Baking-free slag brick and method of making same

A technology of waste slag and construction waste slag, which is applied in the field of non-burning waste slag bricks and its production, can solve the problems of complex production equipment, difficulty in popularization, high cost, etc., and achieve the effects of good hydration, easy film removal, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

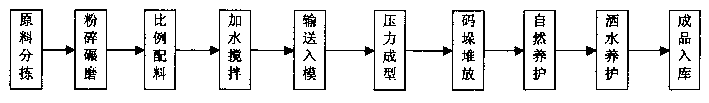

Method used

Image

Examples

Embodiment 1

[0014] Raw material weight ratio is as follows:

[0015] 36-43% of construction waste, 44-51% of inferior rock, 12-20% of cement; 1-2% of its weight water reducer is added to the cement.

Embodiment 2

[0017] Raw material weight ratio is as follows:

[0018] Construction waste 36-43%, inferior rock 44-51%, cement 7-13%, fly ash 5-8%.

Embodiment 3

[0020] The weight ratio of raw materials is as follows: 36-43% of construction waste, 44-51% of inferior rock, 5-10% of cement, 3-6% of fly ash, and 3-6% of lime.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com