Efficient slow-release urea and preparation method thereof

A slow-release urea and high-efficiency technology, which is applied in the fields of agricultural gas emission reduction, fertilizer mixture, fertilization equipment, etc., can solve the problems of easy leaching loss, separation, and influence on nitrification inhibition effect, and achieve great market demand potential and good prospects , Reduce the effect of leaching and runoff loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: High-efficiency slow-release urea suitable for vegetables.

[0032] 1. The coated sustained-release solution is composed of the following substances in mass percentage:

[0033] 3.0% of γ-polyglutamic acid, 3.0% of dicyandiamide, 0.5% of polyvinyl alcohol, 3.0% of carboxymethyl cellulose, 0.3% of sodium dodecylbenzenesulfonate, the rest is water, pH 6.0.

[0034] 2. Preparation of coated sustained-release solution: Add the prescribed amount of water into the reactor, start stirring, heat until the water temperature reaches 55°C, add the prescribed amount of dicyandiamide, stir for 10 minutes, then add the prescribed amount of polyvinyl alcohol, Carboxymethyl cellulose and sodium dodecylbenzene sulfonate, stirred for 10 minutes, and finally added the formula amount of γ-polyglutamic acid and stirred until completely dissolved, adjusted to pH 6.0, cooled and then transferred to a storage tank for later use.

[0035] 3. Preparation of high-efficiency slow-relea...

Embodiment 2

[0036] Embodiment 2: Efficient slow-release urea suitable for peach trees.

[0037] 1. The coated slow-release solution is composed of the following substances in weight percentage:

[0038] 5% of γ-polyglutamic acid powder, 1% of thiourea, 0.5% of polyvinyl alcohol, 0.05% of sodium dodecylbenzenesulfonate, and the rest is water, pH 6.1.

[0039] 2. Preparation of coated sustained-release solution: Add the prescribed amount of water into the reactor, start stirring, heat until the water temperature reaches 65°C, add the prescribed amount of thiourea, stir for 10 minutes, then add the prescribed amount of polyvinyl alcohol, ten Sodium dialkylbenzene sulfonate, stirred for 5 minutes, and finally added γ-polyglutamic acid in the prescribed amount and stirred until completely dissolved, adjusted to pH 6.1, cooled and then transferred to a storage tank for later use.

[0040] 3. Preparation of high-efficiency urea: Under 0.7MPa air pressure, the coated slow-release liquid is sucke...

Embodiment 3

[0041] Example 3: High-efficiency slow-release urea suitable for wheat.

[0042] By γ-polyglutamic acid 1.5% (weight percentage, the same below), dicyandiamide 2.0%, polyvinyl alcohol 0.5%, gum arabic 2.5%, polyoxyethylene alkyl ether 1.0%, the rest is water, pH The coated slow-release liquid composed of 6.5 is coated with a fluidized bed to make high-efficiency slow-release urea suitable for wheat, wherein the sprayed weight of the coated slow-release liquid accounts for 0.6% of the urea weight.

