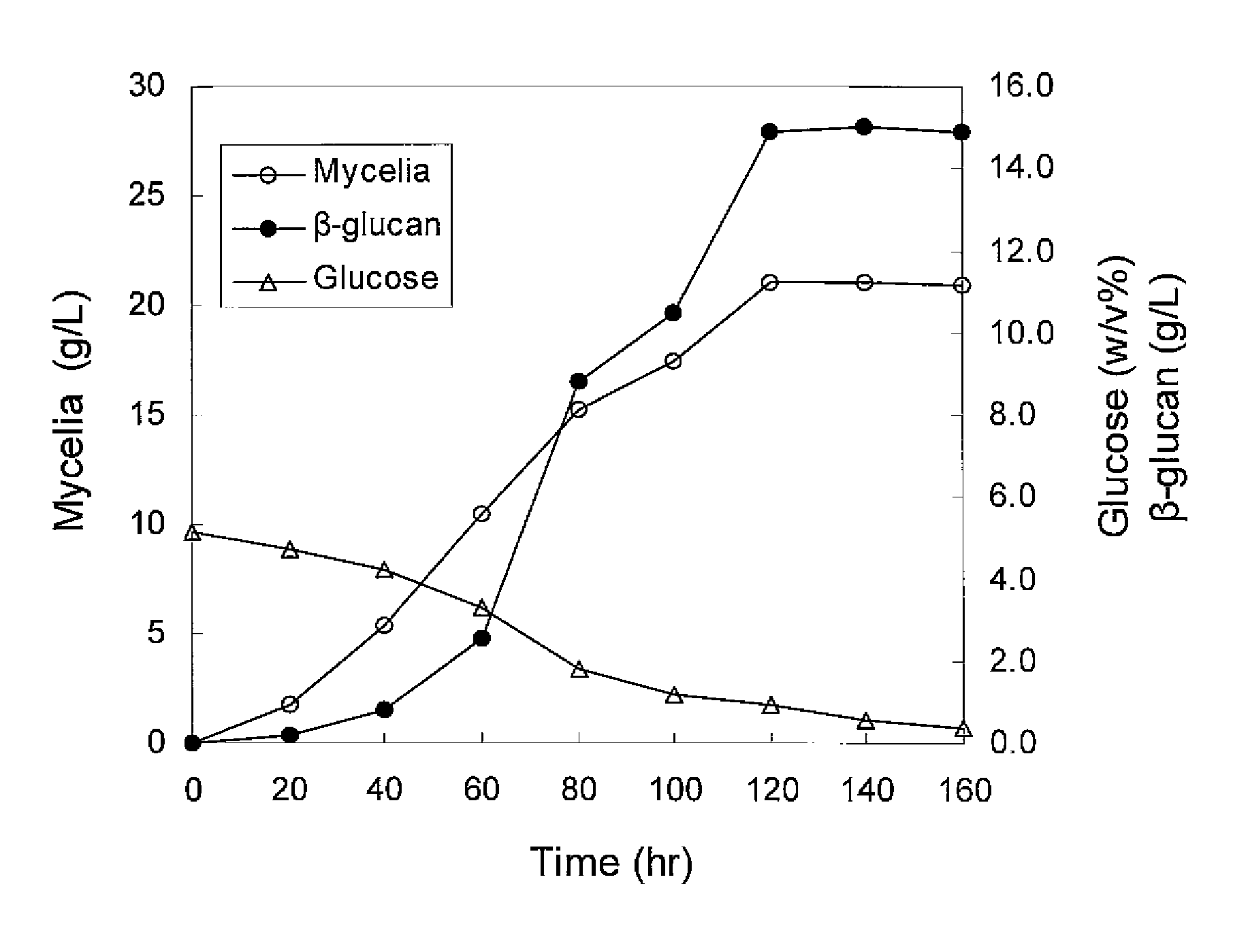

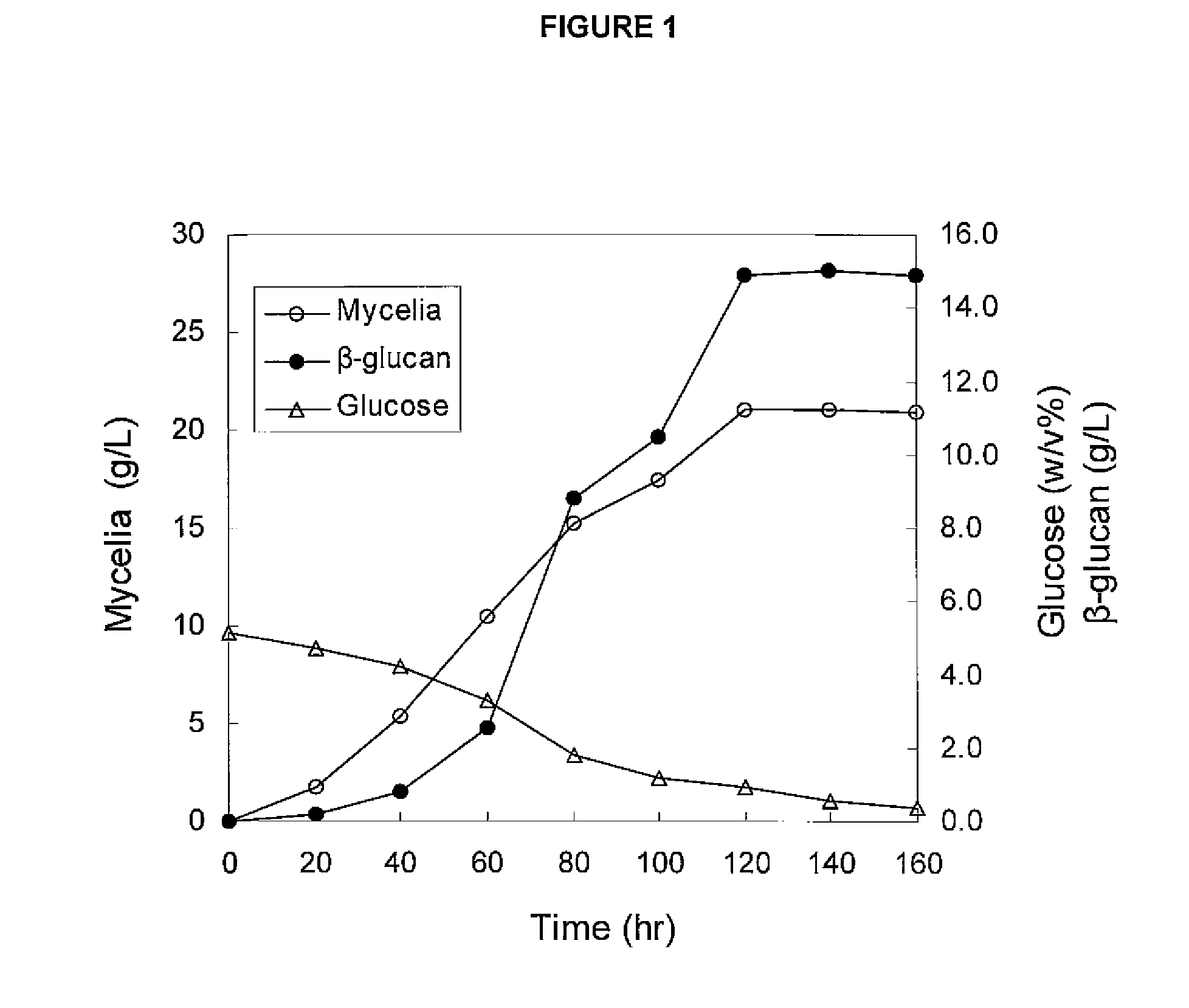

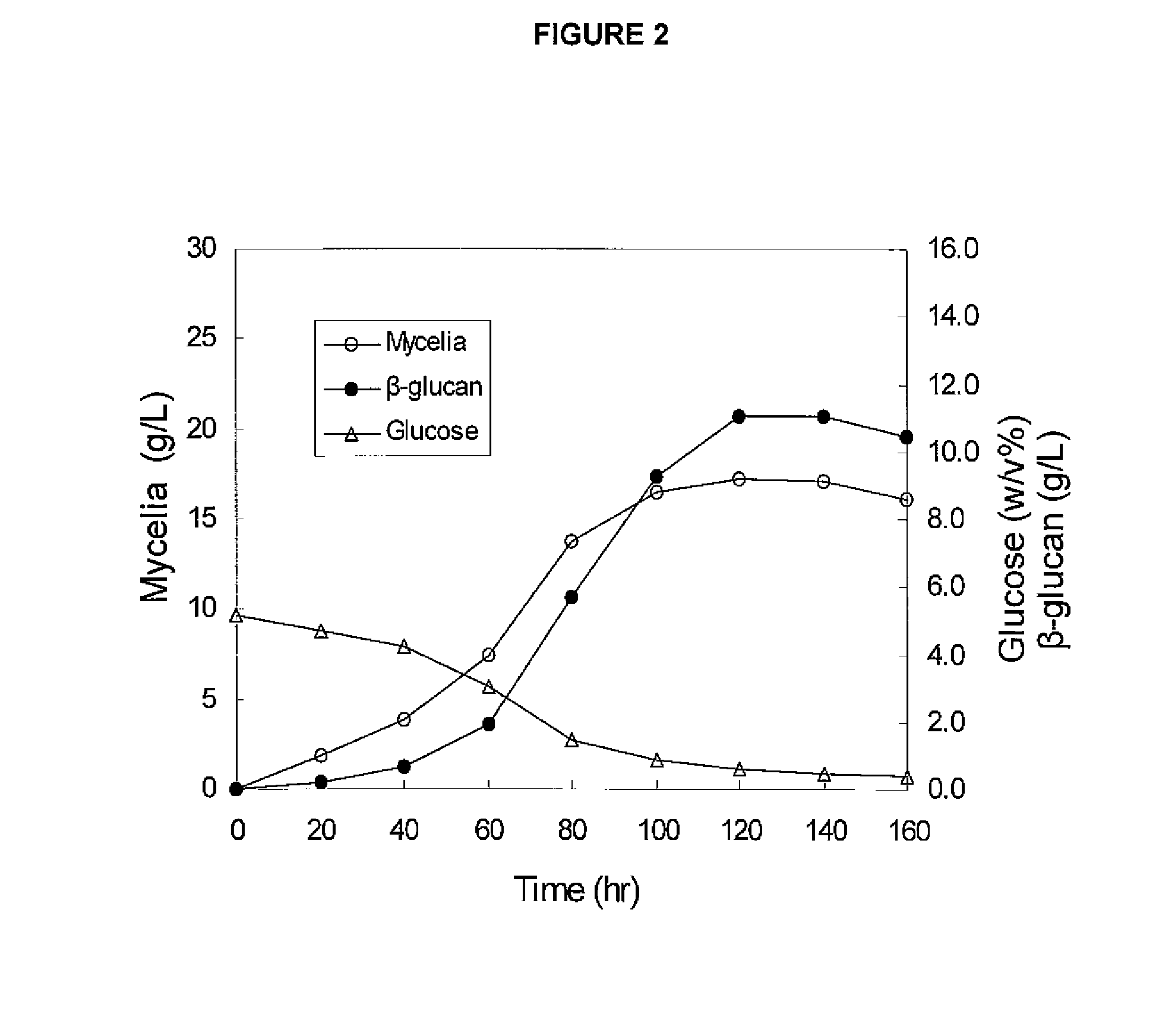

Preparation method of beta-glucan from schizophyllum commune and composition for external application comprising the same

InactiveUS20080160043A1Relieve dry skinRelieve itchingBiocideLichen medical ingredientsExternal applicationAtopic disease

Disclosed herein is a method for high-yield production of Schizophyllum commune-derived beta-glucan having a homogeneous composition, comprising subjecting mycelia of Schizophyllum commune to liquid culture with an addition of a synthetic adsorbent, and a composition for external application comprising the beta-glucan produced therefrom, which is capable of relieving dry skin conditions, atopic diseases and itching.

