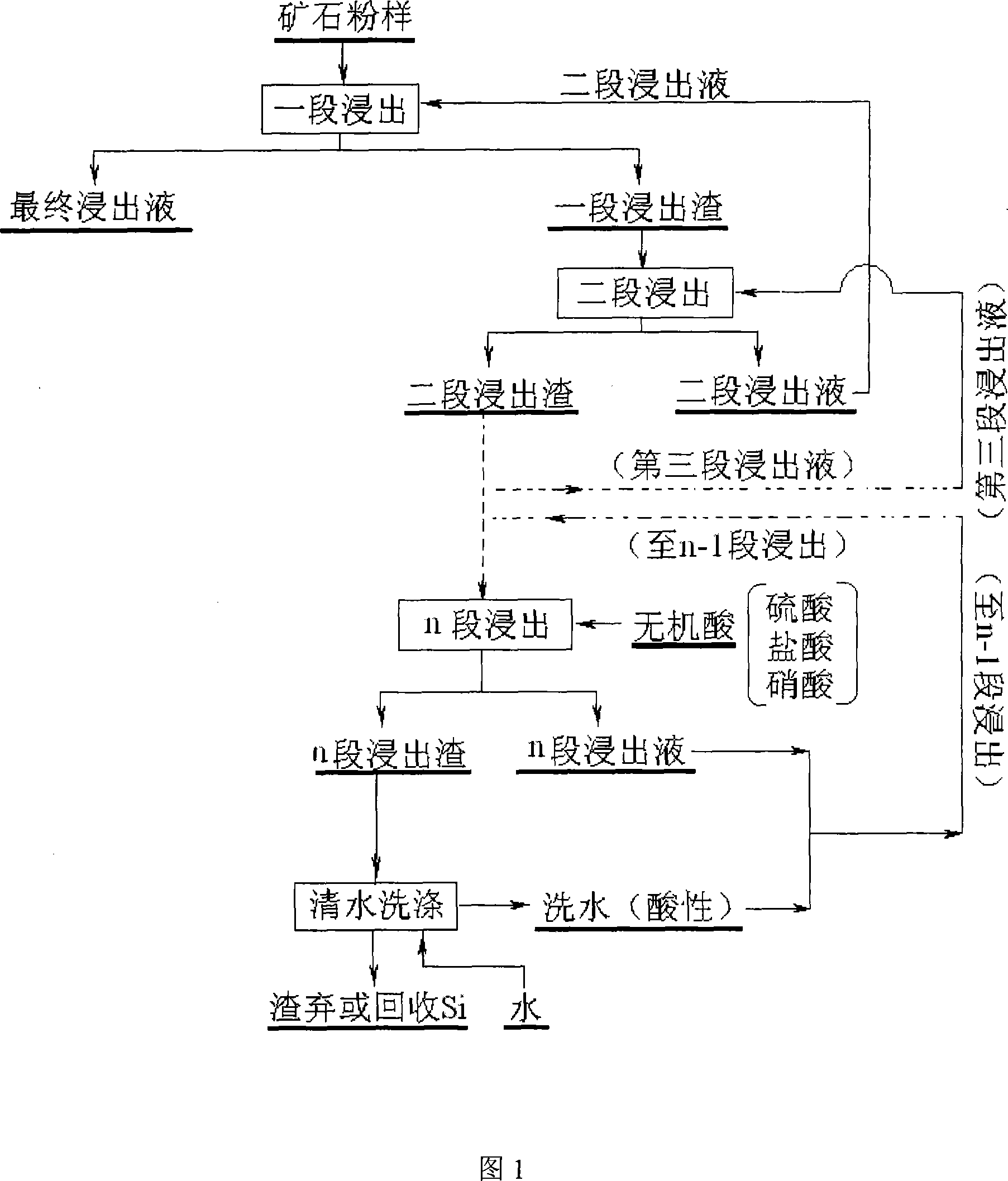

Multistage counter current acid leaching process containing nickel serpentine ore

A technology of serpentine and countercurrent acid, which is applied in the field of hydrometallurgy, can solve the problems of high leaching cost, high production cost, and high acidity of the leaching solution, and achieve the effects of reducing chemical consumption, production cost, and leaching agent waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

