Large-luminosity-angle spherical bulb with diamond light-emitting surfaces

A volume luminescence and diamond technology, applied in the field of electronics, can solve the problems of limited light emitting angle of LED lights, limited light emitting angle of lens adjustment, difficulty in obtaining large light emitting angles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the drawings and embodiments.

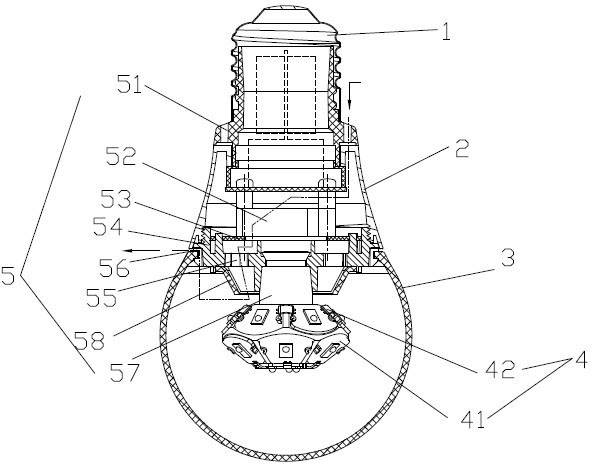

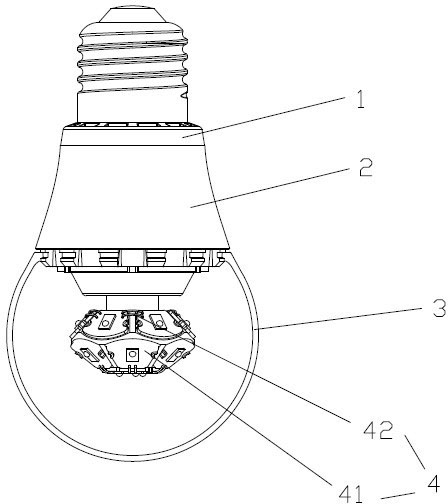

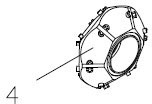

[0032] Such as figure 1 - Figure 14 The illustrated embodiment of the present invention, a large-luminance-angle bulb with a diamond-shaped light-emitting surface, includes: lamp holder insulator 1: clamped on the lamp body; lamp body 2: connecting the heat dissipation device in the bulb and the lamp holder insulator; lamp cover 3: and The heat dissipation device in the bubble is matched with a large hemispherical structure; the diamond polyhedron and the LED light-emitting assembly 4: set near the center of the lampshade, and the light-emitting assembly can be fixed by the self-generating boss; also includes a substrate 41: the LED light source is provided on it, and the front is provided There are solder joints for interconnection, and a thermal conductive film is attached to the back; flexible bridge 42: the connection is set between the substrates, and the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com