Method for reclaiming valuable element from acidic arsenic-containing biological oxidation gold extraction waste liquor

A technology for extracting gold waste liquid and biological oxidation, applied in chemical instruments and methods, iron oxide, arsenic compounds, etc., can solve problems such as waste of resources and achieve the effect of perfect process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

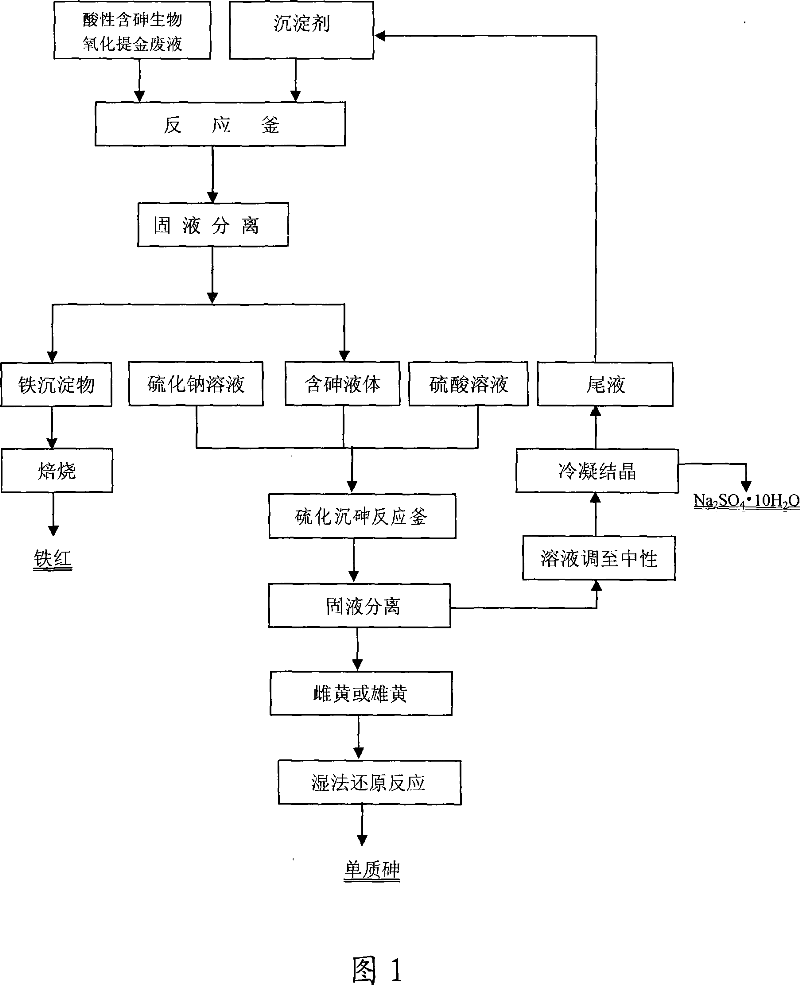

Image

Examples

example 1

[0021] 1. Treat 250m per day 3 Take bio-oxidation gold extraction waste liquid (the main element Fe content is 24g / L, As content is 5g / L) as an example, the recovery process of its valuable elements is: alkali is used as medicine, and 8mol L -1 The alkali solution is used as a precipitant, and the acidic arsenic-containing bio-oxidation gold extraction waste liquid and precipitant are added to the reactor at the same time, and the flow rate of the bio-oxidation solution is adjusted to 10.5m 3 / h, the flow rate of precipitant is about 5.6m 3 / h, and subject to the control of pH=12.5 in the reactor, adjust the flow rate of the precipitant at any time, the reaction temperature is 10°C, and the stirring intensity is 500rpm / min for the separation of arsenic and iron;

[0022] 2. Use filtration or centrifugal separation technology to separate solid and liquid, the solid phase enters the iron red preparation process, and the arsenic-containing liquid enters the arsenic recovery proc...

example 2

[0028] 1. Treat 500m per day 3 Take bio-oxidation gold extraction waste liquid (main element Fe content is 36g / L, As content is 7.5g / L) as an example, the recovery process of its valuable elements is as follows: alkali is used as a drug, and 10mol L -1 The alkali solution is used as a precipitant, and at the same time, acidic arsenic-containing bio-oxidation gold extraction waste liquid and precipitant are added to the reactor, and the flow rate of the bio-oxidation solution is adjusted to 21m 3 / h, the flow rate of precipitant is about 11m 3 / h, and subject to controlling pH=13.5 in the reactor, adjust the flow rate of the precipitant at any time, the reaction temperature is 40°C, and the stirring intensity is 700rpm / min to separate arsenic and iron;

[0029] 2. Use filtration or centrifugal separation technology to separate solid and liquid, the solid phase enters the iron red preparation process, and the arsenic-containing liquid enters the arsenic recovery process;

[00...

example 3

[0035] 500m per day 3 Bio-oxidation waste liquid (main element Fe content is 45g / L, As content is 8.5g / L) as an example. The recovery process of its valuable elements is: alkali is used as a drug, and 10mol L is prepared -1 alkaline solution as a precipitant. At the same time, add acidic arsenic-containing biological oxidation gold extraction waste liquid and precipitant to the reactor, and adjust the flow rate of biological oxidation liquid to 21m 3 / h, the flow rate of precipitant is about 12m 3 / h, and subject to the control of pH=13.5 in the reactor, adjust the flow rate of the precipitant at any time, the reaction temperature is 60°C, the stirring intensity is 800rpm / min, and the separation of arsenic and iron is carried out;

[0036] 2. Use filtration or centrifugal separation technology to separate solid and liquid, the solid phase enters the iron red preparation process, and the arsenic-containing liquid enters the arsenic recovery process;

[0037] 3. After the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com