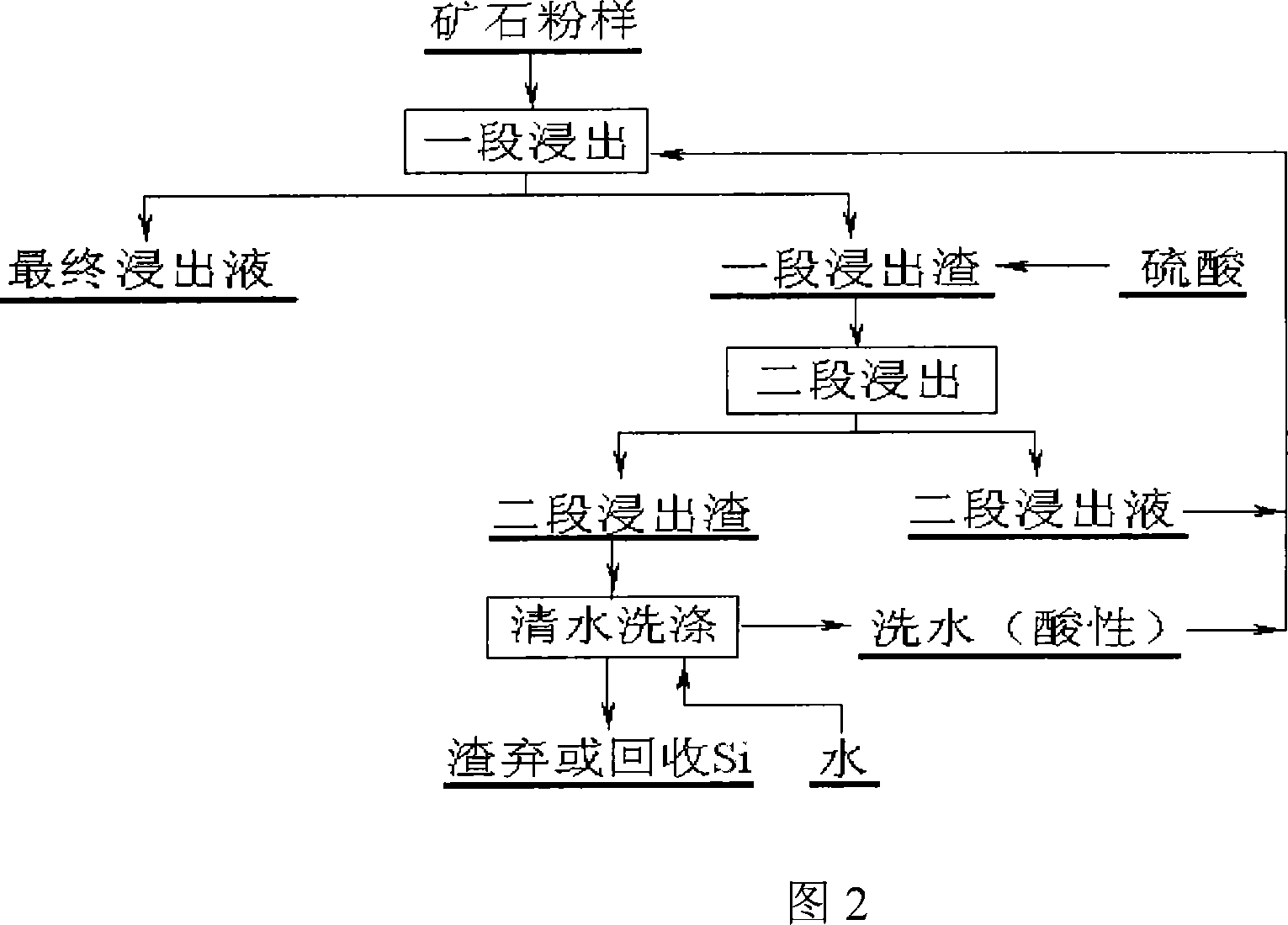

[0033] The nickel-containing serpentine is treated by a two-stage countercurrent sulfuric acid leaching process (see Figure 2 for the process flow). The ore sample was taken from a mine in Fujian, containing 0.20% Ni and 22.27% Mg.

[0034] Take 100 parts of ore samples, add 150 parts of water and ball mill to less than 0.074mm after crushing, and the obtained ore pulp is added to the reaction kettle together with 160 parts of concentrated sulfuric acid (98%) and 50 parts of water, and start stirring (500rpm) , Utilize sulfuric acid dilution and the reaction exotherm can make the system temperature rise to 95 ℃, control the reaction after 120min discharge and filter, obtain the leaching solution containing nickel and magnesium (containing magnesium 70.4g / L, nickel 0.62g / L, H 2 SO 4 74g / L); the obtained leaching solution and 100 ore samples (adding 150 points of water ball milling, less than 0.074mm accounting for 74.5%) were stirred and reacted at 75 ° C for 90min, filtered, ...

Embodiment 2

[0037] The nickel-containing serpentine ore is the same as in Example 1, and is treated by a three-stage countercurrent sulfuric acid leaching process. See Figure 3.

[0038] The raw ore powder is to take 100 ore samples, add 150 points of water ball milling after crushing, and refer to the pulp samples less than 0.074mm accounting for 80.0%.

[0039] The leaching reaction temperature of the first stage and the second stage is controlled at about 75℃, and the reaction time is 60min. The final leachate contains 95.4g / L magnesium, 0.85g / L nickel, H 2 SO 4 2.5g / L.

[0040] The leaching agent of the three-stage leaching is 160 parts of concentrated sulfuric acid (98%) and 100 parts of water, the temperature of the three-stage leaching is controlled at about 95 ° C, and the reaction is stirred (500 rpm) for 90 min, filtered, and the filtrate and filter cake washing water are synthesized into two The leaching agent leached in the first stage; the filter cake was tested, and the ...

Embodiment 3

[0043] The nickel-containing serpentine ore is the same as in Example 1, and is treated by a two-stage countercurrent hydrochloric acid leaching process.

[0044] The first-stage leaching samples are 100 ore samples. After crushing, add 200 parts of water balls and grind them to less than 0.074mm, accounting for 90% of the pulp obtained. The first-stage leaching reaction temperature is controlled at 60°C, and the reaction time is 60min. The final leaching solution contains 82.4g / L magnesium, Nickel is 0.67g / L, and the pH value of the solution is 2.5; the filter cake enters the second-stage leaching reaction.

[0045] The second-stage leaching agent adopts 125 parts of concentrated hydrochloric acid (31%, industrial product), and the control temperature is 90 ° C. After stirring (400 rpm) for 90 min, the discharge is filtered, the filter cake is washed, and the washing water and the filtrate are combined as the first stage of the leaching reaction. Leaching agent; test the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com