Owner:MACROCARE TECH

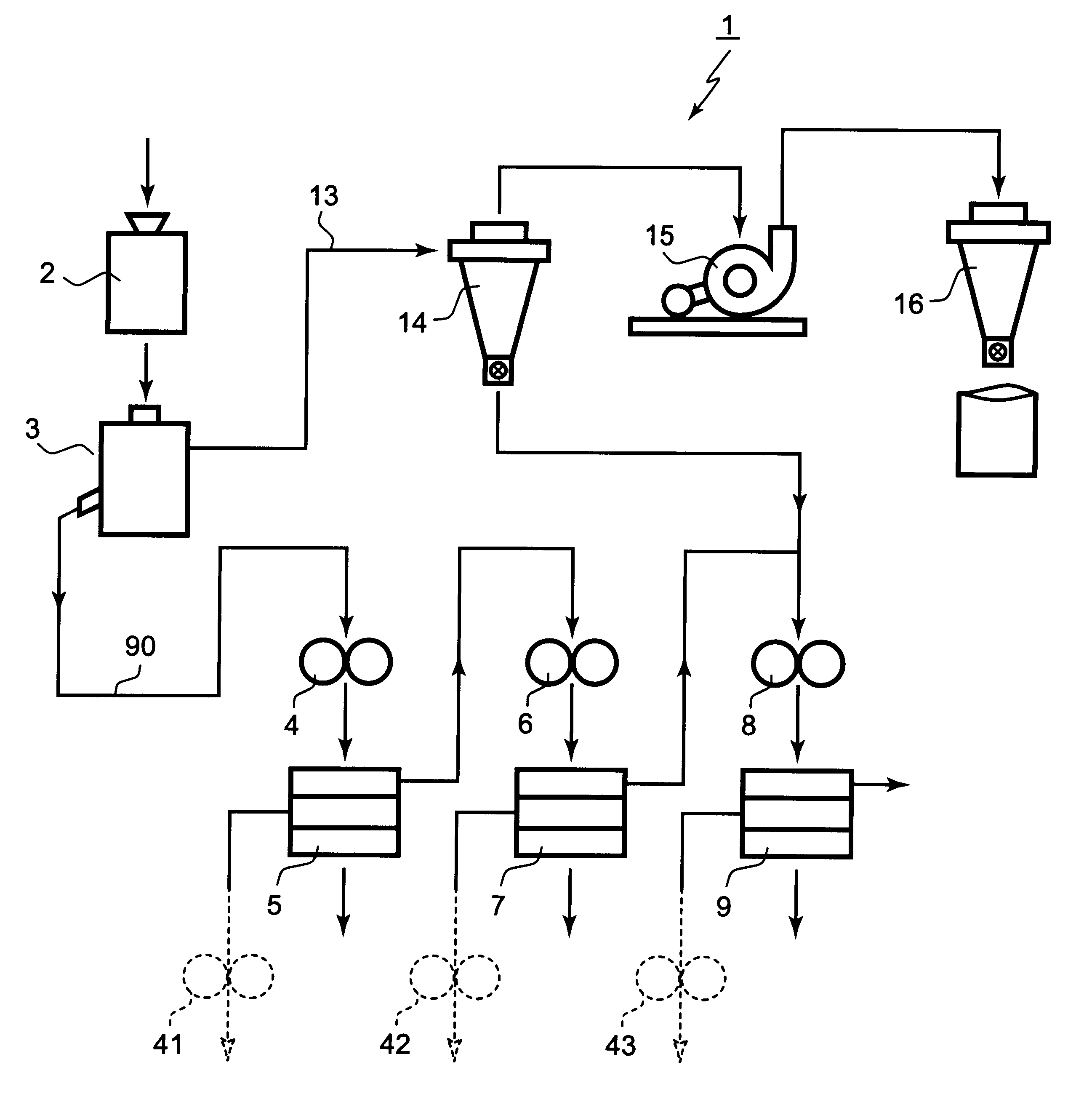

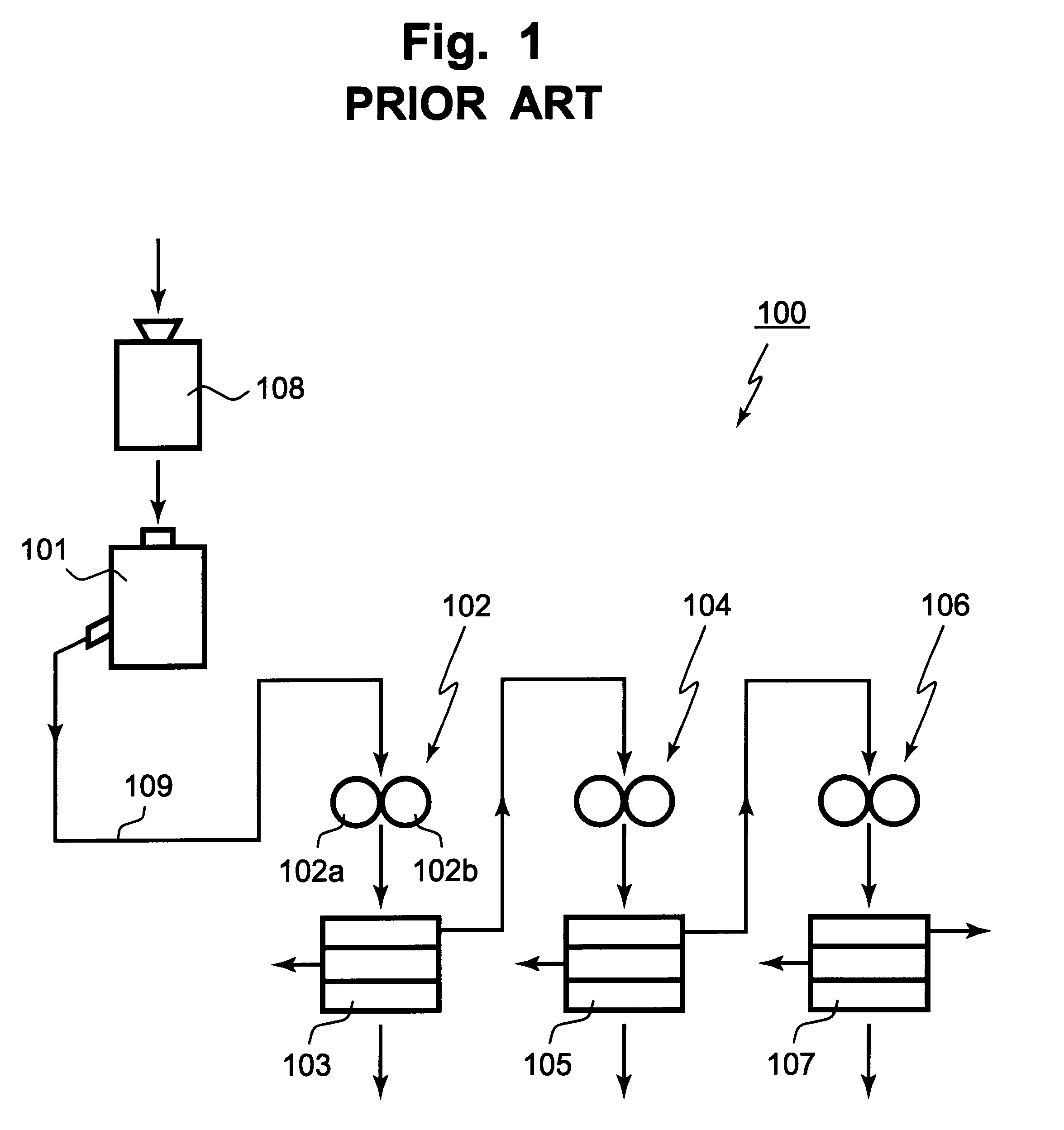

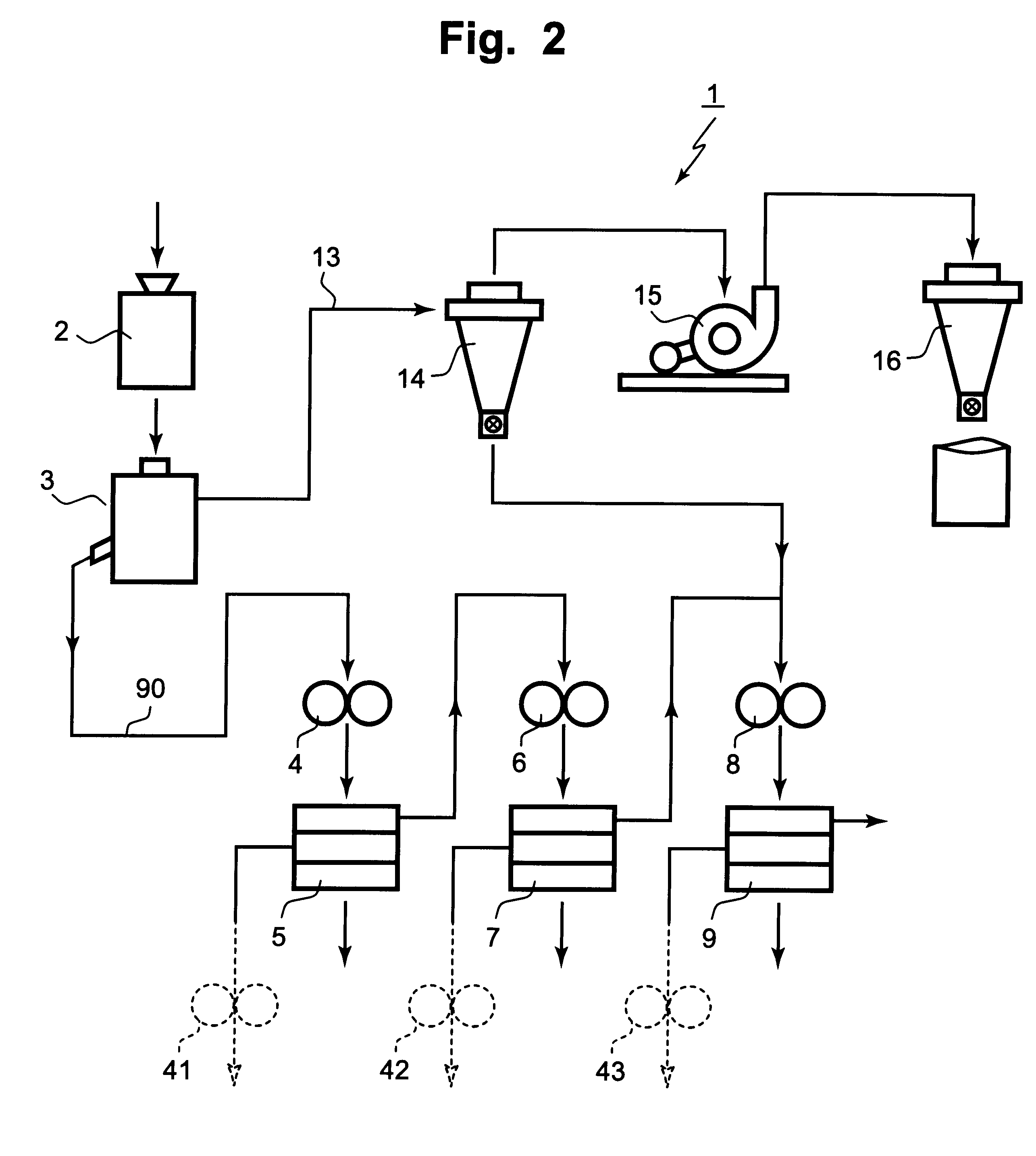

Flour milling method having a sorting step for raw wheat grains and flour milling system adopting the method

InactiveUS6199777B1Enhance advantageous effectHigh yield productionSievingScreeningBiotechnologyRegular Production

A flour milling method and a flour milling system are provided, in which a plurality of milling steps whose milling degrees are different from one another are performed sequentially from an upperstream to a downstream, each of the milling steps including a breaking step and a grading step. The steps are carried out by sorting the raw wheat grains into regular wheat grains and material other than the regular wheat grains, forwarding the sorted regular wheat grains to the uppermost-stream milling step, and forwarding the sorted material other than the regular wheat grains to at least one of downstream milling steps at a downstream of the uppermost-stream milling step. The method and the system enable the production of wheat flour of better quality with better yield than that conventionally produced.

Owner:SATAKE CORP

Catalyst-loaded coal compositions, methods of making and use

ActiveUS8163048B2Efficient and high-yielding gasificationHigh degreeSolid fuelsEnergy inputCoal matrixIon exchange

The present invention relates to catalyst-loaded coal compositions having a moisture content of less than about 6 wt %, a process for the preparation of catalyst-loaded coal compositions, and an integrated process for the gasification of the catalyst-loaded coal compositions. The catalyst-loaded coal compositions can be prepared by a diffusive catalyst loading process that provides for a highly dispersed catalyst that is predominantly associated with the coal matrix, such as by ion-exchange.

Owner:SURE CHAMPION INVESTMENT LTD

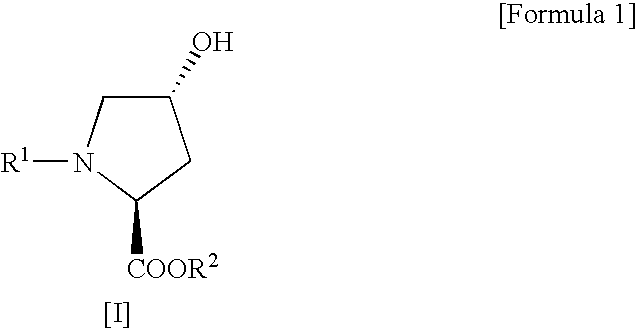

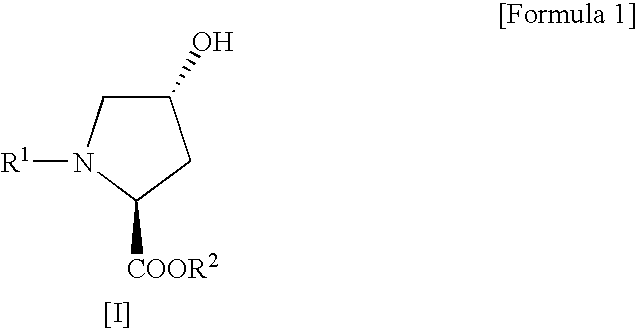

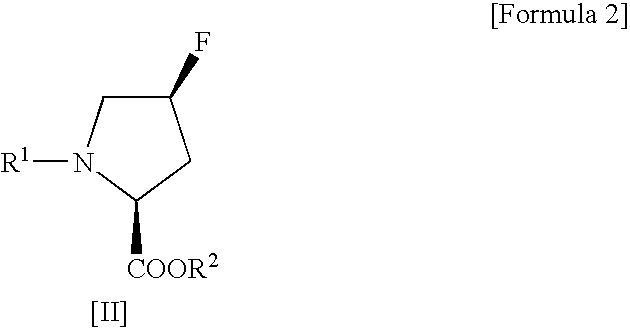

Process for production of cis-4-fluoro-l-proline derivatives

InactiveUS20060281927A1Enables industrial production of a target compound in high yieldInhibit side effectsOrganic chemistryBulk chemical productionHydrogen fluorideScavenger

The present invention provides a safer method for production of a cis-4-fluoro-L-proline derivative under milder conditions and in good yield to give a product of high purity on an industrial scale at low cost. Namely, the present invention provides a method for producing a cis-4-fluoro-L-proline derivative, which comprises reacting a trans-4-hydroxy-L-proline derivative of the following Formula [I]: (wherein R1 represents a protecting group for an α-amino group, and R2 represents a protecting group for a carboxyl group) with N,N-diethyl-N-(1,1,2,3,3,3-hexafluoropropyl)amine in the presence of a hydrogen fluoride-scavenger.

Owner:TAISHO PHARMACEUTICAL CO LTD

Battery pack

InactiveUS7736796B2Reduce riskFirmly connectedPrimary cell to battery groupingSmall-sized cells cases/jacketsElectrical connectionEngineering

A battery pack is made up of a plurality of flat prismatic batteries arranged face to face, each battery having one electrode terminal protruding from one end face in the height direction of the battery case and this end face or a side face of the battery serving as the other electrode terminal. The connector for electrically connecting adjacent prismatic batteries includes a flat part that is welded to one electrode terminal of one prismatic battery of the adjacent prismatic batteries, and a cylindrical part that is fitted onto and welded to the other electrode terminal of the other prismatic battery. The cylindrical part is formed in an attachment part that extends from the flat part through an upright part in the direction in which the batteries are aligned. The connector enables reliable electrical connection of the prismatic batteries despite possible variation in height of the electrode terminals.

Owner:PANASONIC CORP

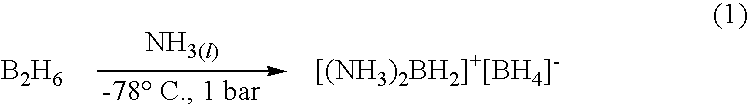

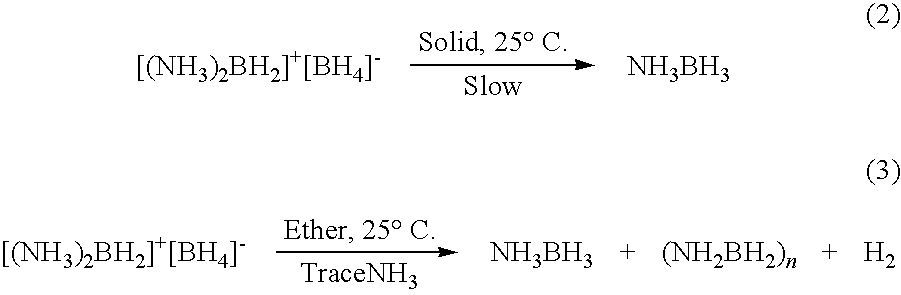

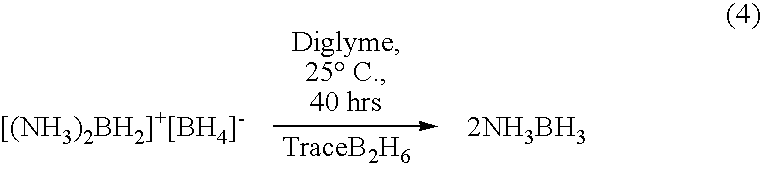

Ambient temperature liquid ammonia process for the manufacture of ammonia borane

InactiveUS20100272623A1High yield productionGroup 3/13 element organic compoundsBoron compoundsChemistryLiquid ammonia

A method of preparing an ammonia borane compound selected from the group consisting of: ammonia borane, ammonia alkyl borane, ammonia aryl borane and mixtures thereof, the method including the steps of: a) incorporating a reaction mixture into a pressure vessel, the reaction mixture including anhydrous liquid ammonia and a boron containing compound that can react under pressure with the liquid ammonia to form the ammonia borane compound; and, b) causing the reaction mixture to warm from a first temperature greater than or equal to −33° C. to a second temperature under pressure to form the ammonia borane compound.

Owner:K ENERGETICS CORP

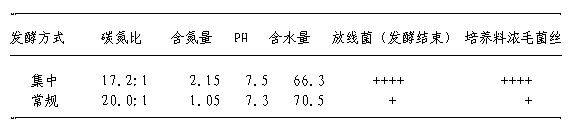

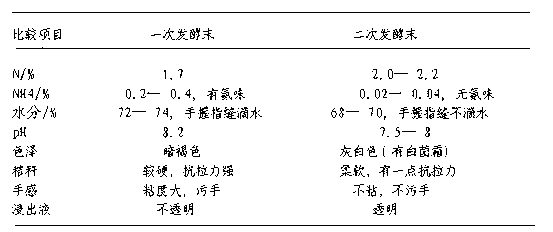

Centralized secondary fermentation method for agaricus bisporus

InactiveCN103319219AQuality productionHigh yield productionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal Foraging

The invention discloses a centralized secondary fermentation method for agaricus bisporus. The culture medium comprises the following raw materials in parts by weight: 45-60 parts of forage, 35-50 parts of chicken manure, 2-8 parts of gypsum and 3-10 parts of oil cakes. The method comprises the following steps of: uniformly spreading forage in a pre-wetting pool for pre-wetting for 2-5 days; adding chicken manure, gypsum and oil cakes and uniformly and adequately mixing; filling the mixed fermentation material in a ventilating floor in a primary fermentation tunnel, and conveying fresh air to the fermentation material through a fan; fermenting for 4-6 days and transferring the fermentation material to another primary fermentation tunnel. The base material of the primary tunnel fermentation is uniformly stacked on the ventilating floor in a secondary fermentation tunnel, and the temperature of the fermentation material is controlled by operation of the fan. Secondary fermentation comprises the following steps: a balancing stage, a heating stage, pasteurization, cultivation at constant temperature and discharge at low temperature. According to the method, local wheat straw hoods, straws, chicken manure and the like are used as main raw materials to form the culture medium. Centralized scaled production cultivation materials are formed by the technology of pre-treatment of the raw materials, primary fermentation and secondary fermentation.

