High-speed milling process parameter optimizing method based on dynamic model

A technology of process parameter optimization and dynamic model, which is applied in the field of mechanical processing, can solve the problems that cannot reflect the real working conditions of high-speed milling, achieve the maximum material removal rate, improve accuracy, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

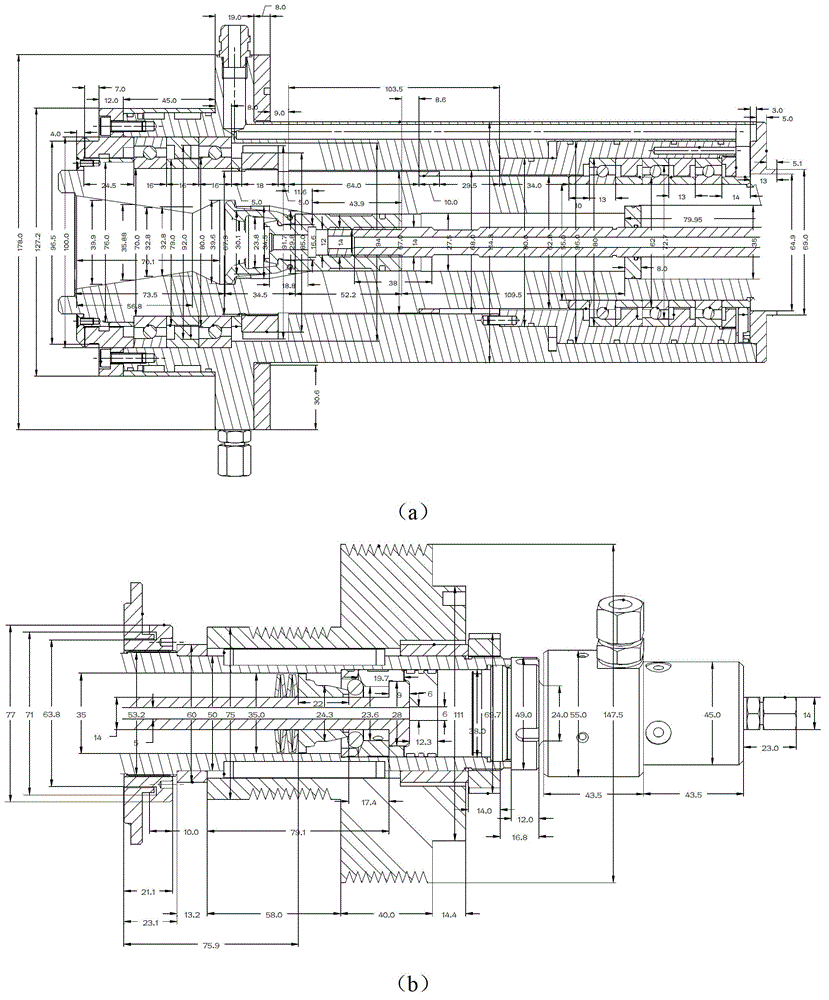

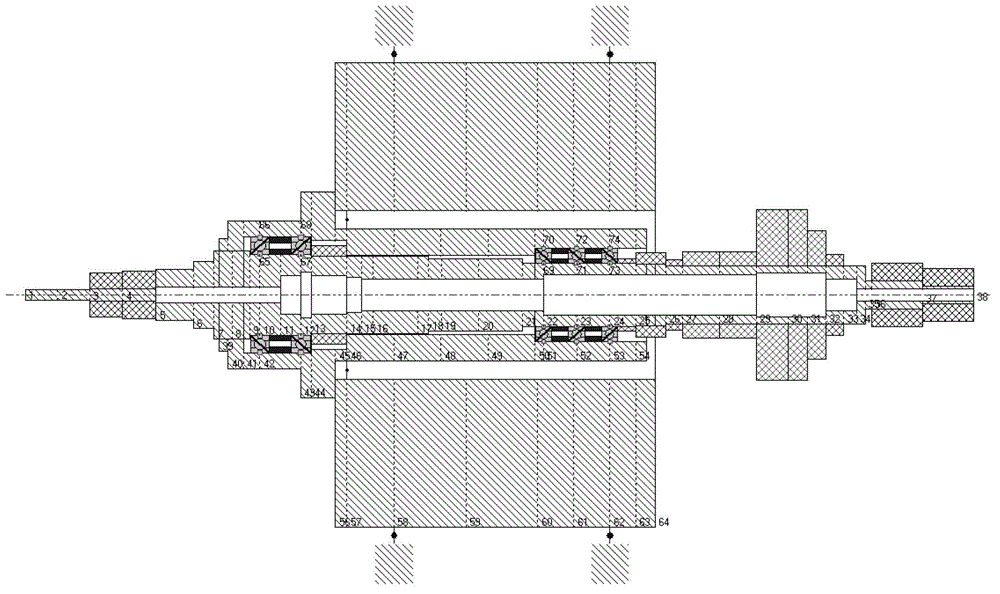

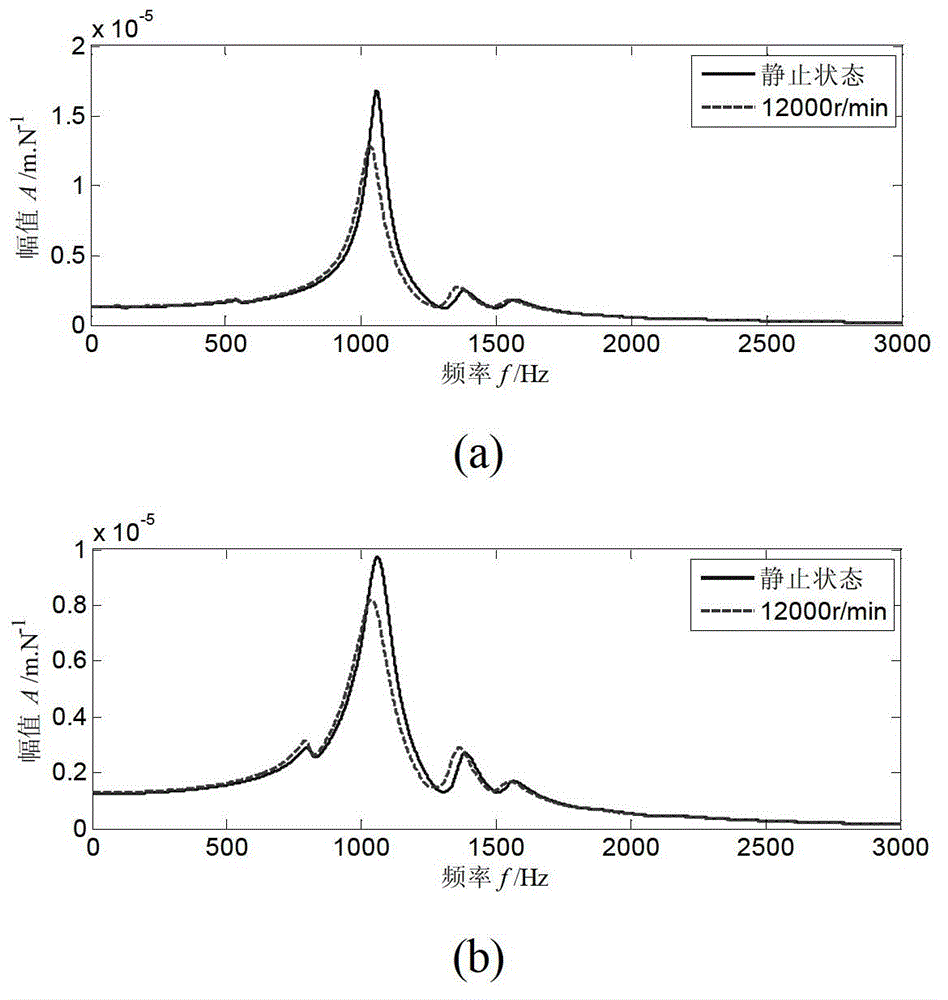

[0038] see Figure 1 to Figure 5 Shown, a kind of dynamic model-based high-speed milling process parameter optimization method of the present invention comprises the following steps:

[0039]1) Input the structural parameters and initial cutting conditions of the spindle-tool system to provide data support for the dynamic modeling of the high-speed spindle system and the modeling of the cutting process;

[0040] 2) Consider the effects of centrifugal force and gyro moment, establish a dynamic model of the spindle-tool system, and calculate the frequency response function at the tool tip; meanwhile, according to the input cutting conditions, use the test method to determine the cutting force coefficient;

[0041] 3) Establish the interactive process model of high-speed spindle-tool dynamic characteristics and milling, and obtain the characteristic equation of the closed-loop dynamic milling system;

[0042] 4) Using the Nyquist stability criterion, solve the characteristic equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com