Bionic concrete artificial fish reef and preparation method thereof

An artificial fish reef and concrete technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of artificial fish reefs such as short durability, lack of roughness and bionicity, and inability to obtain fish collection effects, etc. Achieve better fish collection effect, improve roughness and bionicity, and improve the effect of marine ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

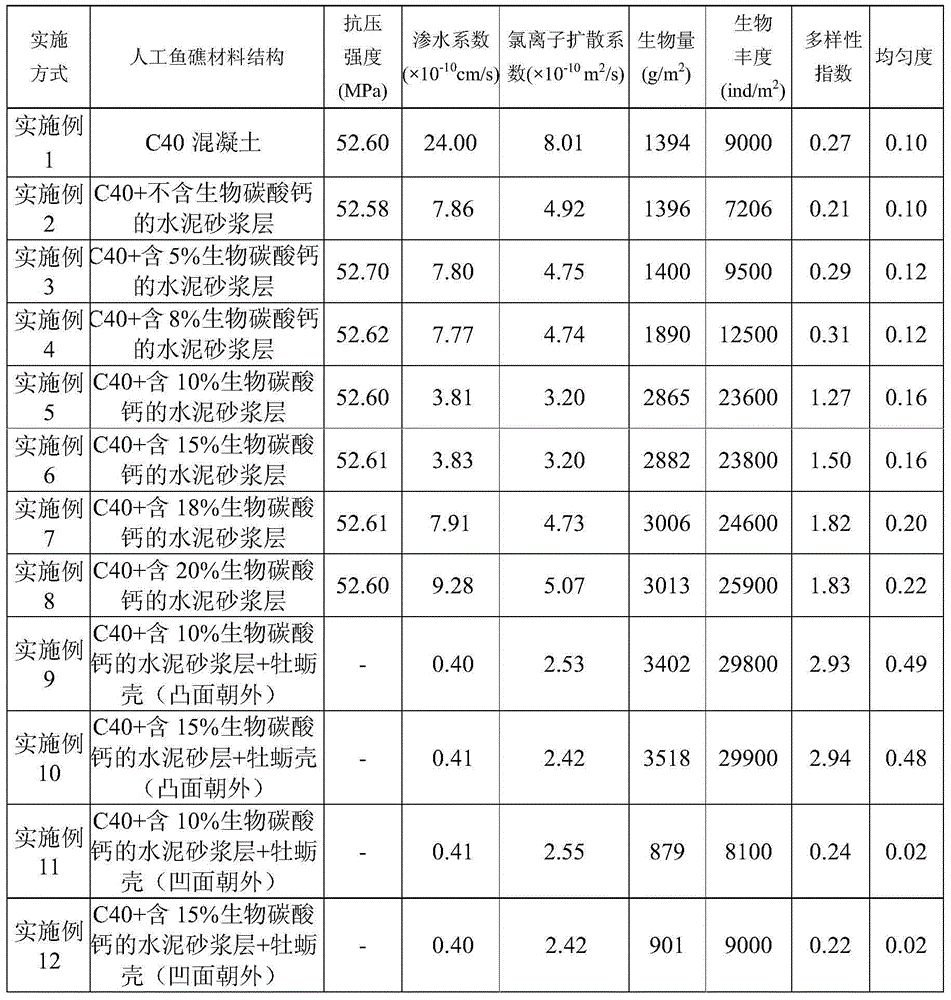

Embodiment 2

[0027] Example 2 Preparation of fish reefs with cement mortar overlay without biological calcium carbonate and oyster shells:

[0028] (1) Take water, cement and sand, and mix them uniformly according to the mass ratio of 434:1085:1035 to obtain cement mortar;

[0029] (2) Sprinkle water to wet the surface of the fish reef substrate prepared in Example 1, apply cement mortar batches on the surface to form a cement slurry layer with a thickness of 25mm, and maintain it for 28 days to obtain final product.

Embodiment 3

[0030] Embodiment 3 Containing the cement mortar covering layer of 5% bio-calcium carbonate and the preparation of fish reefs not inlaid with oyster shells:

[0031] (1) High-pressure cook the discarded fish bones to remove residual protein and fat. After drying, mix them with the mass ratio of fish bones: eggshell: coral: shell = 1:1:1:1, and place them in a grinder Pulverize and sieve to obtain the biological calcium carbonate external admixture particles with a particle size of 180 mesh;

[0032] (2) Take water, cement and sand, mix them uniformly according to the mass ratio of 434:1085:1035, then add bio-calcium carbonate particles accounting for 5% of the cement mass, put them together in a mixer, stir at a high speed until uniform, and obtain a cement paste material;

[0033] (3) Sprinkle water to wet the surface of the fish reef substrate prepared in Example 1, apply cement slurry material batches on the surface to form a cement slurry layer with a thickness of 25 mm, a...

Embodiment 4

[0034] Embodiment 4 Containing the cement mortar covering layer of 8% bio-calcium carbonate and the preparation of fish reefs not inlaid with oyster shells:

[0035] (1) Get water, cement, sand, mix evenly by mass ratio 434:1085:1035, then add the biological calcium carbonate particle that makes by the method for embodiment 3, consumption is 8% of cement quality, put into the blender jointly, high-speed Stir until uniform to obtain cement slurry material;

[0036] (2) Sprinkle water to wet the surface of the fish reef substrate prepared in Example 1, apply the cement slurry material batches on the surface to form a cement slurry layer with a thickness of 25 mm, and maintain it for 28 days to obtain final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com