Owner:SICHUAN MAOSEN BIOLOGICAL SCI & TECH

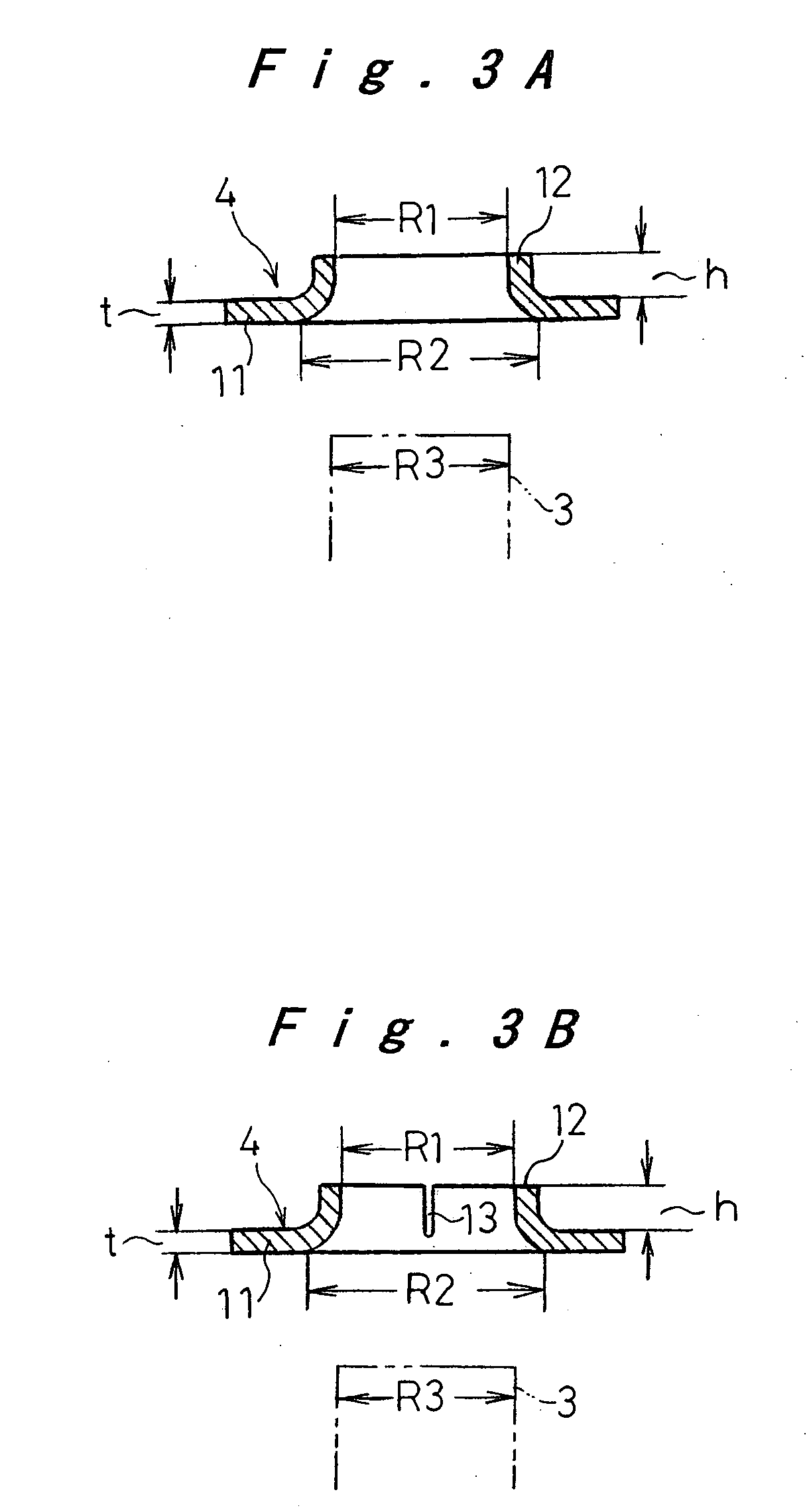

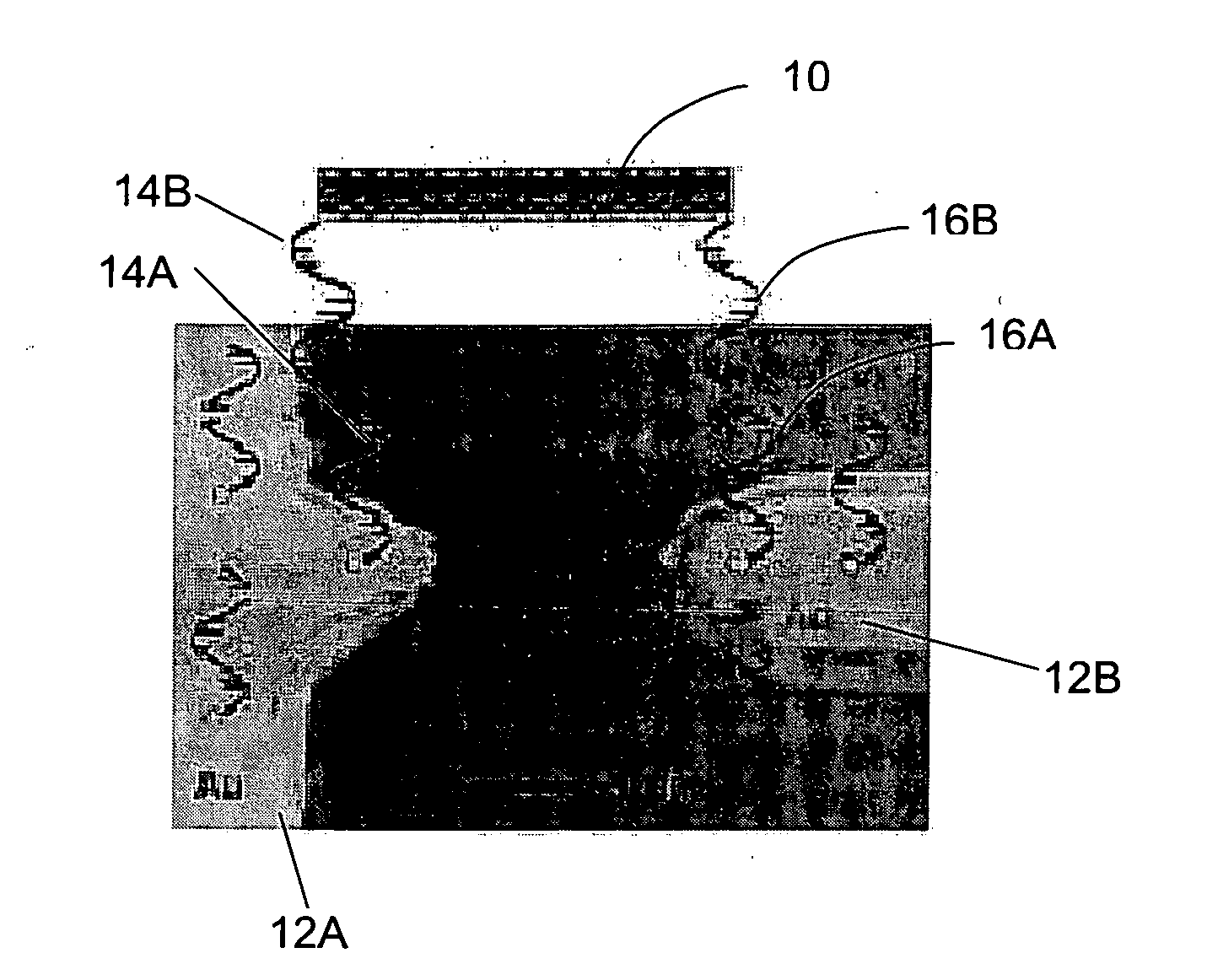

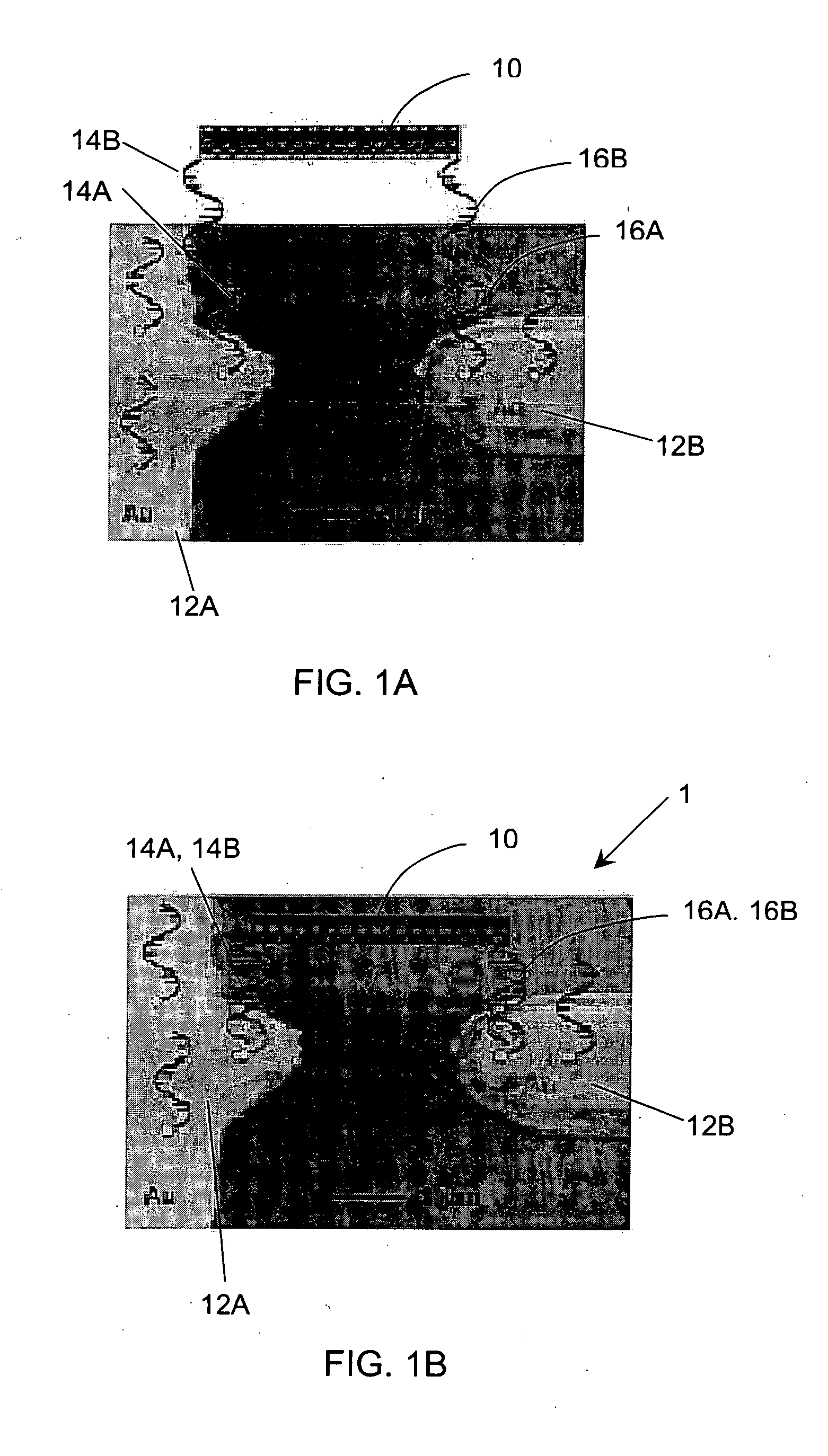

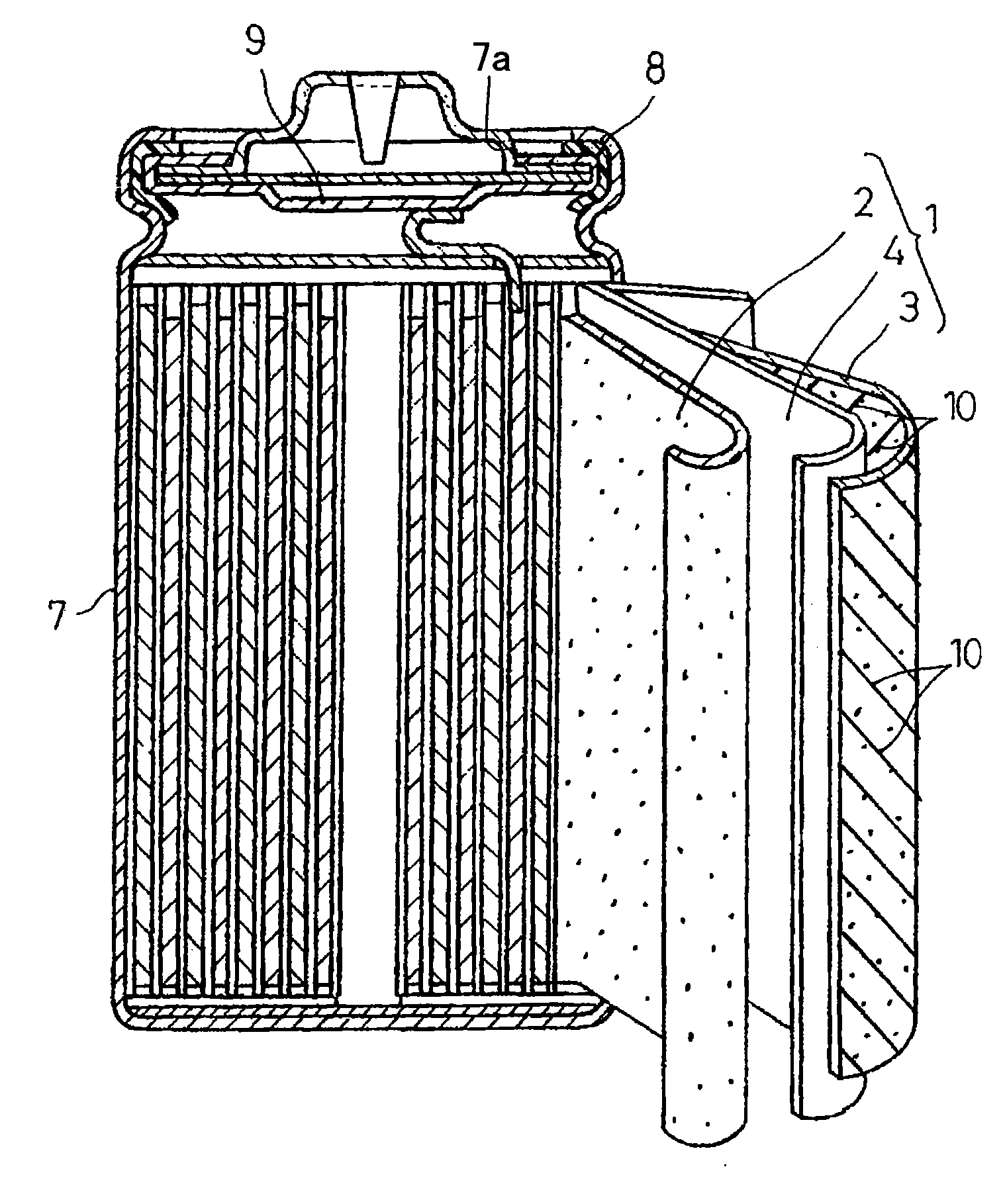

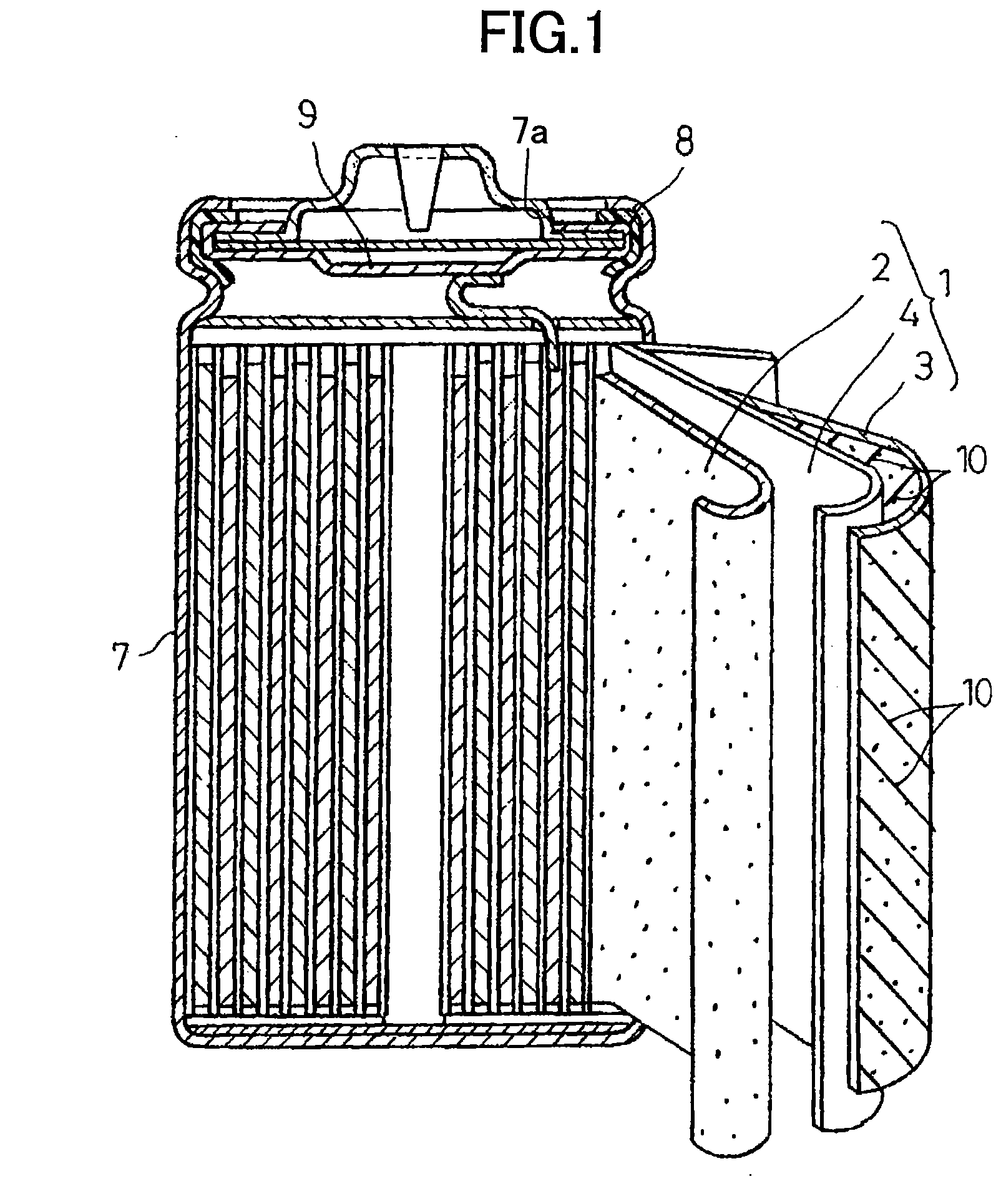

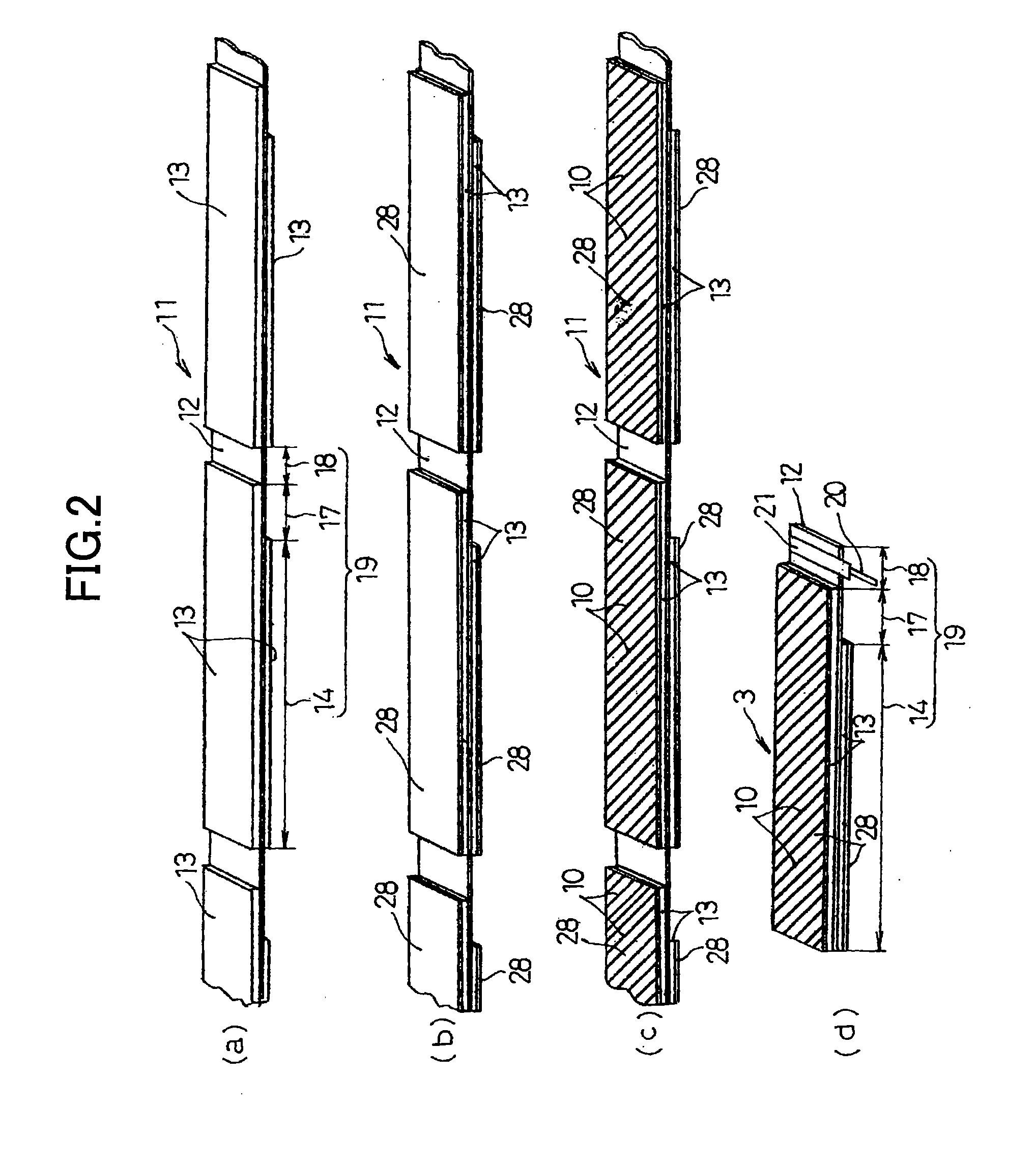

Secondary battery and method for producing the same

InactiveUS20100136394A1High yield productionAvoid it happening againFinal product manufactureElectrode carriers/collectorsEngineeringElectrolyte

A secondary battery includes an electrode plate group (1) in which a positive electrode plate (2) and a negative electrode plate (3) are wound or stacked with a separator (4) interposed therebetween and a battery case (7) in which the electrode plate group (1) and an electrolyte are contained. At least one of the positive electrode plate (2) and the negative electrode plate (3) includes a porous protective film (28) formed on a surface of an active material layer. In a surface of the at least one of the electrode plates on which the porous protective film (28) is provided, a plurality of grooves (10) are formed, and the grooves (10) are also formed in the surface of the active material so that each of the grooves (10) extends from the surface of the porous protective film (28) to the surface of the active material layer.

