Biological oxidation and thiourea resin slurry method gold extraction technology for difficultly leachable gold concentrate

A technology of biological oxidation and thiourea resin, applied in the direction of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

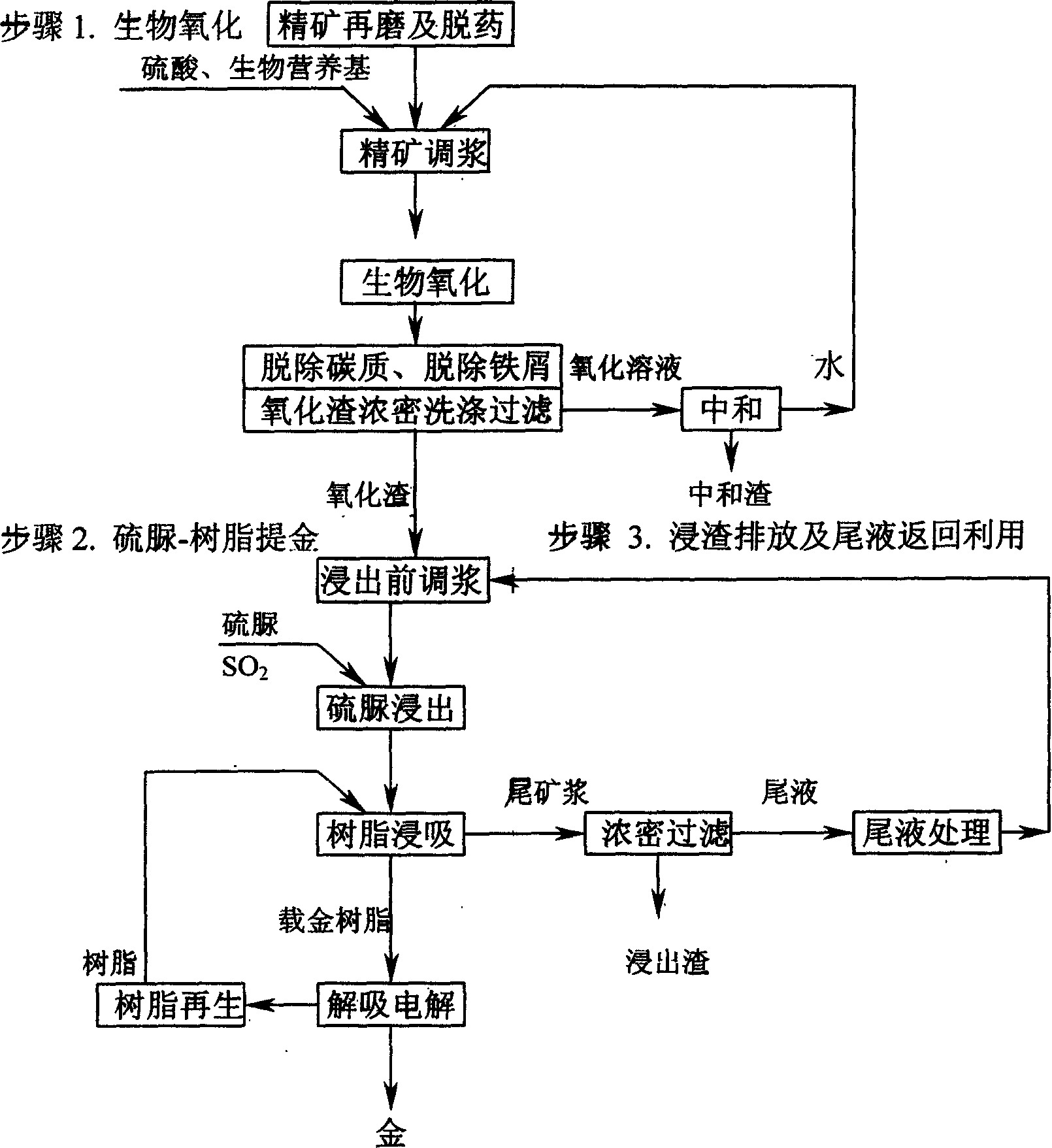

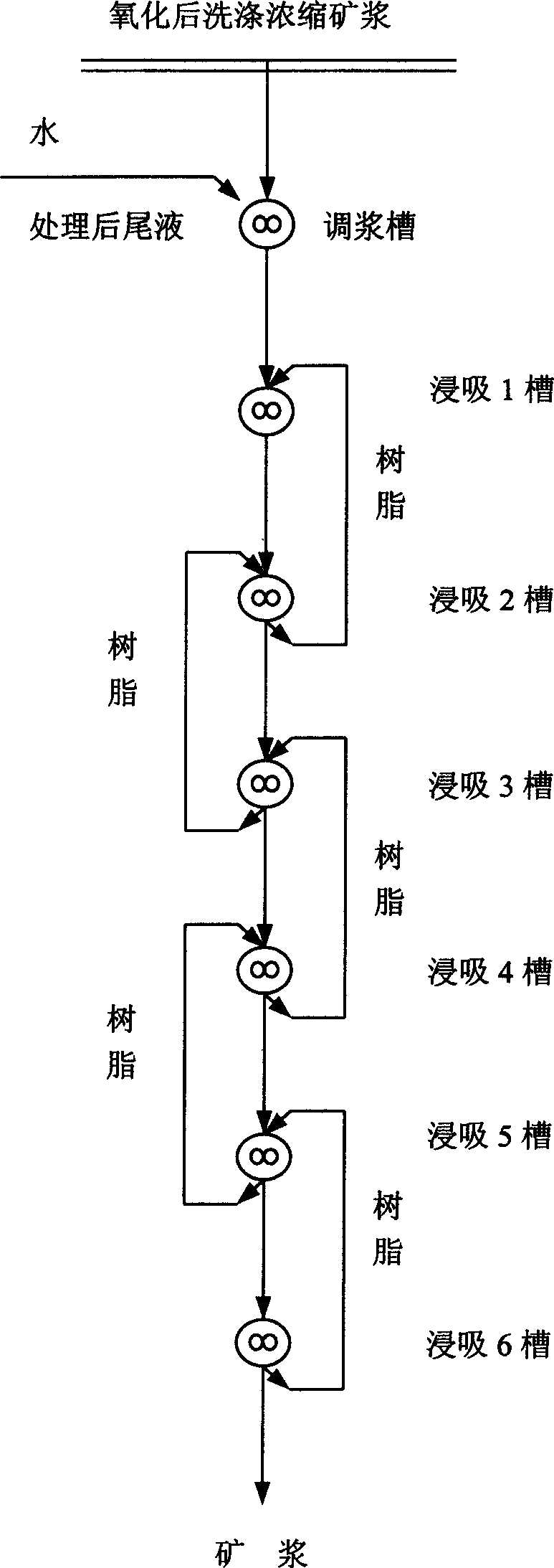

[0028] According to attached figure 1 and attached figure 2 , Example 2 is carried out according to several steps in the following order, wherein the concentrate grade is: Au: 86.5g / t; Ag: 39.8g / t; Cu: 0.11%; Pb: 0.07%; Zn: 0.75%; Fe: 29.77%; S: 26.32%; As: 12.65%; C: 0.45%; the gold particle size is fine, and the gold particle size is less than 0.5μm, nearly 60%. These gold mainly occur in pyrite and arsenopyrite. Arsenic fine-grained gold refractory concentrate, without pretreatment, the direct cyanide leaching rate is only 39.1%.

[0029] Step 1 is biological oxidation:

[0030] (1) Concentrate regrinding and drug removal: Concentrate regrinding particle size is less than 0.045μm, and its particle size content reaches 95%;

[0031] (2) Concentrate pulping: after dense drug removal, add biological nutrient base, sulfuric acid and water in proportion, adjust the pulp concentration to 16%, and adjust the pH to 1.6 with sulfuric acid;

[0032] (3) Biological oxidation: Aft...

Embodiment 3

[0045] According to attached figure 1 and attached figure 2 , Example 3 is carried out according to several steps in the following order, wherein the concentrate grade is: Au: 43.1g / t; Ag: 205.0g / t; Cu: 0.043%; Pb: 0.040%, Zn: 0.15%; Fe: 15.52%; S: 15.76%; As: 3.45%; C: 3.85%; the gold particle size is fine, about 90% of the gold particle size is less than 0.5μm, which belongs to the fine and difficult-to-leach gold concentrate, the organic carbon content is 0.12%, and it can be leached directly by cyanide The gold leaching rate is 12.56%;

[0046] Step 1 is biological oxidation:

[0047] (1) Concentrate regrinding and drug removal: Concentrate regrinding particle size is less than 0.045μm particle size content is 98%, magnetic material yield of magnetic separation iron removal is 0.84%;

[0048] (2) Concentrate pulping: after thickening and demedication, add biological nutrient base, sulfuric acid and water in proportion, adjust the pulp concentration to 20%, and pH to 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com