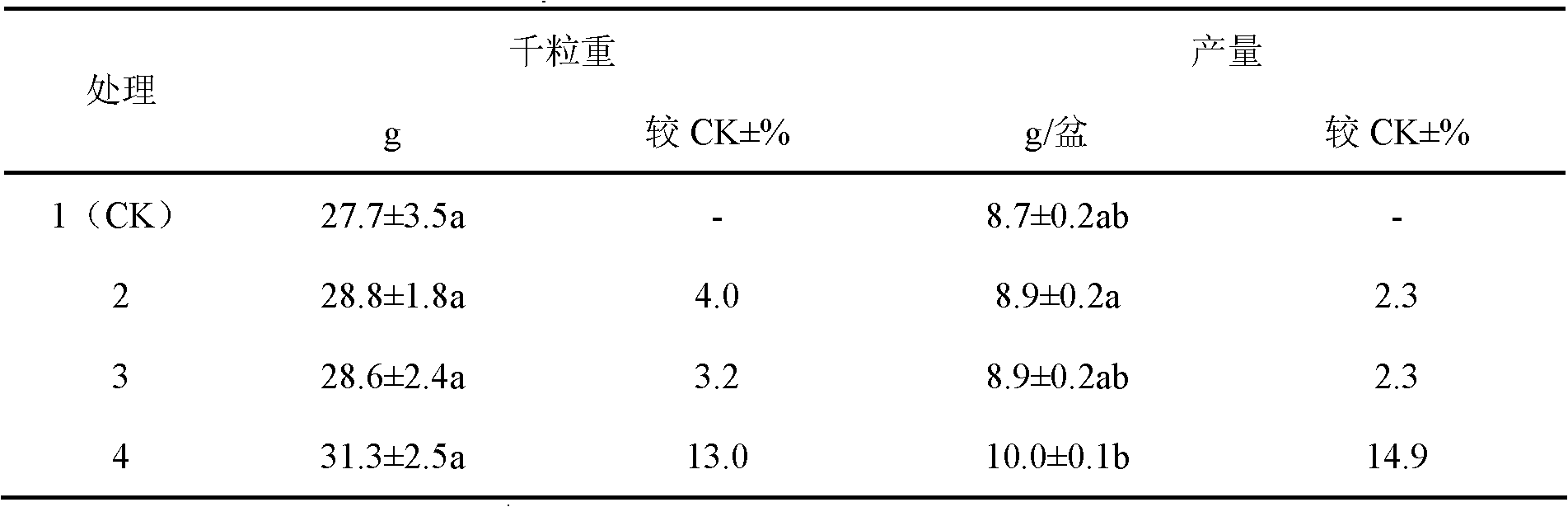

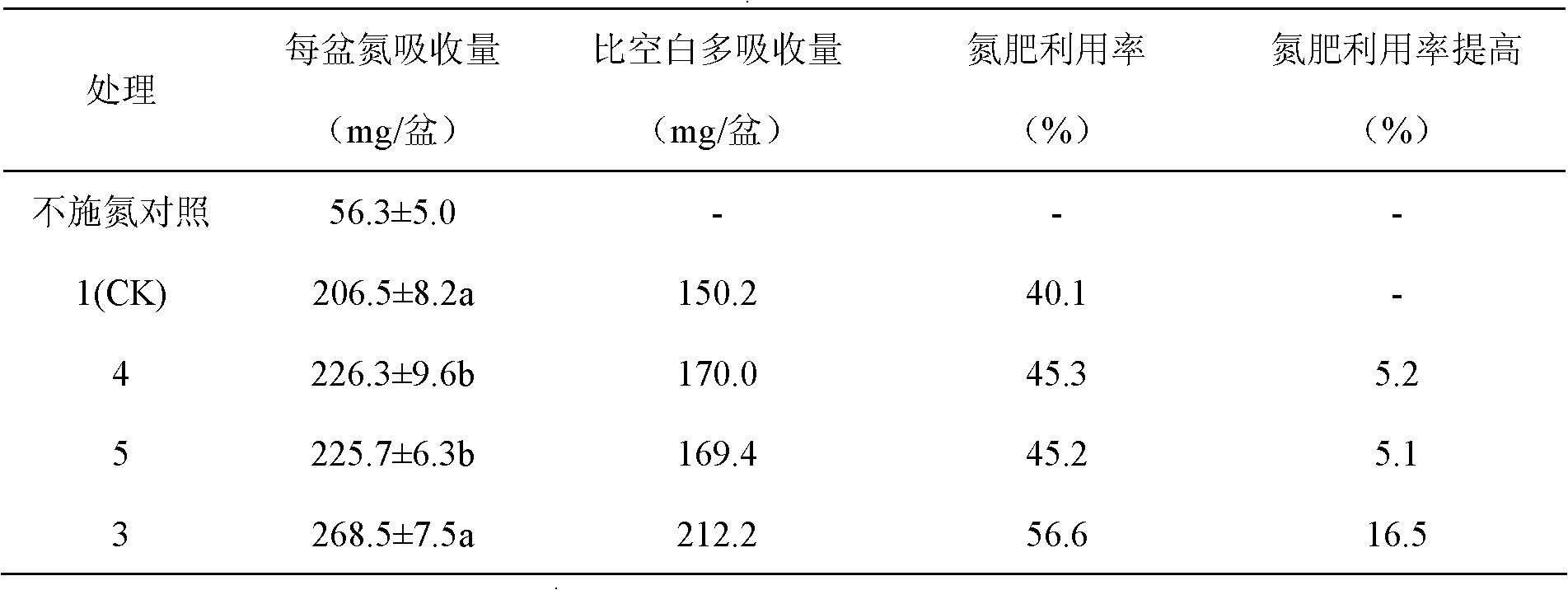

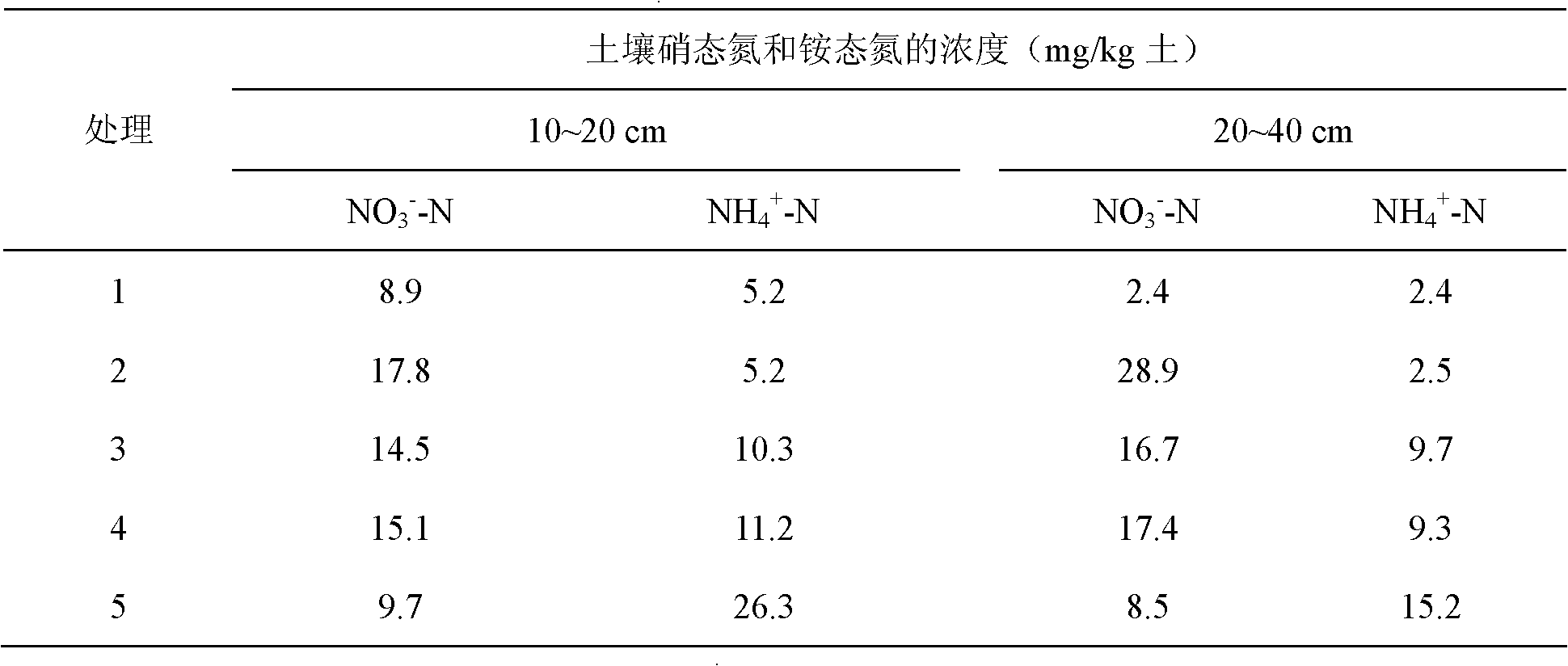

[0043] In order to study the impact of this product on the yield and fertilizer utilization efficiency of potted wheat, we also processed the following two kinds of fertilizers as a contrast, (1) made of γ-polyglutamic acid 1.5%, polyvinyl alcohol 0.5%, and gum arabic 2.5% , polyoxyethylene alkyl ether 1.0%, the rest is water, and the coated slow-release liquid composed of pH 6.5 is made into gamma-polyglutamic acid coated urea through fluidized bed coating; (2) made of dicyandiamid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com