Owner:PANASONIC CORP

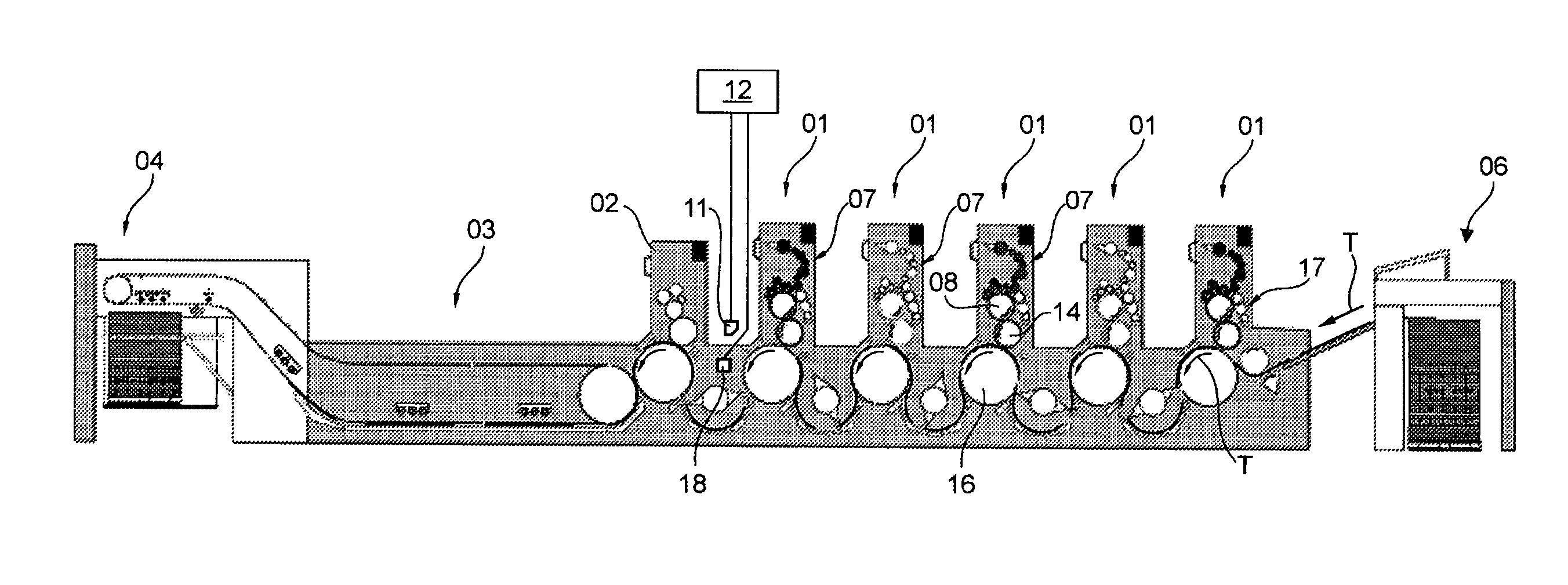

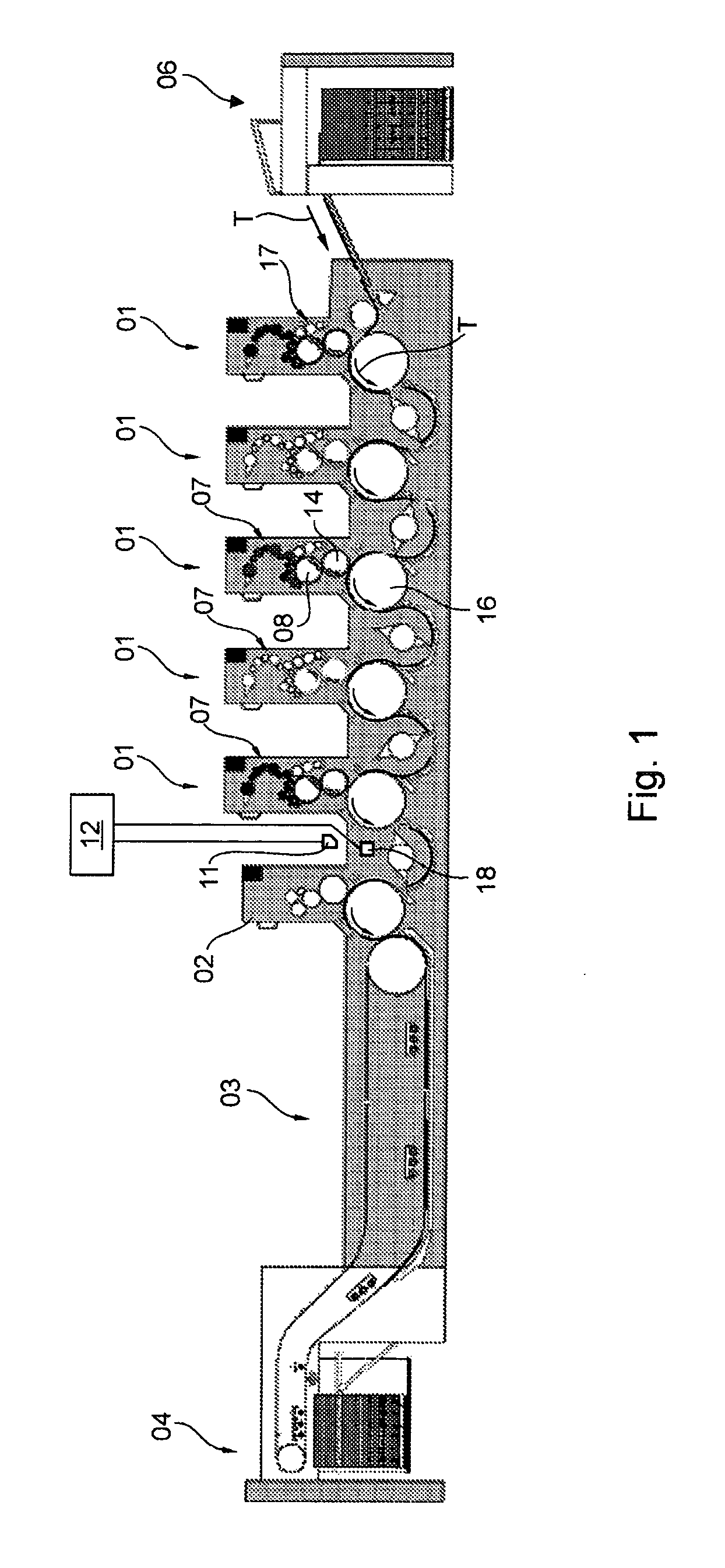

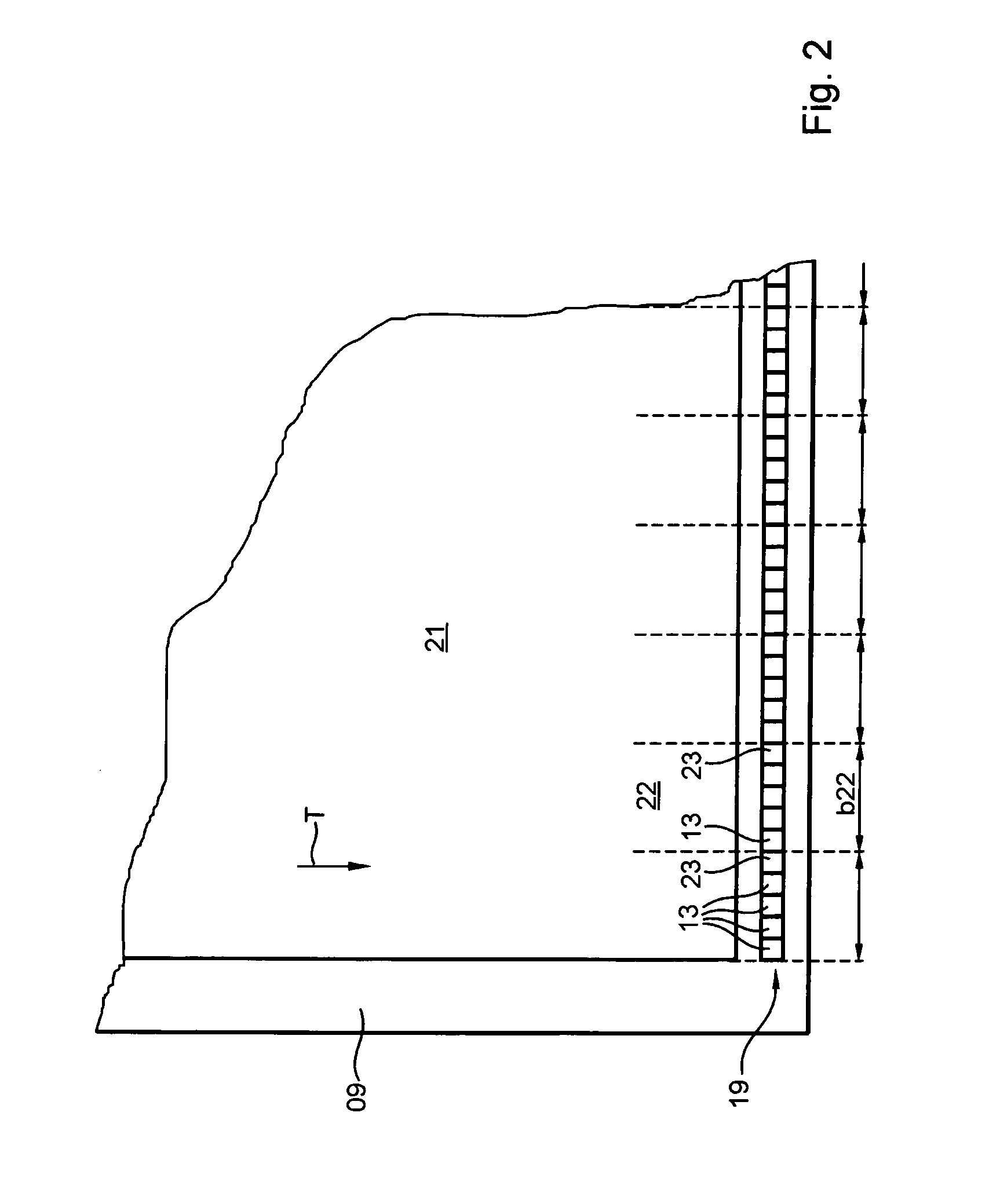

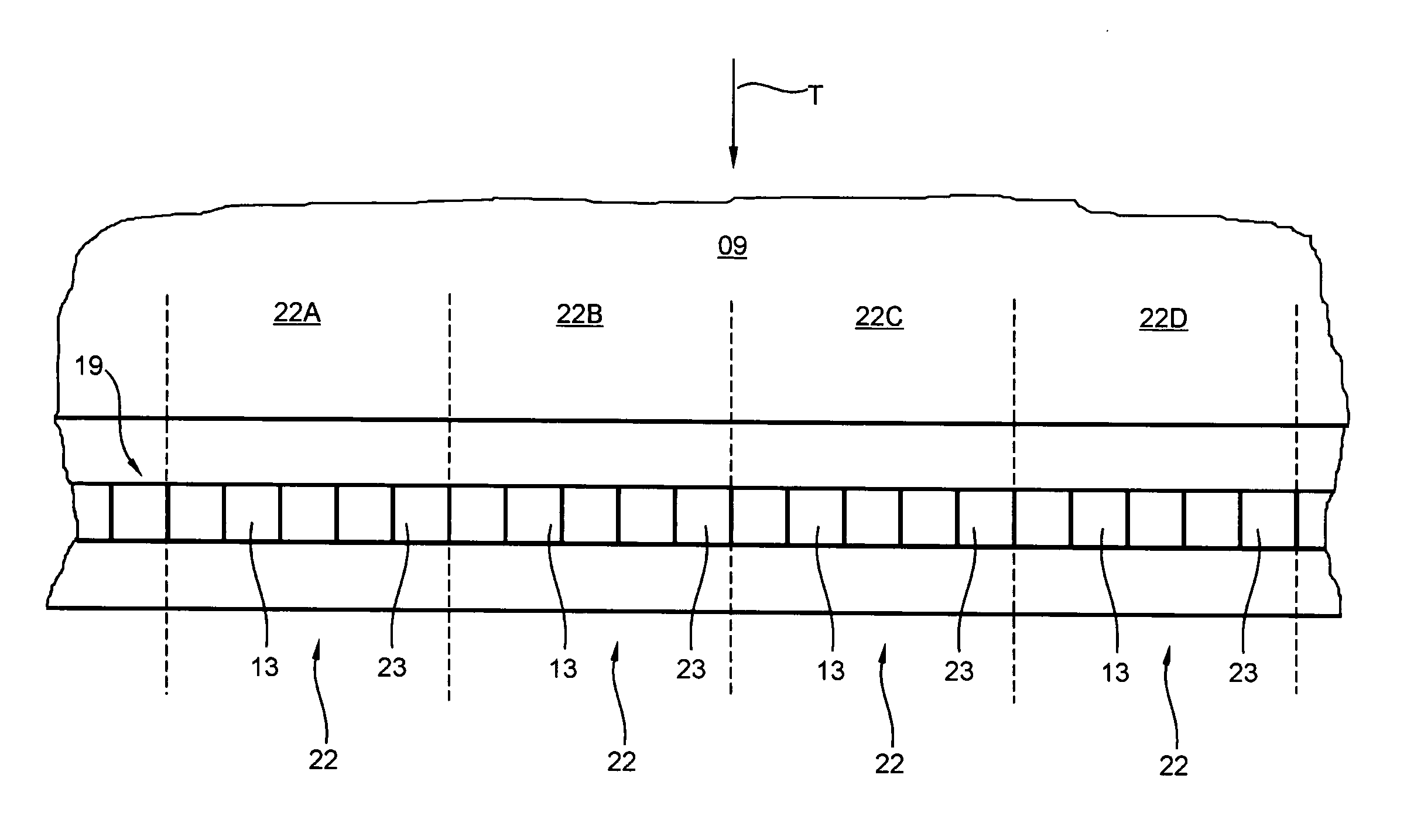

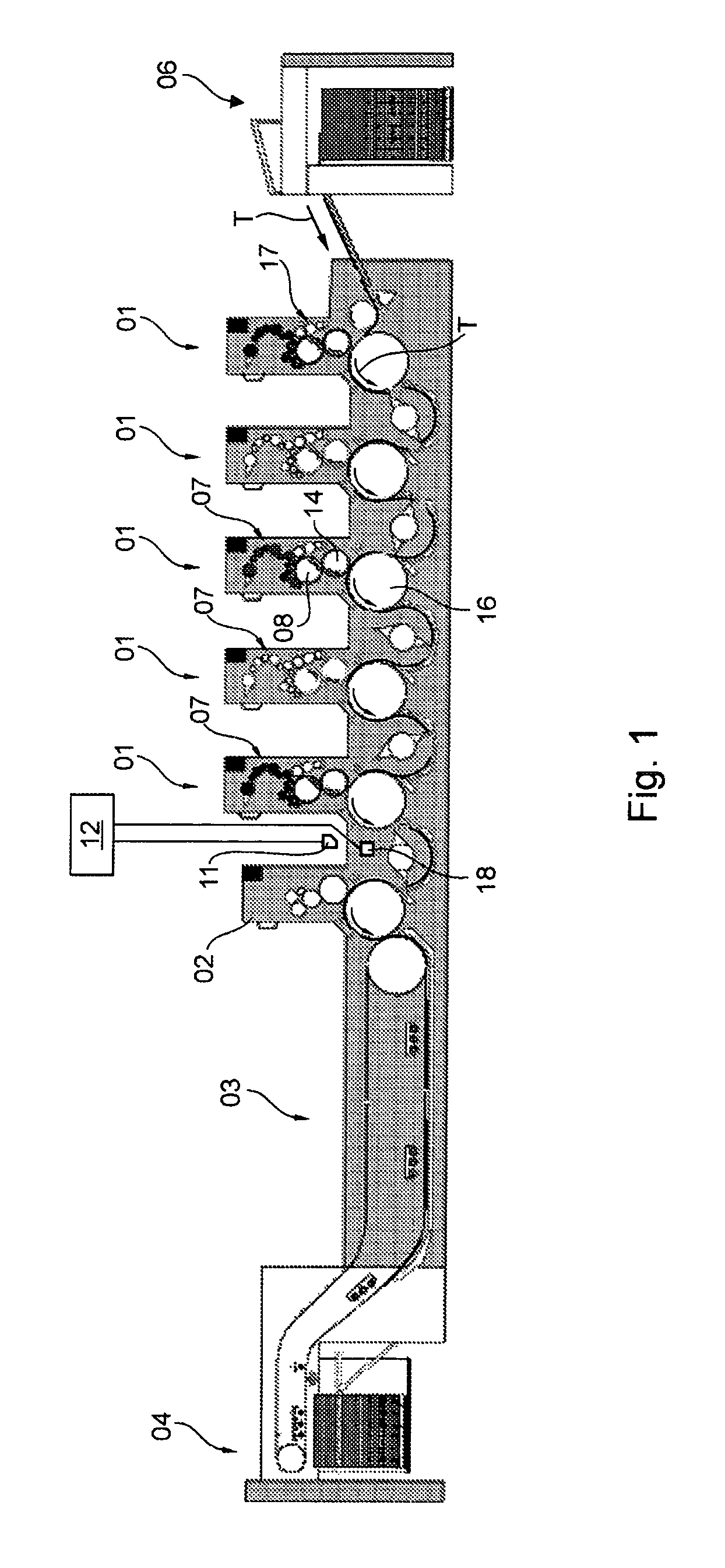

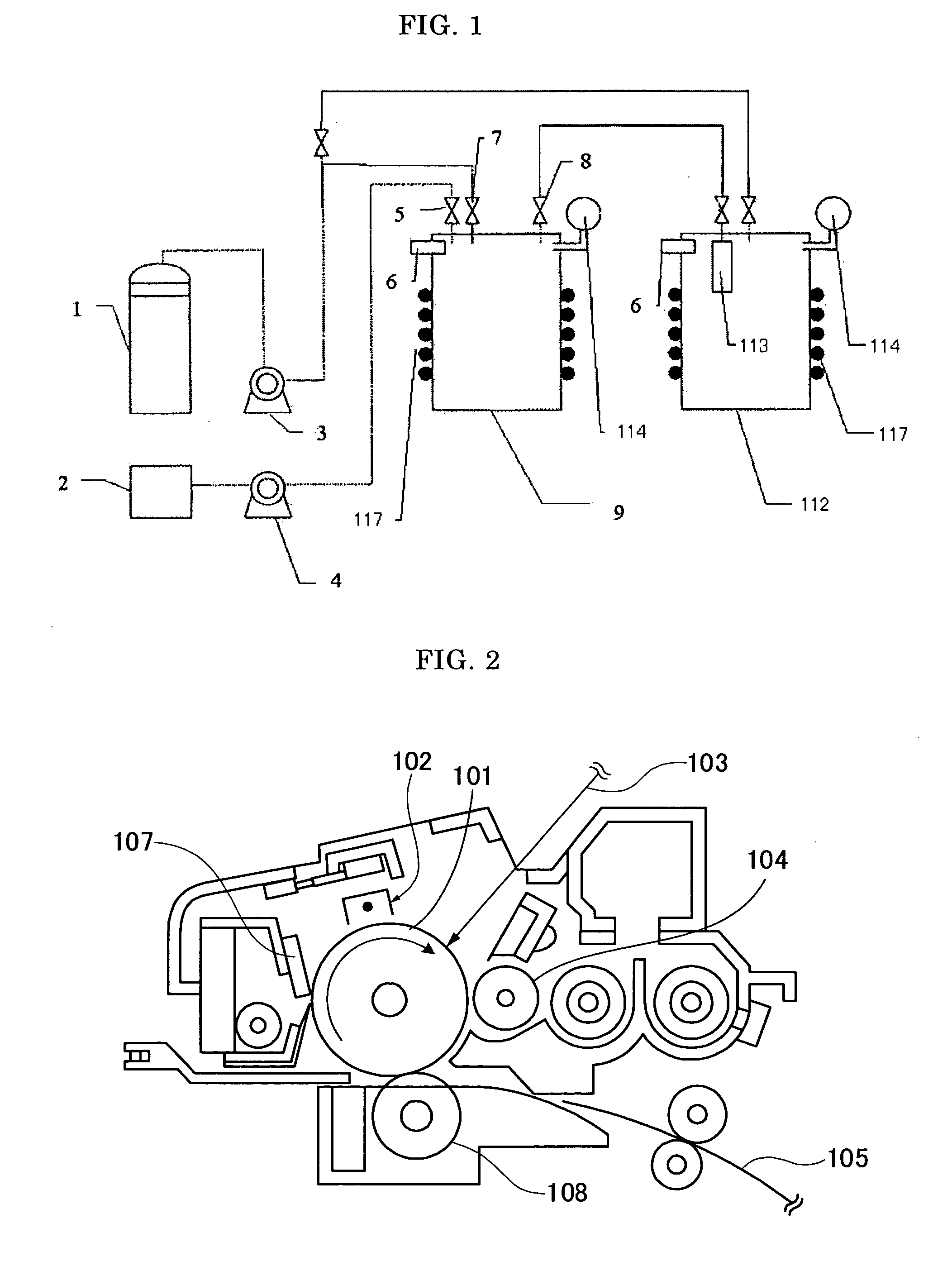

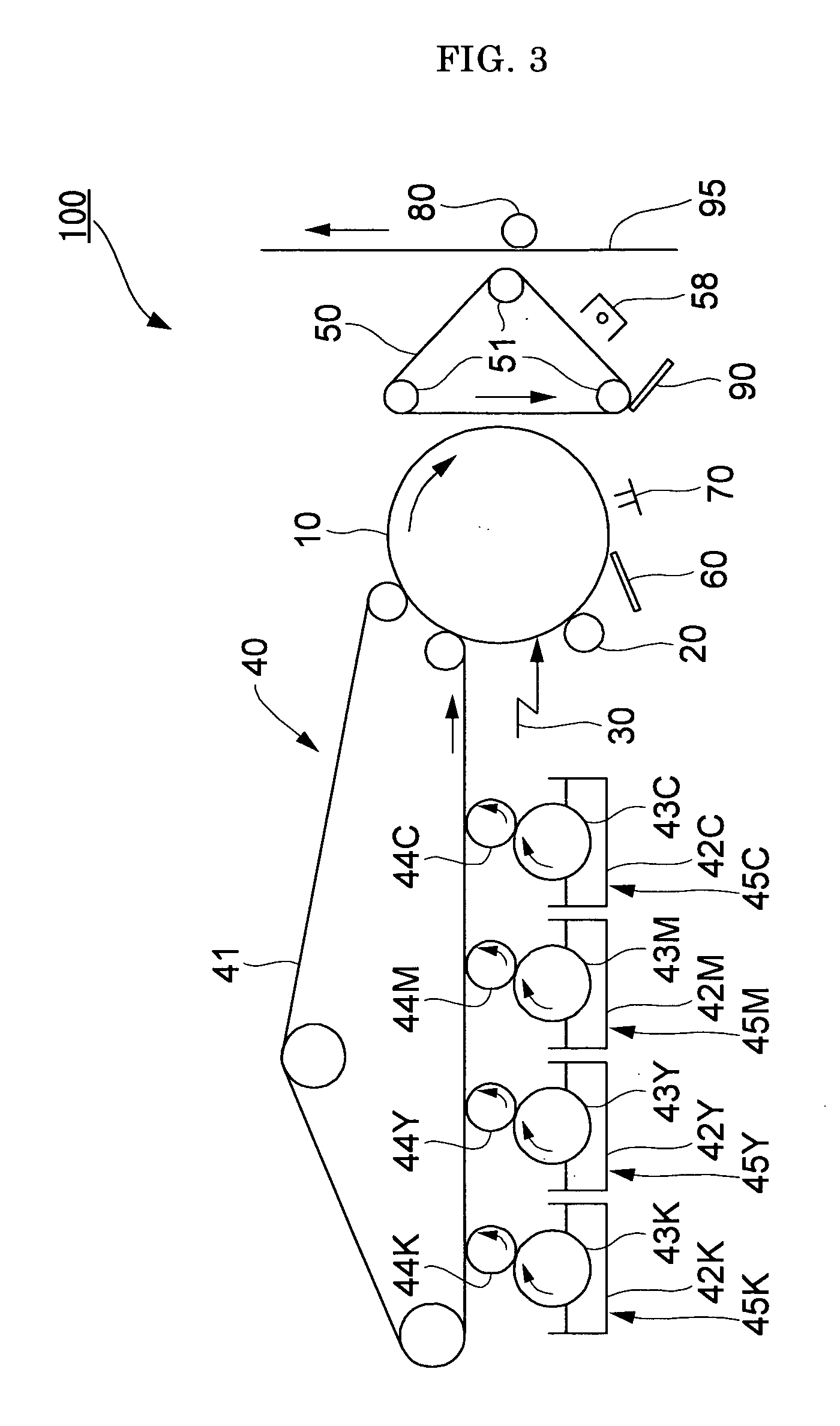

Method for regulating the ink in a printing press

ActiveUS20110132218A1Prevent disruptionHigh qualityAddressographsInking apparatusEngineeringElectrical and Electronics engineering

The ink in a printing press, in which a stock of material is being printed in an ongoing printing process, is registered. At least one ink is applied to the stock in several inking zones. A measured value, indicating an ink density, is determined for the at least one ink which is being applied to the stock in the printing process and within the printing press. A relation is formed between the measured ink density for a specific ink in a selected ink zone and a measured ink density value determined for the same ink in at least one other inking zone. The relation between the measured ink density values in different inking zones is formed only if the majority of the inking zones of a specific inking unit of the printing press supply one respective measured ink density value for an ink supplied by that inking unit, and when the measured ink density value reaches at least a predetermined fraction of a preset, desired value in the respective inking zone.

Owner:KOENIG & BAUER AG

Method for regulating the ink in a printing press

ActiveUS8100057B2Guaranteed stable actionHigh yield productionInking apparatusAddressographsPrinting pressElectrical and Electronics engineering

The ink in a printing press, in which a stock of material is being printed in an ongoing printing process, is registered. At least one ink is applied to the stock in several inking zones. A measured value, indicating an ink density, is determined for the at least one ink which is being applied to the stock in the printing process and within the printing press. A relation is formed between the measured ink density for a specific ink in a selected ink zone and a measured ink density value determined for the same ink in at least one other inking zone. The relation between the measured ink density values in different inking zones is formed only if the majority of the inking zones of a specific inking unit of the printing press supply one respective measured ink density value for an ink supplied by that inking unit, and when the measured ink density value reaches at least a predetermined fraction of a preset, desired value in the respective inking zone.

Owner:KOENIG & BAUER AG

Novel maize culture technology

InactiveCN103947324AHigh yield productionQuality productionFertilising methodsSeed coating/dressingBiotechnologyMechanical equipment

The invention discloses a novel maize culture technology. The implementation method of the novel maize culture technology comprises the following steps: selection and preparation of land, selection and treatment of seeds, treatment before sowing, sowing, field management, in-time herbicide spraying, and harvesting. The novel maize culture technology has the characteristics that novel mechanical equipment is adopted for reasonable planting, and the traditional maize cultivation technology is broken through, and high-yield, high-quality and high-efficiency maize production is realized.

Owner:黎雁欣

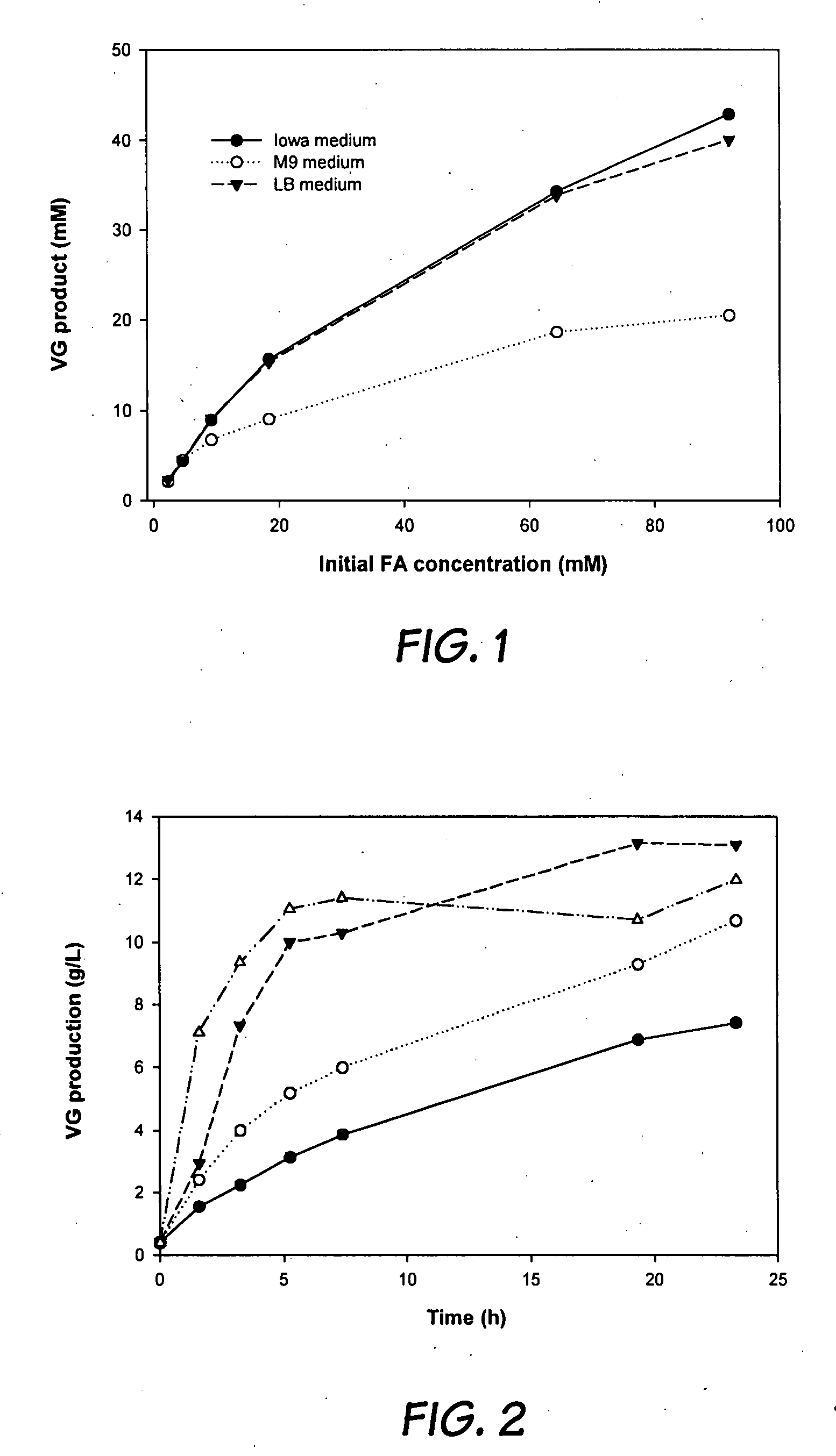

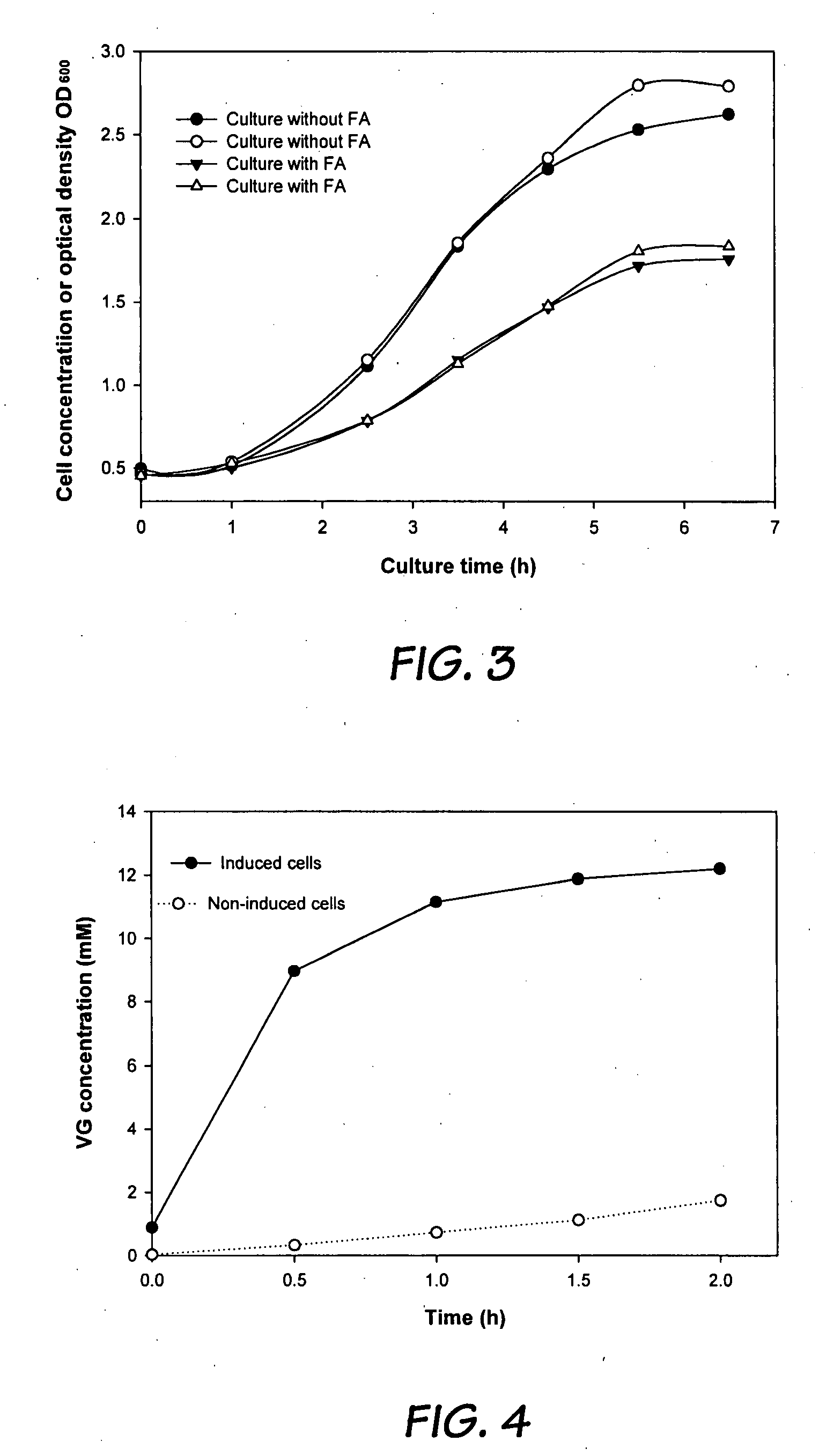

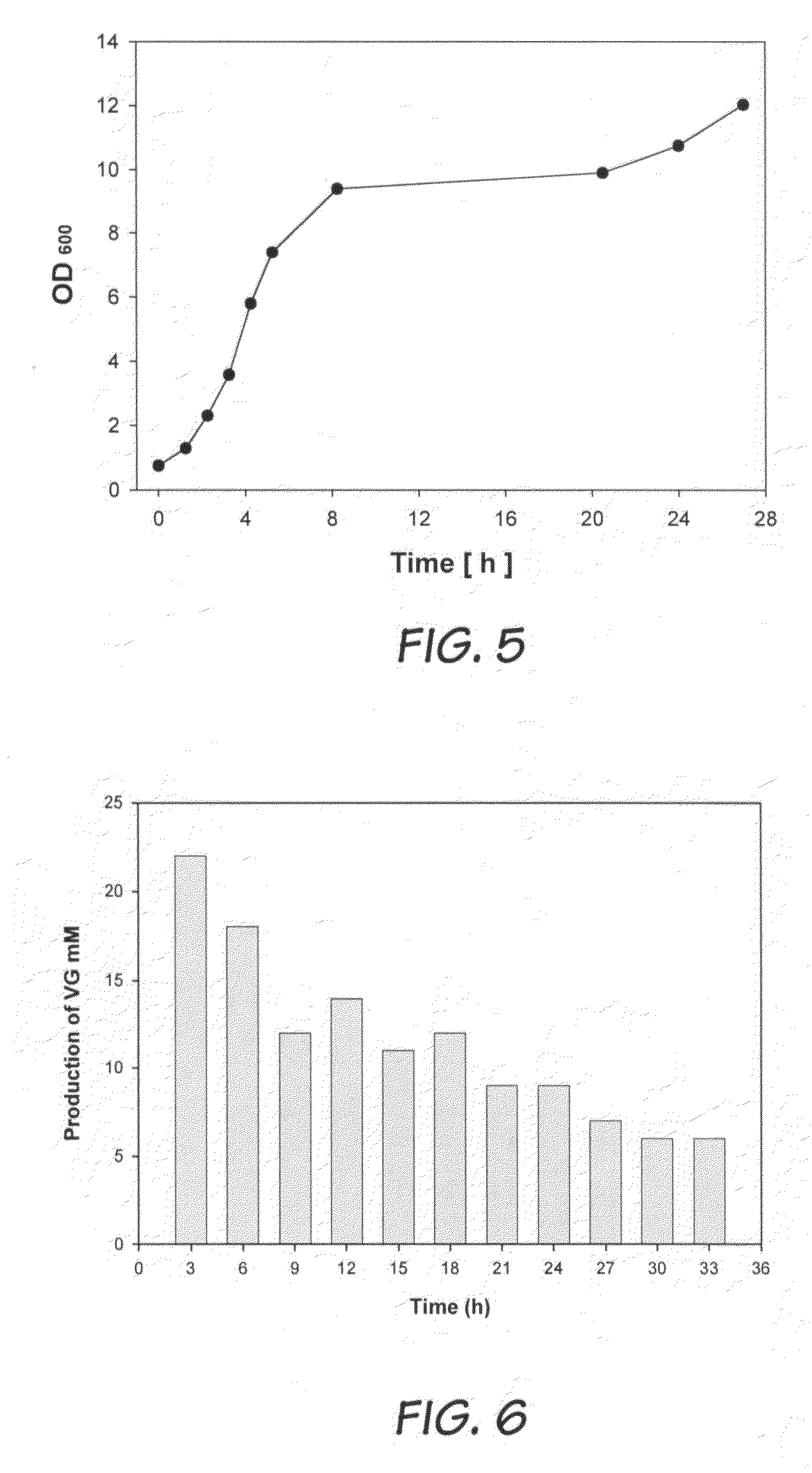

Process for producing 4-vinylguaiacol by biodecaroxylation of ferulic acid

InactiveUS20070224668A1Increase productionIncrease ratingsBacteriaFermentationHydrocarbon solvents4-vinylguaiacol

4-vinylguaiacol is produced using recombinant E. coli containing a decarboxylase gene from Bacillus pumilis in an aqueous fermentation broth and in an immobilized whole cell system. The 4-vinylguaiacol is extracted and recovered from an organic hydrocarbon solvent, preferably n-octane, whereby the product can readily be separated.

Owner:NAT RES COUNCIL OF CANADA

Process for the preparation of tetrabromobisphenol-A

InactiveUS6218584B1High yieldImprove processing efficiencyOrganic chemistryOrganic compound preparationOrganic solventTetrabromobisphenol A

This invention relates, inter alia, to a process for the production of tetrabromobisphenol-A by the bromination of bisphenol-A and / or underbrominated bisphenol-A, which process features: a water and water-miscible organic solvent reaction medium; a relatively high reaction temperature; and the presence, in the reaction medium, of both (i) excess unreacted Br2 during the feed of bis-phenol-A to the reactor, and (ii) sufficient HBr to protect the tetrabromobisphenol-A produced against undesirable color formation. Tetrabromobisphenol-A precipitates from the reaction mass and is easily recovered. Product of high purity (97% or more) and very low color (APHA of 50 or less) can be produced, even when using large excesses of bromine in the reaction.

Owner:ALBEMARLE CORP

Stretched Film, Process For The Production Thereof And Laminated Material

InactiveUS20070196592A1Lower latencyHigh yield productionLiquid crystal compositionsPolarising elementsIn planeLiquid-crystal display

This invention provides an optical-anisotropy-controlled stretched film suitable for use as a retardation film and a retardation-functioning protective film for a sheet polarizer in a liquid crystal display, a process for the production thereof and a laminated material using the same. The present invention is a stretched film (X) obtained from a resin composition by melt-extrusion casting followed by stretching at least in one direction, (1) the resin composition containing a specific maleimide-olefin copolymer (A) and an acrylonitrile-styrene copolymer (B) containing 21 to 45% by weight of an acrylonitrile unit, and having a copolymer (A) content of at least 50% by weight but not more than 99% by weight and a copolymer (B) content of at least 1% by weight but not more than 50% by weight, (2) its maximum retardation (Rp) at 550 nm in an in-plane direction, satisfying the following expression, 10 nm<Rp≦400 nm (3) its retardation (Rth) at 550 nm in the thickness direction, satisfying the following expression, 0 nm<|Rth|≦400 nm.

Owner:TEIJIN DUPONT FILMS JAPAN

Mannanases

ActiveUS7846705B2High yield productionPrecise and reproducible enzyme dosageTissue cultureFruits/vegetable preservation using acidsWild typeBiofuel

The present invention provides an insertion, deletion and / or substitution mutein of wild-type Trichoderma reesei β-mannanase having enhanced thermostability, proteolytic stability, specific activity and / or stability at low pH, a nucleic acid molecule encoding said mannanase mutein, a composition comprising said mannanase mutein; a method for its preparation, and its use for food and feed processing, for coffee extraction and the processing of coffee waste, as a supplement to food and feed, for enzyme aided bleaching of paper pulps, as bleaching and / or desizing agent in textile industry, for oil and gas well stimulation by hydraulic fracturing, as detergent, for removal of biofilms and in delivery systems, or for the processing of renewable resources intended for the production of biological fuels.

Owner:BASF SE

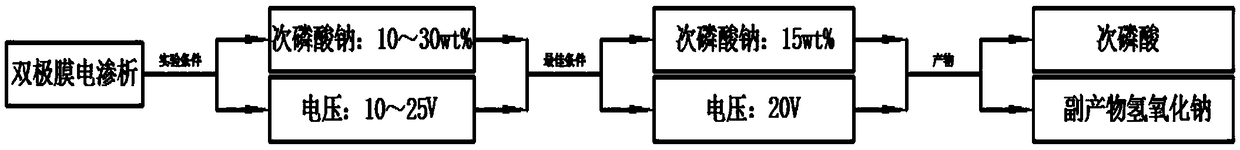

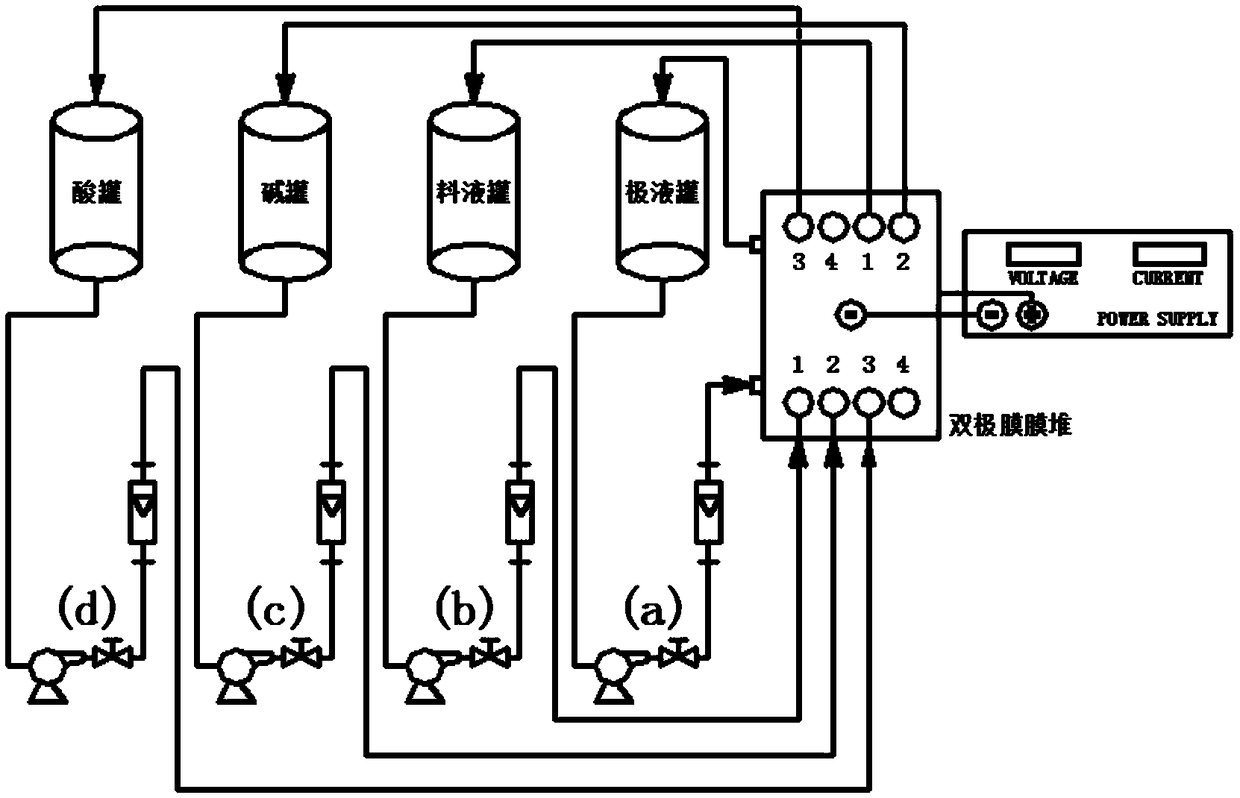

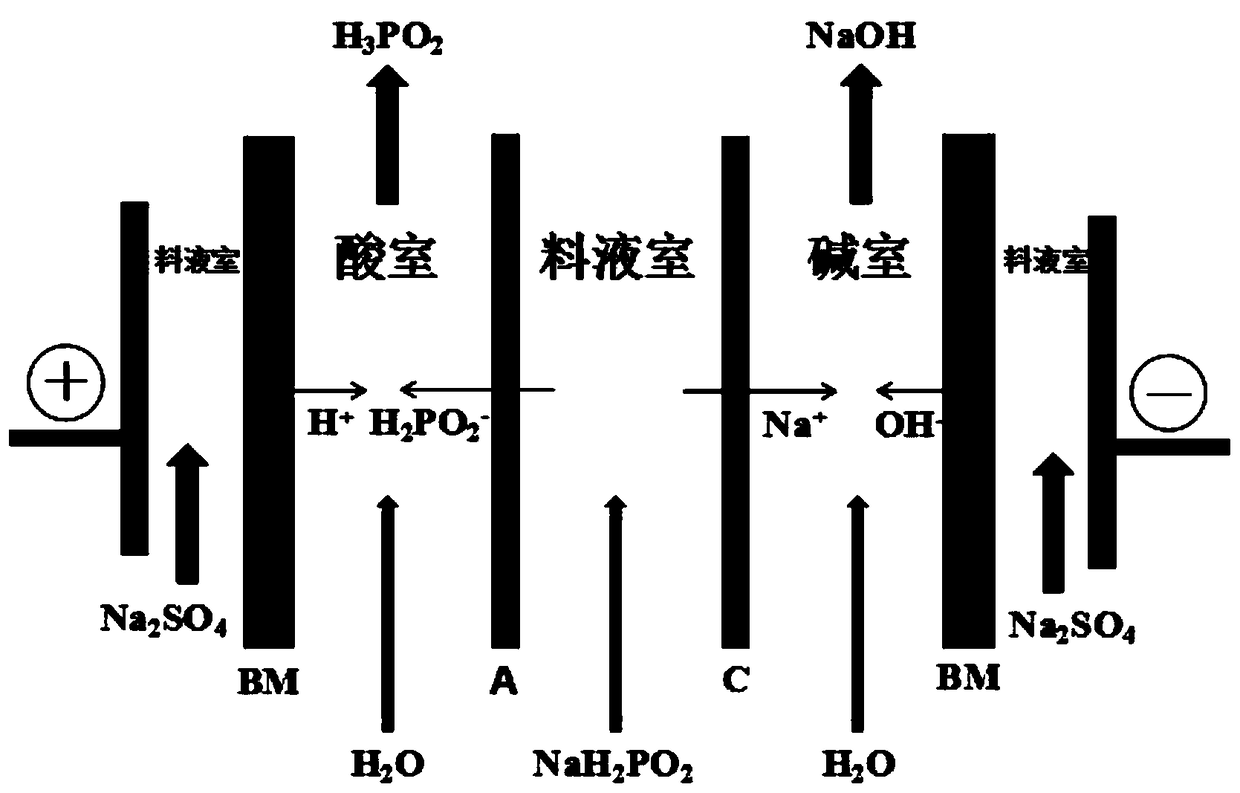

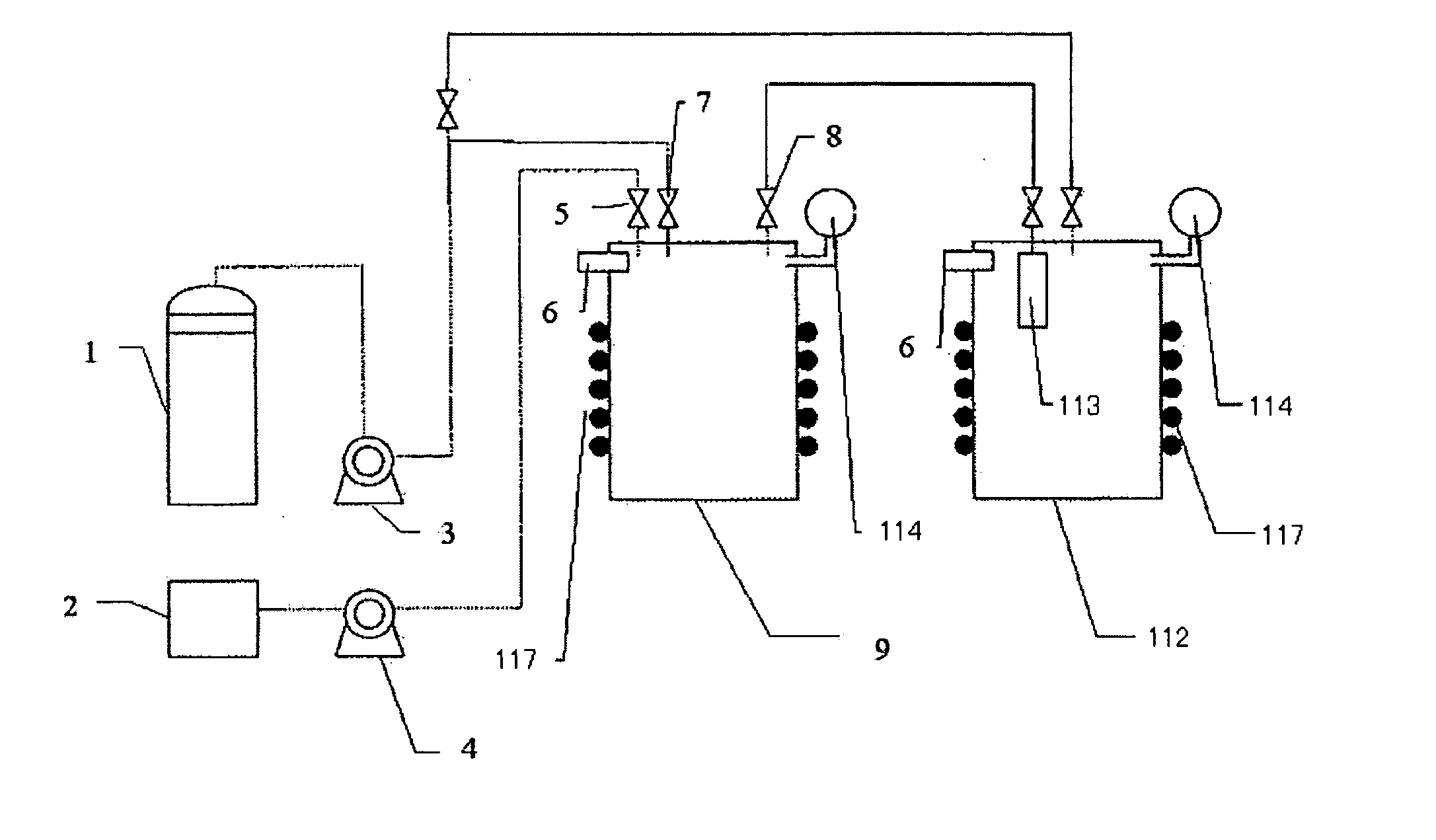

Bipolar membrane electrodialysis method for preparing hypophosphorous acid from sodium hypophosphite

InactiveCN108636123AHigh yield productionOptimum production process conditionsElectrodialysisHypophosphorous acidPhosphoric acidReaction temperature

The present invention discloses a bipolar membrane electrodialysis method for preparing hypophosphorous acid from sodium hypophosphite. The method comprises the following steps: (1) a sodium hypophosphite aqueous solution with a mass fraction of 10 wt%-30 wt% is prepared; (2) the sodium hypophosphite aqueous solution is added into a material liquid tank; 3 wt% of a sodium sulfate solution is addedinto an electrode liquid tank; and pure water at equal volume is added into an alkali tank and an acid tank; (3) a bipolar membrane electrodialysis device is turned on; voltage is controlled at 10 V-25 V; reaction temperature in each compartment is controlled to be 20 DEG C-40 DEG C for electrodialysis; and end of reaction is reached when content of hydrogen ions titrated by a sodium hydroxide standard solution in an acid chamber is no longer increased; and (4) a hypophosphorous acid solution in the acid tank is taken to be concentrated and crystallized to obtain hypophosphorous acid crystals. The whole technology basically realizes zero discharge. The hypophosphorous acid prepared by the provided bipolar membrane electrodialysis method has high yield. The bipolar membrane electrodialysismethod has remarkable environmental benefits and economic benefits.

Owner:ZHEJIANG UNIV OF TECH

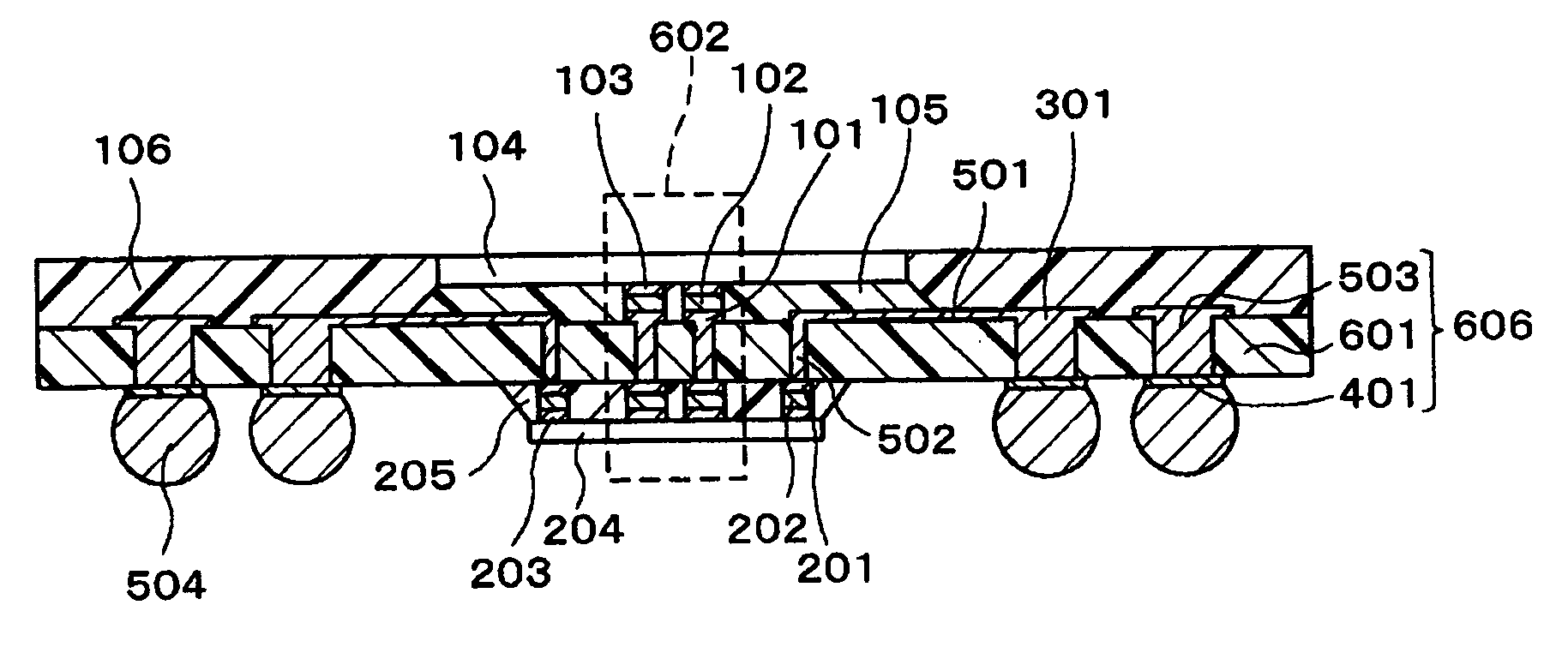

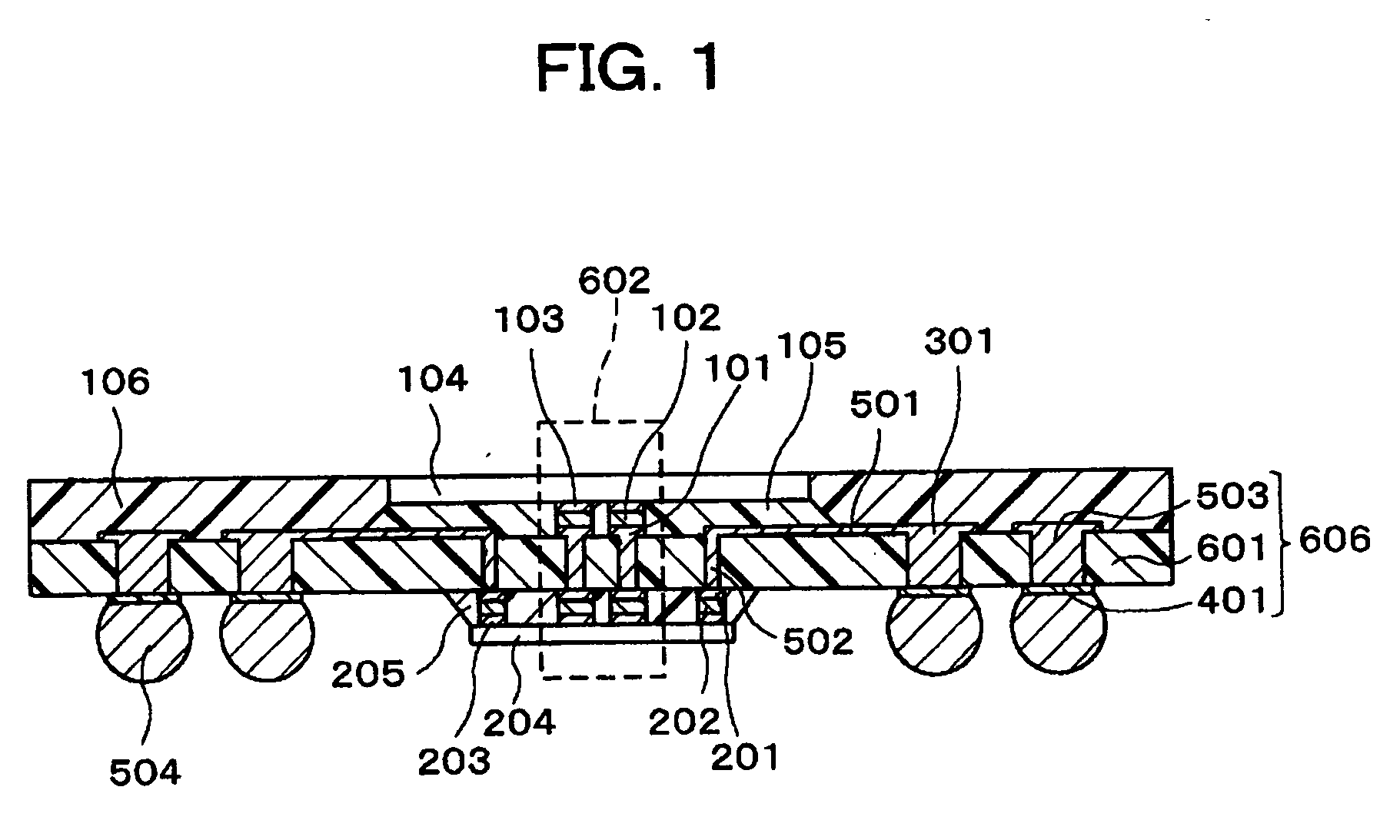

Wiring board, semiconductor device, and method of manufacturing the same

ActiveUS20070079987A1Run at high speedHigh yield productionSemiconductor/solid-state device detailsPrinted electric component incorporationDevice materialEngineering

A semiconductor device comprising a flat wiring board, a first LSI disposed on one surface of the wiring board, a sealing resin for covering the one surface and a side face of the first semiconductor element, and a second LSI disposed on another surface of the wiring board. The wiring board has conductive wiring as a wiring layer, an insulation resin as a support layer for the wiring layer, and a conductive through-hole that passes through the wiring layer and the support layer. Connection points between lands disposed in positions in which the external peripheral edges of the semiconductor elements transverse the interior of the lands as viewed vertically from above, which lands are selected from land portions on which the external connection terminals are formed, and the wiring board formed in the same plane as the lands, are unevenly distributed toward one side of the wiring board. Connections for very small wiring are thereby made possible, and a plurality of semiconductor elements can be very densely connected.

Owner:RENESAS ELECTRONICS CORP

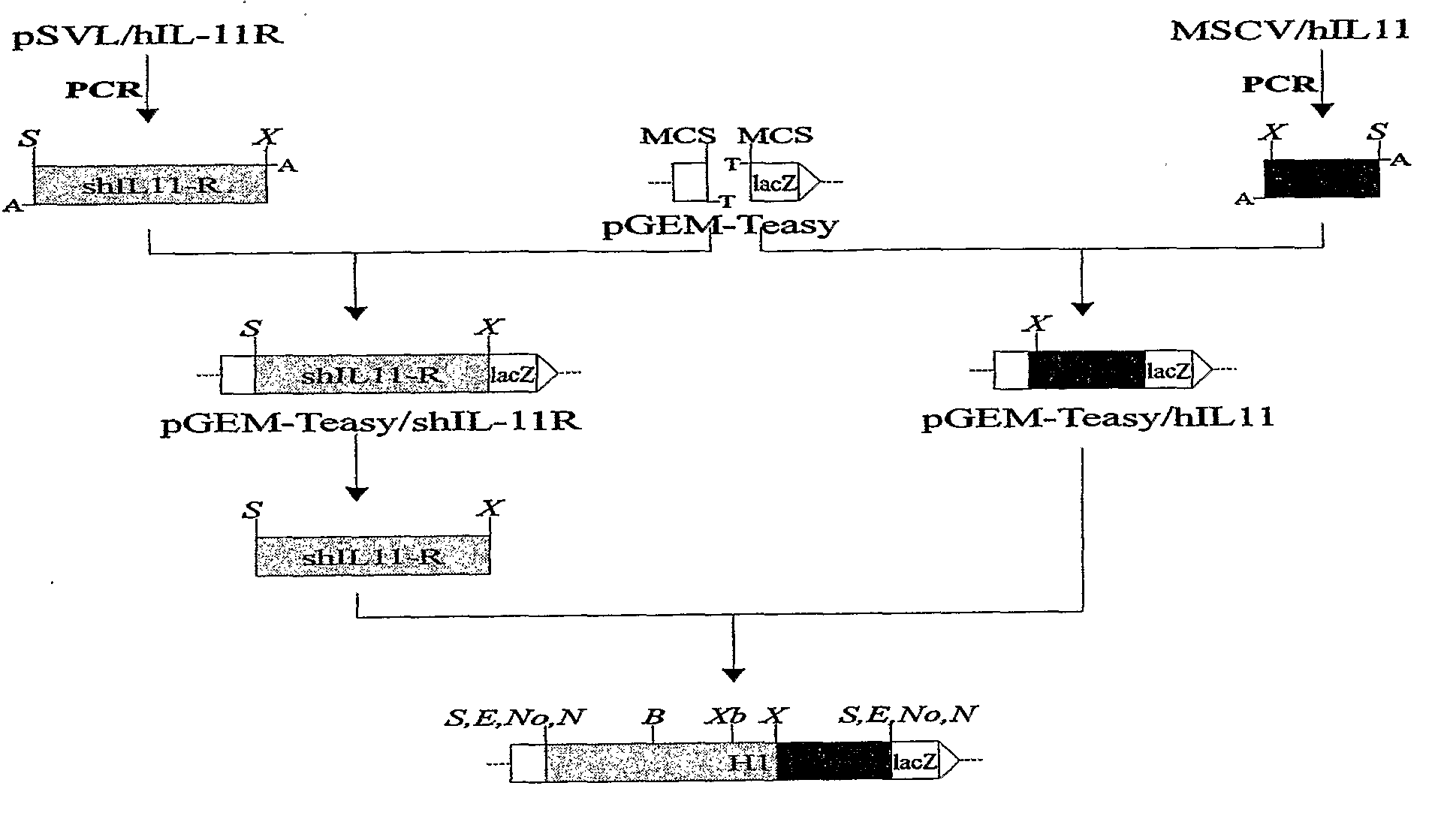

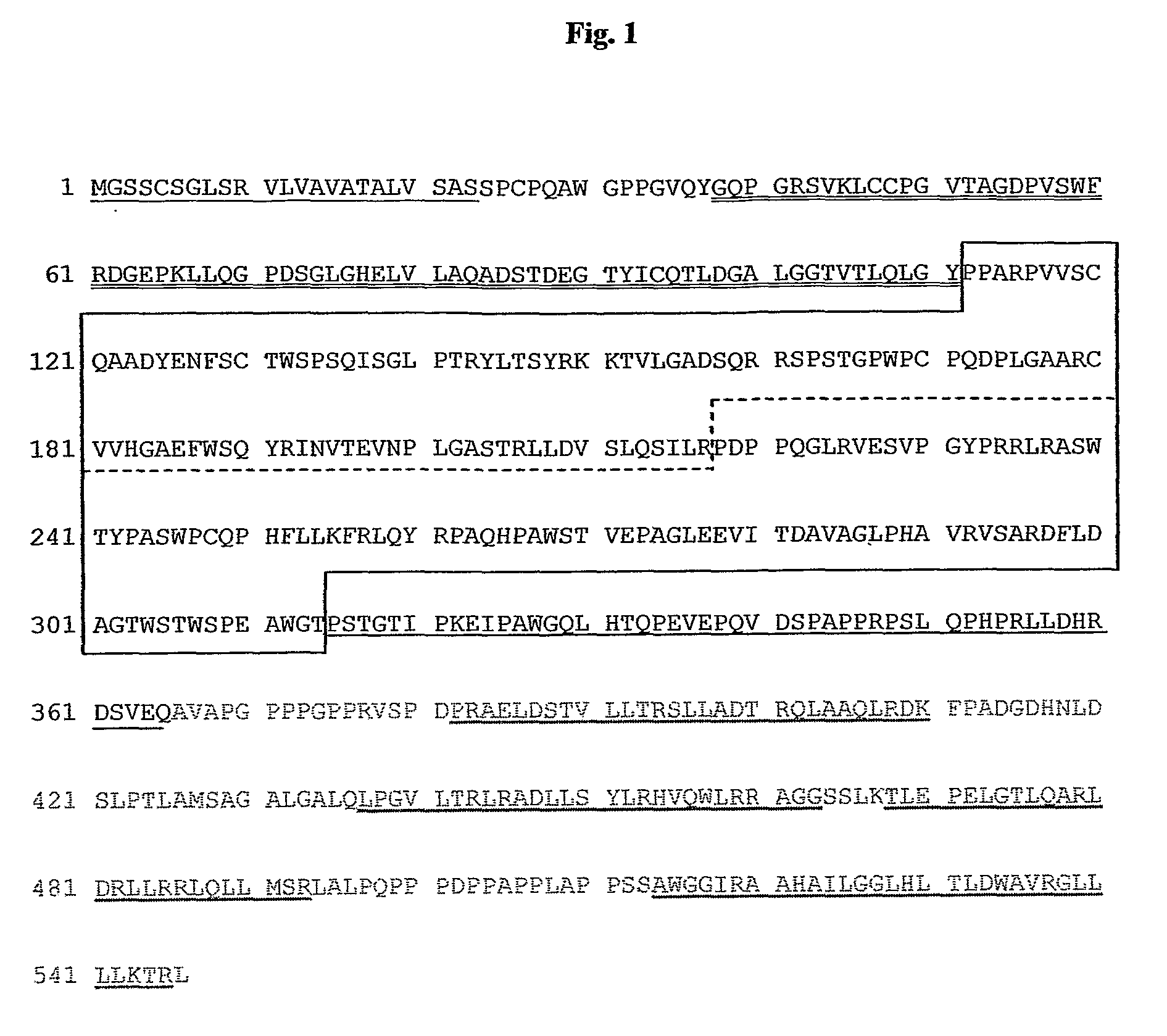

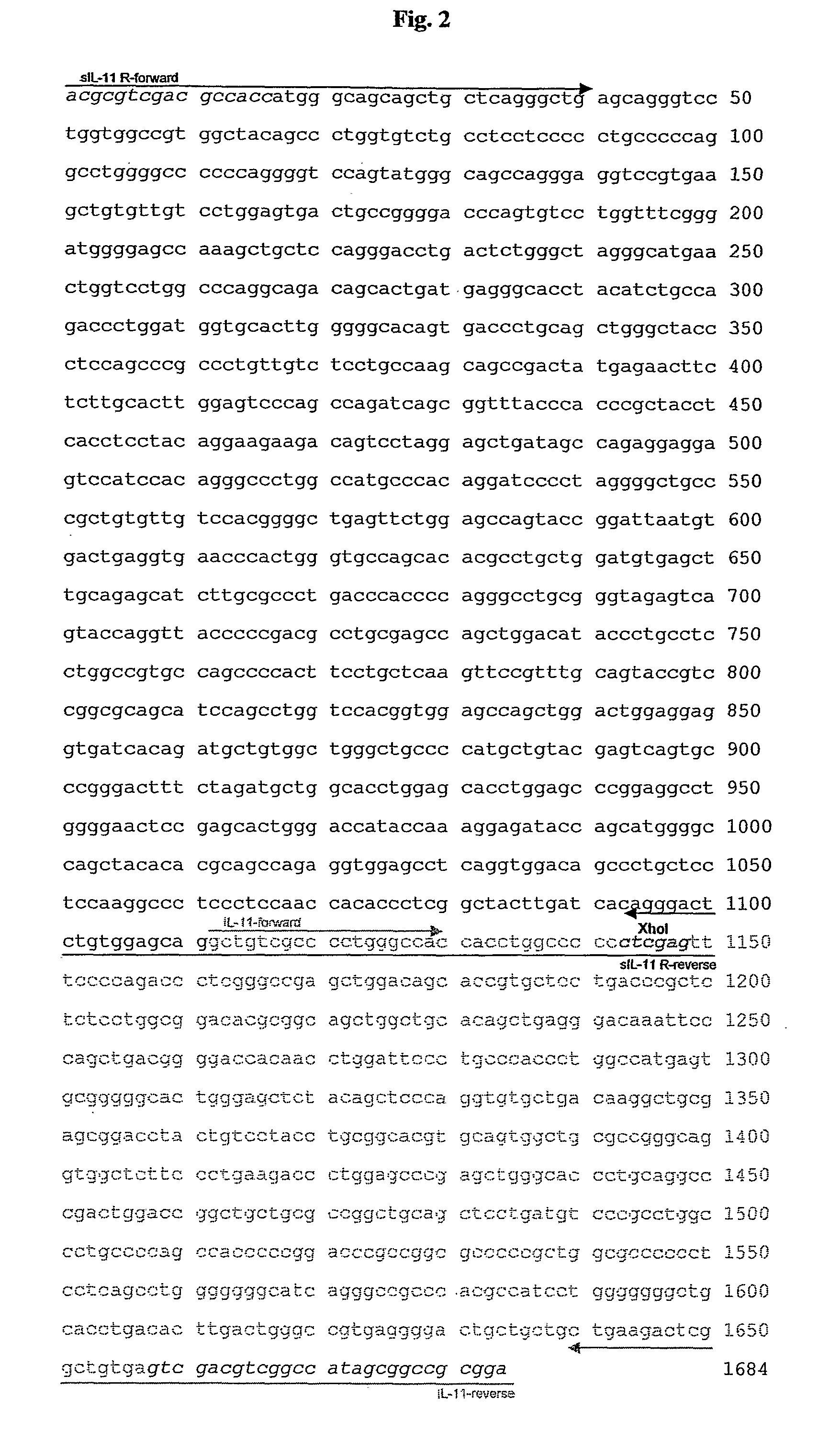

Chimeric soluble hyper il-11 and use thereof

InactiveUS20090010872A1Reduce riskLess shear forceAntibacterial agentsFungiInterleukin-11 receptorFactor ii

The present invention concerns a new designer cytokine termed H11, which is constructed by fusion of two soluble components, soluble interleukin 11 receptor (sIL-11 R) and interleukin 11 (IL-11) using their natural sequence and its use for the production of a medicament for treating or preventing a disease selected from the group consisting of a proliferative disease, a cytopathy, radiation damage, an IL-11 dependent inflammatory disorder, IL-11 dependent degenerative disorder and IL-11 dependent or mediated soft tissue disorder.

Owner:AGIRX

Toner, production process for the same, and image forming method

InactiveUS20070020548A1Improve featuresEfficient productionDevelopersElectrographic processes using charge patternMonomerSupercritical fluid

To provide a toner production process in which at least radically polymerizable monomers are polymerized in at least one of a supercritical fluid and a subcritical fluid to thereby produce toner particles, wherein a polymer of the radically polymerizable monomers is insoluble in at least one of the supercritical fluid and the subcritical fluid.

Owner:RICOH KK

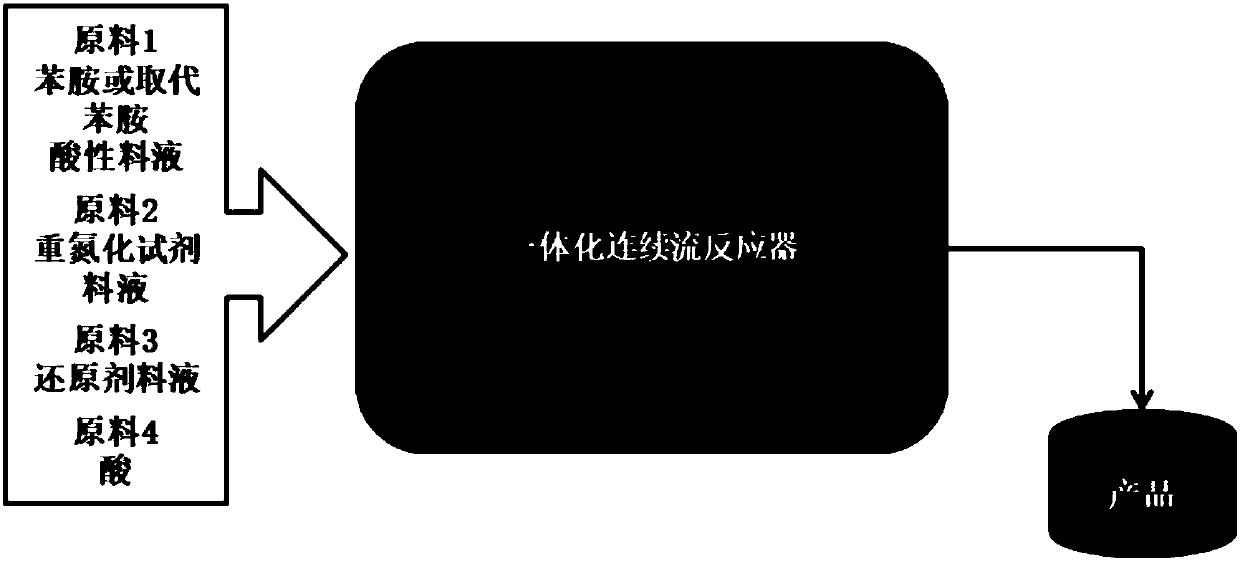

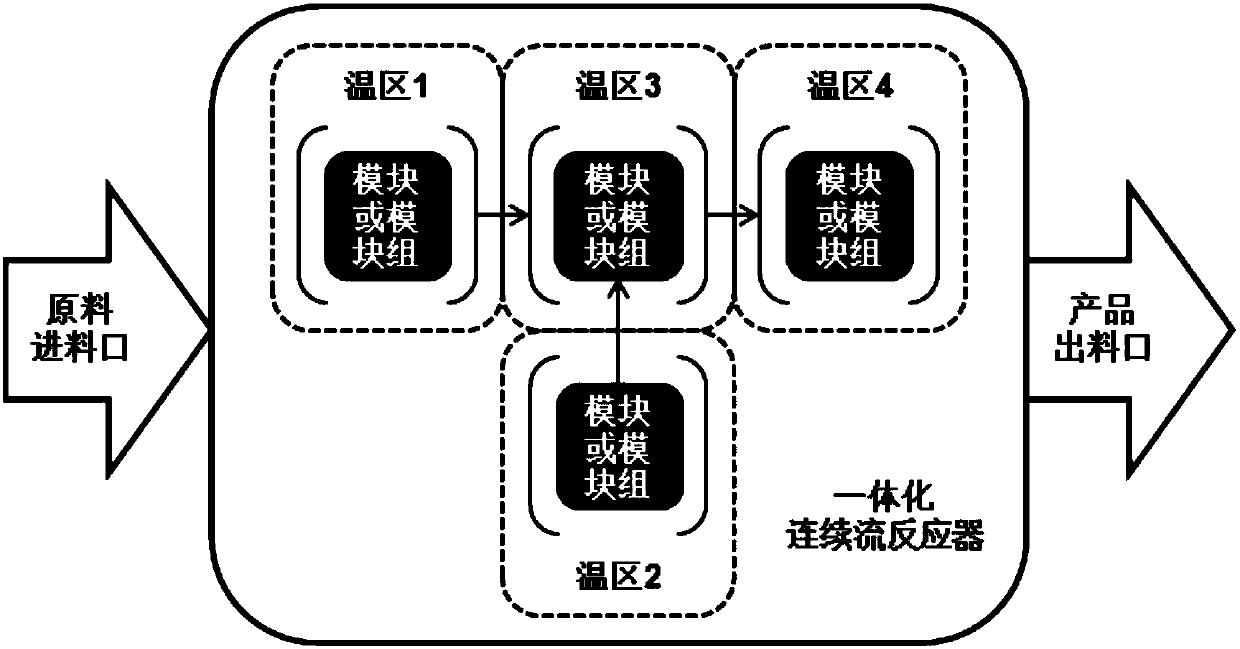

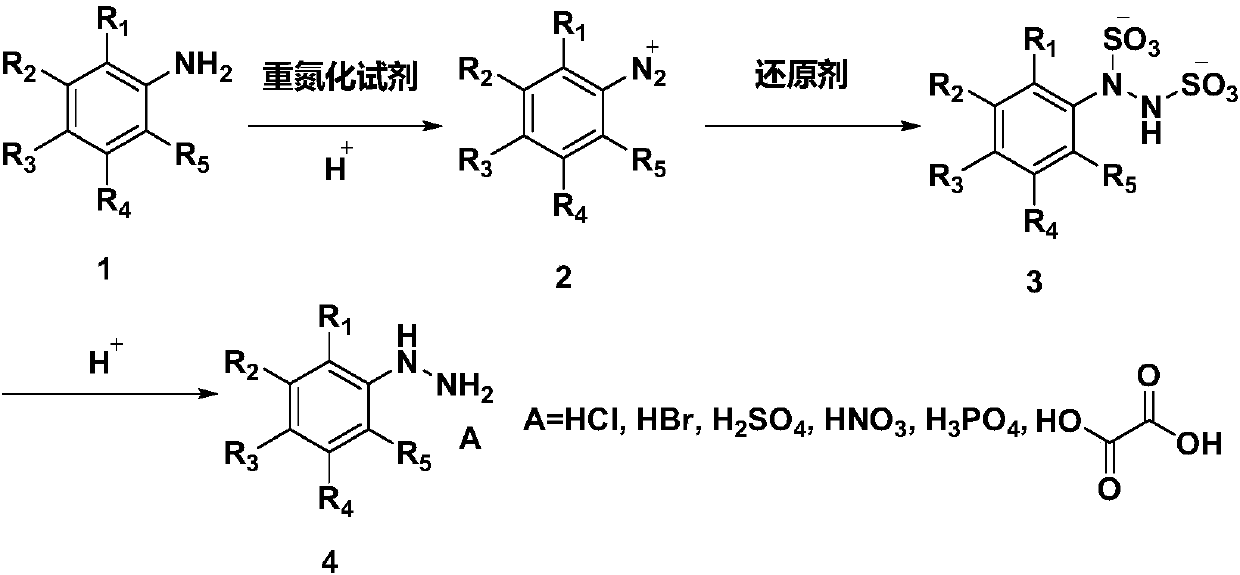

Phenyl hydrazine and substituted phenyl hydrazine continuous flow synthesis process

ActiveCN107663161ARealize the whole process of continuous flow synthesisSolve the technical problems of continuous production in the whole processHydrazine preparationSequential/parallel process reactionsReaction intermediateDiazoamino Compounds

The invention provides a phenyl hydrazine and substituted phenyl hydrazine continuous flow synthesis process. Three-step reactions of diazotization, reduction and acidolysis salt formation are creatively and organically integrated; phenylamine or substituted phenylamine acid material liquid, diazotization reagents, reducing agents and acid are used as raw materials to be subjected to three-step reaction of diazotization, reduction and acidolysis salt formation to obtain phenyl hydrazine derivative salts. The synthesis process is performed in an integral reactor, and belongs to an integrated solution. The reaction raw materials are continuously added through a feeding opening of the integral reactor; the reactions of diazotization, reduction and acidolysis salt formation are continuously performed in the integral reactor; the phenyl hydrazine derivative salts are continuously obtained in the integral reactor; the total reaction time is less than or equal to 20min. Compared with a conventional production process, the continuous flow synthesis process has the advantages that the total reaction time is greatly shortened; the safety is greatly improved; no reaction byproducts (such as diazoamino compounds and reduction reaction midbodies) are included in the reaction process and the reaction products; the continuous flow process can prepare the high-purity products with the purity as high as 99 percent or higher without the additional purification steps.

Owner:SHANGHAI HYBRID CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com